Closed explosion test device for quantitative temperature pressure effect evaluation of thermobaric explosives

A temperature-pressure effect, quantitative evaluation technology, applied in fuel testing, material inspection, etc., can solve the problems of difficult to cause combustion reaction, difficult to achieve secondary combustion, incomplete and other problems, and meet the requirements of temperature-pressure effect characteristic parameter test. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

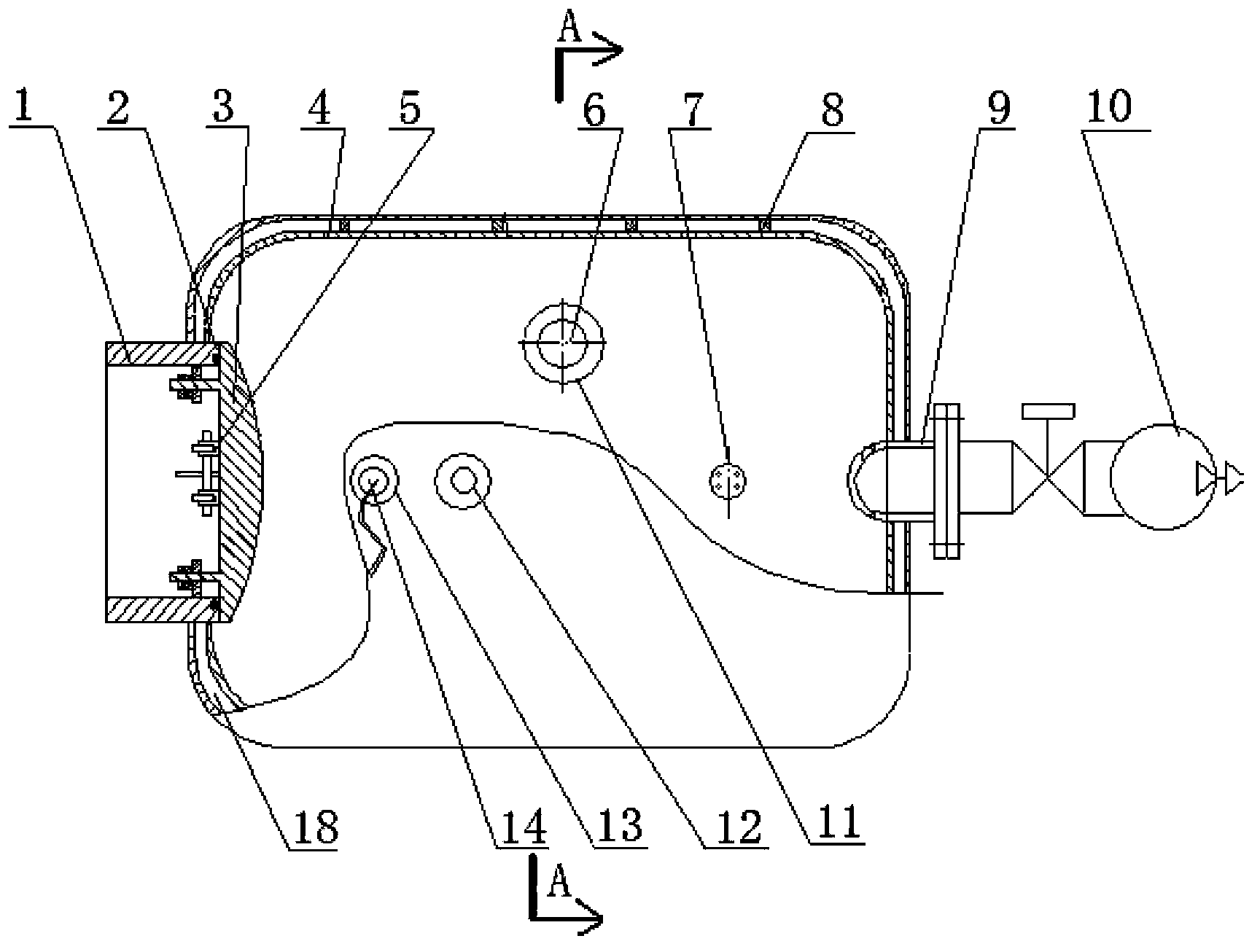

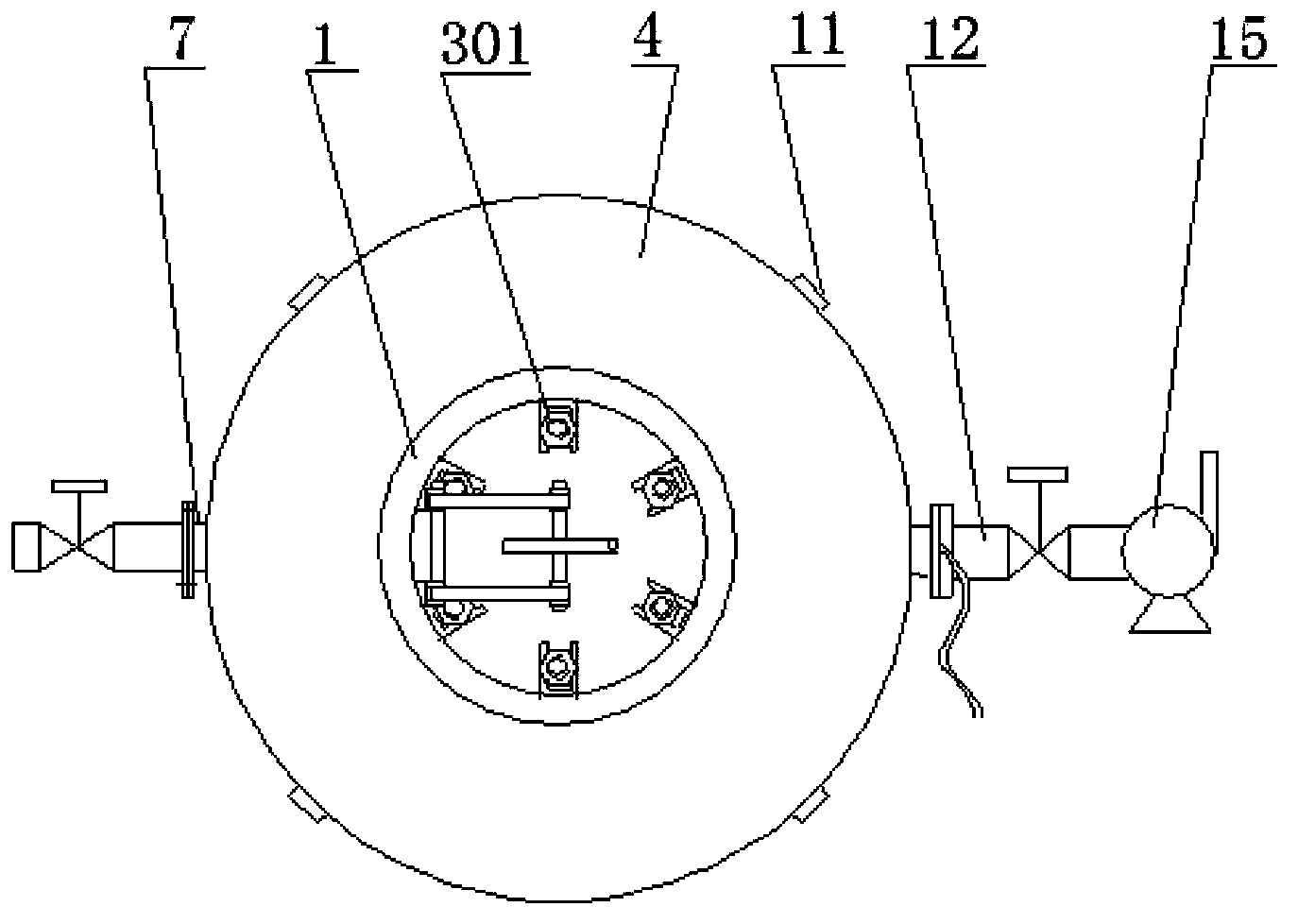

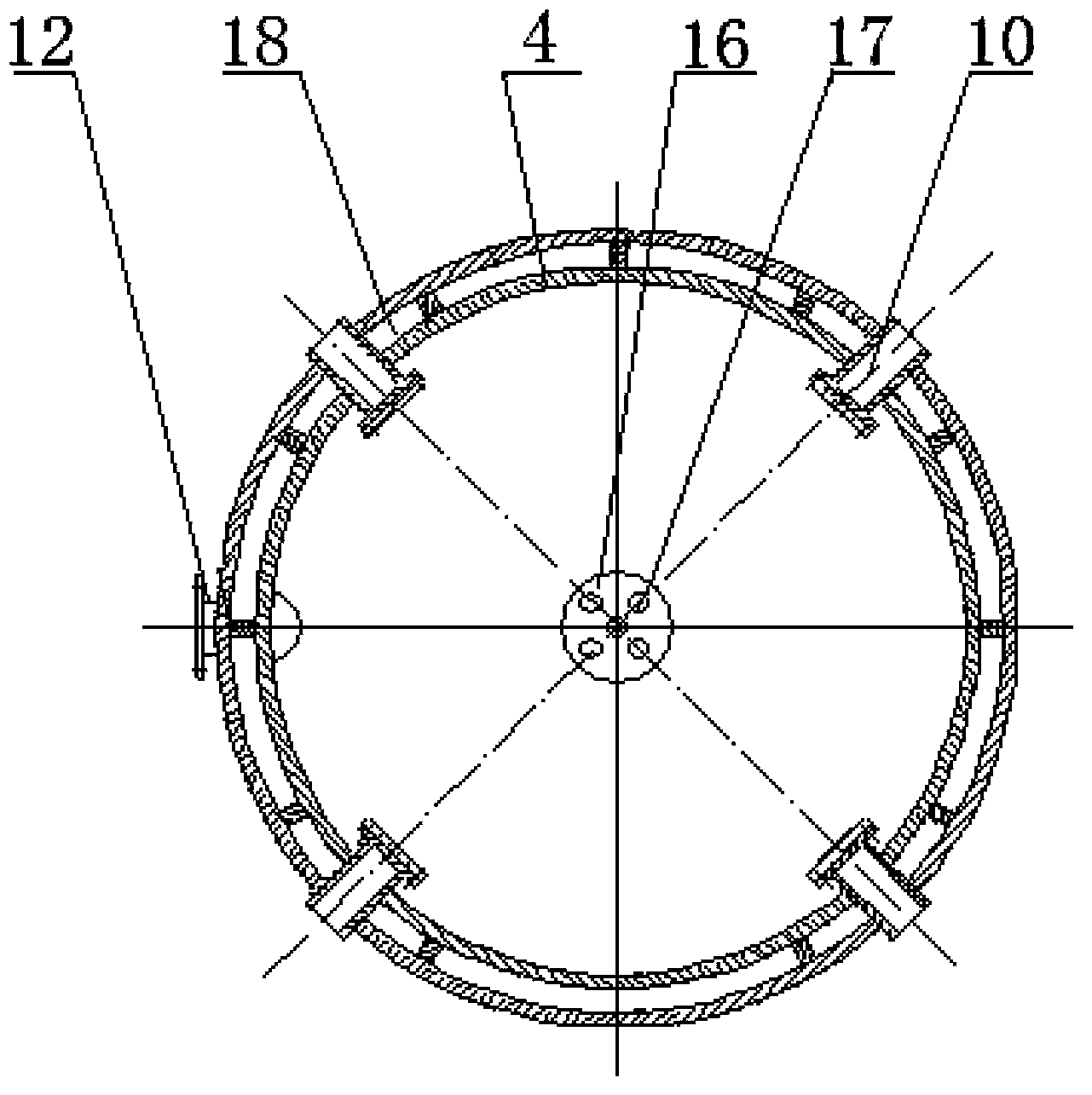

[0034] Comply with the above technical solutions, such as Figure 1 to Figure 3 As shown, a closed explosion test device for quantitative evaluation of the temperature-pressure effect of thermo-pressure explosives includes a tank body 4, and the tank body 4 is an airtight double-layer tank body, and a shock-absorbing layer is arranged between the double-layer tank bodies 18; One end of the tank body 4 is provided with a vacuum tube 9, and the other end of the tank body 4 is provided with a loading port 2, a sealing door 3 is installed on the loading port 2, and a tank body 4 is provided on the outside of the sealing door 3. body outlet 1; sensor mounting plate 6 is evenly distributed on the circumference of tank body 4 inner wall, and sensor mounting plate 6 is provided with sensor mounting hole 601; Intake pipe 7, exhaust pipe 12 and Connector 14.

[0035] The main structure of the present invention is a double-layer cylindrical sealed tank body 4, the tank body 4 is a doubl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com