Shock-absorbing noise-reducing reinforced engine rear suspension

An enhanced engine technology, applied in the direction of power plant, jet propulsion device, internal combustion propulsion device, etc., can solve the problem of low first-order modal frequency, failure to meet vibration and noise index requirements, and engine rear mount shock absorption and noise reduction effect It is not ideal enough to achieve the effect of improving the effect of shock absorption and noise reduction and improving the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

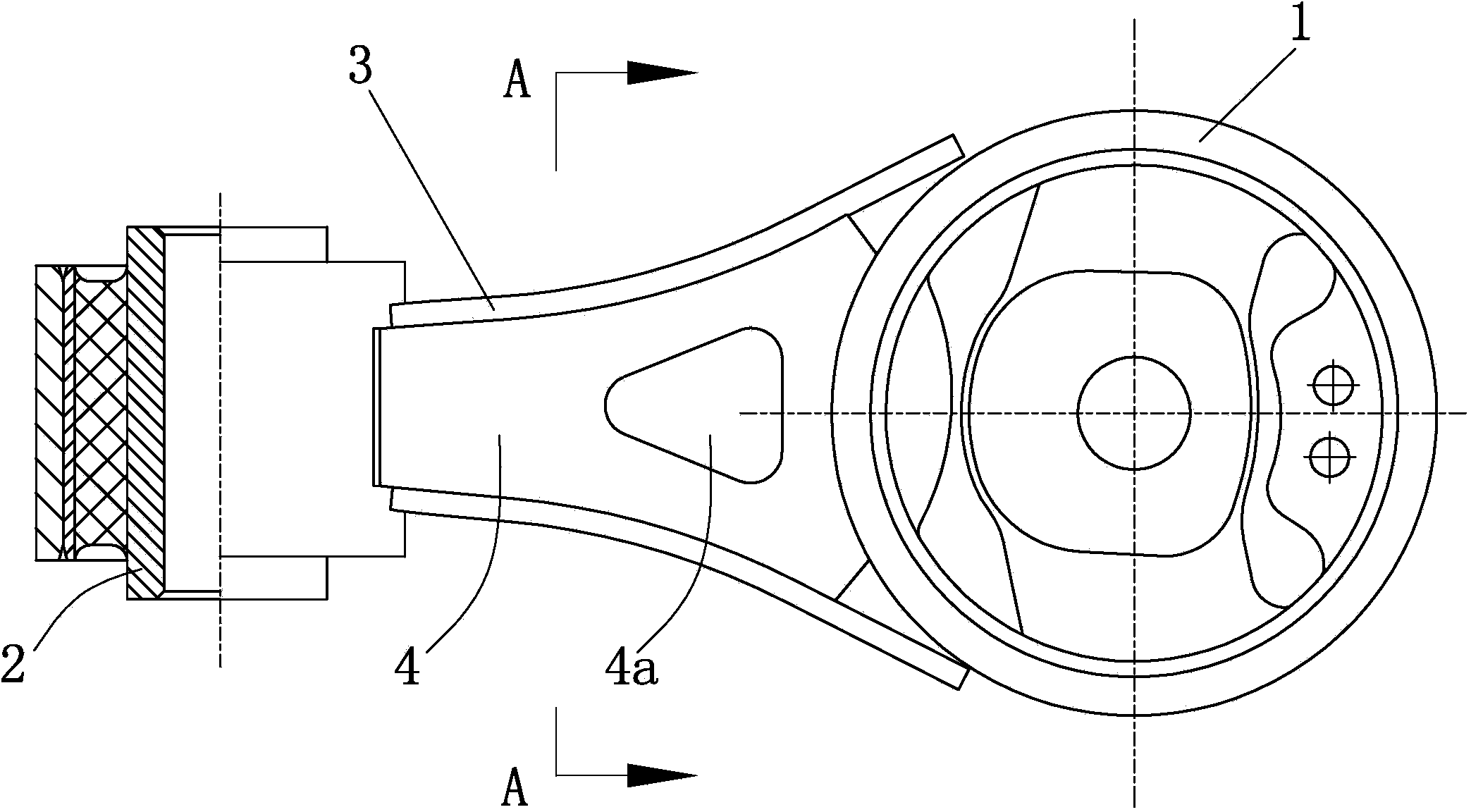

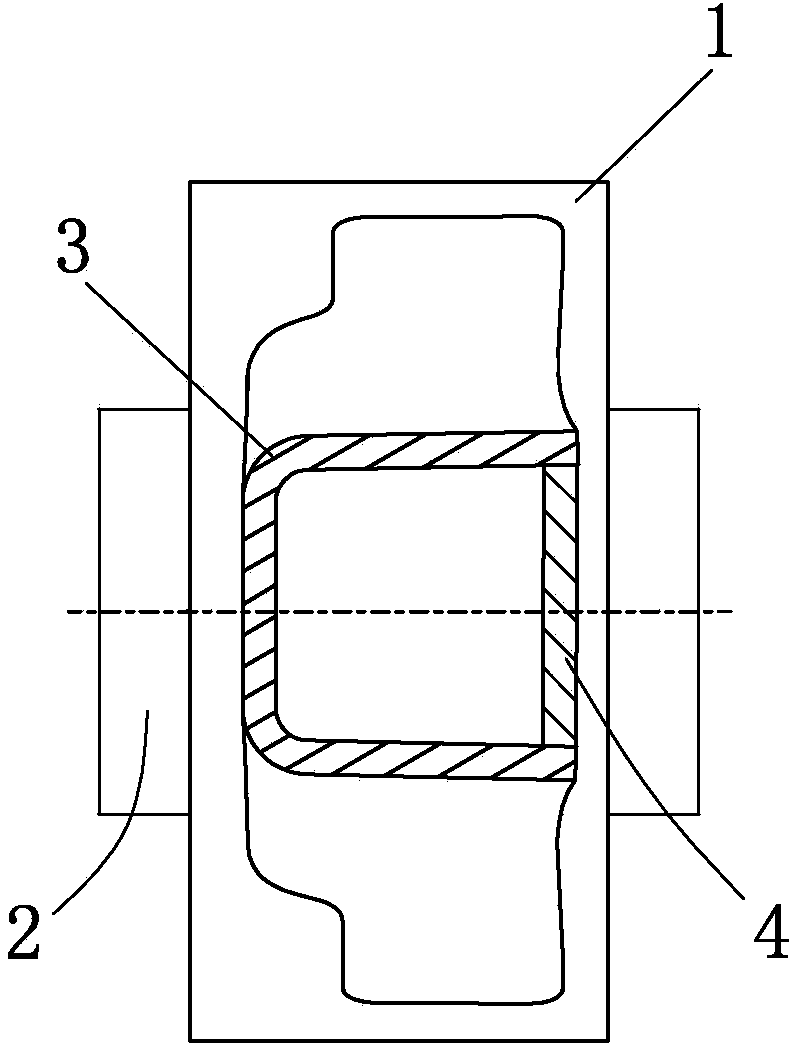

[0013] combine figure 1 , figure 2 The shown shock-absorbing and noise-reducing reinforced engine rear mount is mainly composed of a large bush 1, a small bush 2 and a connecting plate 3. The large bushing 1 is connected with the sub-frame through bolts, the small bushing 2 is connected with the rear suspension bracket through the combination of bolts and nuts, and the rear suspension bracket is connected with the engine again. The large bushing 1 and the small bushing 2 are spaced left and right, and the axes of the two are perpendicular to each other. The connecting plate 3 is arranged between the large bush 1 and the small bush 2, and connects the large bush 1 and the small bush 2 as a whole. The left end of connecting plate 3 is welded with large bushing 1, and the right end of connecting plate 3 is welded with small bushing 2.

[0014] The connecting plate 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com