Manufacturing method of semiconductor fin ray, manufacturing method of finfet device

A manufacturing method and semiconductor technology, which are applied in the manufacturing of semiconductor/solid-state devices, semiconductor devices, electrical components, etc., can solve the problems that the fins cannot be perpendicular to the surface of the substrate, and the sides of the fins are rough.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

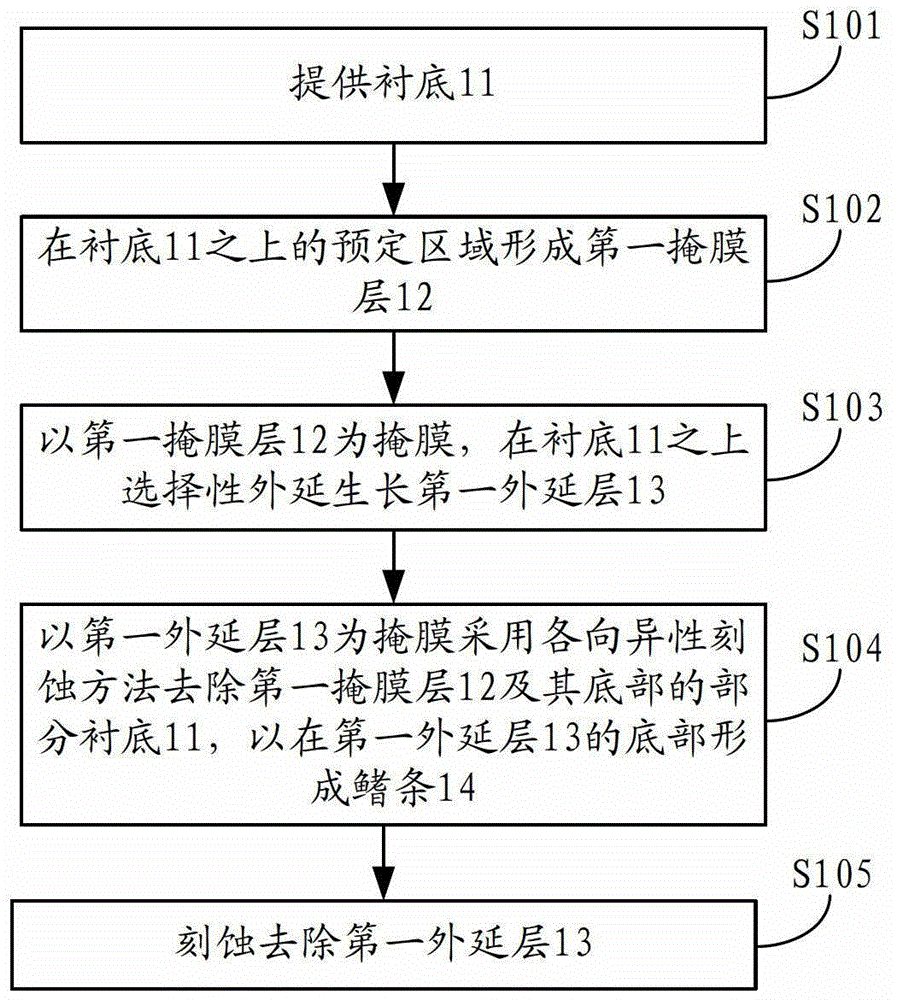

[0088] figure 1 A schematic flow chart showing a method for manufacturing semiconductor fins according to an embodiment of the present invention, Figure 2a(1)~Figure 2d(2) It shows the structural diagrams of semiconductor fins at various stages in the manufacturing process, wherein Figure (1) is a top view, and Figure (2) is a cross-sectional view of Figure (1) along the AA' direction, combined together Figure 1 ~ Figure 2d (2) , the flow process of the manufacturing method of the semiconductor fin ray is as follows:

[0089] S101, providing the substrate 11, such as Figure 2a(1) and 2a(2) shown.

[0090] The substrate 11 in Embodiment 1 of the present invention is a bulk silicon substrate. The bulk silicon substrate may be a P-well substrate, an N-well substrate or a double-well substrate.

[0091] S102: Form a first mask layer 12 on a predetermined region above the substrate 11, such as Figure 2b(1) and 2b(2) shown.

[0092] The first mask layer 12 can be fabrica...

Embodiment 2

[0107] image 3 A schematic flow chart showing a method for manufacturing semiconductor fins according to an embodiment of the present invention, Figure 4a ~ Figure 4i Schematic diagrams showing the structure of semiconductor fins at various stages in the fabrication process, combined with Figure 3 ~ Figure 4i , the flow process of the manufacturing method of the semiconductor fin ray is as follows:

[0108] Considering that S301-S305 are the same as or corresponding to S101-S105 in the above embodiment, correspondingly, Figure 4a ~ Figure 4e and Figure 2a(2)~Figure 2d(2) They are the same or corresponding, and will not be repeated here. For details, refer to related descriptions in the foregoing embodiments.

[0109] S306, forming sidewalls 15 on both sides of the fin ray 14, such as Figure 4f shown.

[0110]The sidewalls 15 are formed on both sides of the fin 14 by a combination of deposition and etch-back. For example, one or more layers of materials (such as sil...

Embodiment 3

[0121] Figure 5 It shows a schematic flow chart of the manufacturing method of the FinFET device according to the embodiment of the present invention, wherein the FinFET device adopts the semiconductor fin bars manufactured by the manufacturing method described in the above embodiment, Figure 6a (1) ~ 6l (3) It shows the structure schematic diagram of the FinFET device at various stages in the manufacturing process, where Figure (1) is a top view, Figure (2) is a cross-sectional view of Figure (1) along the AA' direction, and Figure (3) is a cross-sectional view of Figure (1) along Sectional view in BB' direction. combined Figure 5 ~ Figure 6l (3) , the flow of the manufacturing method of the FinFET device is as follows:

[0122] S501, providing the substrate 11, such as Figure 6a(1) and 6a(2) shown.

[0123] In the embodiment of the present invention, the substrate 11 is a bulk silicon substrate. The bulk silicon substrate may be a P-well substrate, an N-well substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com