Full-automatic oil-chromatography sample feeding device for transformer and operation method

A transformer oil and sampling device technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of cumbersome steps, inability to use together, fast consumption of calibration gas, etc., to improve detection efficiency, avoid volume errors, and save manpower Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

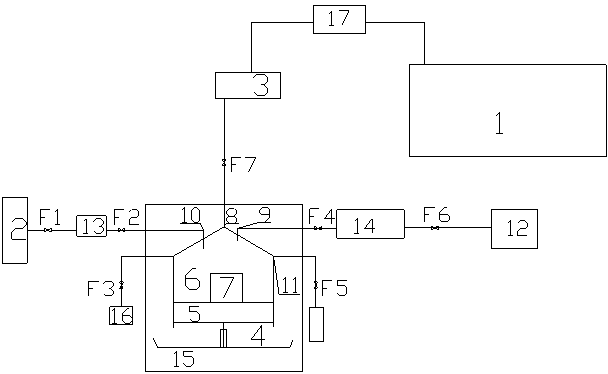

[0030] Example 1 as figure 1 with figure 2 As shown, the oil-gas separation device includes a movable degassing tank 6 at the bottom of the tank 5, a tank bottom propulsion device and a gravity compensation device 4 are connected on the tank bottom 5, and a stirring device 7 is provided in the degassing tank 6. The stirring The device 7 is a magnetic stirrer, the degassing tank 6 is located in the thermostat 15, and the degassing tank 6 is provided with a gas intake port 8, a sampling port 9, a nitrogen gas inlet 10 and an oil discharge port 11, and the gas intake port 8 is connected to the gas collection port. The device 3 is connected, and an oil-proof valve F7 is arranged between the gas-taking port 8 and the gas-collecting device 3; the sampling port 9 is connected to the sample 12, and a liquid quantitative sampler 14 is connected between the sampling port 9 and the sample 12; 9 and the pipeline between the liquid quantitative sampler 14 are connected with a degassing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com