Arc punching device and arc punching method at both ends of a circular tube

A technology of arc punching and round pipe, which is applied in the field of arc punching machining at the end of pipe fittings, can solve the problems of inability to guarantee the orthogonality of the arc, low machining efficiency, poor machining accuracy, etc., and achieve automatic arc punching and blanking operations. , The effect of reducing labor intensity and improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

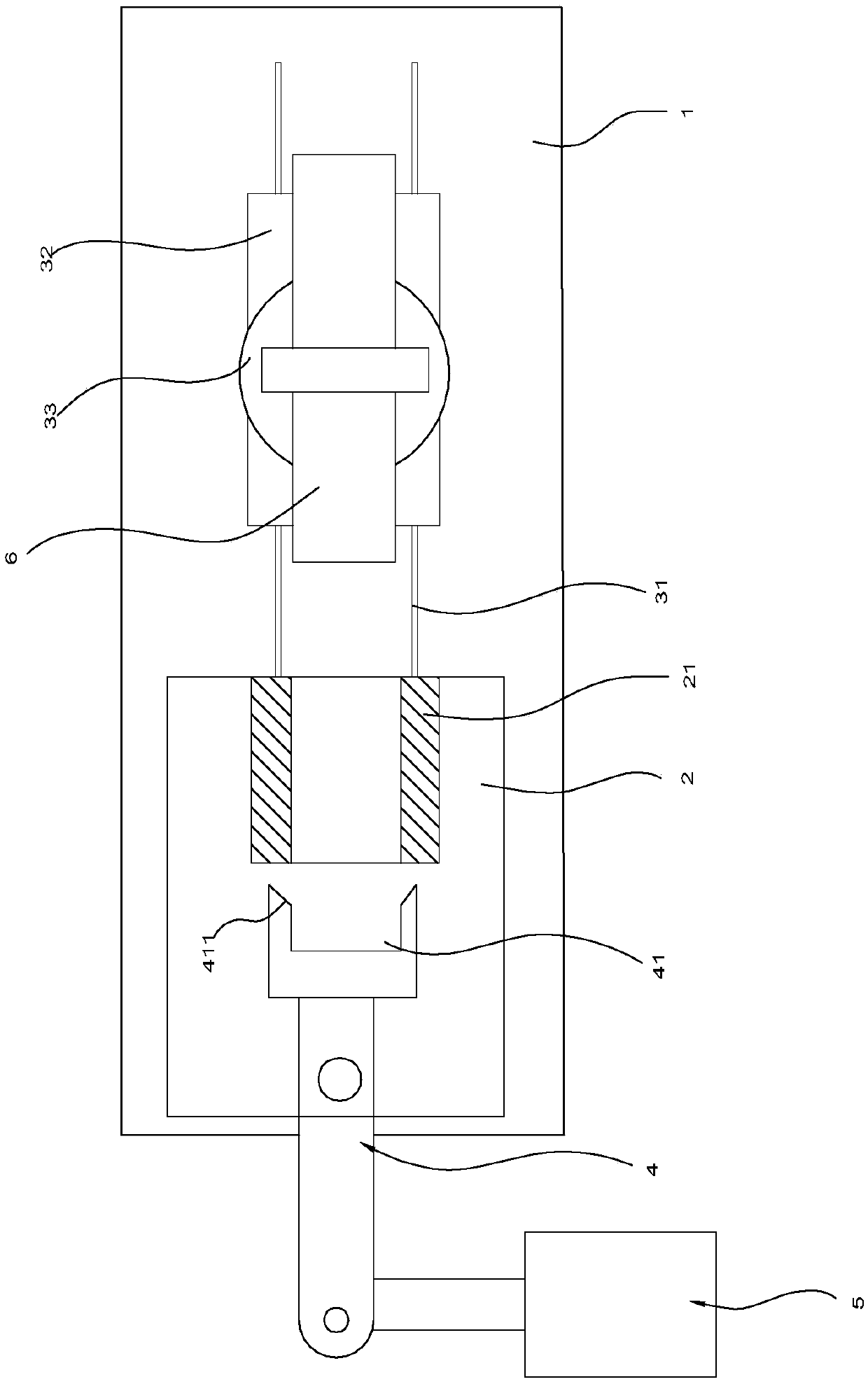

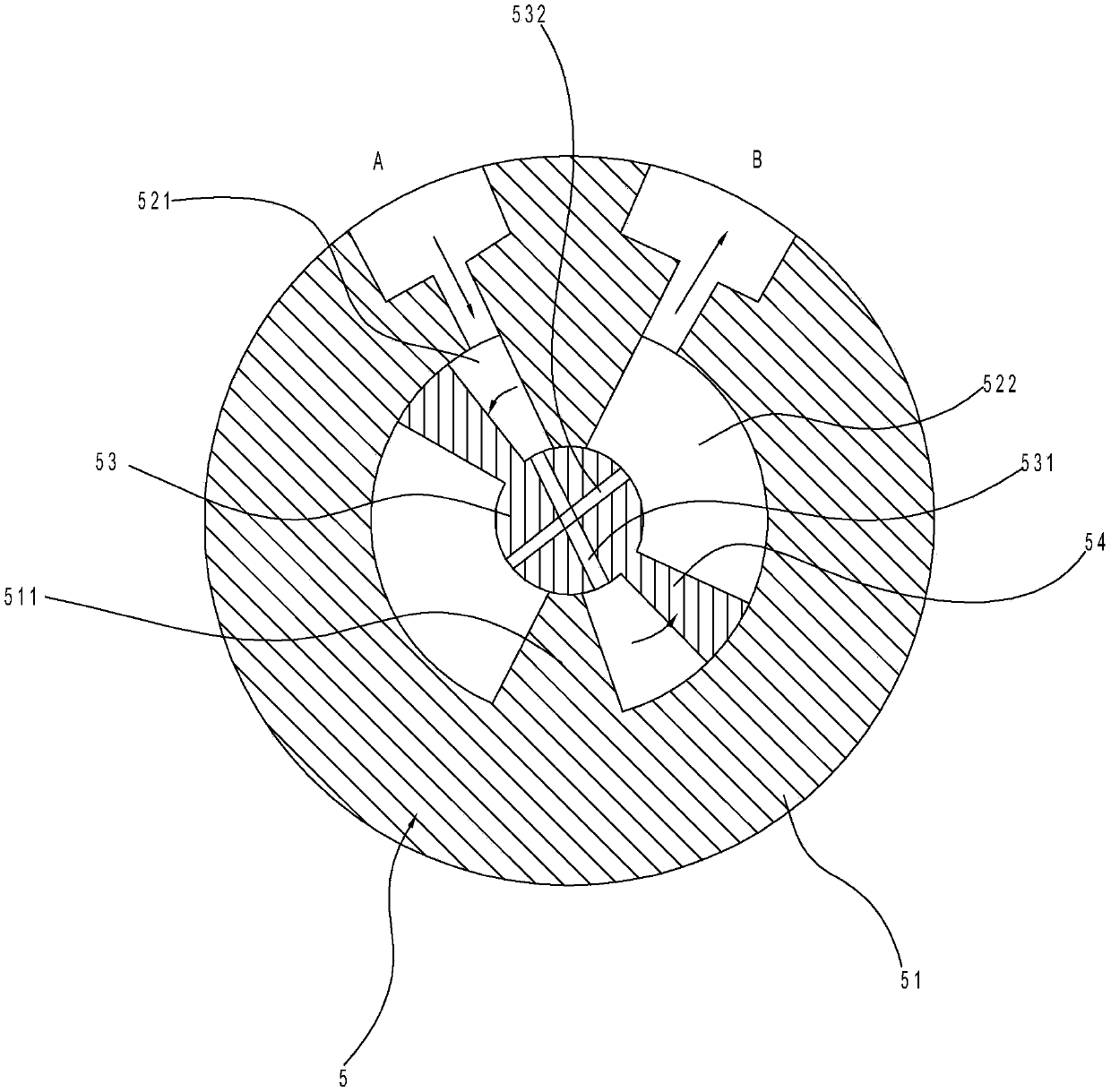

[0029] Such as Figures 1 to 7 As shown, the arc punching device at both ends of the round pipe in this implementation includes a platform 1, a feeding rotation mechanism and a toggle arc punching mechanism.

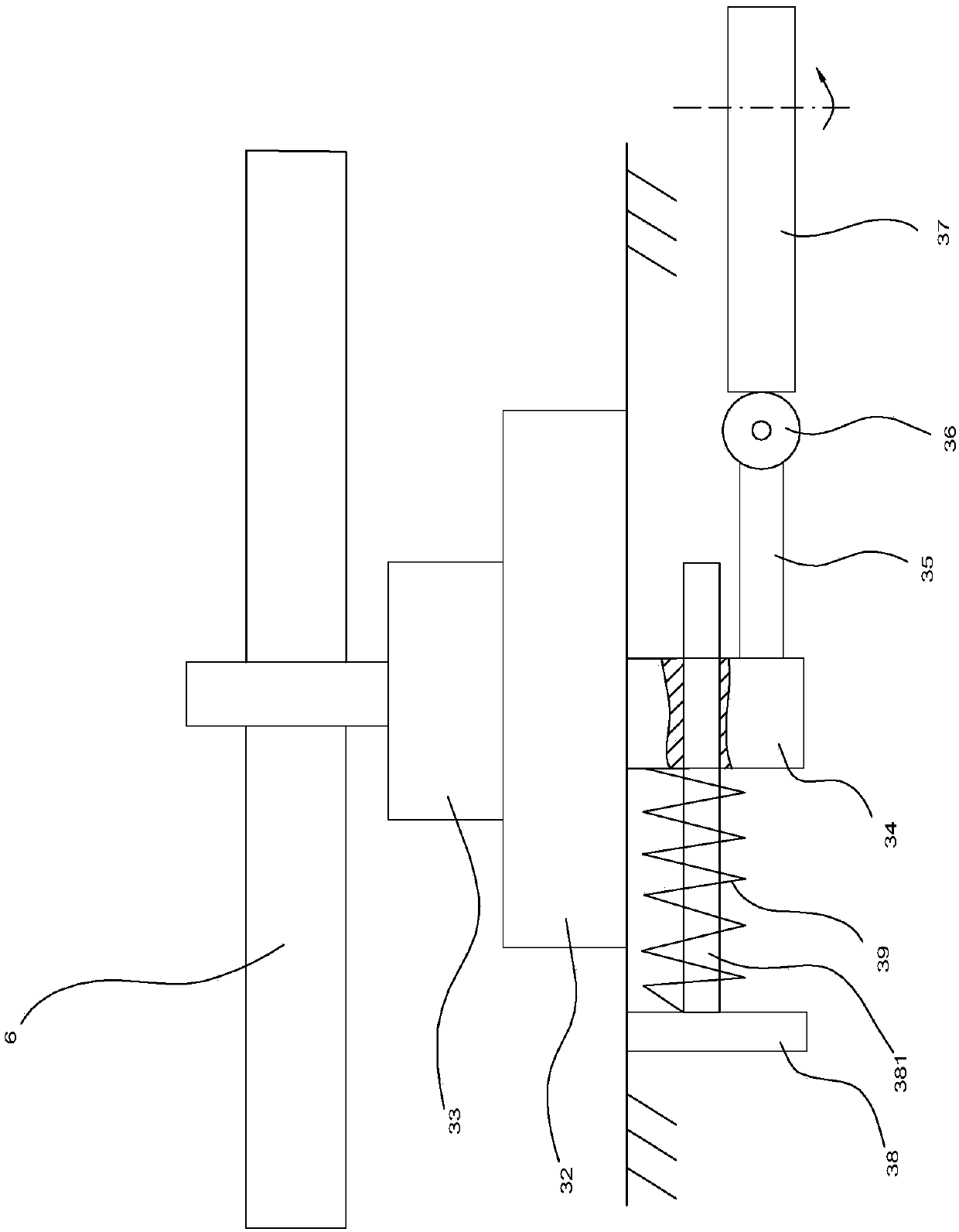

[0030]Among them, an arc punching seat 2 is arranged on the platform 1, and one end of the arc punching seat 2 is provided with a guide rail 31. The interior of the seat 2 is hollow, and a limit sleeve 21 is provided at the end of the punching seat 2 close to the feeding rotating mechanism. The feeding rotating mechanism includes a base 32 slidably arranged on the guide rail 31, and a rotating cylinder 33 arranged on the base 32. , the connecting block 34 that is arranged on the lower end surface of the base 32, the connecting rod 35 that is connected with the connecting block 34 and arranged transversely, the roller 36 that is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com