A Method of Improving the Opening Precision of Split Seat Ring

A seat ring and precision technology, which is applied in the field of improving the opening accuracy of the split-valve seat ring, can solve problems such as the inability to guarantee the high-precision requirements of the hydraulic opening size and the lack of seat ring openings, so as to improve the marking inspection accuracy, improve the assembly combination accuracy, and ensure reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

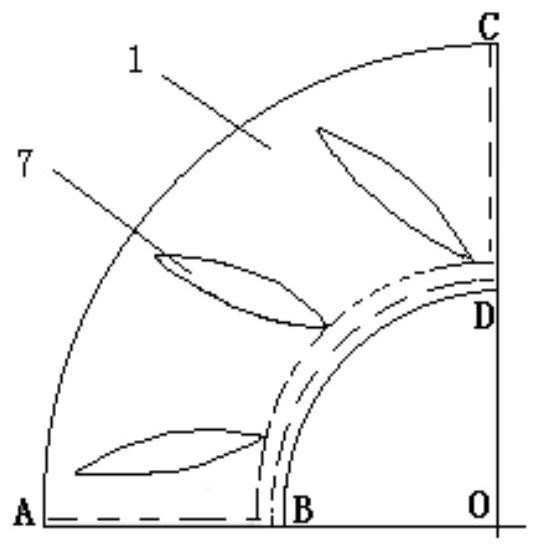

[0036] A) The welded single-lobe 1 / 4 seat ring 1 is placed on the platform of the boring machine, with the seam facing the CNC boring machine, align and adjust according to the three horizontal reference lines 4 drawn on the fixed guide vane 7 of the 1 / 4 seat ring Flat seat ring 1, see figure 1 . The three horizontal reference lines are respectively located at the water outlet edge position of the two fixed guide vanes 7 on the joint surface and the water inlet edge position of the outer circle of the fixed guide vane 7 in the middle. Check the leveling accuracy of the horizontal reference line with a digital level to ensure that the mutual deviation of the three reference horizontal lines is less than 0.50mm.

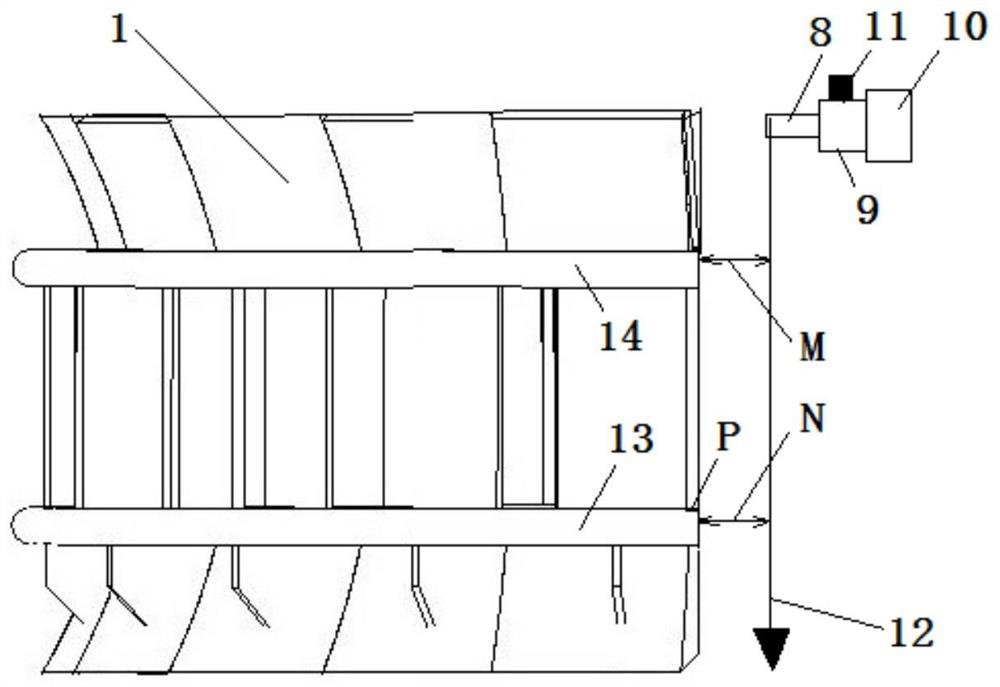

[0037] B) The boring shaft 8 of the CNC boring machine aligns the seat ring 1 according to the processing line AB drawn on the upper plane of the lower ring plate 13 of the joint surface, see image 3 , make the processing line of the joint surface of the seat ring t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com