High-strength weather-resistant low-temperature-resistant hot-rolled cap-shaped steel used for railway freight open wagon and production technology of high-strength weather-resistant low-temperature-resistant hot-rolled cap-shaped steel used for railway freight open wagon

A railway freight and production process technology, applied in the field of rolling steel production, can solve the problems of strength, high weather resistance, poor low temperature resistance, difficult one-time hot rolling forming, complex and cumbersome process, etc., to simplify the rolling production process and improve low temperature toughness , reducing the effect of dynamic recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

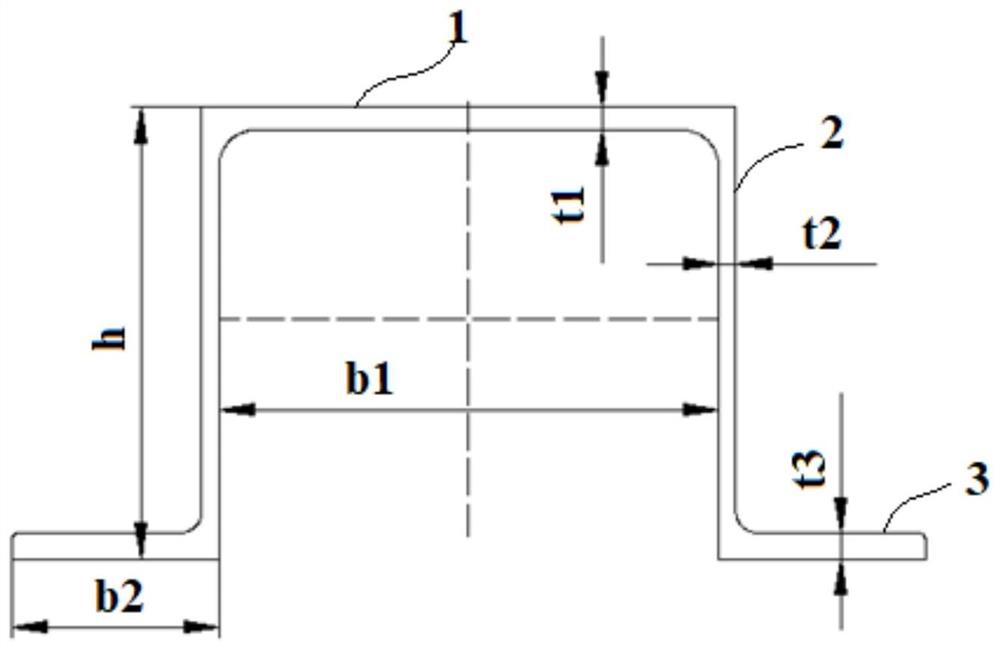

[0044] A hot rolled steel cap according to the present embodiment, its components in weight percentage: C: 0.12%, Si: 0.45%, Mn: 1.5%, P≤0.020%, S≤0.015%, Cr: 0.7%, Ni : 0.055%, Cu: 0.40%, Nb: 0.035%, H≤0.0002%, N≤0.008%, Alt: 0.030%, the balance being Fe and trace residual elements. Production using the production process of the present invention, wherein control of rolling process parameters as follows:

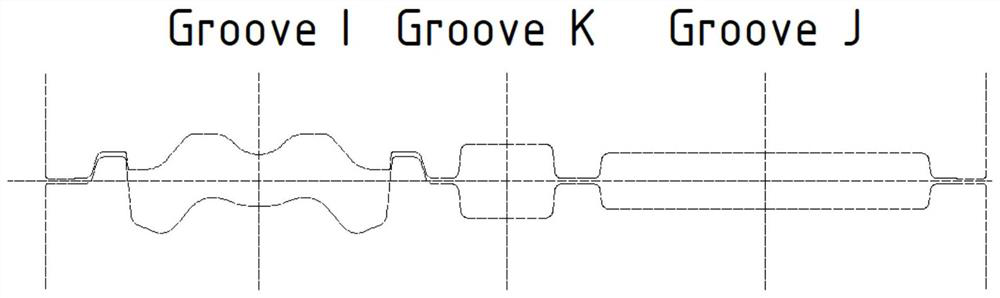

[0045] BD1 slabbing process parameters for phase control: blank after K, J hole co-rolling of 7 passes, with a total compression ratio of 1.23; when I holes rolling, rolling the compression ratio was 1.36. This BD1 stage control start rolling temperature of 1245 ℃, the final rolling temperature is 1205 ℃.

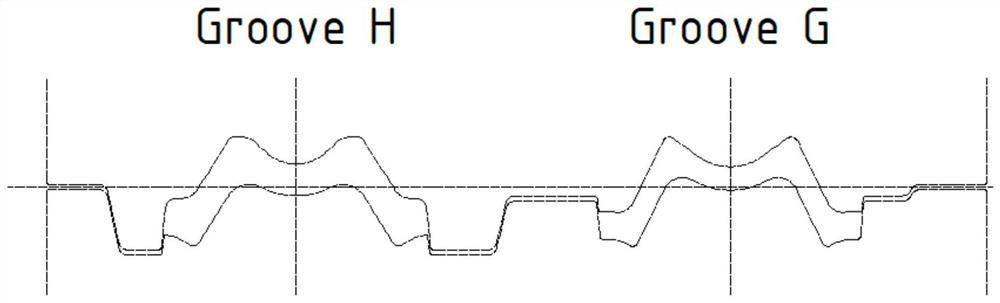

[0046] BD2 slabbing process parameters for phase control: when the configuration of a hole H through the hole H rolling member rolling pressure value is 60 ~ 65mm, compression ratio of 1.32. Pressure rolling through rolling when G holes, a hole disposed between G 37 ~ 42mm, ...

Embodiment 2

[0052] A hot-rolled steel, which is a hot-rolled steel having a mass percentage: C: 0.1%, Si: 0.65%, Mn: 1.40, p ≤ 0.020%, s ≤ 0.012%, Cr: 0.3%, Ni: 0.065%, Cu: 0.30%, Nb: 0.030%, H ≤ 0.0002%, N ≤ 0.008%, Alt: 0.020%, and the rest is Fe and trace residual elements. The production process of the present invention is carried out, in which the rolling process parameters are controlled as follows:

[0053] The process parameters controlled by the BD1 billed rolling stage are: the blank passes through K, J hole rolling 5, with a total compression ratio of 1.20; when the I hole rolling is performed, the compression ratio of the rolling member is 1.36. The opening temperature of this BD1 stage was 1241 ° C, and the final rolling temperature was 1206 ° C.

[0054] The process parameters controlled by the BD2 billet rolling stage are: the pressure value configured to the H hole is 65 mm when rolled by the H hole rolling, and the compression ratio is 1.35. When rolling is rolled by the G ho...

Embodiment 3

[0060] A hot-rolled steel, which is: 0.20%, Mn: 1.55%, p ≤ 0.020%, s ≤ 0.015%, CR: 1.0%, Ni : 0.025%, Cu: 0.55%, Nb: 0.045%, H ≤ 0.0002%, N ≤ 0.008%, Alt: 0.040%, the rest is Fe and trace residual elements. The production process of the present invention is carried out, in which the rolling process parameters are controlled as follows:

[0061] The process parameters controlled by the BD1 billed rolling phase are: the blank passes through K, J hole rolling 6, with a total compression ratio of 1.25; when the I hole rolling is performed, the compression ratio of the rolling member is 1.31. The BD1 stage is 1241 ° C, and the final rolling temperature is 1210 ° C.

[0062] The process parameters controlled by the BD2 billet rolling stage are: the pressure value configured to the H hole is 60 mm when the rolling is rolled, and the compression ratio is 1.30. When the rolling is rolled, the compression ratio is 1.27. This BD1 stage is 1205 ° C, and the final rolling temperature is 1164 °...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com