Hole site measuring device

A technology of hole position measurement and positioning column, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., which can solve the problems of not being able to know the deviation value of the hole position, eliminate cumbersome actions, facilitate collection and installation, and manufacture convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

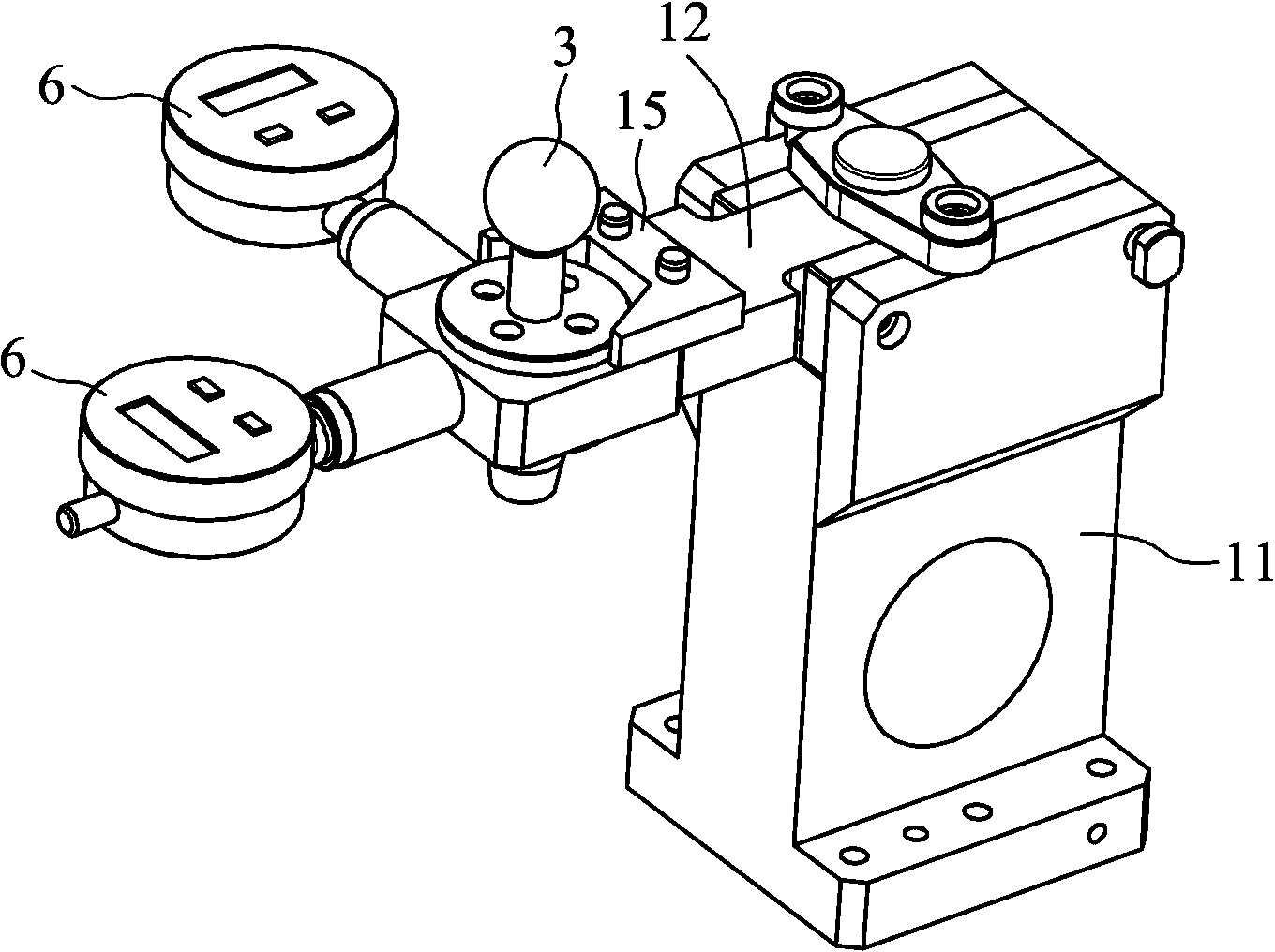

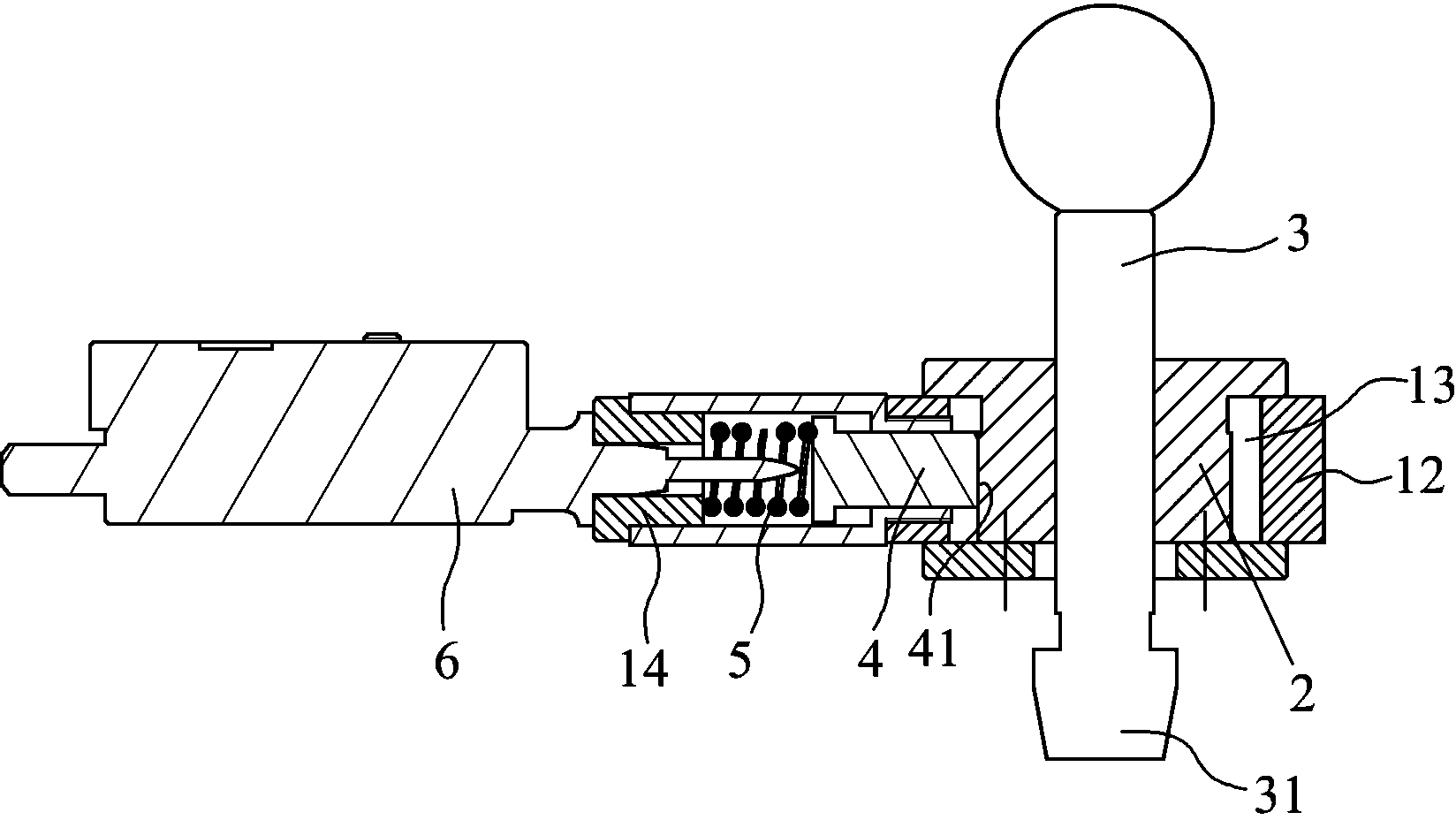

[0018] The embodiment discloses a hole position measuring device, which is used to measure the deviation of the positioning holes on the subframe of the vehicle.

[0019] Such as figure 1 and figure 2 As shown, the device includes a base for support. The base includes a body 12 and a cantilever 11. The cantilever 11 is slidably arranged on the body 12. The cantilever 11 can be drawn out for a certain distance and then fixed with the body 12.

[0020] A cylindrical sliding part 2 that can slide freely in the horizontal direction is provided on the cantilever 11, and a positioning column 3 that can slide up and down is inserted in the center hole of the sliding part 2, and the positioning column 3 can move downward to be inserted into the subframe At this time, since the sliding part 2 can slide arbitrarily in the horizontal direction, the sliding part 2 will have a certain offset relative to its initial position, and this offset is the positioning hole of the subframe offset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com