Expansion capsule providing power and power drive device

A power-driven, capsule technology, applied in the direction of mechanisms, machines/engines, and mechanical equipment that generate mechanical power, can solve problems such as slow ejection and recovery speeds of the ejector rod and piston, damage to seals 3, and long expansion distances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

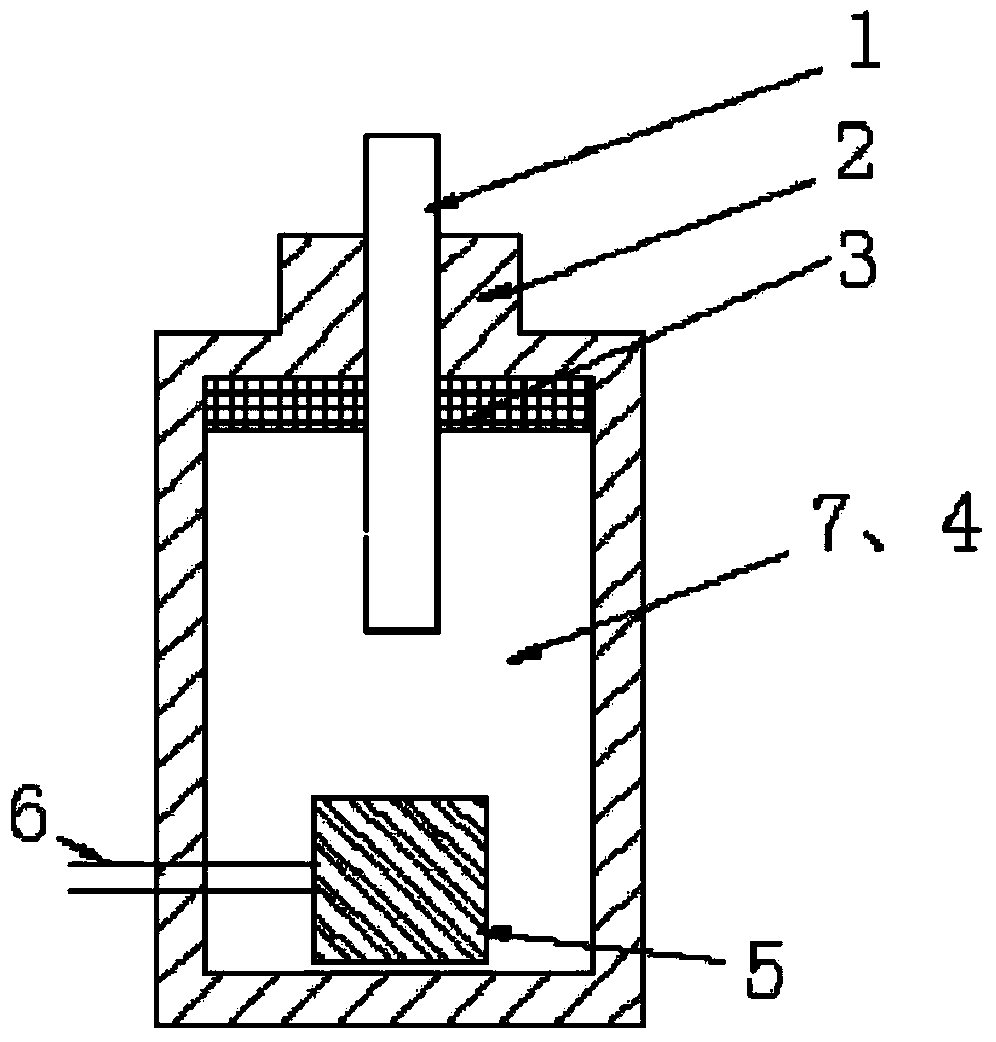

[0059] Figure 2-4 It is a structural schematic diagram of the first embodiment of the present invention. in, figure 2 It is a perspective view of the expanding capsule in the first embodiment of the present invention. image 3 It is a sectional view of the expanding capsule in the first embodiment of the present invention. Figure 4It is a sectional view of the power drive device in the first embodiment of the present invention.

[0060] Such as image 3 As shown, the powered expansion capsule 100 includes a heating element 10 and an expansion medium 20 , the expansion medium 20 evenly wraps the heating element 10 , and together constitute an expansion assembly, the expansion assembly is wrapped with a layer of elastic member 30 . In this embodiment, the expansion capsule 100 is in the shape of a ring column, and the heating element 10 is a resistance wire. The resistance wire can be wound into multiple turns and then folded up and down and directly stored in the elastic...

Embodiment 2

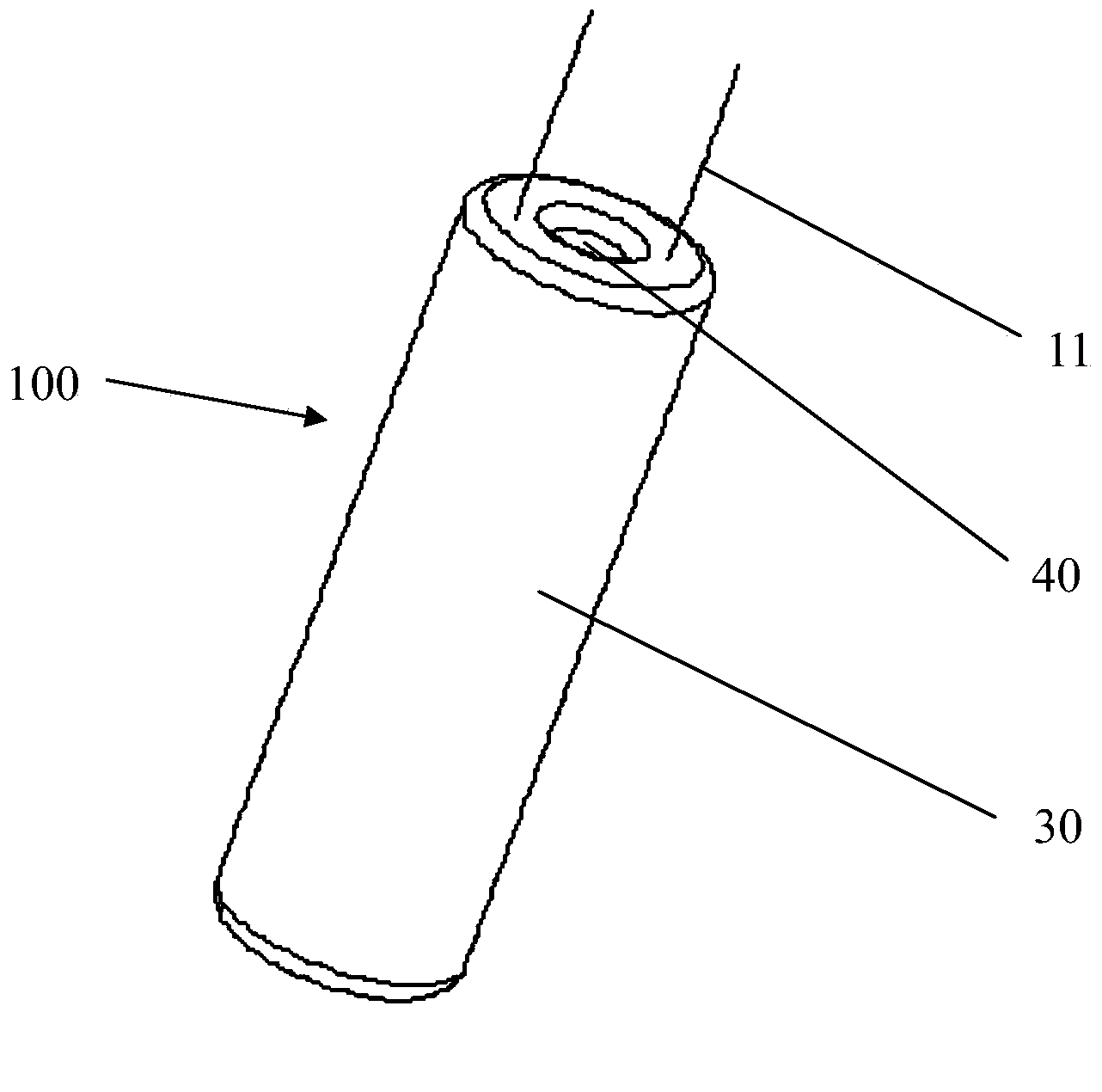

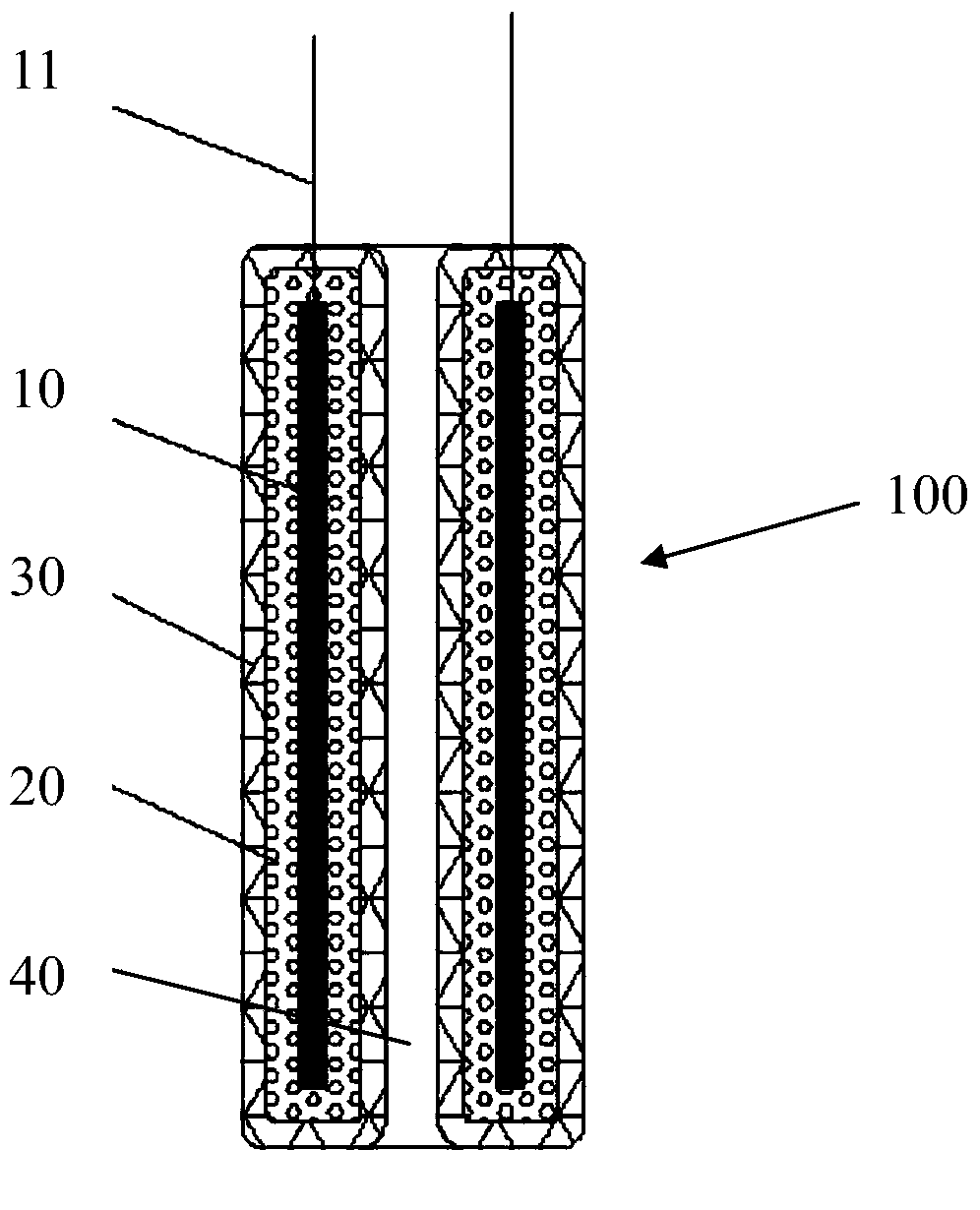

[0075] Figure 6-8 It is a structural schematic diagram of the second embodiment of the present invention. in, Figure 6 It is a perspective view of the expanding capsule in the second embodiment of the present invention. Figure 7 It is a sectional view of the expanding capsule in the second embodiment of the present invention. Figure 8 It is a sectional view of the power drive device in the second embodiment of the present invention.

[0076] The difference between this embodiment and the first embodiment is that the expansion capsule is cylindrical, the elastic member 30 is a cylindrical hollow closed capsule, and the heating element 10 and the expansion medium 20 are accommodated in the elastic member 30 . Two wires 11 are drawn out from the heating element 10, and the expansion medium 20 and the elastic member 30 are sequentially wrapped on the outer surface of the heating element 10 to form a cylindrical expansion capsule. The bottom end of the piston rod 60 is loca...

Embodiment 3

[0082] Figure 10-12 It is a structural schematic diagram of the third embodiment of the present invention. in, Figure 10 It is a perspective view of the expansion assembly and the elastic member in the expansion capsule in the third embodiment of the present invention, Figure 11 It is a perspective view of the rigid shell in the expandable capsule in the third embodiment of the present invention, Figure 12 It is a sectional view of the power drive device in the third embodiment of the present invention.

[0083] The difference between this embodiment and the first embodiment is that the expansion capsule is in the shape of a ring column, the heating element 10 is a resistance wire, the resistance wire can be wound into multiple turns, and the heating element 10 is heated after being energized through the wire 11; the outer surface of the heating element 10 The expansion medium 20 is completely and evenly wrapped to form the expansion assembly 12 together; the elastic me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com