Patents

Literature

35results about How to "Guaranteed to be perpendicular to each other" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

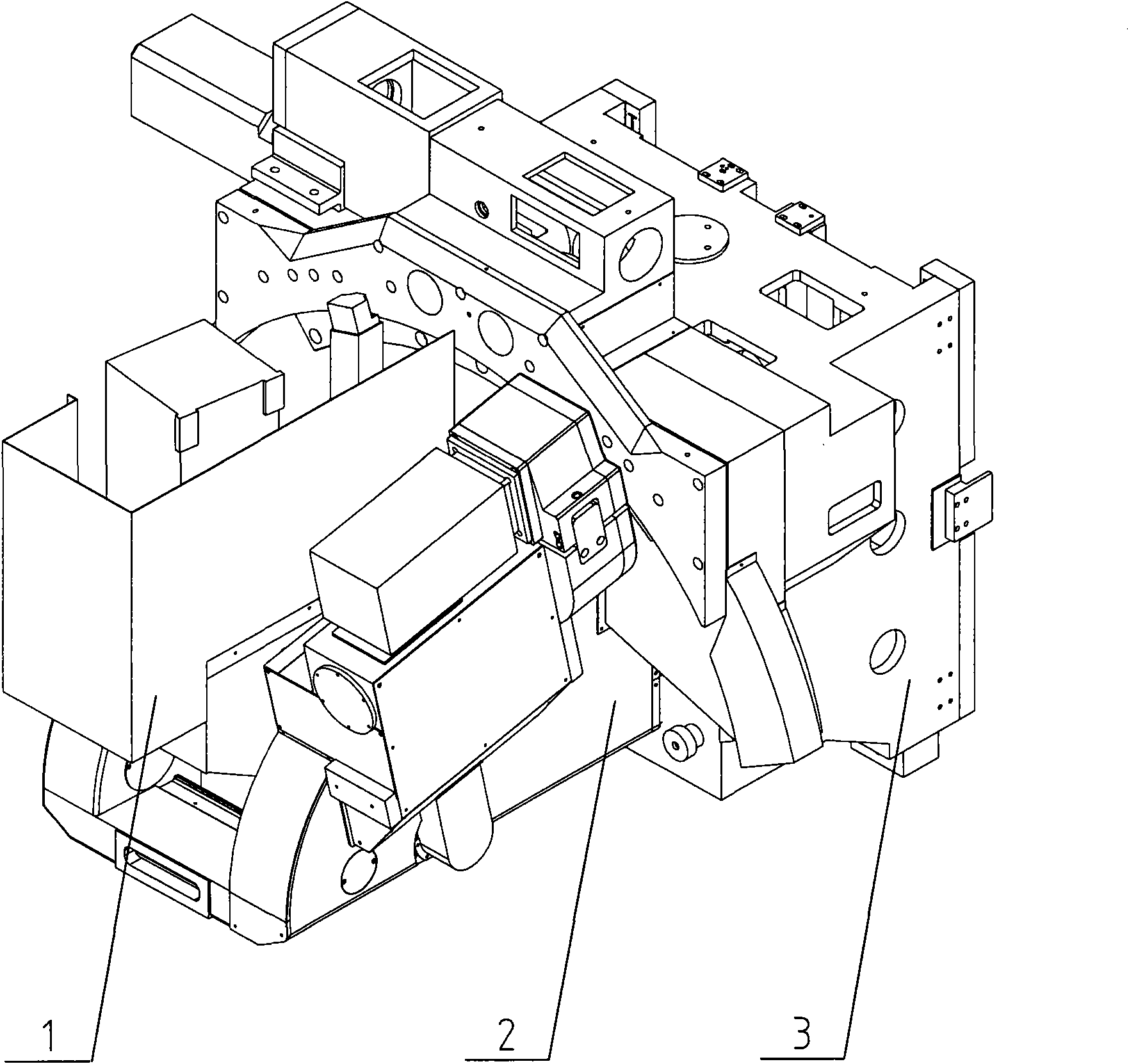

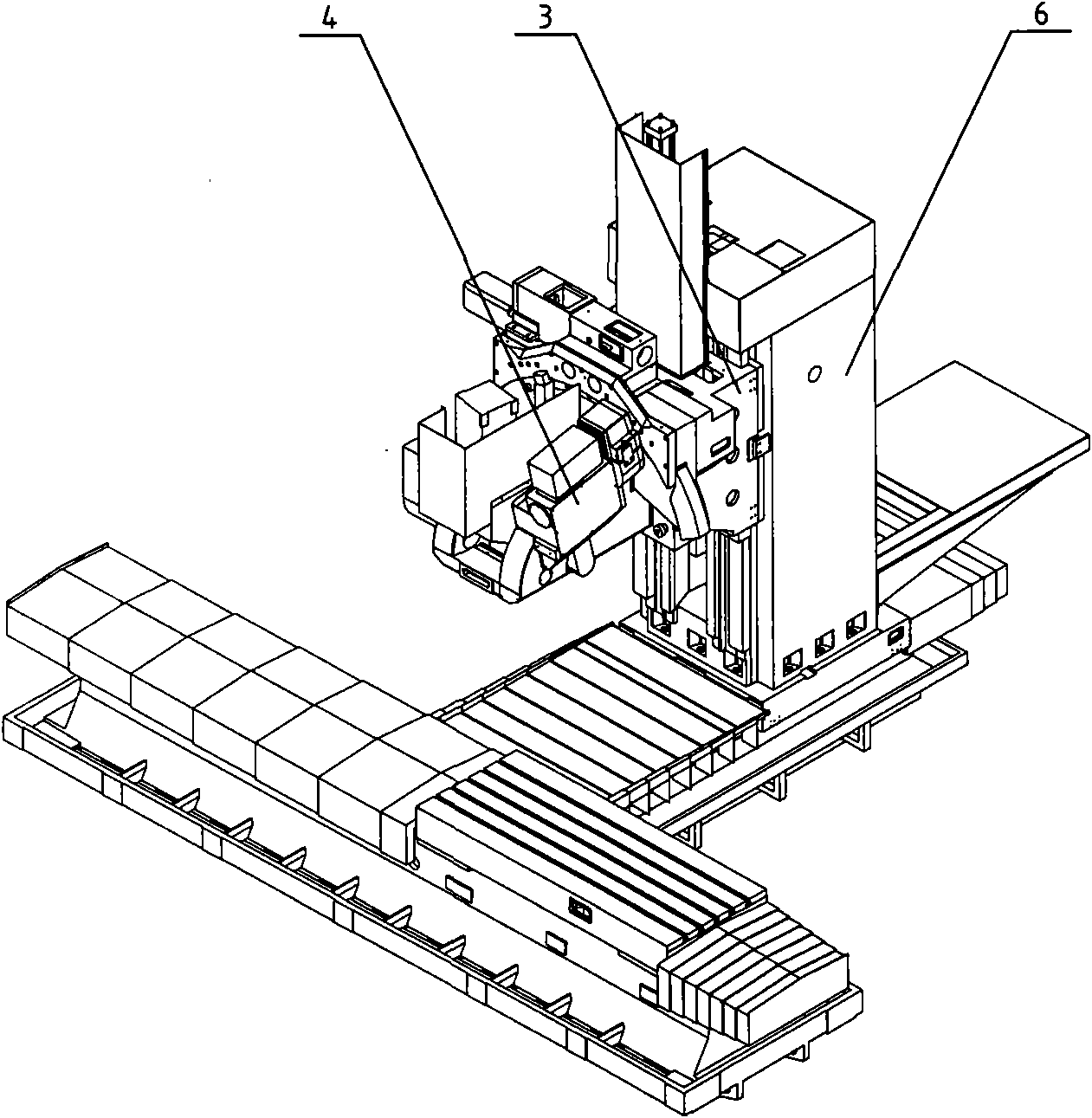

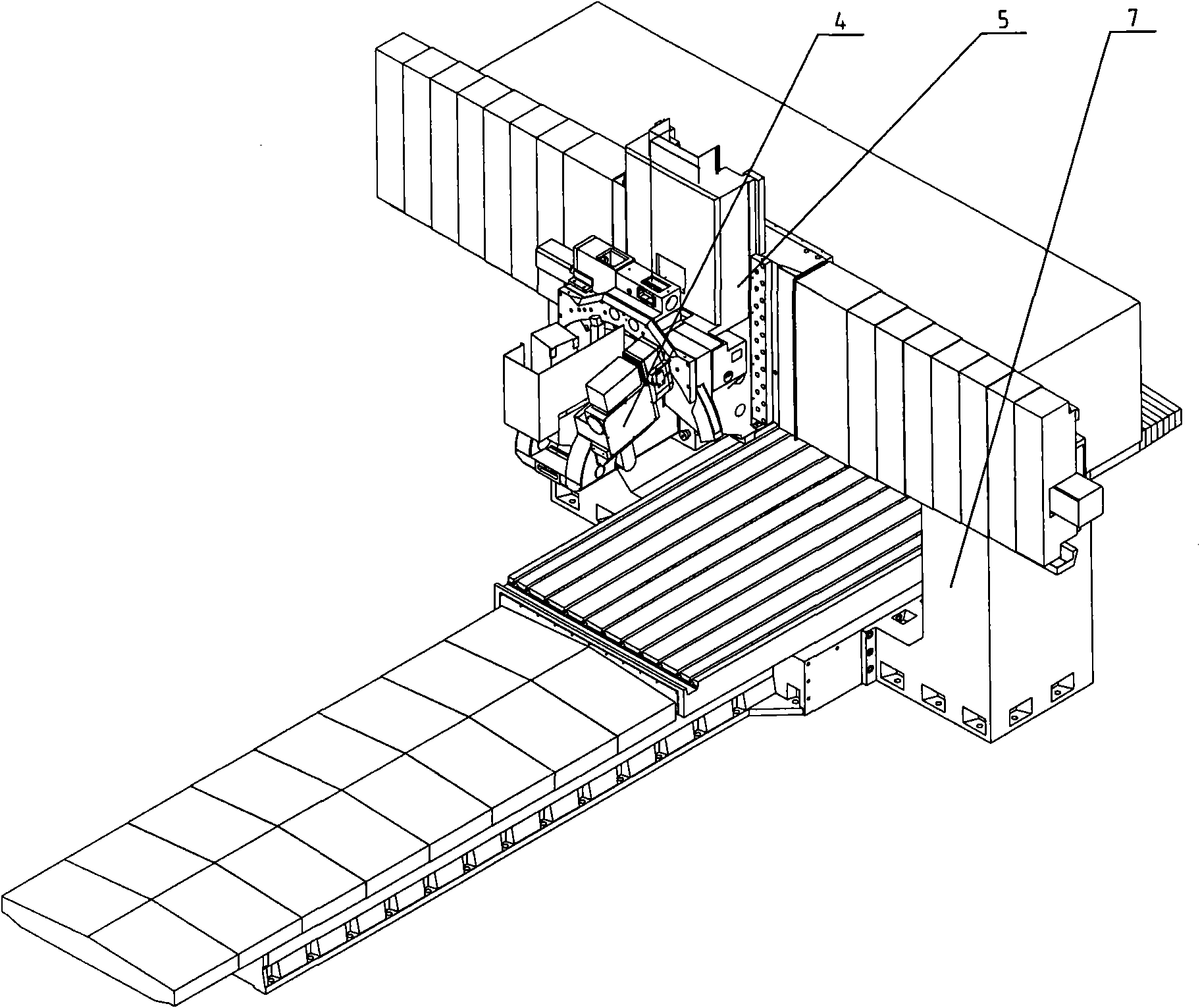

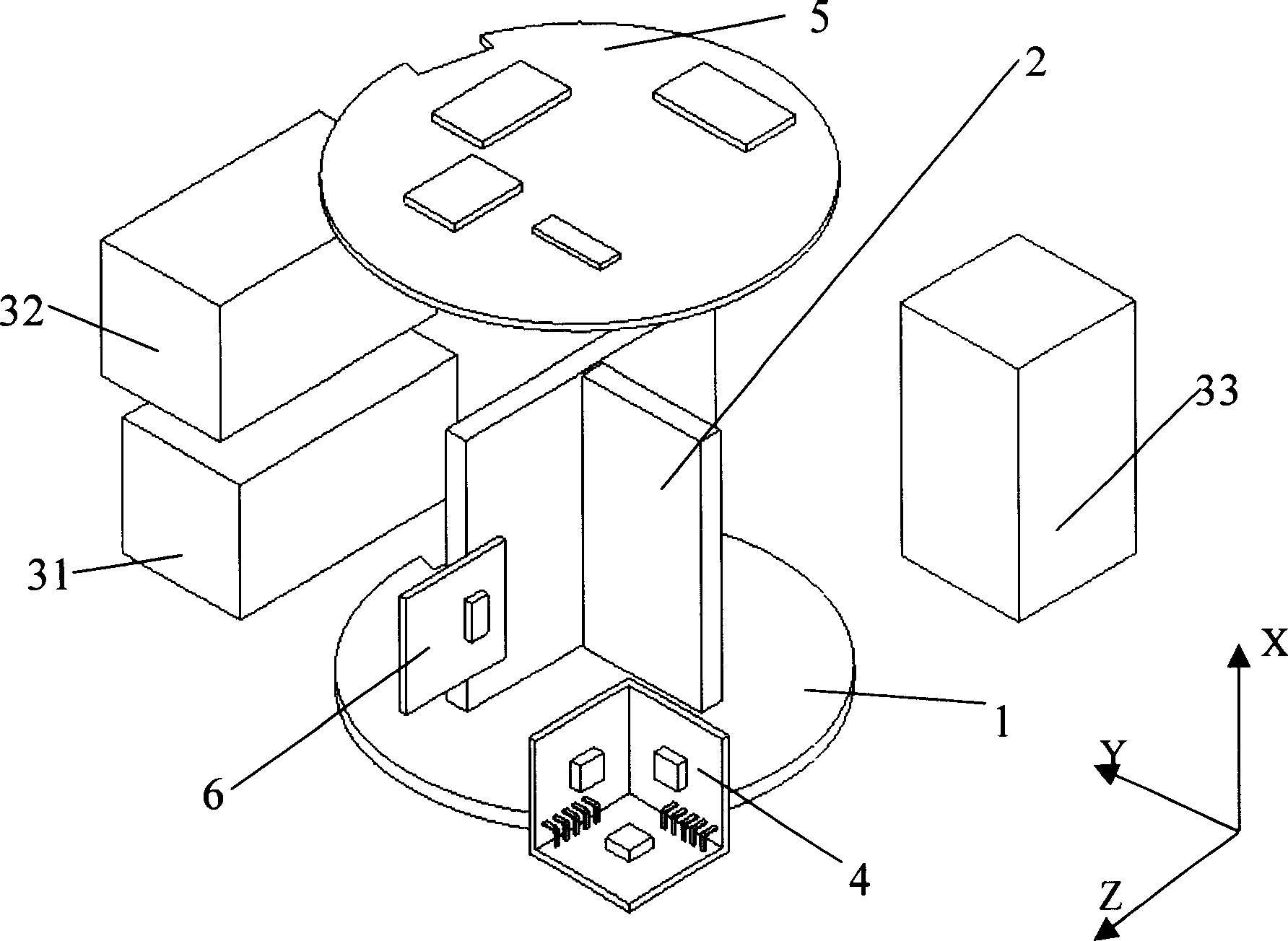

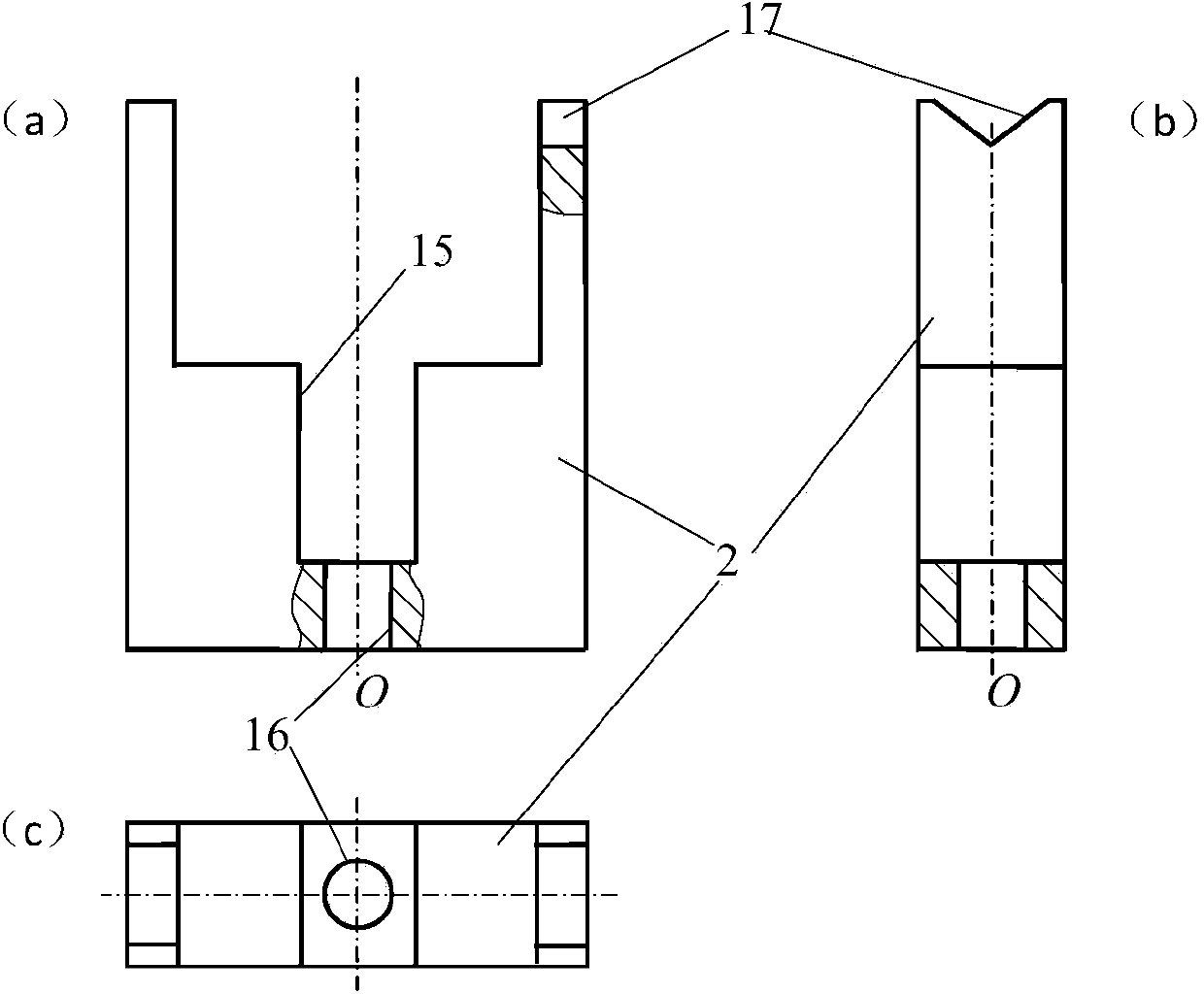

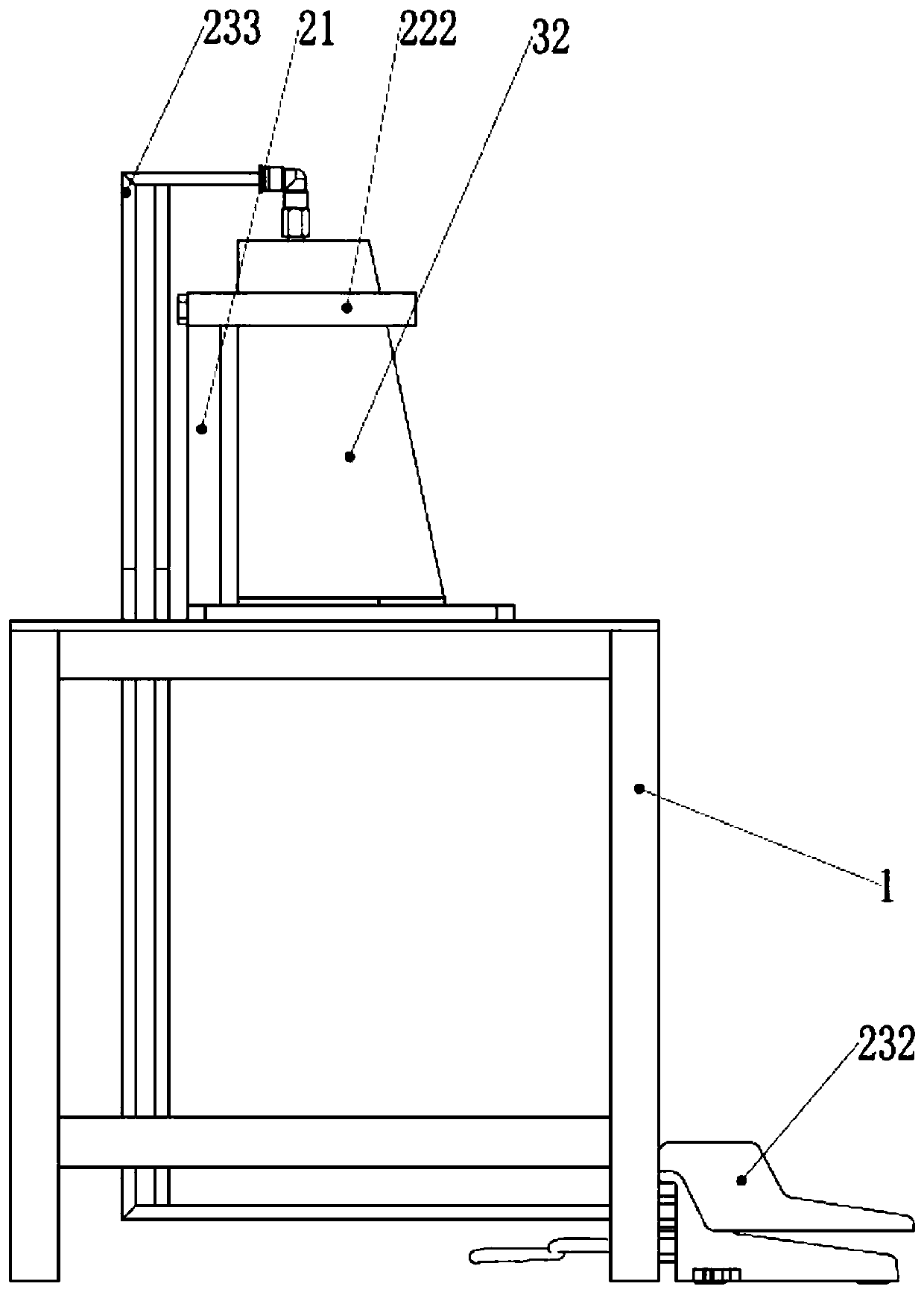

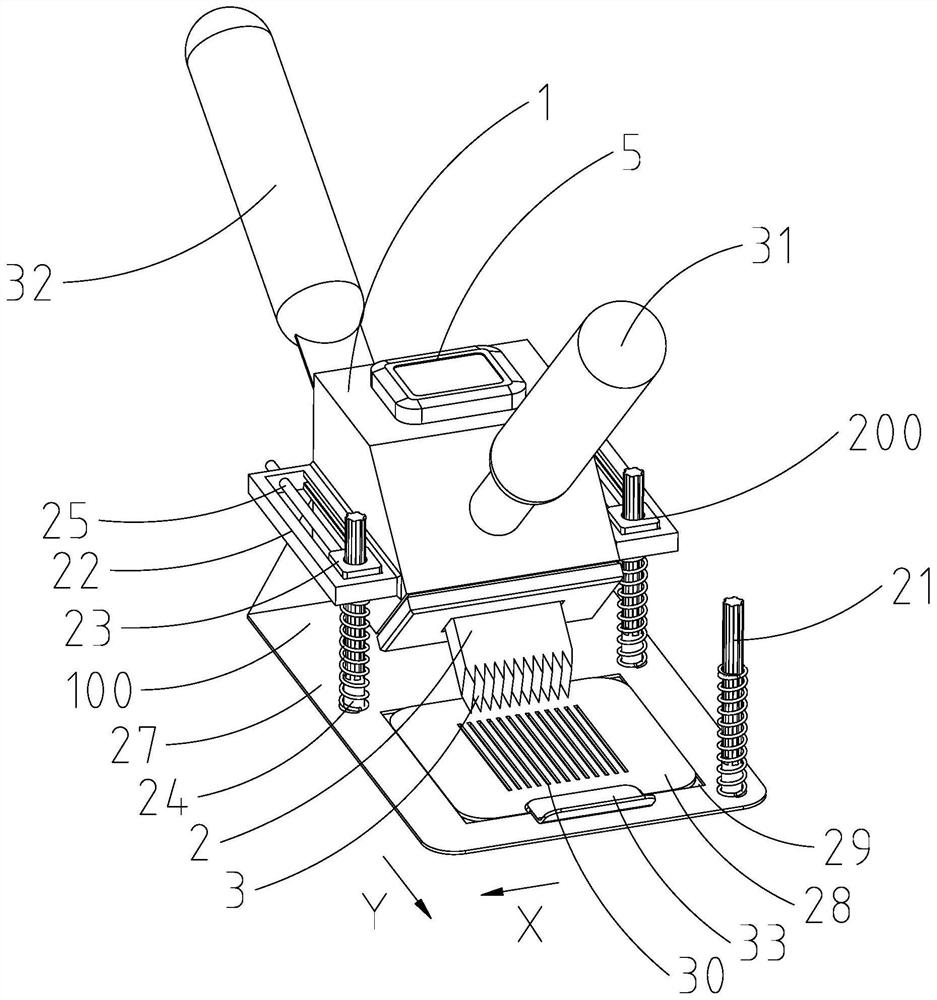

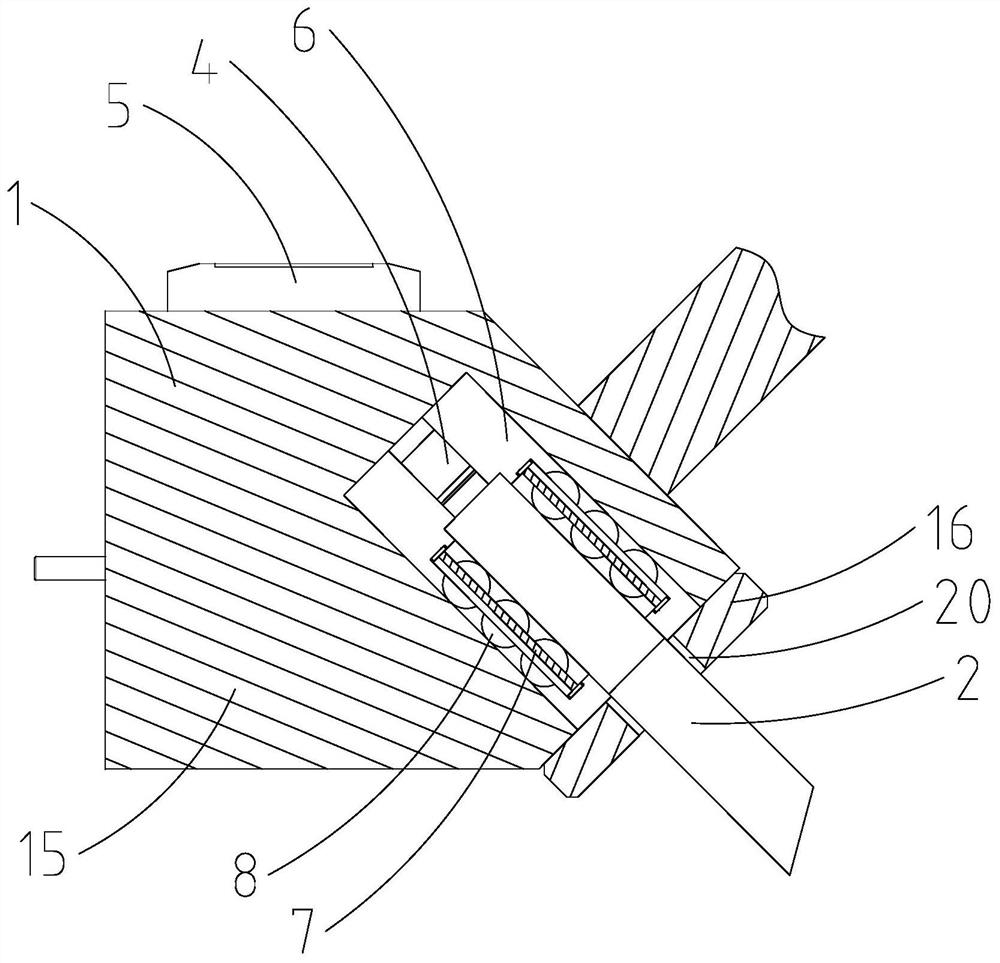

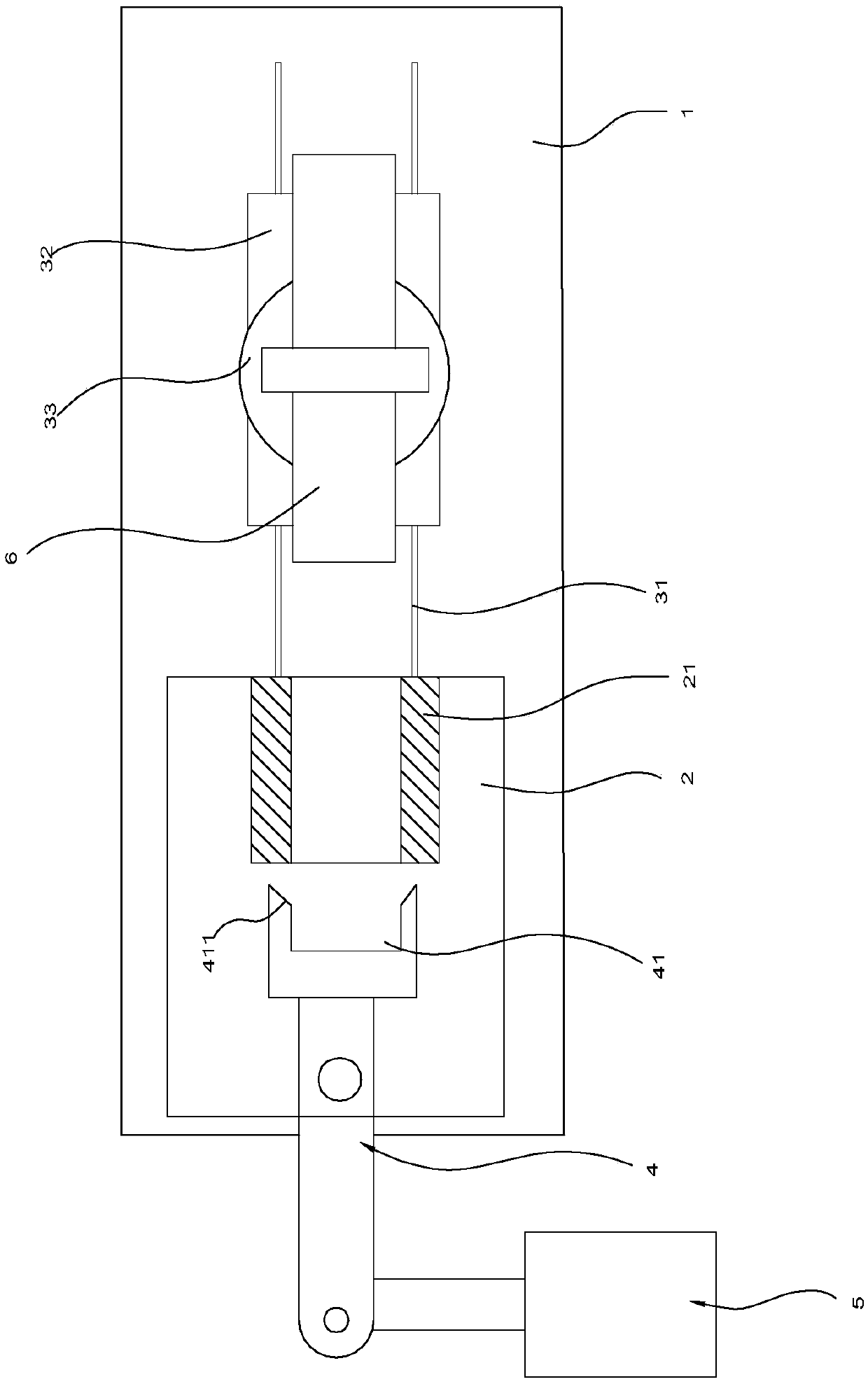

Additional device with A and B-axis oscillating structure and manufacturing method thereof

InactiveCN102009371AMeet processing needsHigh torqueDriving apparatusMetal working apparatusSlide plateLoop control

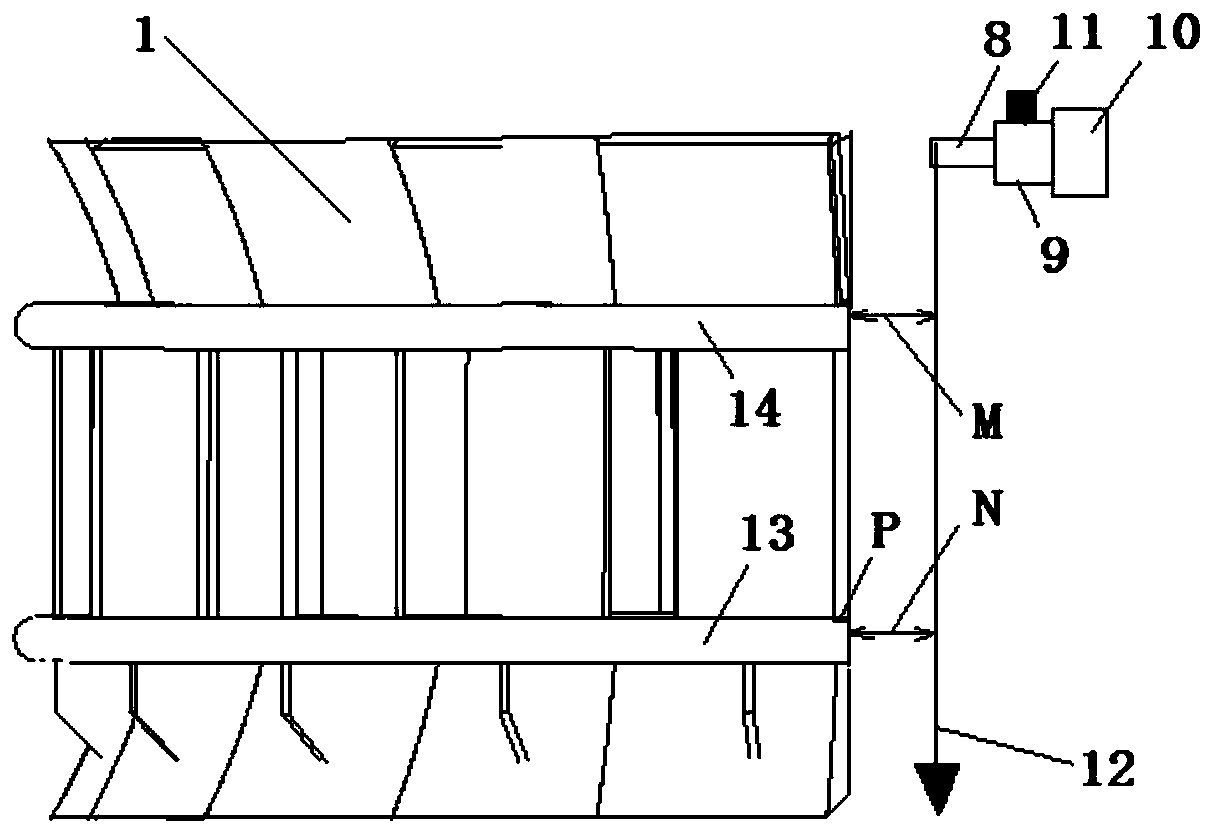

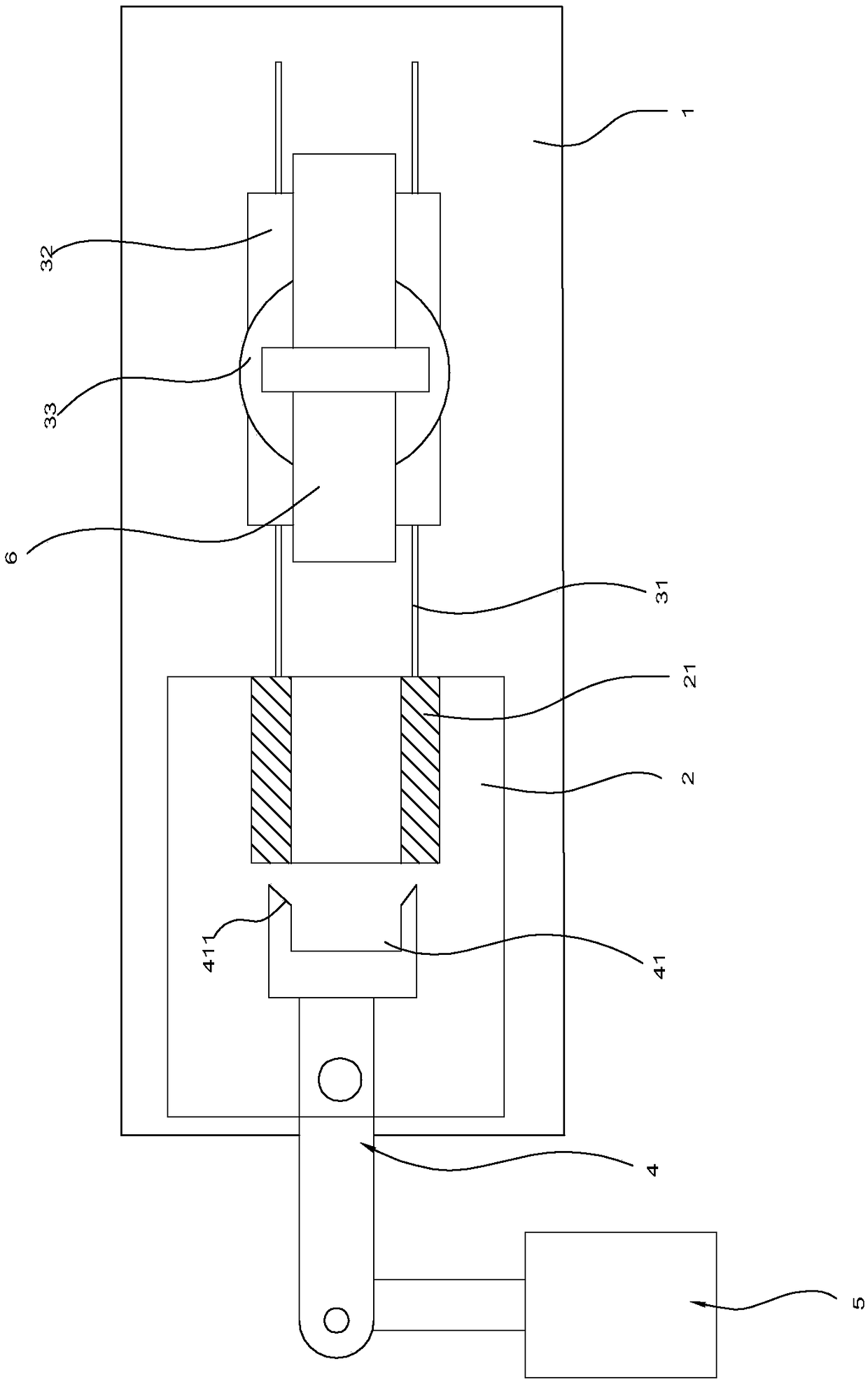

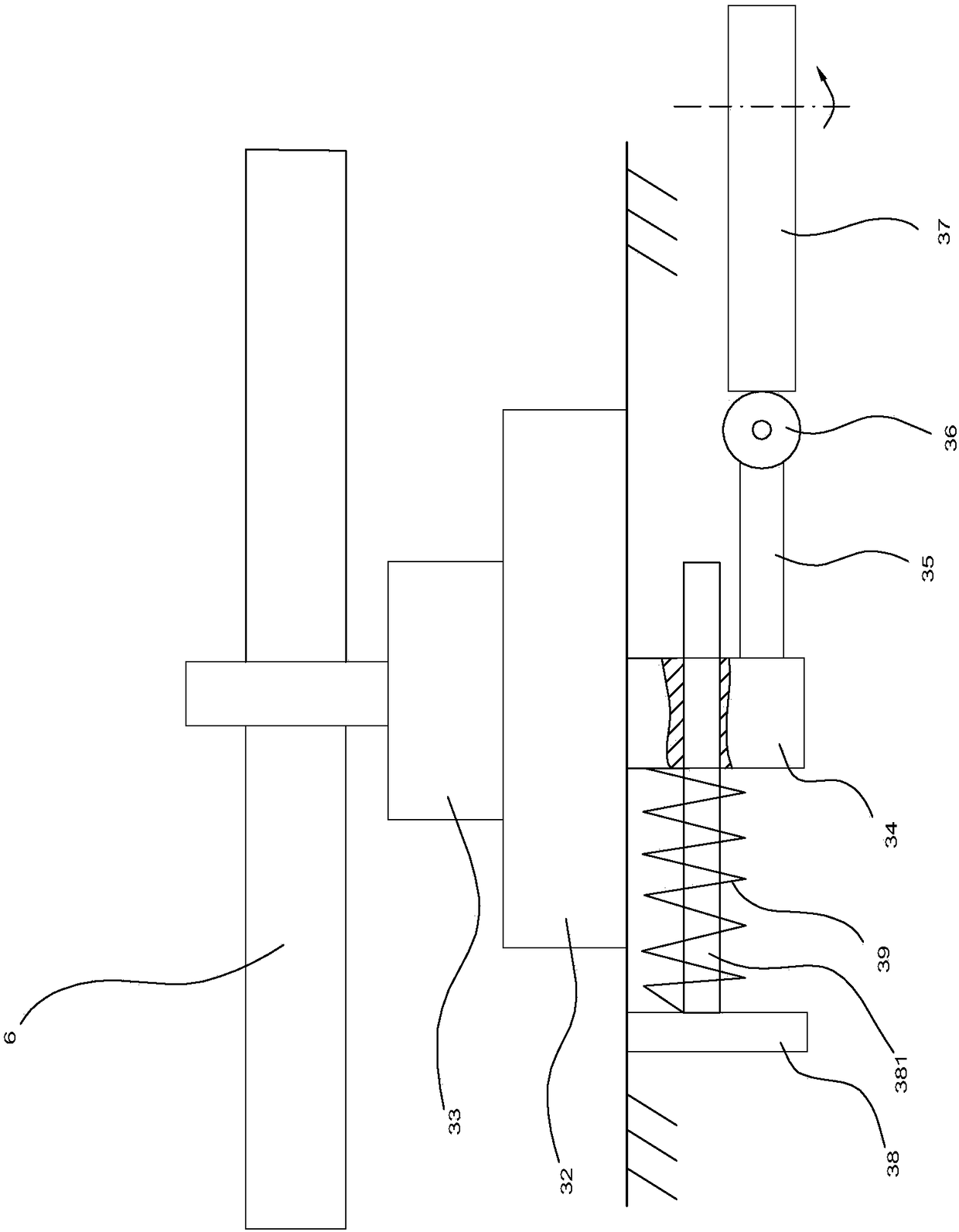

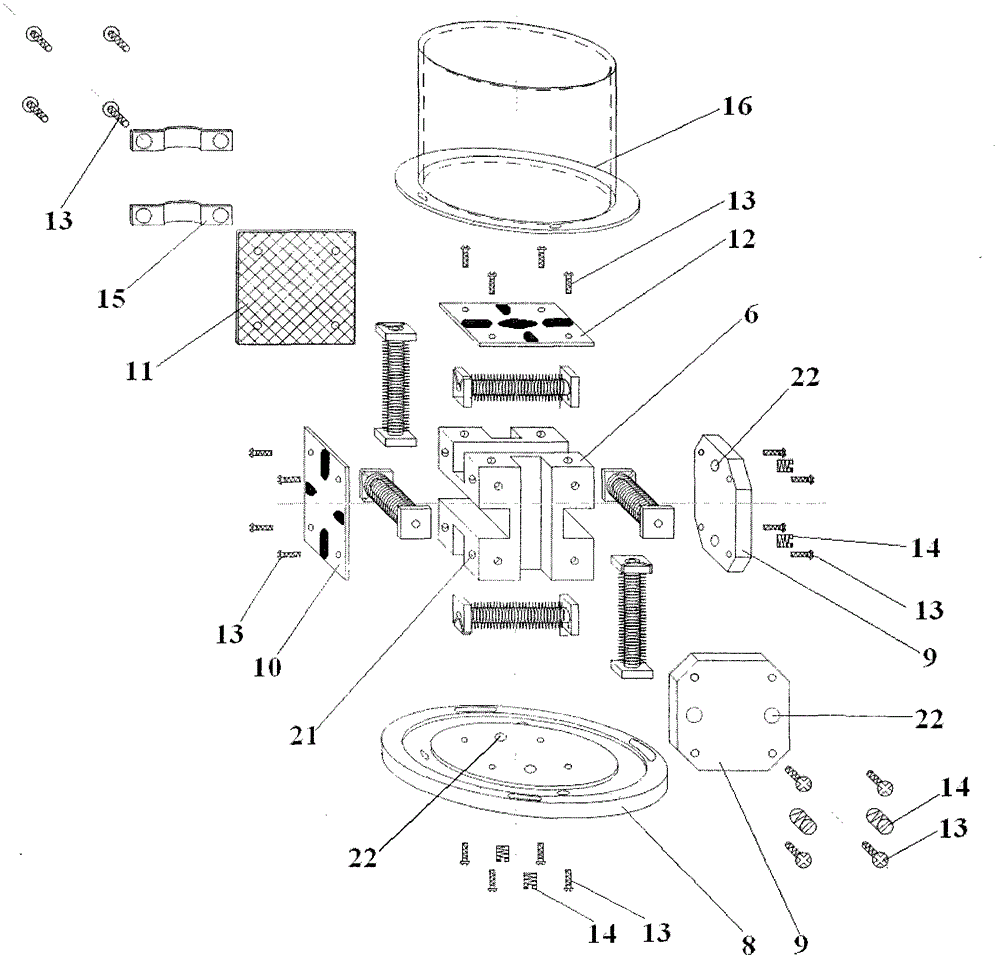

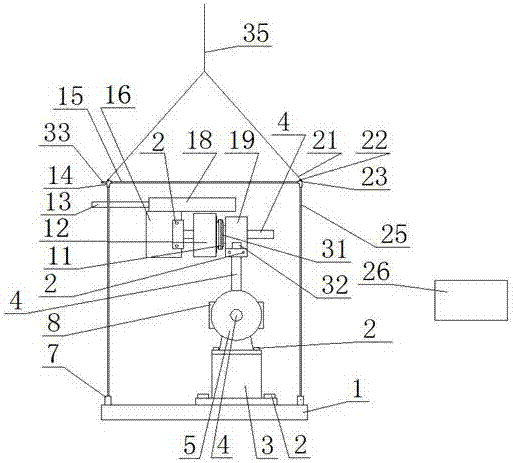

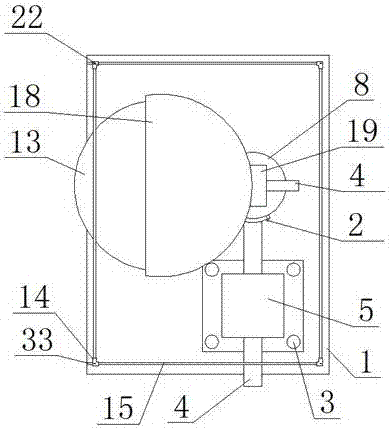

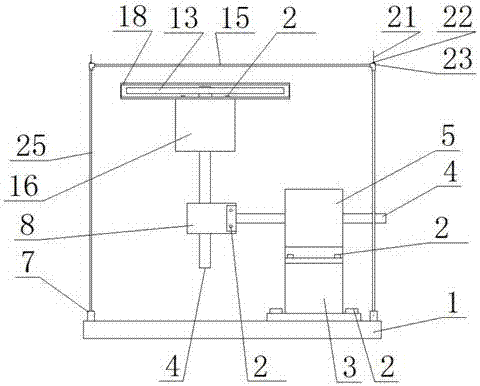

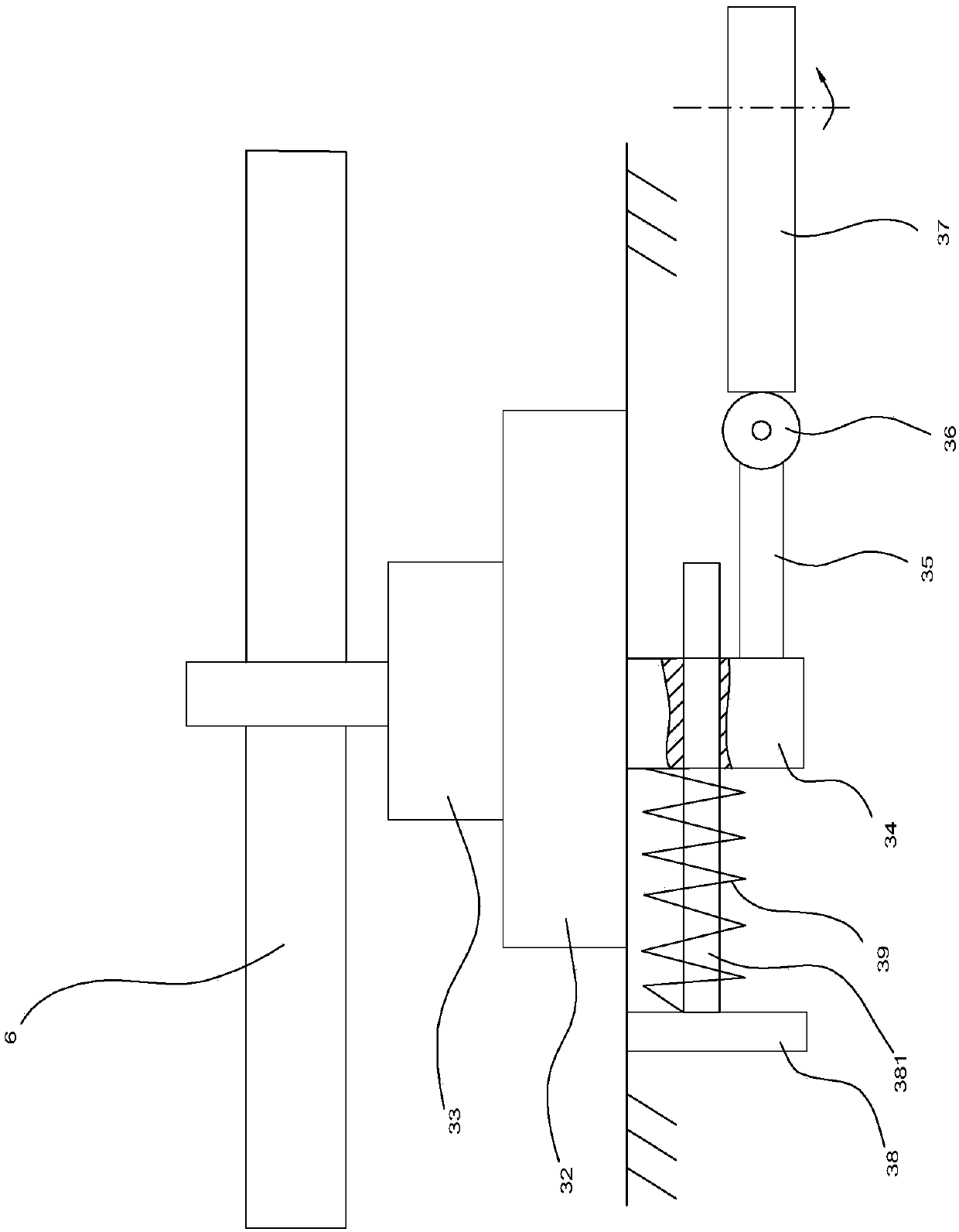

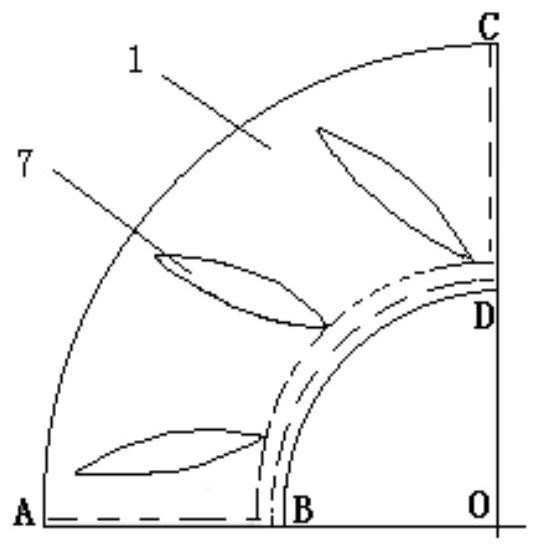

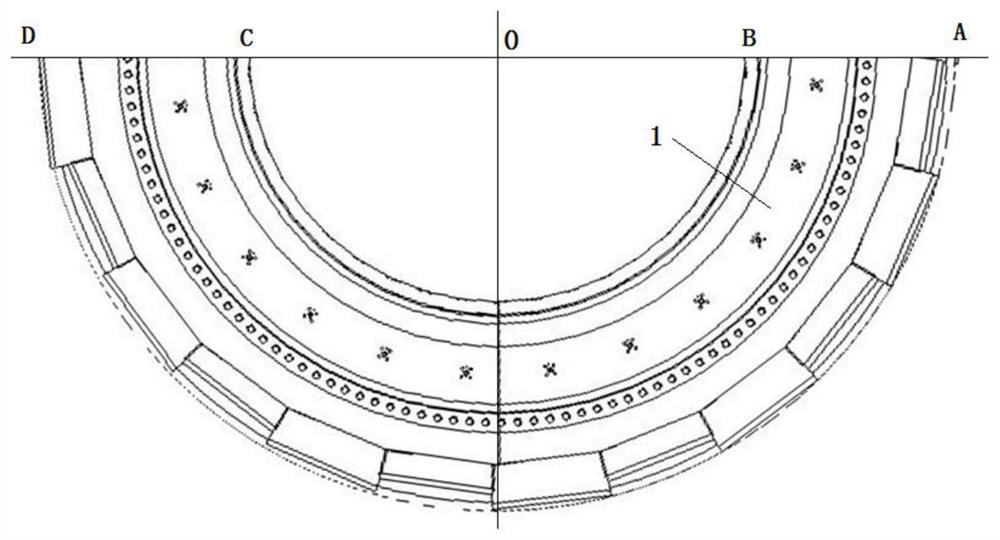

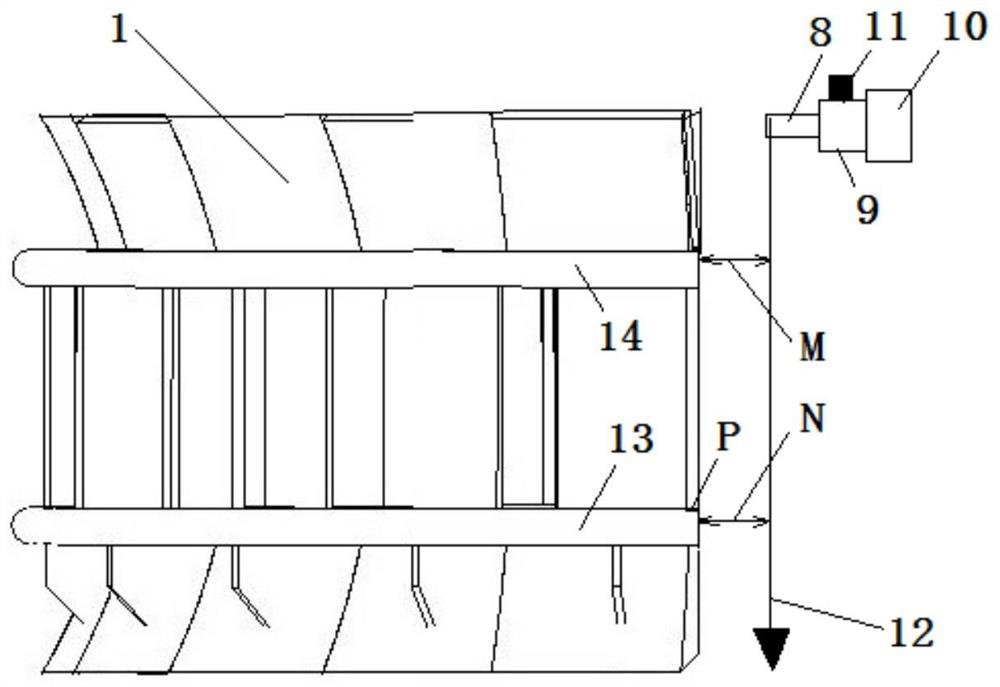

The invention relates to an additional device with an A and B-axis oscillating structure and a manufacturing method thereof. The additional device is used for five-axis linkage machining, and is characterized in that: a B-axis structure is fixed to the upper side of a sliding plate, a B-axis large gear ring is fixed with a B-axis support, and the B-axis support rotates around an oscillating shaft to form a B axis; an A-axis structure is fixed on the right side of the B-axis support; a main shaft box is fixed between two arms of the B-axis support; an A-axis large gear ring is fixed with the main shaft box; a left revolving shaft and a right revolving shaft are respectively, axially and horizontally fixed on the main shaft box; and the main shaft box rotates synchronously on a left shaft sleeve and a right shaft sleeve respectively to form an A axis; and thus, the additional device is formed. In the integral design of the device, the A axis allows for oscillating + / -30 degrees around an X axis, the B axis allows for oscillating + / -30 degrees around a Y axis, and the A axis and the B axis are subjected to closed-loop control by a circular grating; and the position control function of a computerized numerical control (CNC) system is realized by software and circuit hardware serving as electrical appliance circuits. In the device, three straight line axes of X, Y and Z are subjected to linkage to machine a complex space curved surface, so the device has the characteristics of compact structure, high accuracy and rigidity, large torsion and the like.

Owner:ZHONGJIE MACHINE TOOL

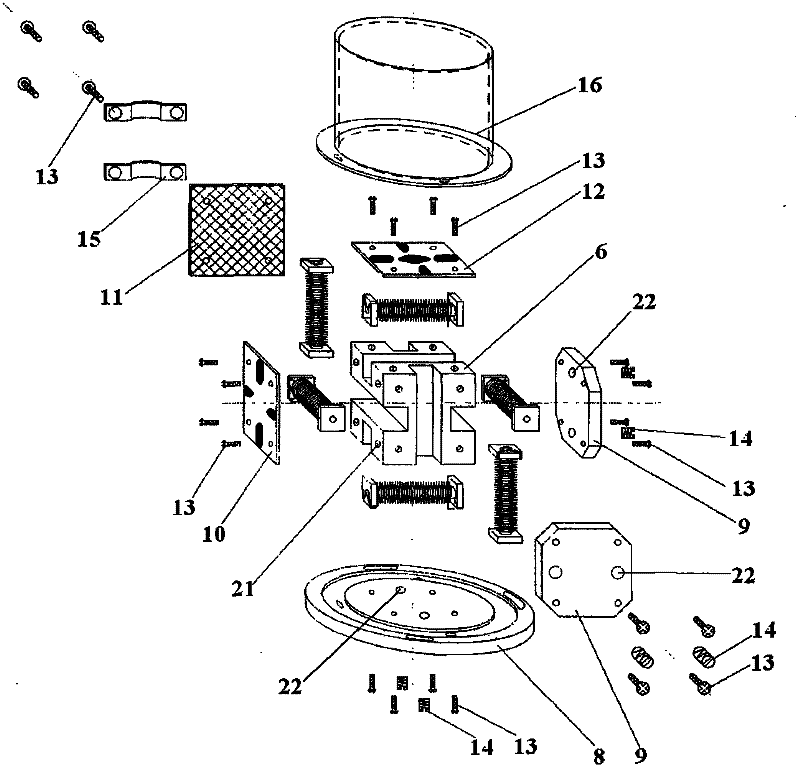

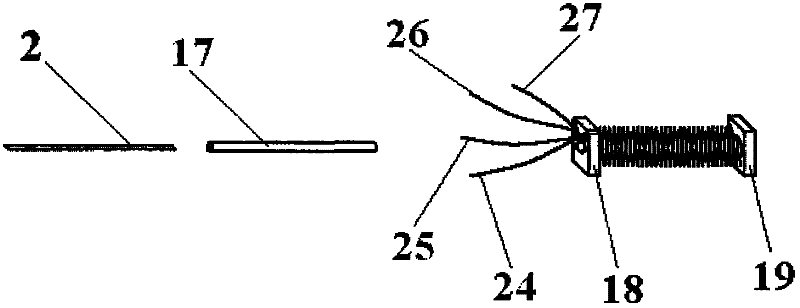

Fluxgate with single iron core and three-axis fluxgate sensor

InactiveCN102129049AEnsure consistencyEasy processing and windingMagnitude/direction of magnetic fieldsEngineeringConductor Coil

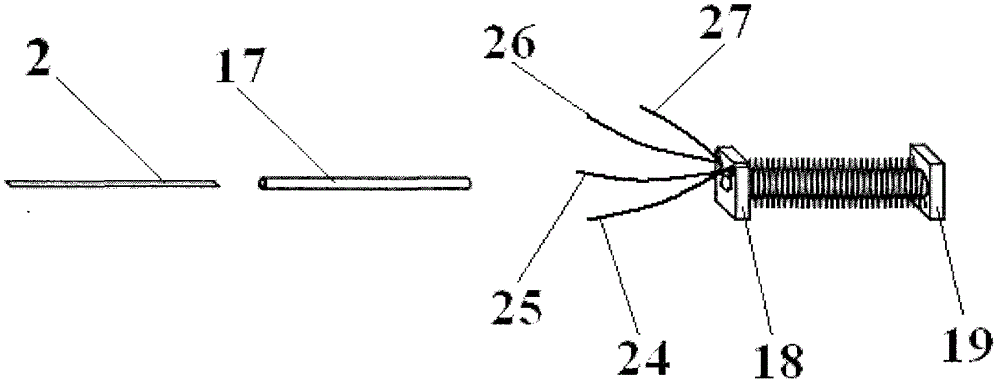

The invention discloses a fluxgate with a single iron core and a three-axis fluxgate sensor, solving the technical problem of processing difficulty of a traditional three-axis fluxgate sensor. The invention adopts the technical scheme that the iron core of the fluxgate is of a strip shape, is more convenient to process and wind, and can better ensure consistency between a measuring shaft and a mounting shaft and decrease the manufacture cost. The three-axis fluxgate sensor adopting the strip iron core fluxgate is of a separation structure of the fluxgate and a sensor base, thus, the complexity for processing, winding and assembling of the iron core the coil is lessened, the three single-axis fluxgates are ensured to be mutually perpendicular and convenient to fix, and the reliability and the maintainability of the three-axis fluxgate sensor are improved.

Owner:JIANGSU ZHONGHAI HEAVY MACHINE TOOL +1

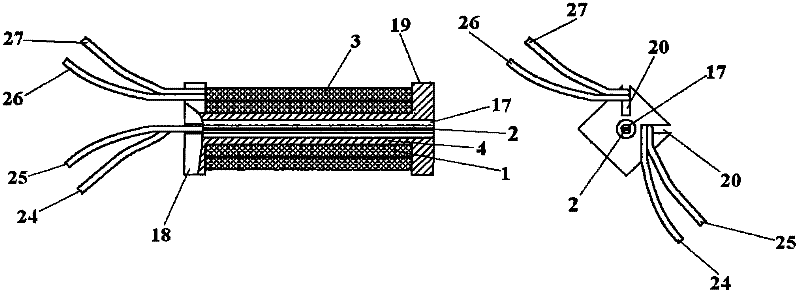

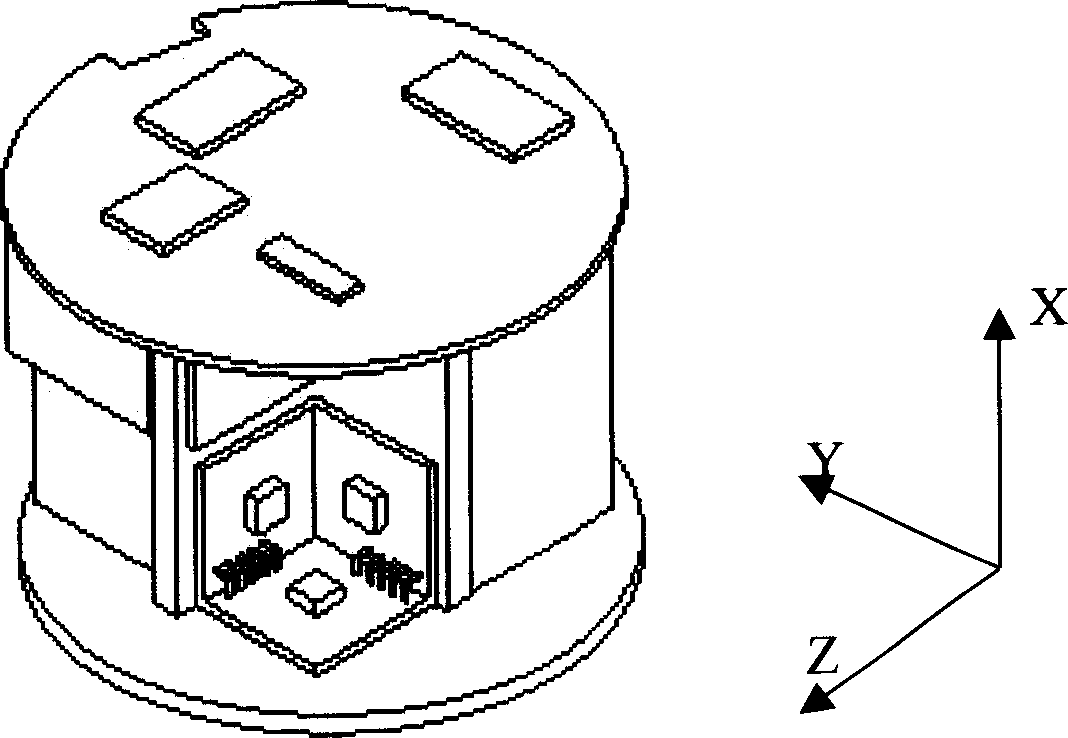

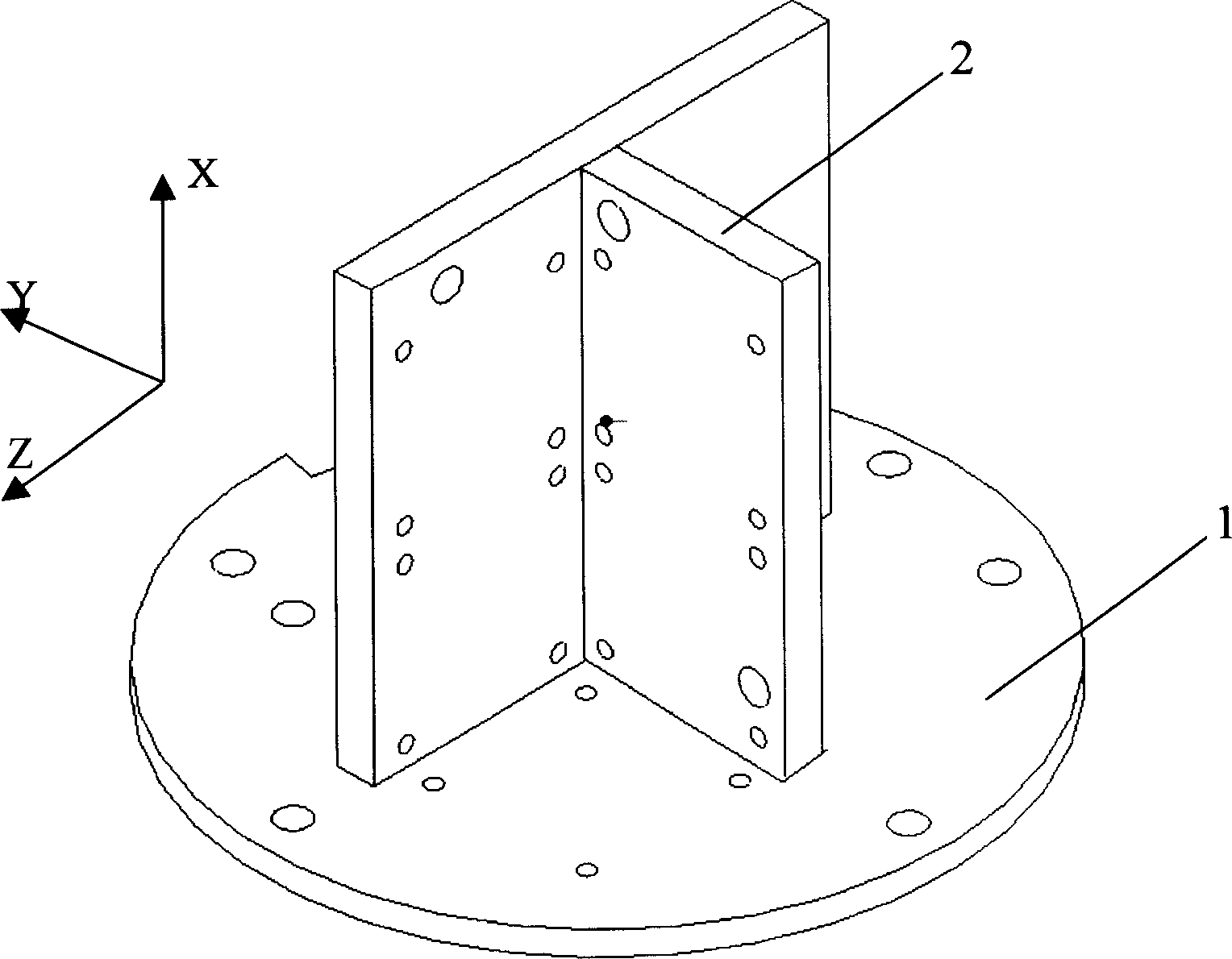

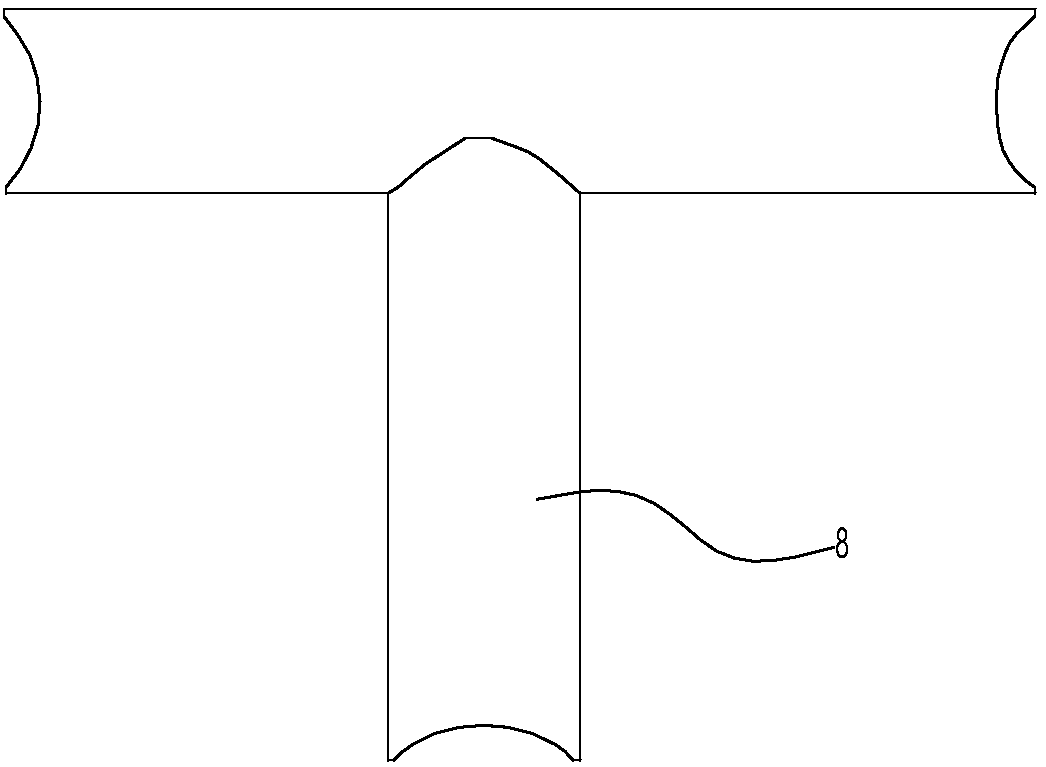

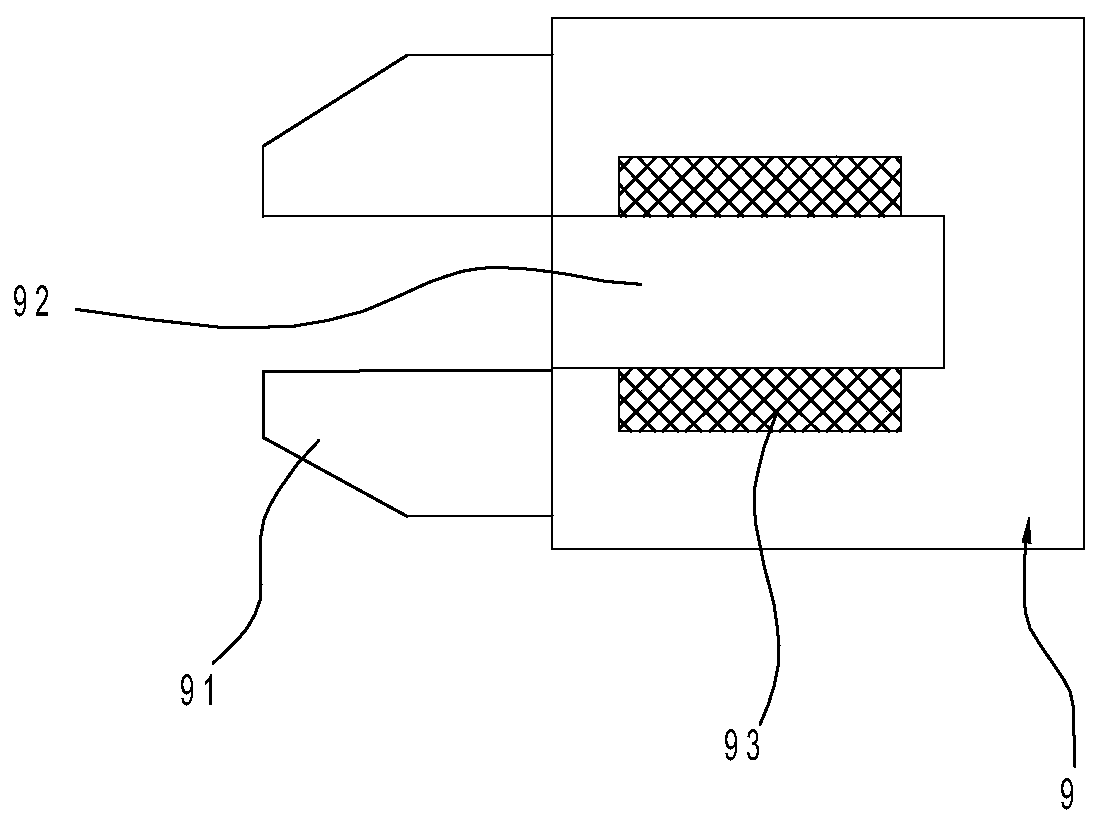

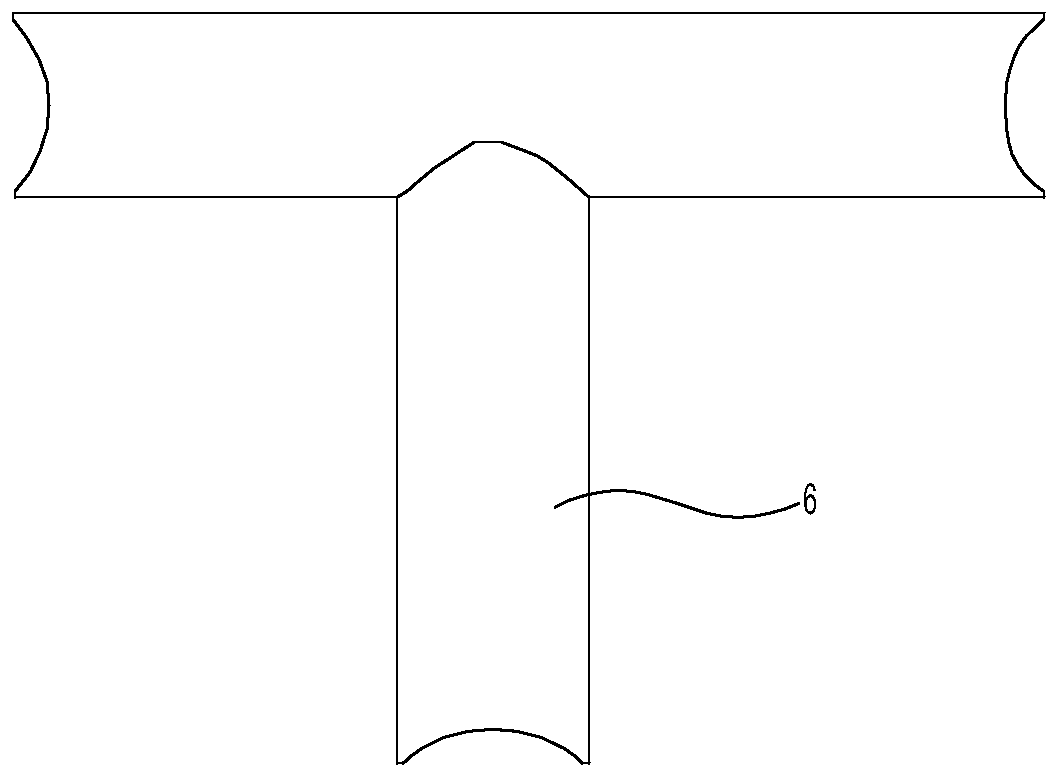

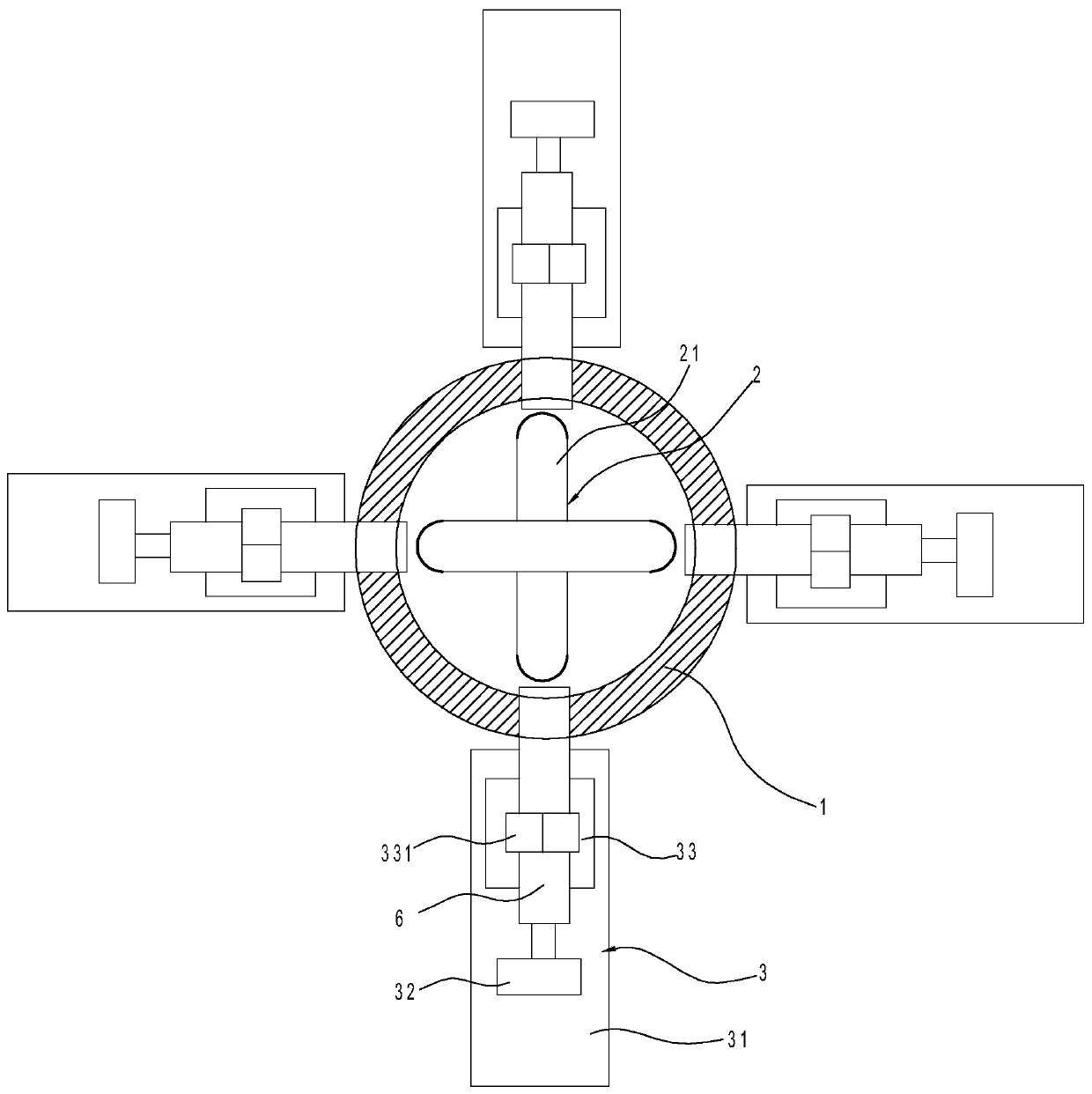

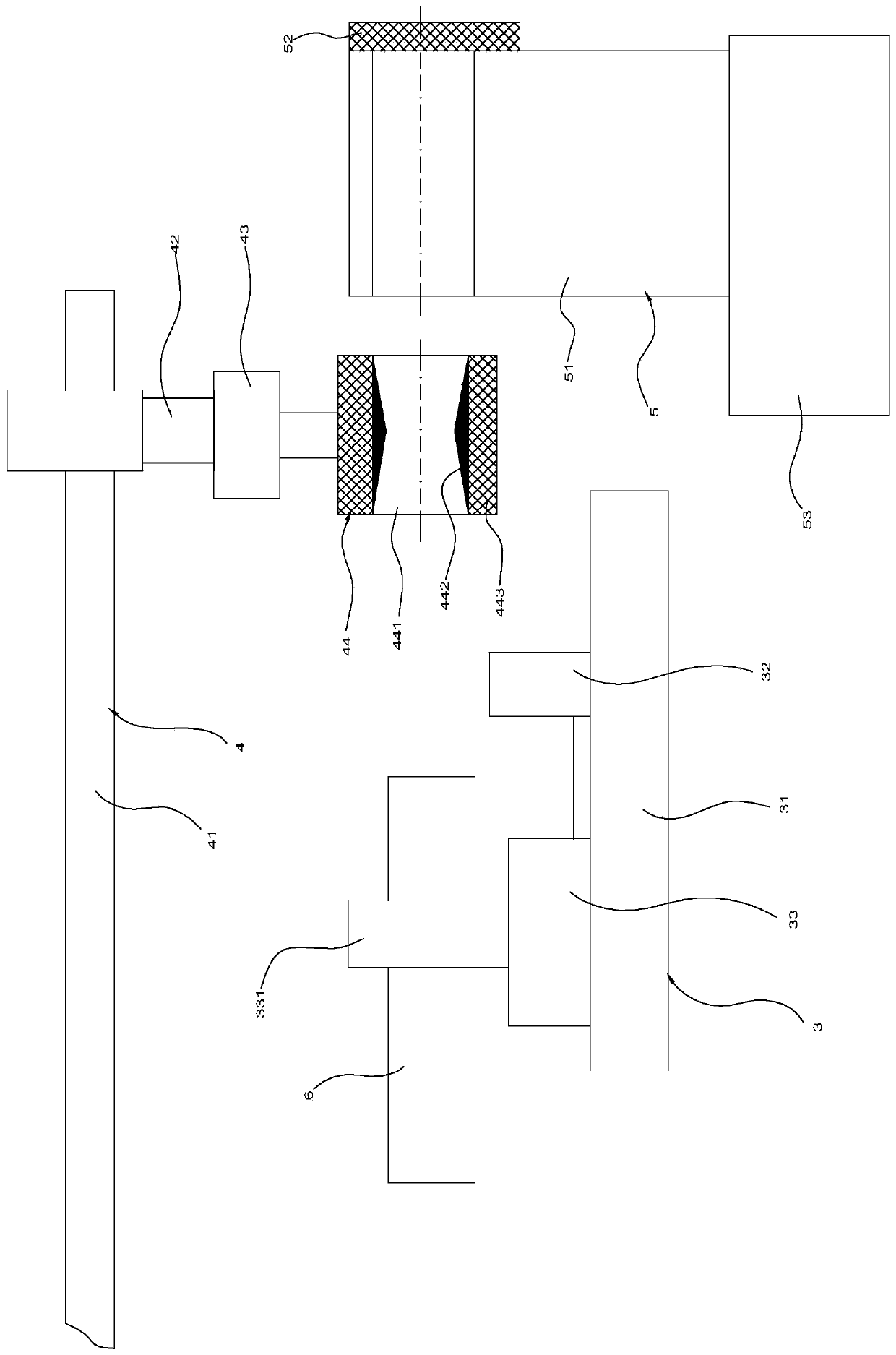

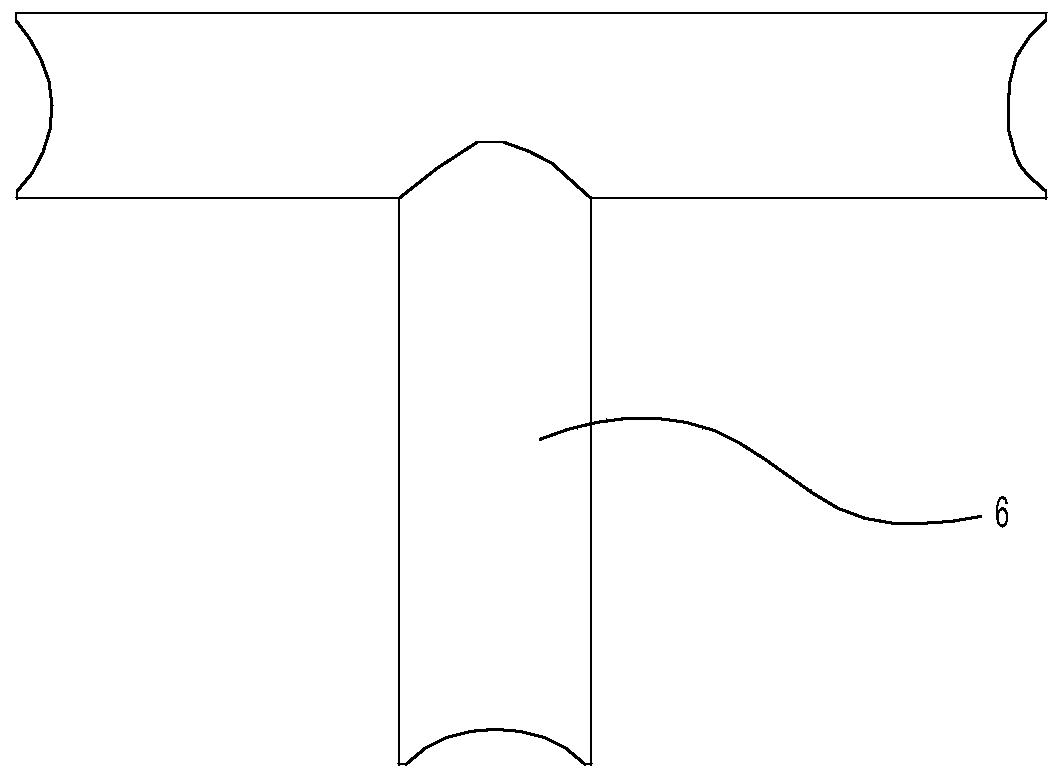

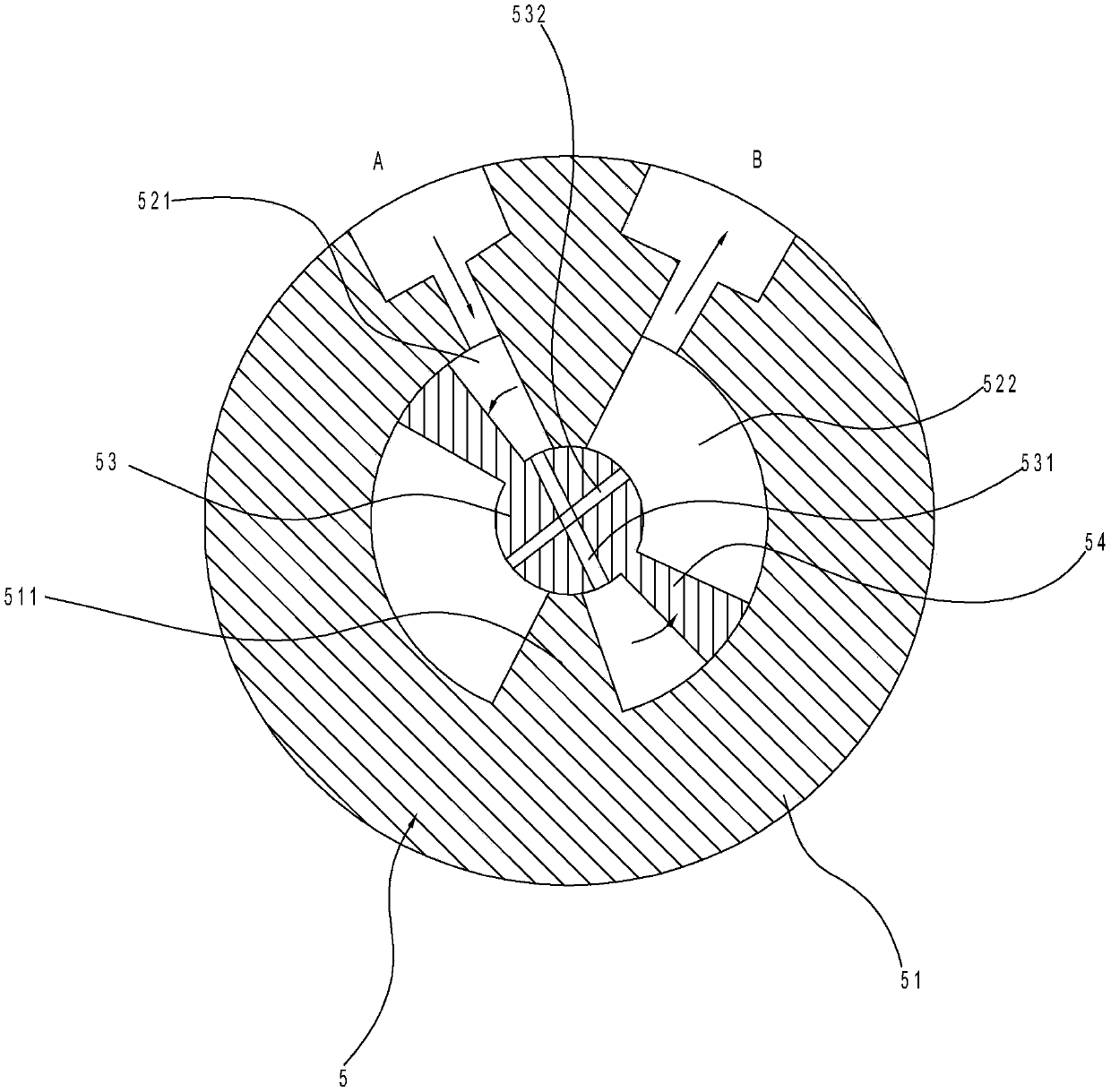

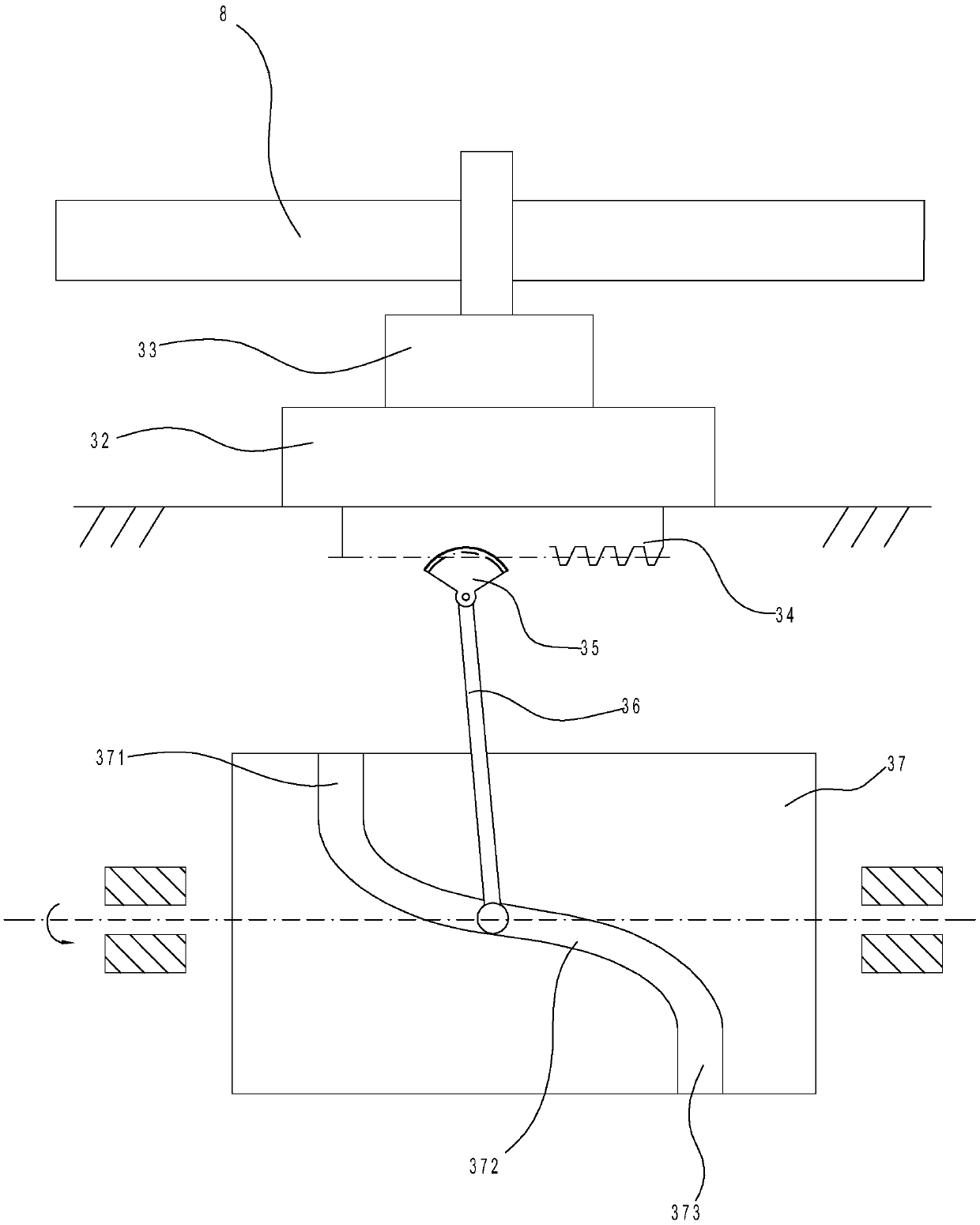

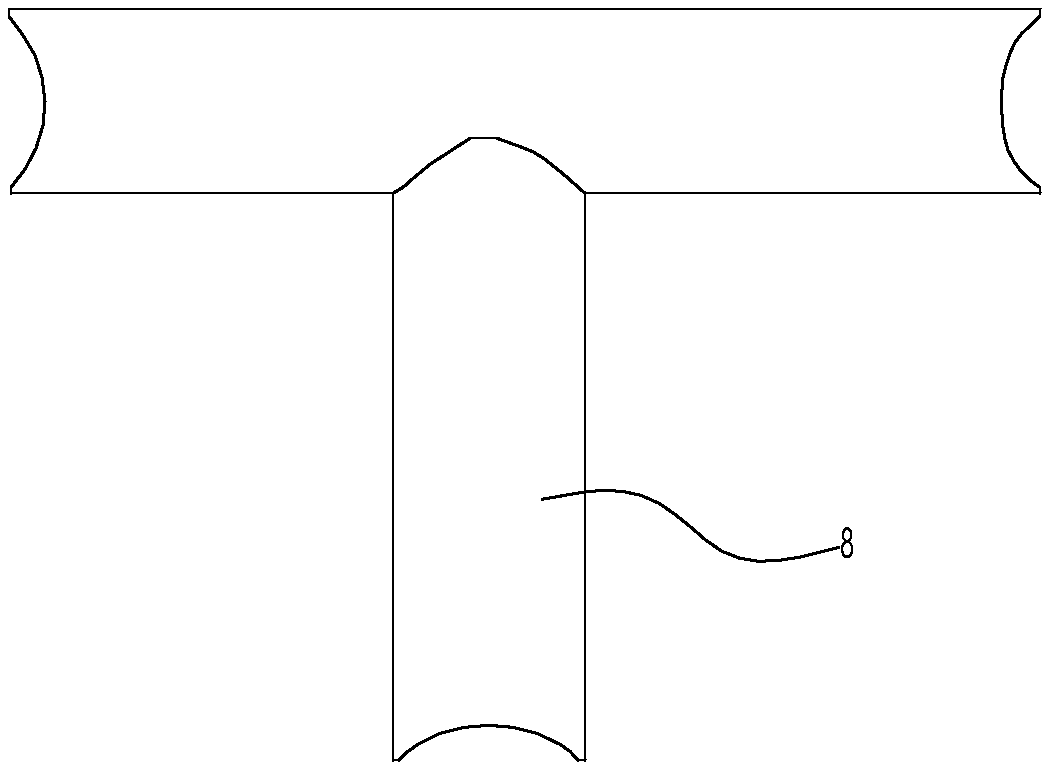

Connected inertia measuring device of open-loop fibre-optical

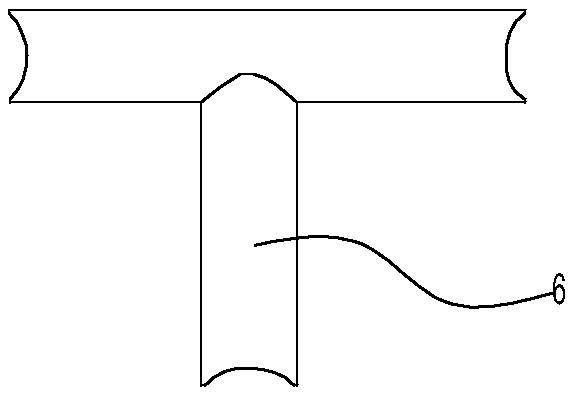

InactiveCN1818556AGuaranteed to be perpendicular to each otherReduce volumeNavigation by speed/acceleration measurementsGyroscopeAccelerometer

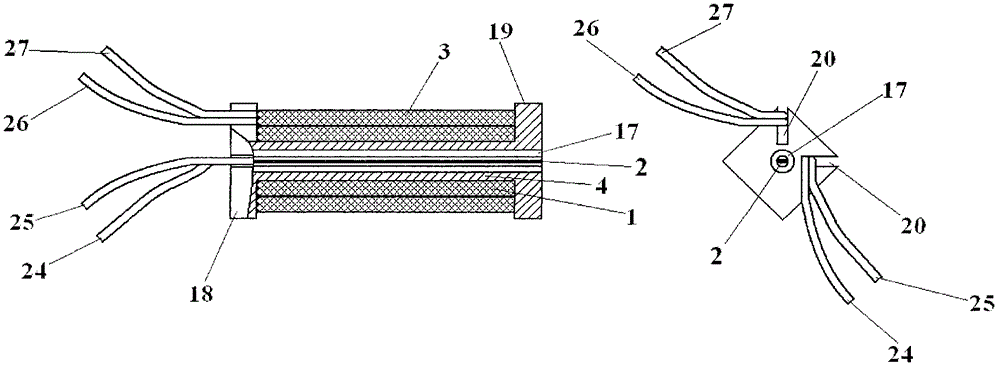

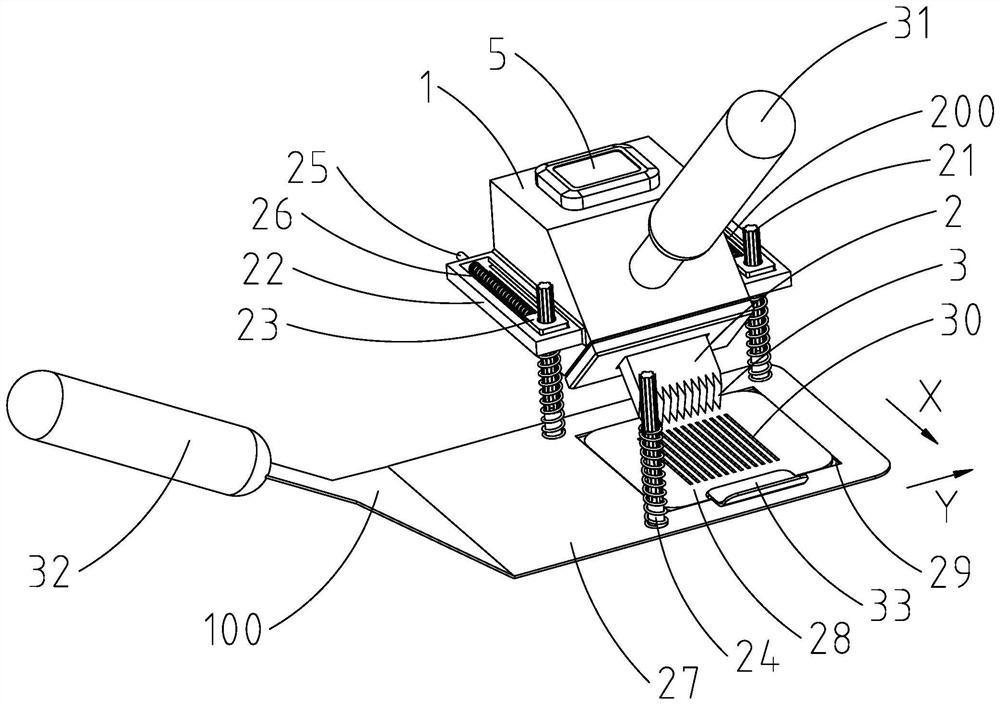

A device for measuring strap down inertia of gyroscope in small volume and open ring optical fiber type consists of three open ring optical fiber gyroscopes, accelerometer, signal collection module, data processing module, data transmission interface and mechanical framework .It is featured as forming mechanical framework by T form structure and base plate, setting X-axis gyroscope on base plate and setting Y-axis gyroscope and Z-axis gyroscope on T form structure, setting accelerometer on said framework and setting signal collection and data processing modules on T form structure .

Owner:BEIHANG UNIV

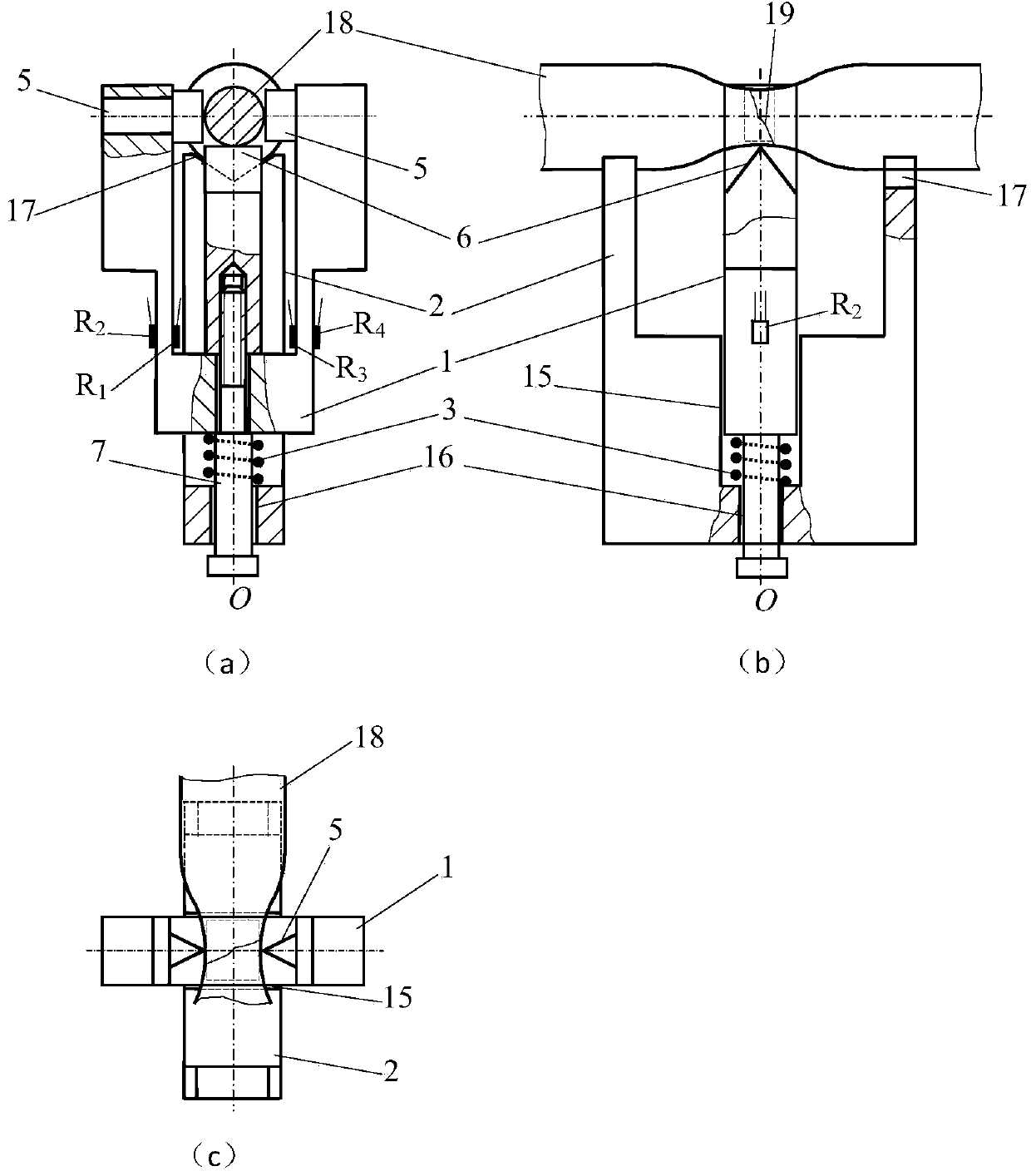

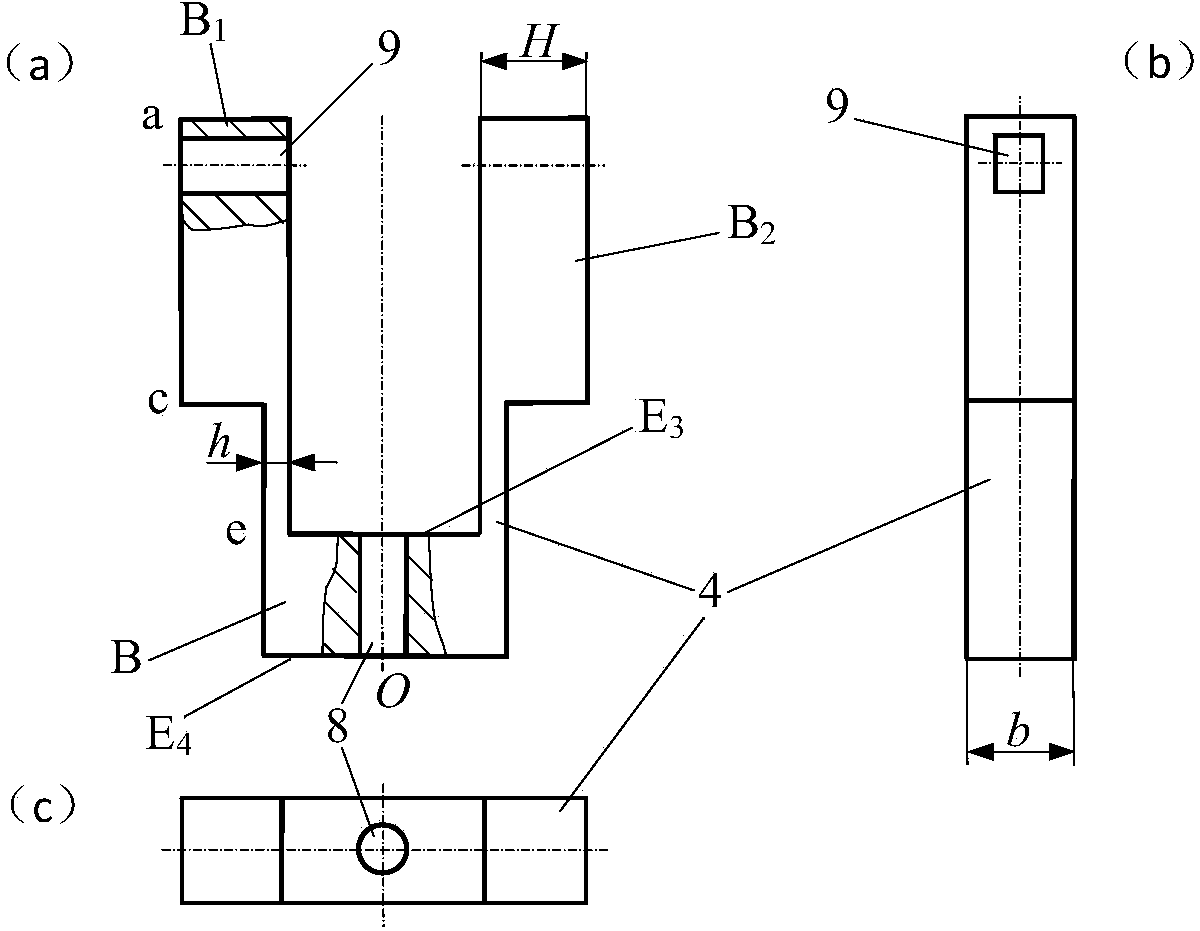

Device and method for measuring minimum diameter of diameter shrinkage portion of tensile sample after fracture

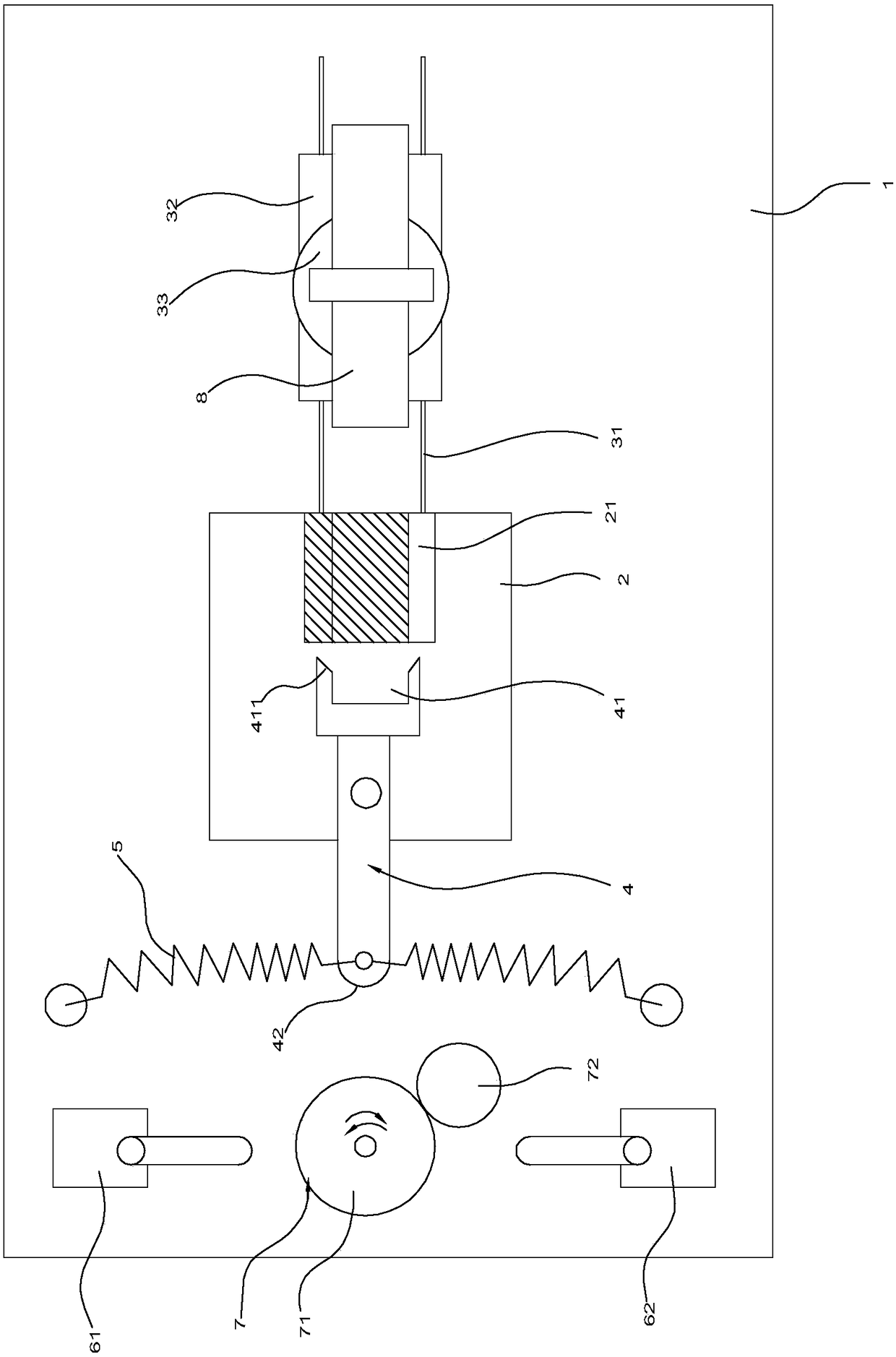

ActiveCN103994715AEliminate offset errorsEliminate contact offset errorsElectrical/magnetic diameter measurementsElectrical resistance and conductanceData acquisition

The invention relates to a device and method for measuring the minimum diameter of a diameter shrinkage portion of a tensile sample after fracture. The device comprises a resistance-strain U-shaped sensor with a positioning rod and a measurement clamping tool edge, a U-shaped support, a plurality of standard units of standard cylinders and a data collector provided with measurement software. The sensor is installed on the standard cylinders or the tensile failure sample through cooperation of the positioning rod and the support, a measurement signal containing a standard diameter value or the minimum diameter value of the diameter shrinkage portion of the sample and the contact offset of the measurement clamping tool edge is transmitted to the data collector; a standardization algorithm of the measurement software provides a diameter fitting formula, and contact offset errors caused by different diameters of the standard cylinders are eliminated; a measurement algorithm of the measurement software provides a diameter value of the sample, and the contact offset errors caused by different diameters of the sample are eliminated.

Owner:NINGBO YINZHOU FUCHUN PRECISION CASTING

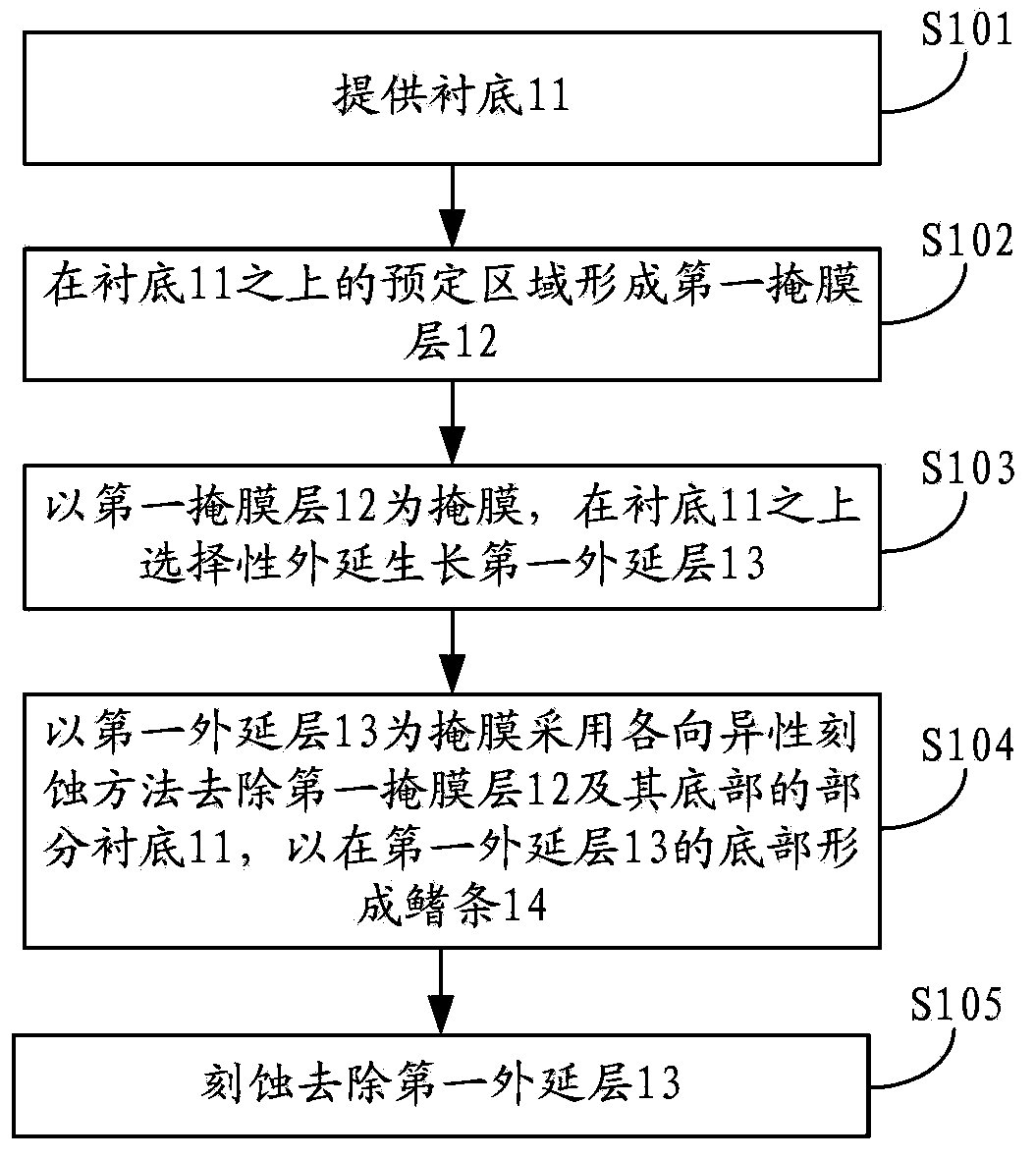

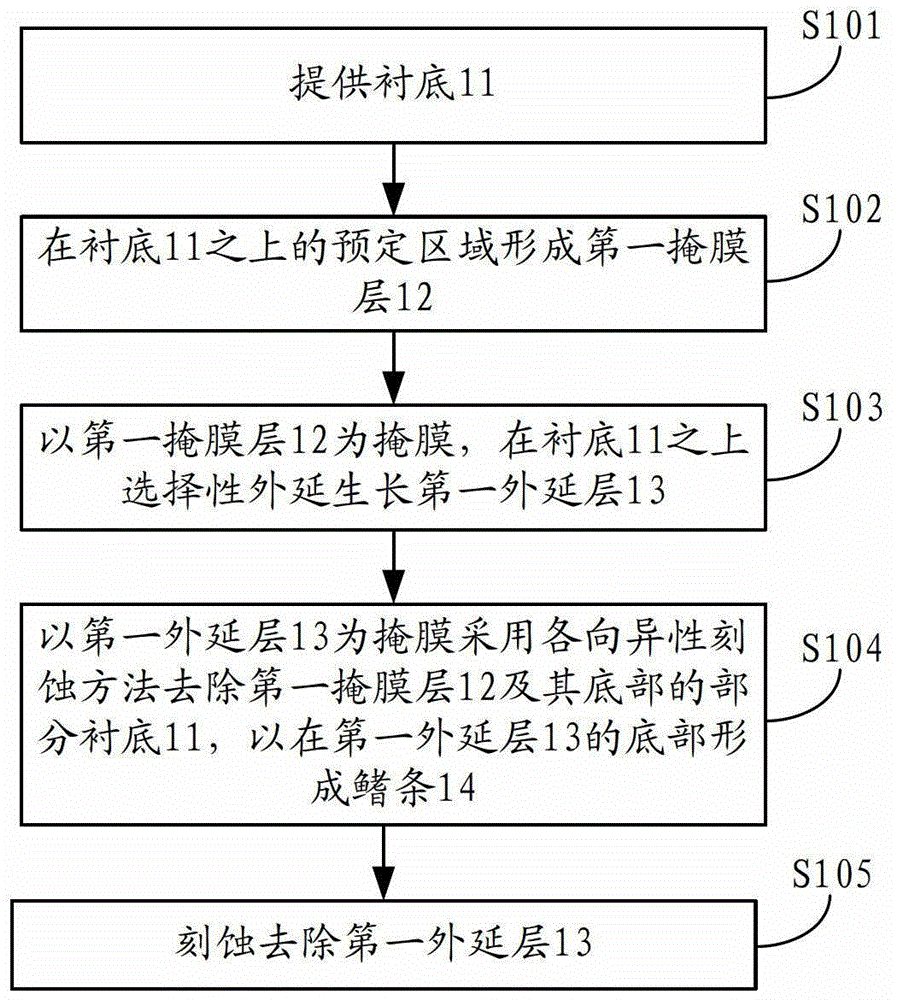

Manufacturing method for semiconductor fin ray and manufacturing method for FinFET device

ActiveCN103413758AGuaranteed to be perpendicular to each otherReduce roughnessSemiconductor/solid-state device manufacturingSemiconductor devicesRegioselectivityEngineering

The embodiment of the invention discloses a manufacturing method for a semiconductor fin ray and a manufacturing method for a FinFET device. The manufacturing method for the semiconductor fin ray comprises the steps that a substrate is provided, a first mask layer is selectively and epitaxially grown in a preset area above the substrate; a first epitaxial layer is selectively and epitaxially grown on the substrate by taking the first mask layer as a mask; an anisotropic etching method is used for removing the first mask layer and part of the substrate at the bottom of the first mask layer by taking the first epitaxial layer as a mask, and the fin ray is formed at the bottom of the first epitaxial layer. According to the technical scheme, selective epitaxial growth and an anisotropic etching process are combined, photolithography does not need to be adopted, the fact that the surface of the semiconductor fin ray is perpendicular to the surface of a gate oxide layer can be ensured, roughness of the surface of the semiconductor fin ray is lowered, and the fin ray with the smooth side face is formed.

Owner:浙江海宁经编产业园区开发有限公司

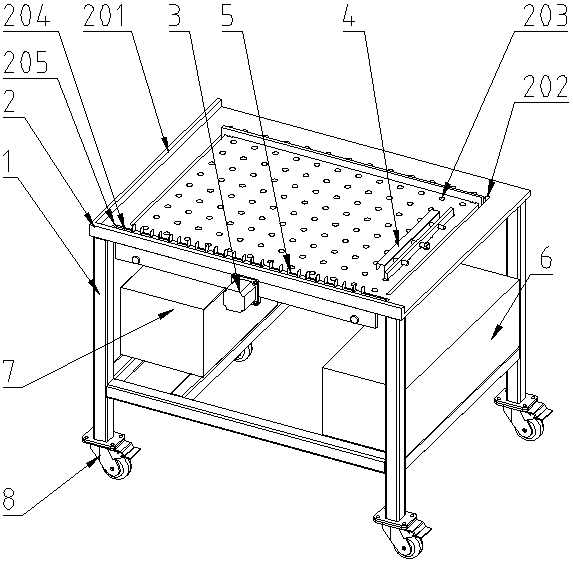

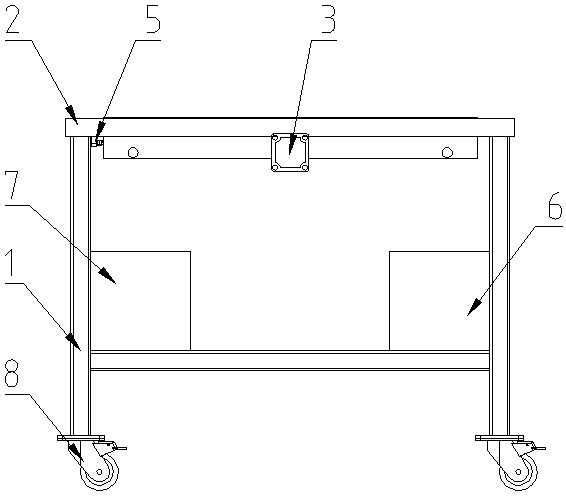

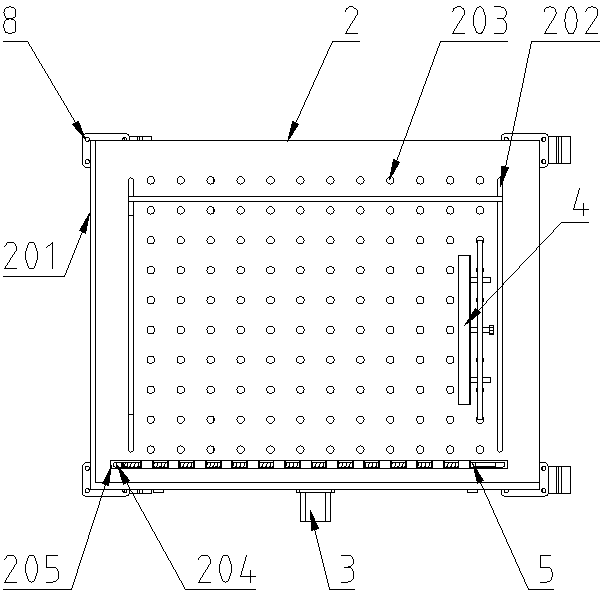

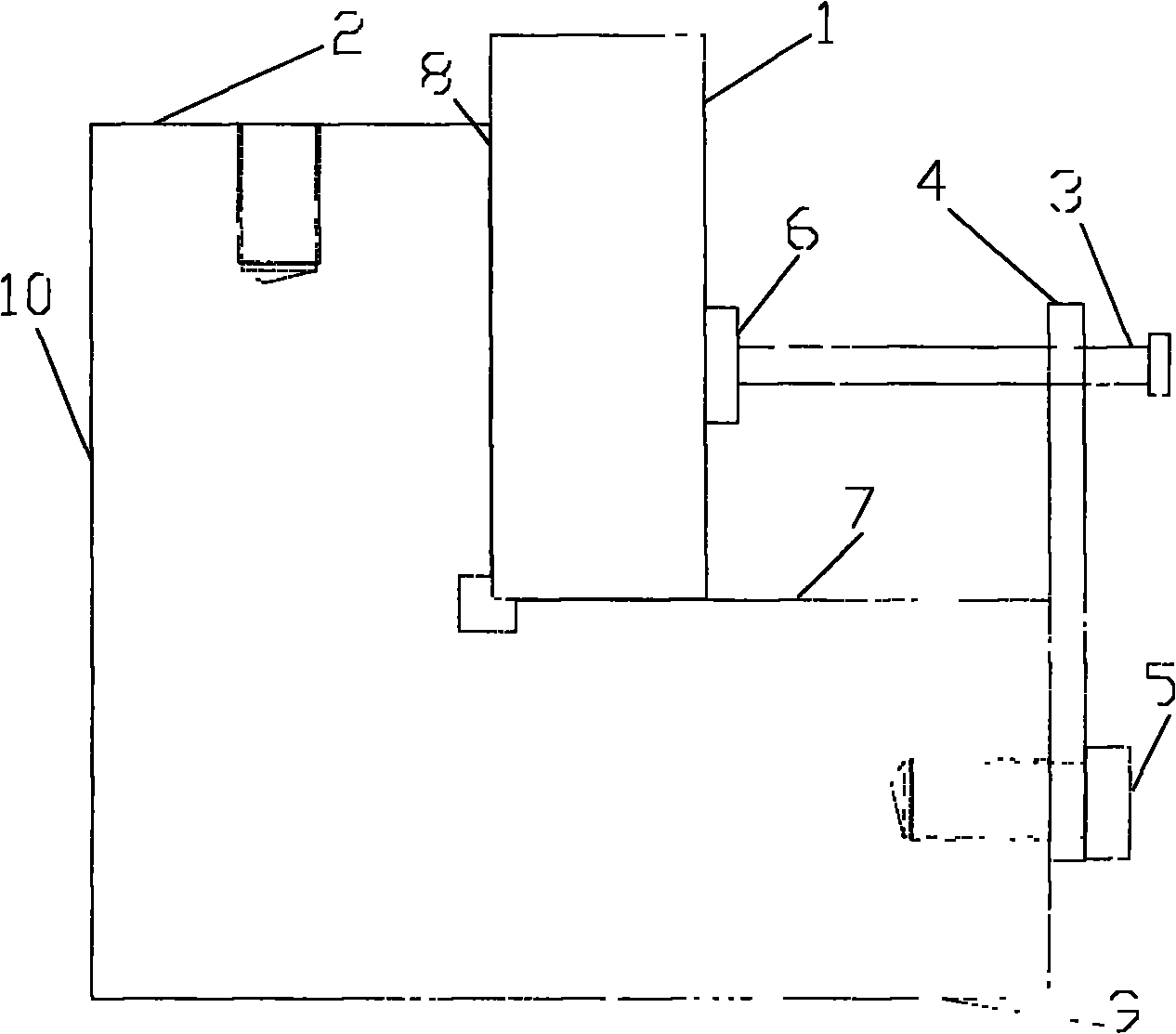

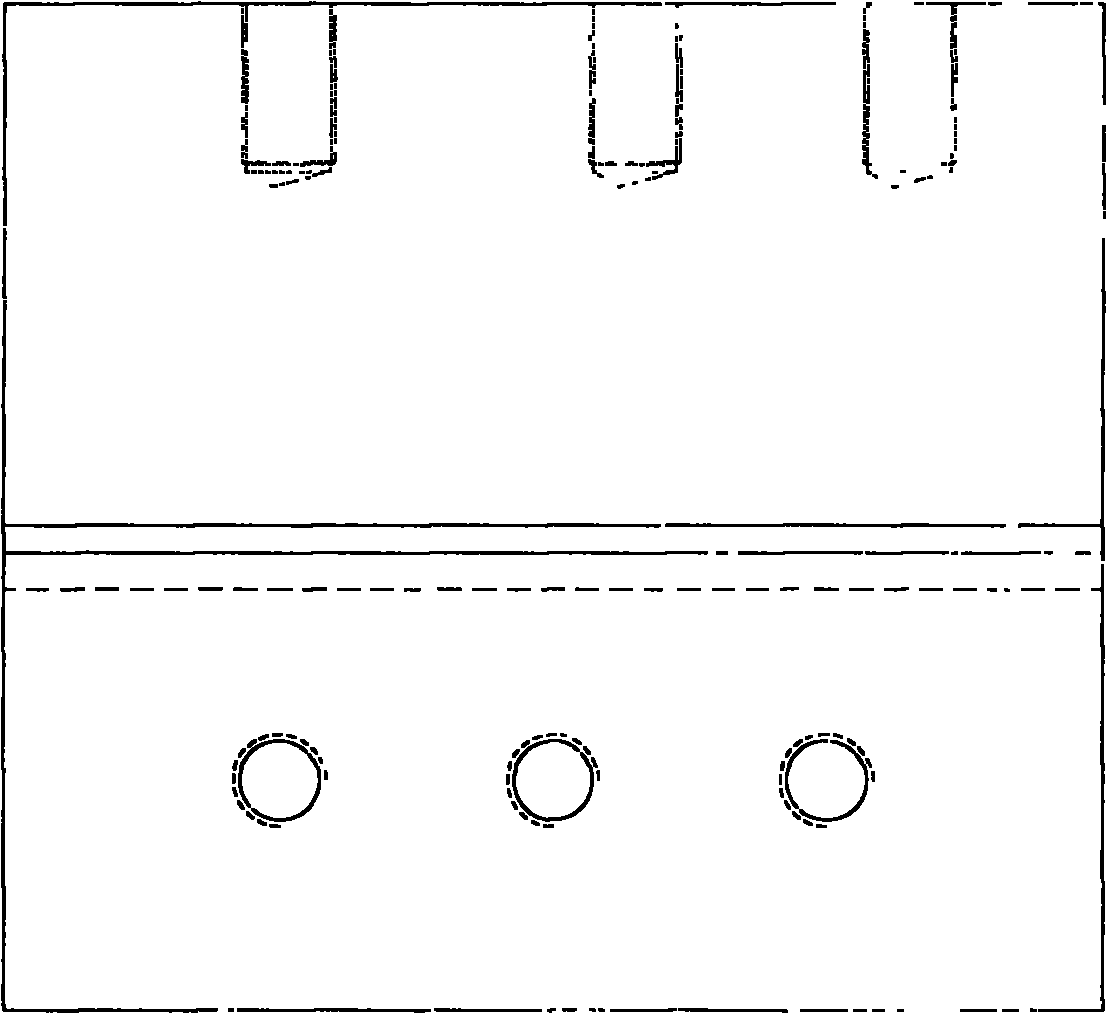

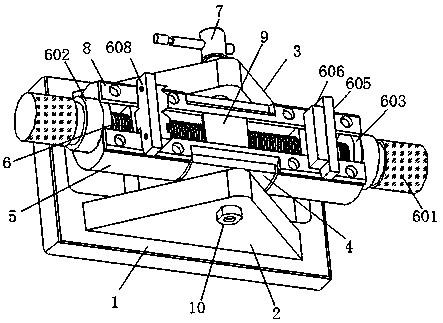

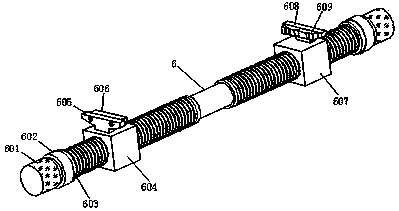

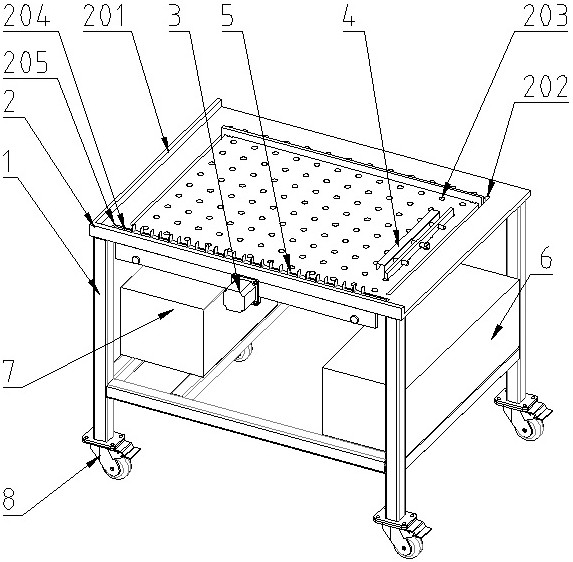

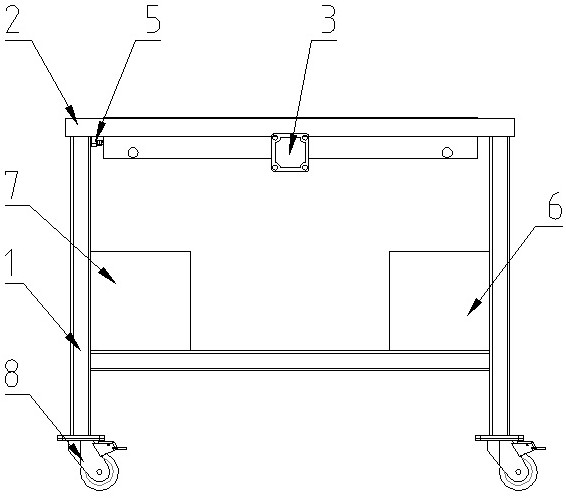

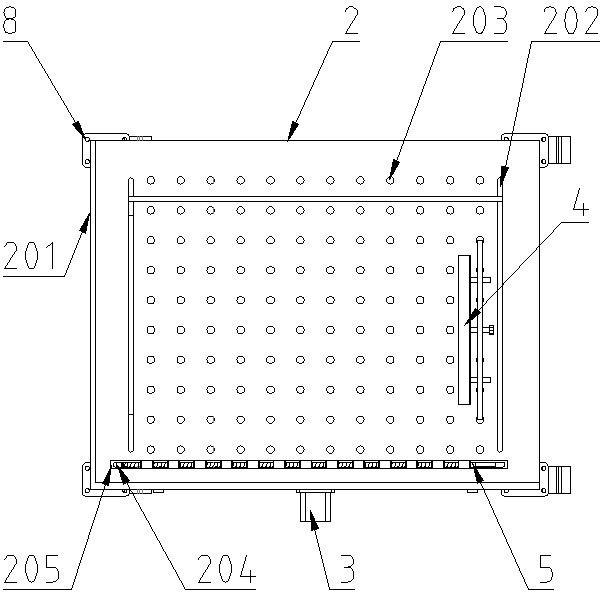

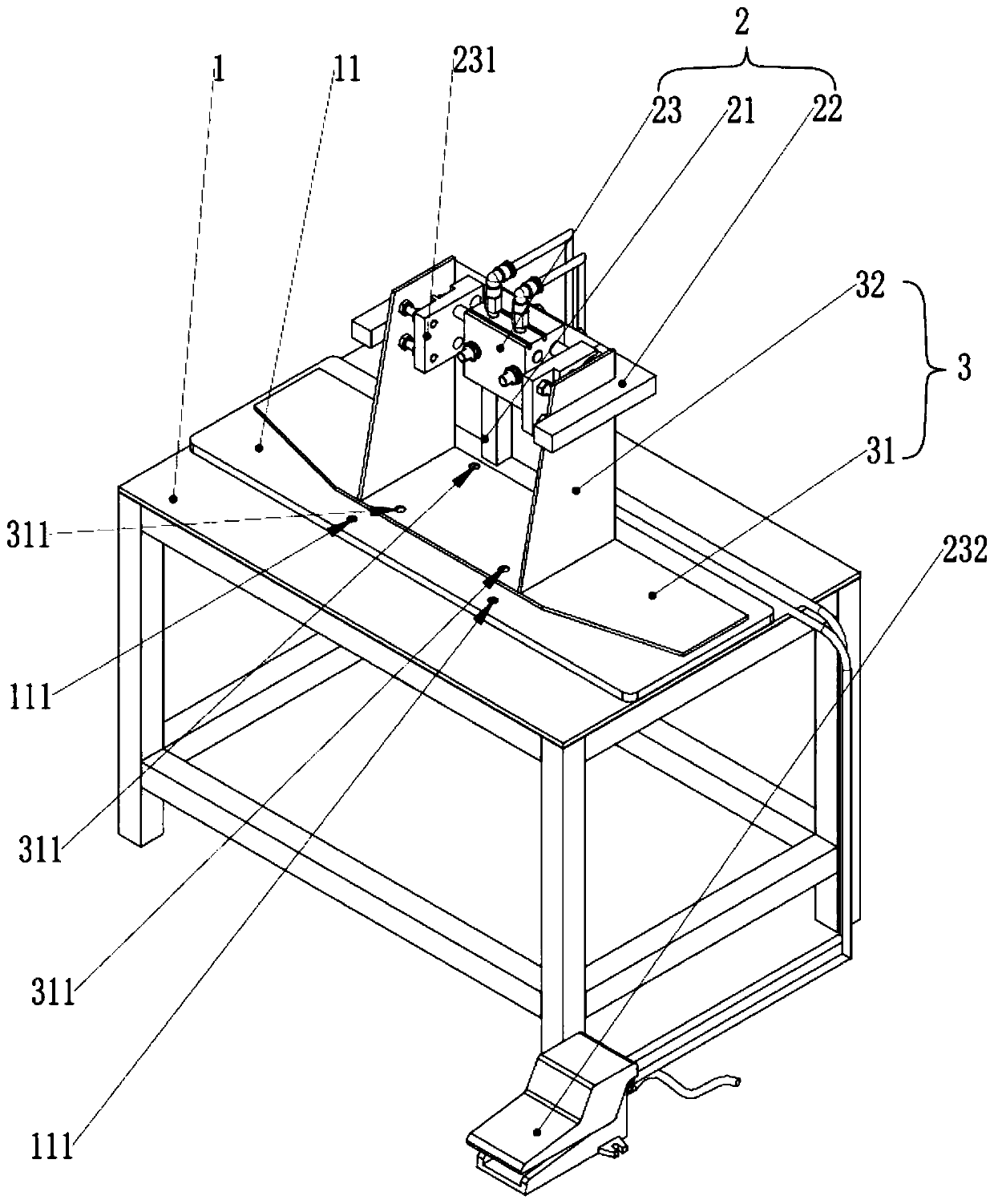

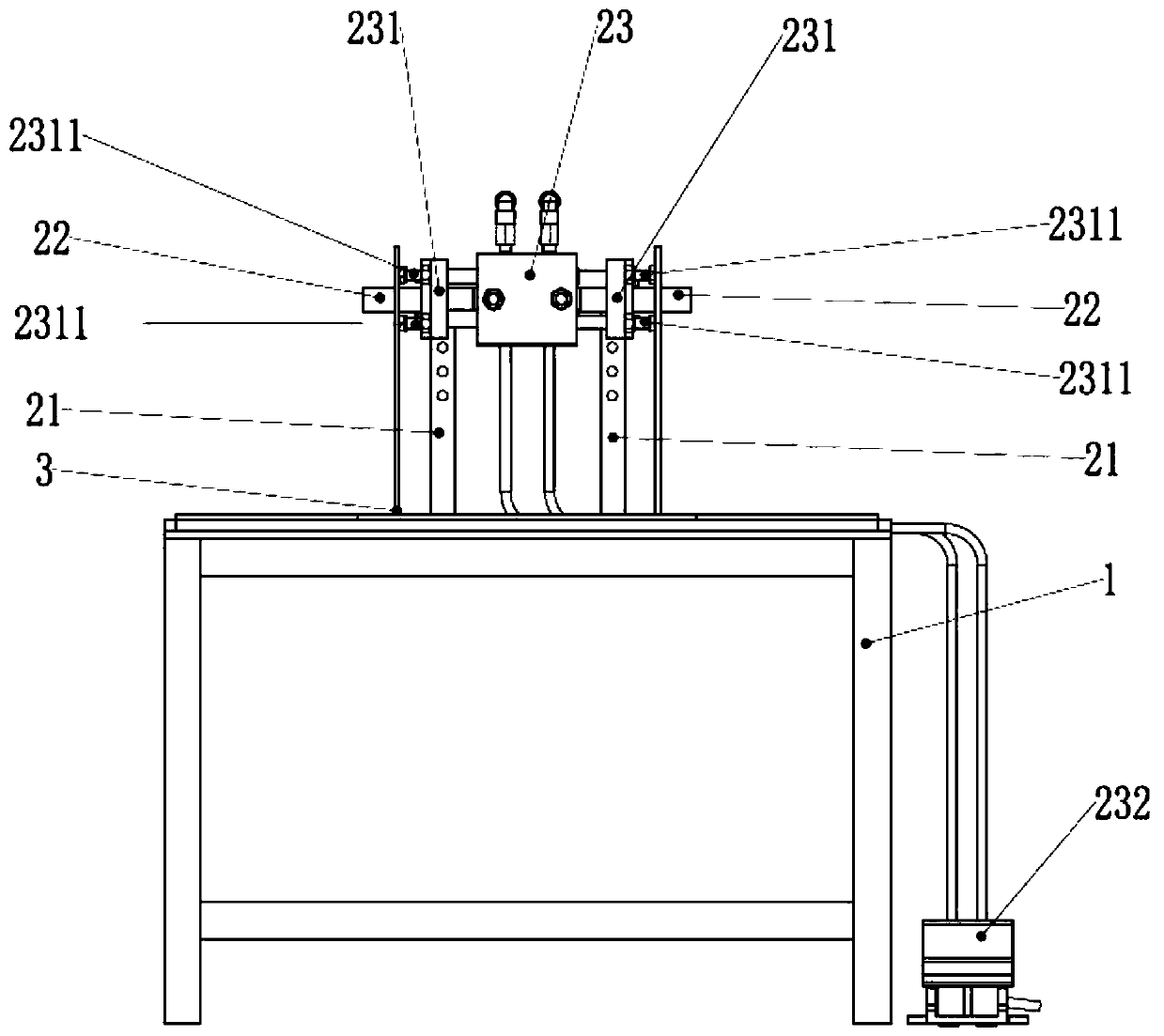

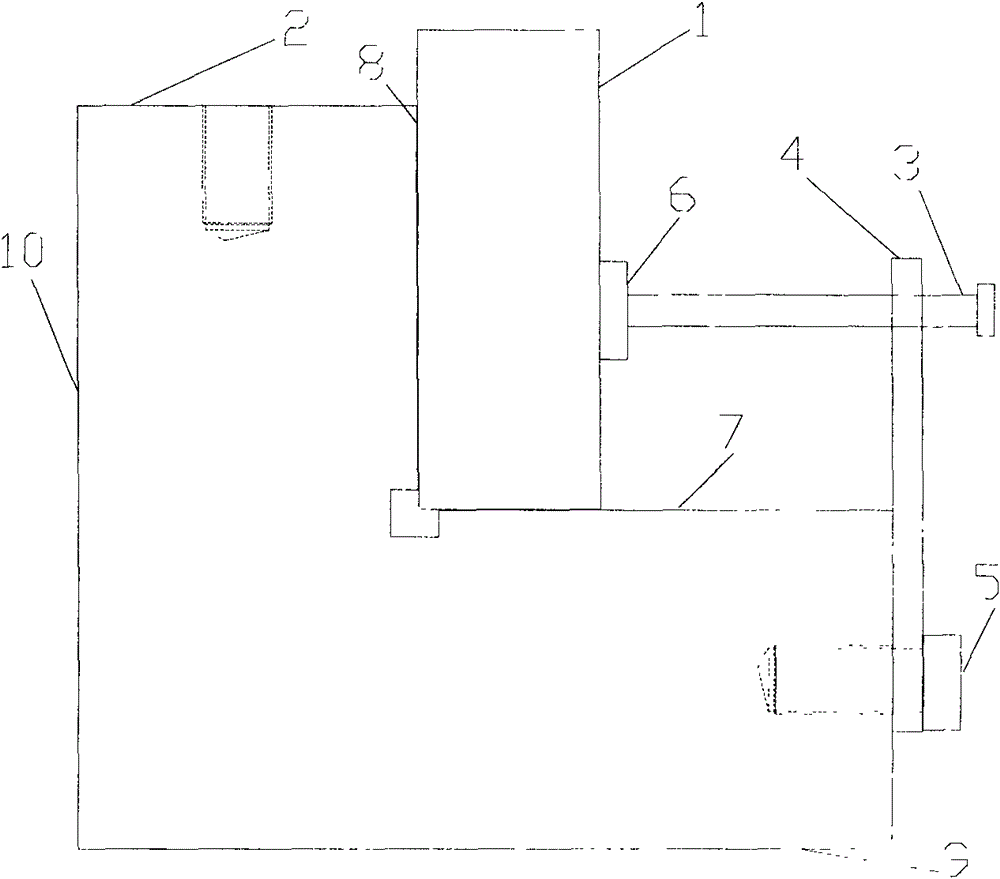

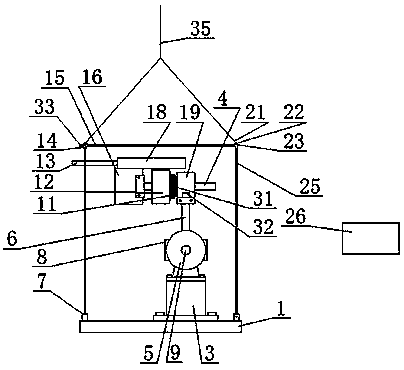

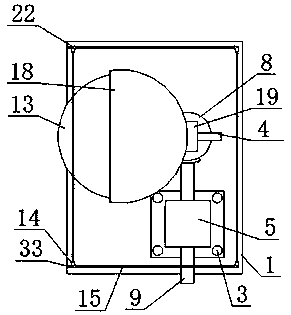

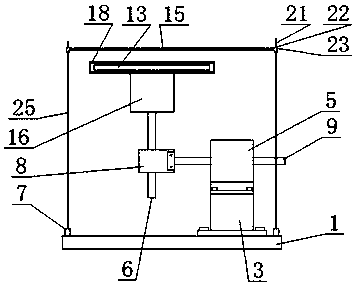

Welding platform for anti-theft window

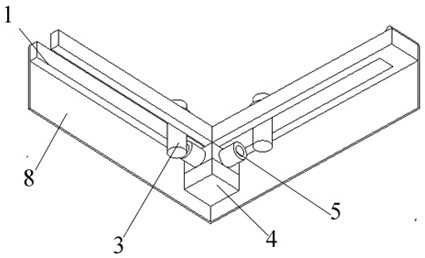

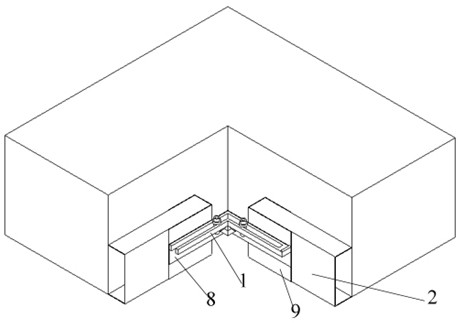

ActiveCN109014718AGuaranteed to be verticalPrevent tamperingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringBolt connection

The invention discloses a welding platform for an anti-theft window. The welding platform comprises a frame body and a platform plate. The top of the frame body is fixedly provided with the platform plate in a welded mode. A front-rear positioning device is fixedly arranged on the lower side of the platform plate, and a left-right positioning device is arranged on the upper portion of the platformplate. An even positioning device is arranged on the lower portion of the platform plate, and a tool box is fixedly arranged on the right side of the middle of the frame body. An electrical box is fixedly arranged on the left side of the middle of the frame body, and travelling wheels are connected to and arranged at the bottom of the frame body through bolts. During using, rods of the anti-theftwindow are placed on the platform plate, thus it is ensured that a frame of the anti-theft window is mutually perpendicular through the front-rear positioning device and the left-right positioning device, and through the left-right positioning device and the left-right positioning device, handrails in the anti-theft window are evenly distributed; and the welding platform has the advantages of being simple in structure and convenient to use.

Owner:诸暨市云傲机械配件厂

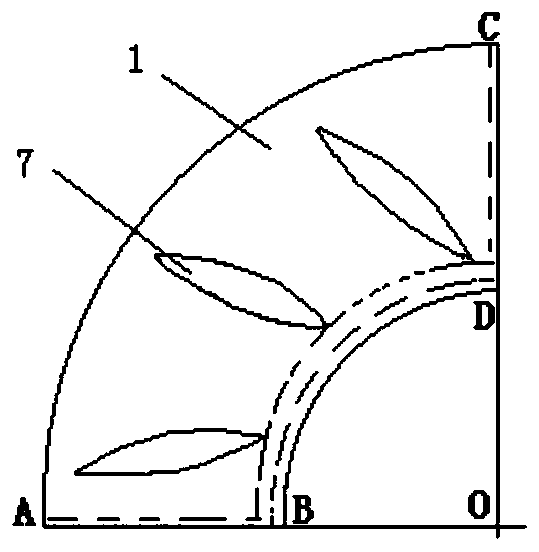

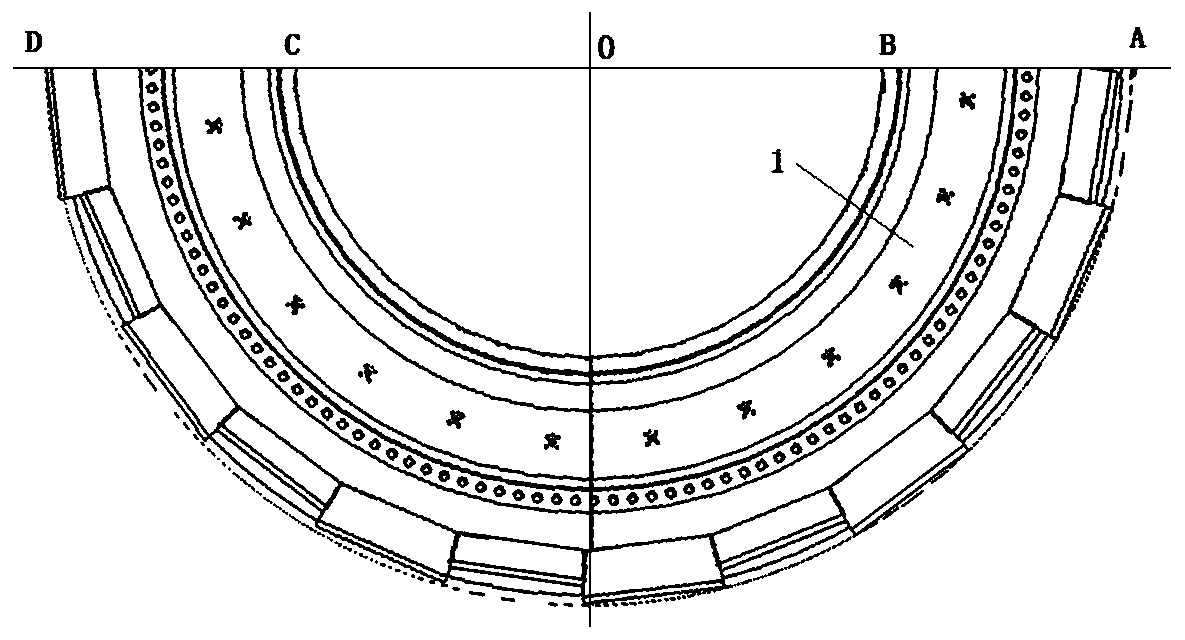

Method for improving sectioning base ring opening precision

ActiveCN109909679AEliminate measurement system biasGuaranteed reliabilityOther workshop equipmentNumerical controlEngineering

The invention discloses a method for improving sectioning base ring opening precision. According to different points of the method from a conventional technology, for perpendicularity after sectioningbase ring joint close face machining, a steel wire is hoisted to check various parts of the joint close face, a numerical control program is utilized for correcting joint close face perpendicularitydeviation, and precision of the joint close face is guaranteed; 1 / 2 of a base ring is machined on a boring machine, boring machine stroke precision is utilized, a digital level gage is placed on a boring box, fixed guide vane opening measuring in the whole 1 / 2 base ring stroke is achieved, and precision of base ring 1 / 2 datum lineation is guaranteed; a 360-degree rotation center column is utilizedin the integral base ring for measuring and datum lineation and checking, datum uniformity of the integral base ring is guaranteed, and the datum lineation and checking precision is improved; sectioning base ring datum plane machining and combining are conducted, the sectioning base ring is assembled and combined with the datum plane as the reference, and the assembling and combining precision isimproved. The method has the advantages that the base ring opening size control technology is simple, the machining quality is controllable, and precision is high.

Owner:HARBIN ELECTRIC MASCH CO LTD

Optical angle reflection target ball and manufacturing method thereof

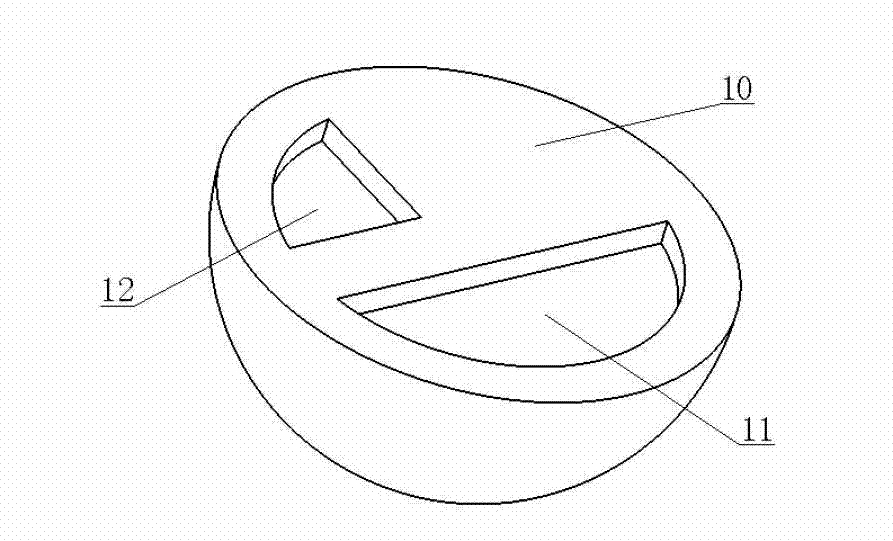

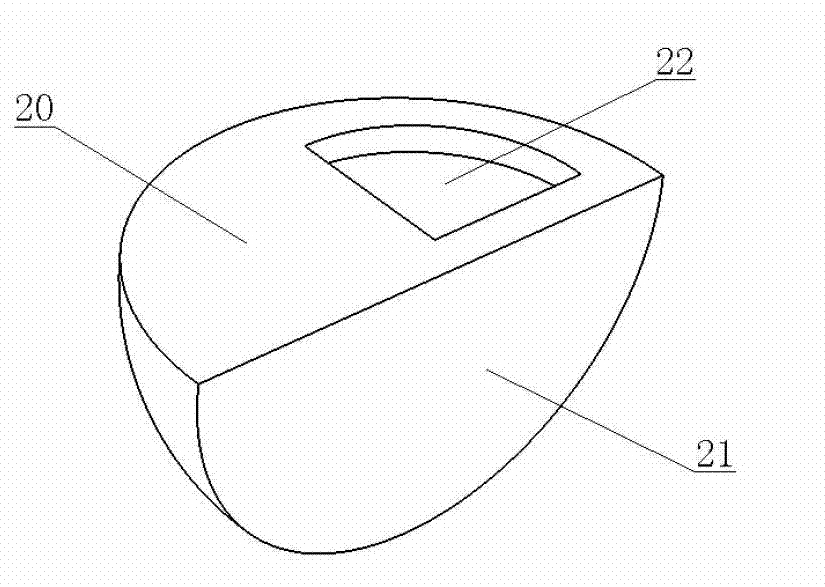

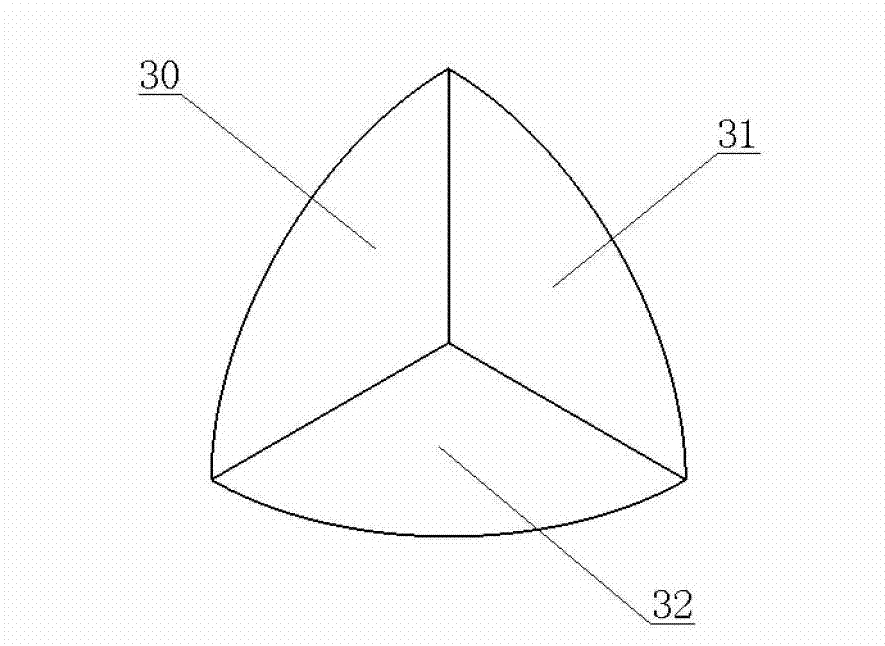

The invention provides an optical angle reflection target ball which is an integrated structure of an angle reflector and a ball body and is a seven-eighths ball body. Three reflection surfaces which are perpendicular to each other are formed at the position where a one-eighth ball body is lacked, the seven-eighths ball body is an all-metal structure, and the three reflection surfaces are polishing and coating surfaces. A manufacturing method of the optical angle reflection target ball is further provided. The angle reflector and the ball body are formed synchronously. The manufacturing method includes the following steps: shaping a solid metal ball body in a processing mode; performing three-time half-and-half cutting, obtaining a one / second metal ball body, a one / fourth metal ball body and two one / eighth metal ball bodies respectively, removing a one / eighth ball body, and forming three reflection surfaces and three groups of corresponding junction surfaces in the one / second metal ball body, the one / fourth metal ball body and the one / eighth metal ball body; performing polishing and coating on the three reflection surfaces; and combining each group of corresponding junction surfaces in a fixed mode, forming the seven / eighths ball body, and forming the three reflection surfaces which are perpendicular to each other. The optical angle reflection target ball is high in target ball accuracy, simple in structure, low in cost, firm and durable and strong in anti-fall capacity.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI +1

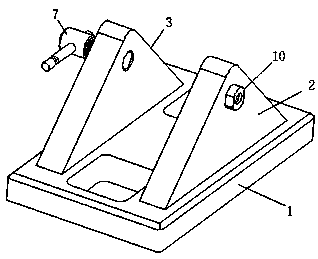

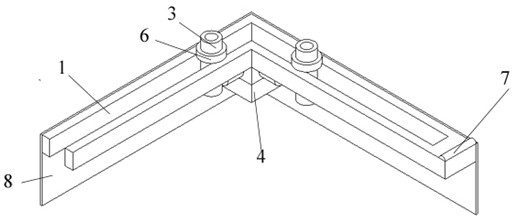

Grinding machine corner corrector

ActiveCN102152181AHigh precisionGuaranteed to be perpendicular to each otherPlane surface grinding machinesMechanical engineeringEngineering

The invention discloses a grinding machine corner corrector, which comprises a corner correction baffle and a force clamp. The corner correction baffle comprises a first working surface and a second working surface which are mutually vertical; a groove corner is arranged at the intersection part between the first working surface and the second working surface; the corner correction baffle also comprises a first fixing surface and a second fixing surface which are mutually vertical; and moreover, the first fixing surface is parallel with the second working surface, and the second fixing surface is parallel with the second working surface.

Owner:KUNSHAN XINTAILI PRECISION COMPONENTS CO LTD

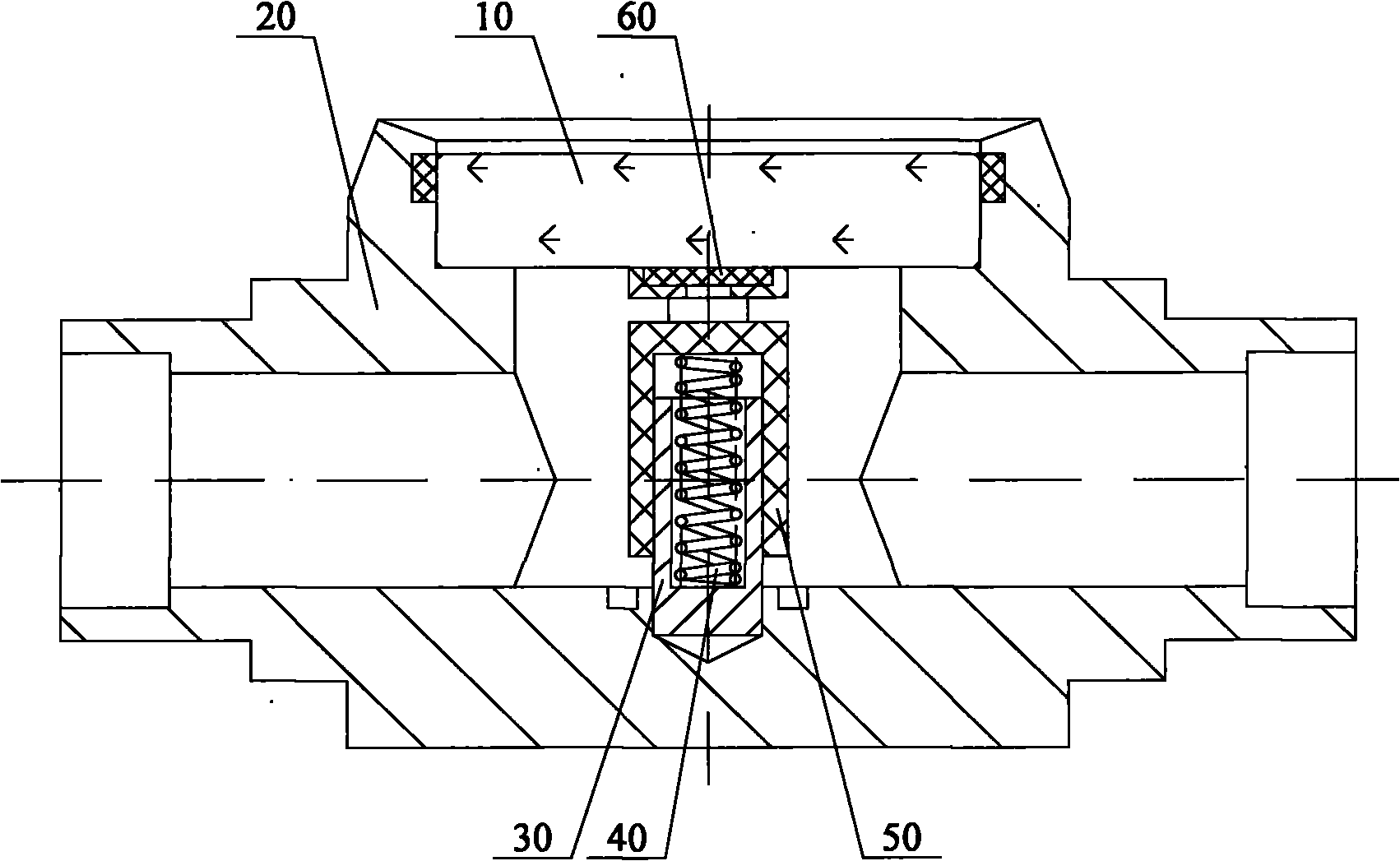

Liquid observation mirror

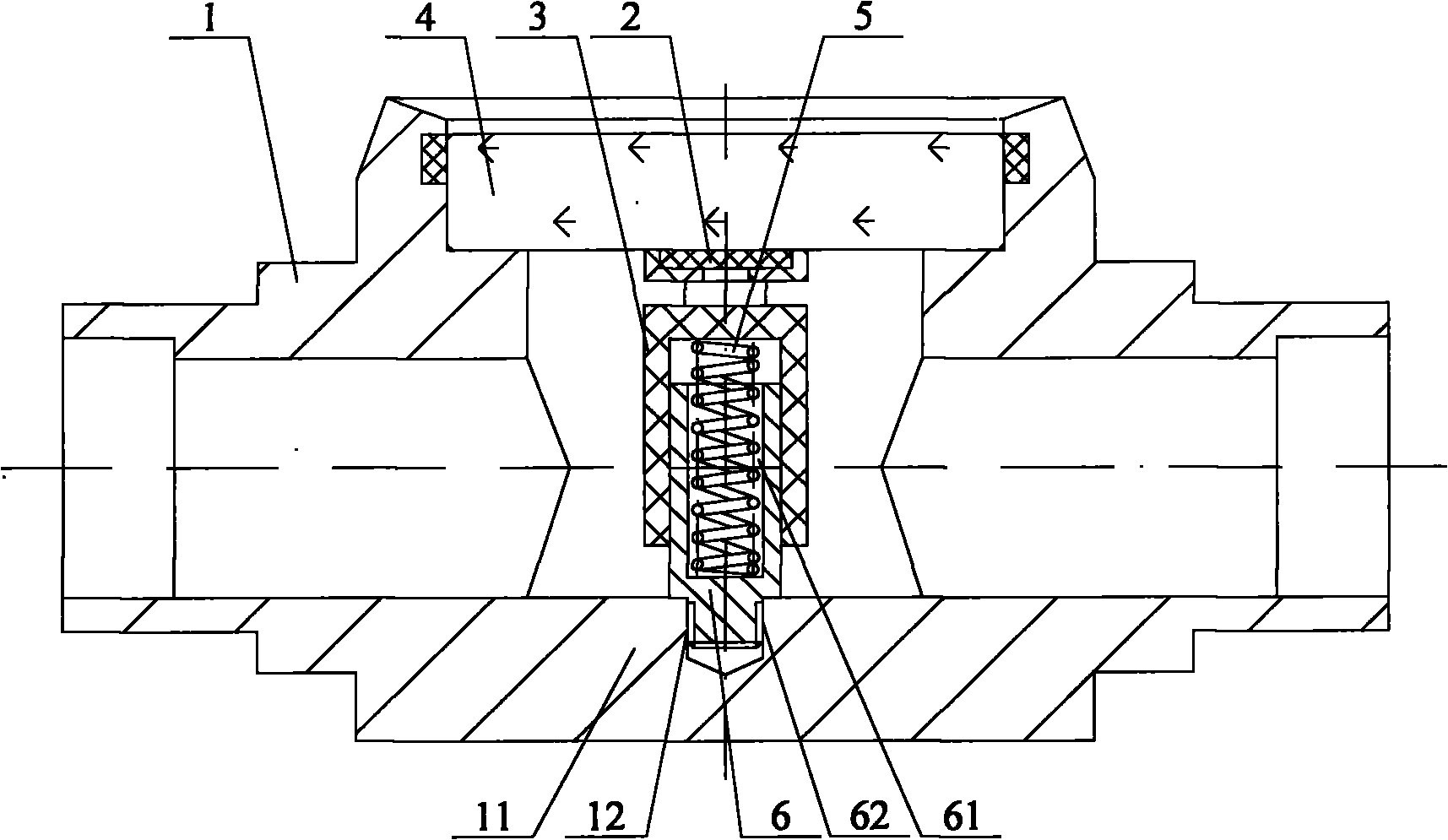

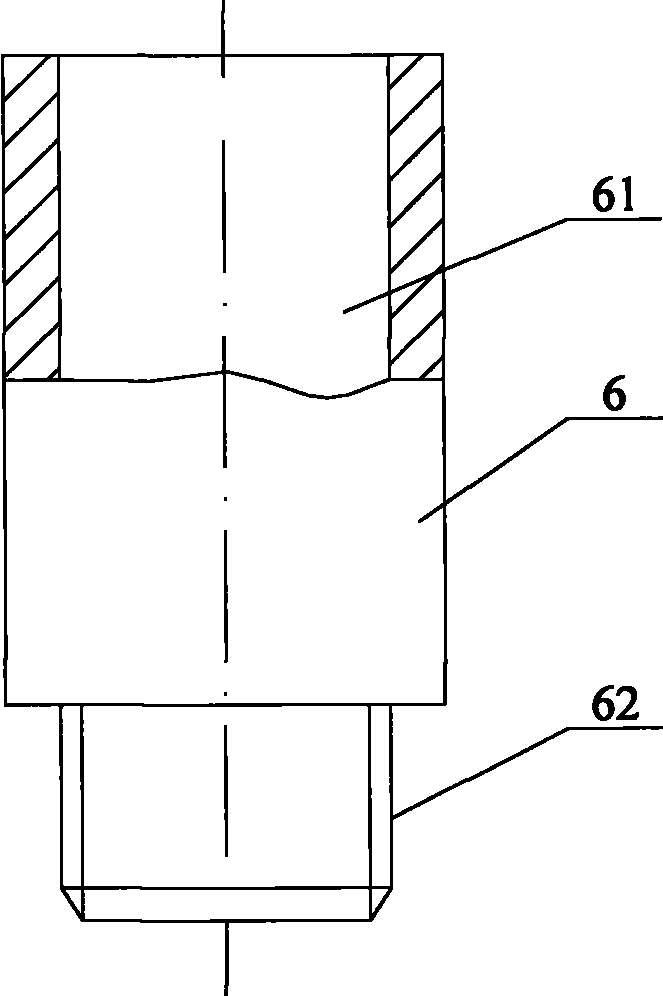

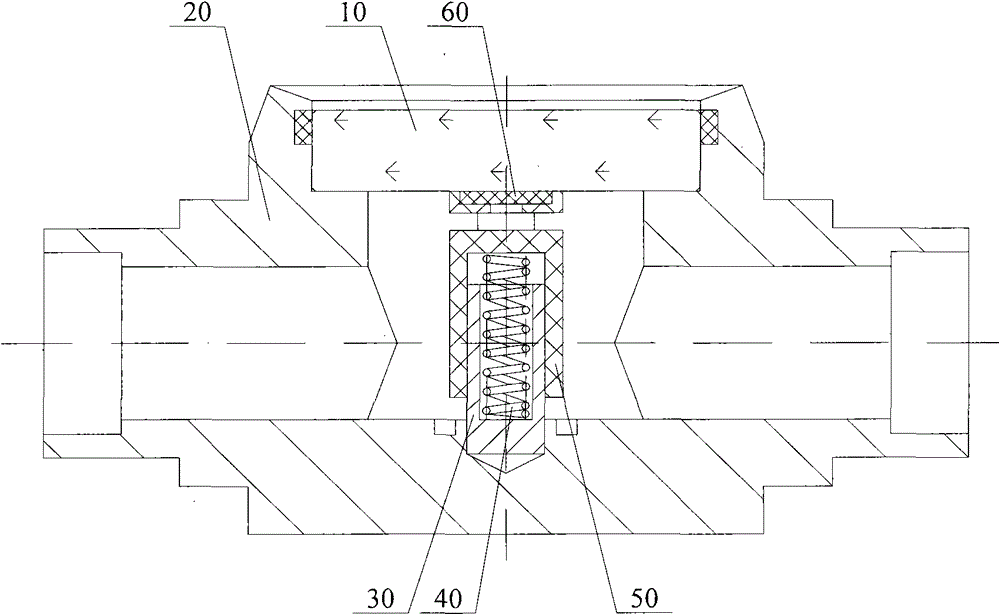

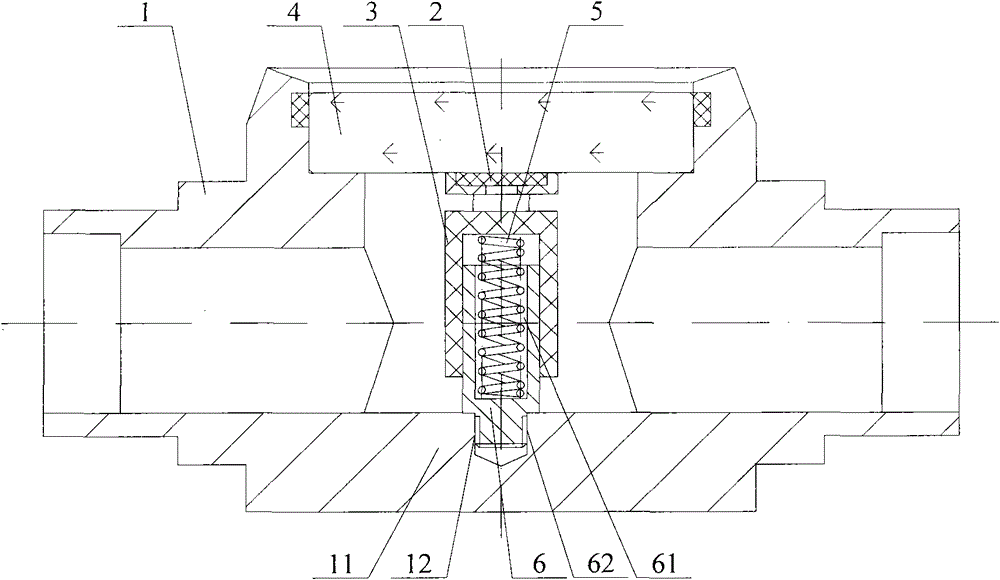

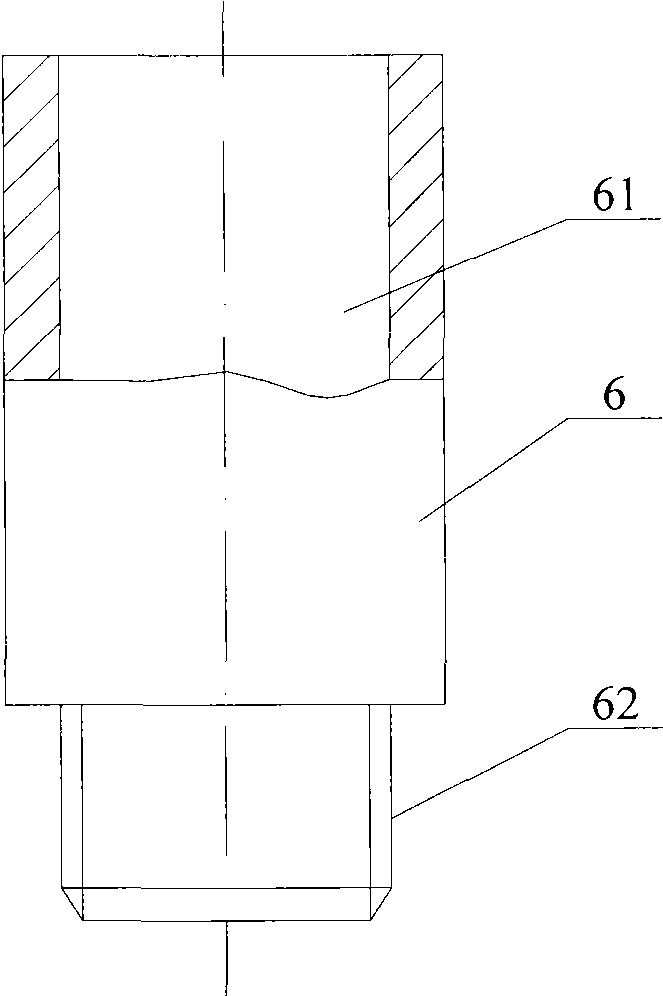

ActiveCN102236144ASimple structureStable structureMaterial analysis by observing effect on chemical indicatorMountingsEngineeringCentral spindle

The invention discloses a liquid observation mirror. The liquid observation mirror comprises a mirror body, an indicator retainer, a central spindle and a spring, wherein the mirror body is provided with an internal chamber as well as a liquid inlet and a liquid outlet which are communicated with the internal chamber, the indicator retainer is arranged in the internal chamber of the mirror body, the central spindle is in threaded connection with the bottom wall of the internal chamber of the mirror body, the upper end face of the central spindle is provided with an axial hole, the spring is inserted in the axial hole of the central spindle, and the upper end face of the spring butts against the indicator retainer. Compared with the prior art, the liquid observation mirror has the advantages of simple and reliable structure since the central spindle is in threaded connection with the mirror body; on the premise of maintaining the stable position relation between the central spindle and the mirror body, the assembly manufacturability is improved greatly, and the production cost of the product is effectively controlled further.

Owner:浙江三花商用制冷有限公司

Clamp suitable for testing microhardness at different angles

InactiveCN110763557AGuaranteed accuracyGuaranteed stabilityInvestigating material hardnessStructural engineeringMechanical engineering

The invention provides a clamp suitable for testing microhardness at different angles. The clamp comprises a base, a first support table and a second support table are respectively arranged at two sides above the base, an arc sleeve is arranged between the first support table and the second support table, an arc clamp seat is arranged in the sleeve, and a transmission screw rod is arranged in theclamp seat; the first support table, the second support table, the sleeve and the clamp base are fixed through a pressing base and a clamping base. Cover plates are arranged on the two sides of the upper portion of the clamping base respectively, an operation table is arranged between the cover plates, the cover plates are fixedly connected with the clamping base through screws, and the cover plates are fixedly connected with the operation table through welding. The clamp is novel in structure, reasonable in design, suitable for hardness samples of various sizes and shapes, high in stability,good in fixing performance and high in test result repeatability, the hardness detection efficiency and detection precision can be effectively improved, the working efficiency of inspection personnelis greatly improved, and the device has wide applicability.

Owner:NANCHANG HANGKONG UNIVERSITY

An anti-theft window welding platform

ActiveCN109014718BGuaranteed to be verticalPrevent tamperingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringToolbox

The invention discloses a welding platform for an anti-theft window. The welding platform comprises a frame body and a platform plate. The top of the frame body is fixedly provided with the platform plate in a welded mode. A front-rear positioning device is fixedly arranged on the lower side of the platform plate, and a left-right positioning device is arranged on the upper portion of the platformplate. An even positioning device is arranged on the lower portion of the platform plate, and a tool box is fixedly arranged on the right side of the middle of the frame body. An electrical box is fixedly arranged on the left side of the middle of the frame body, and travelling wheels are connected to and arranged at the bottom of the frame body through bolts. During using, rods of the anti-theftwindow are placed on the platform plate, thus it is ensured that a frame of the anti-theft window is mutually perpendicular through the front-rear positioning device and the left-right positioning device, and through the left-right positioning device and the left-right positioning device, handrails in the anti-theft window are evenly distributed; and the welding platform has the advantages of being simple in structure and convenient to use.

Owner:诸暨市云傲机械配件厂

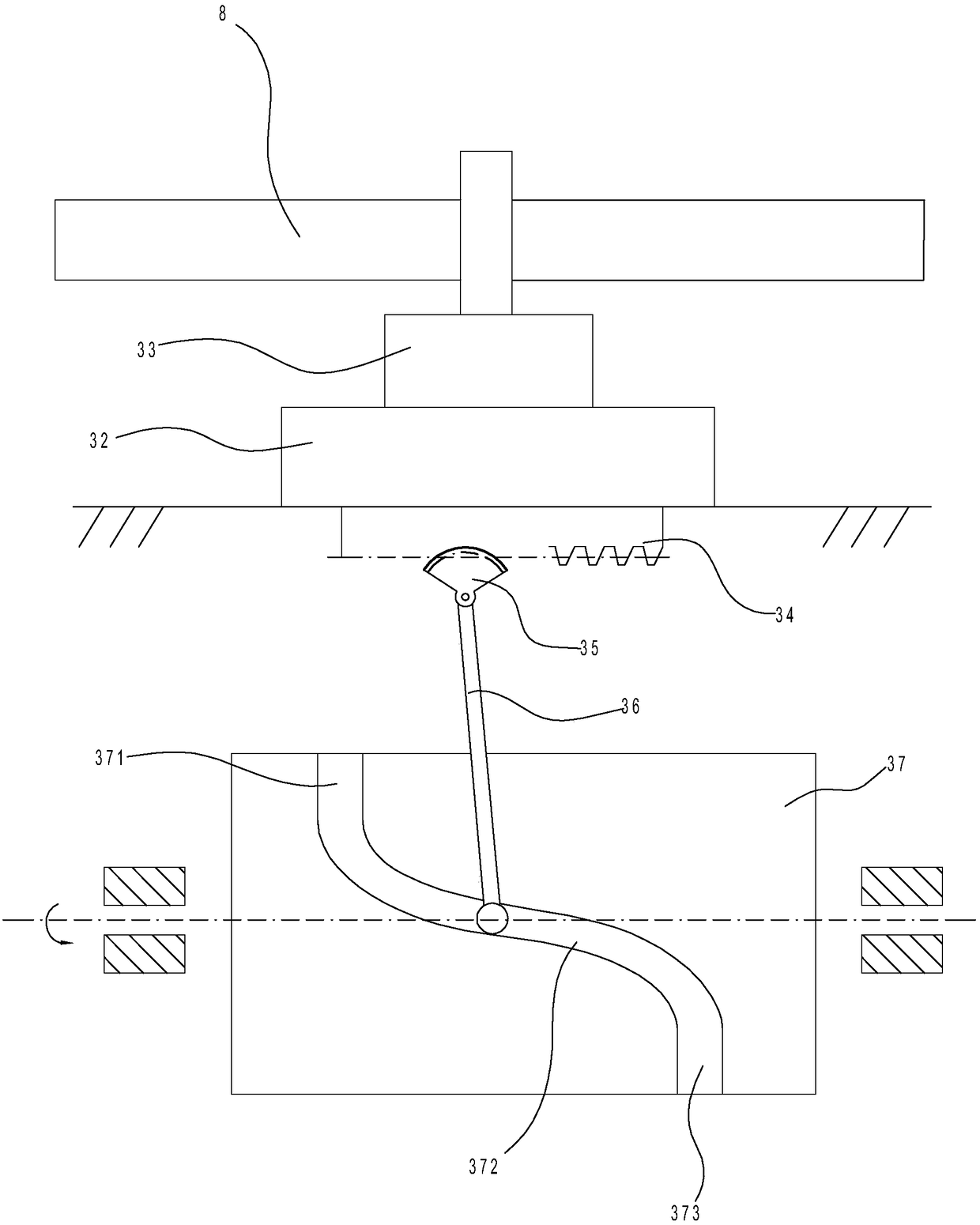

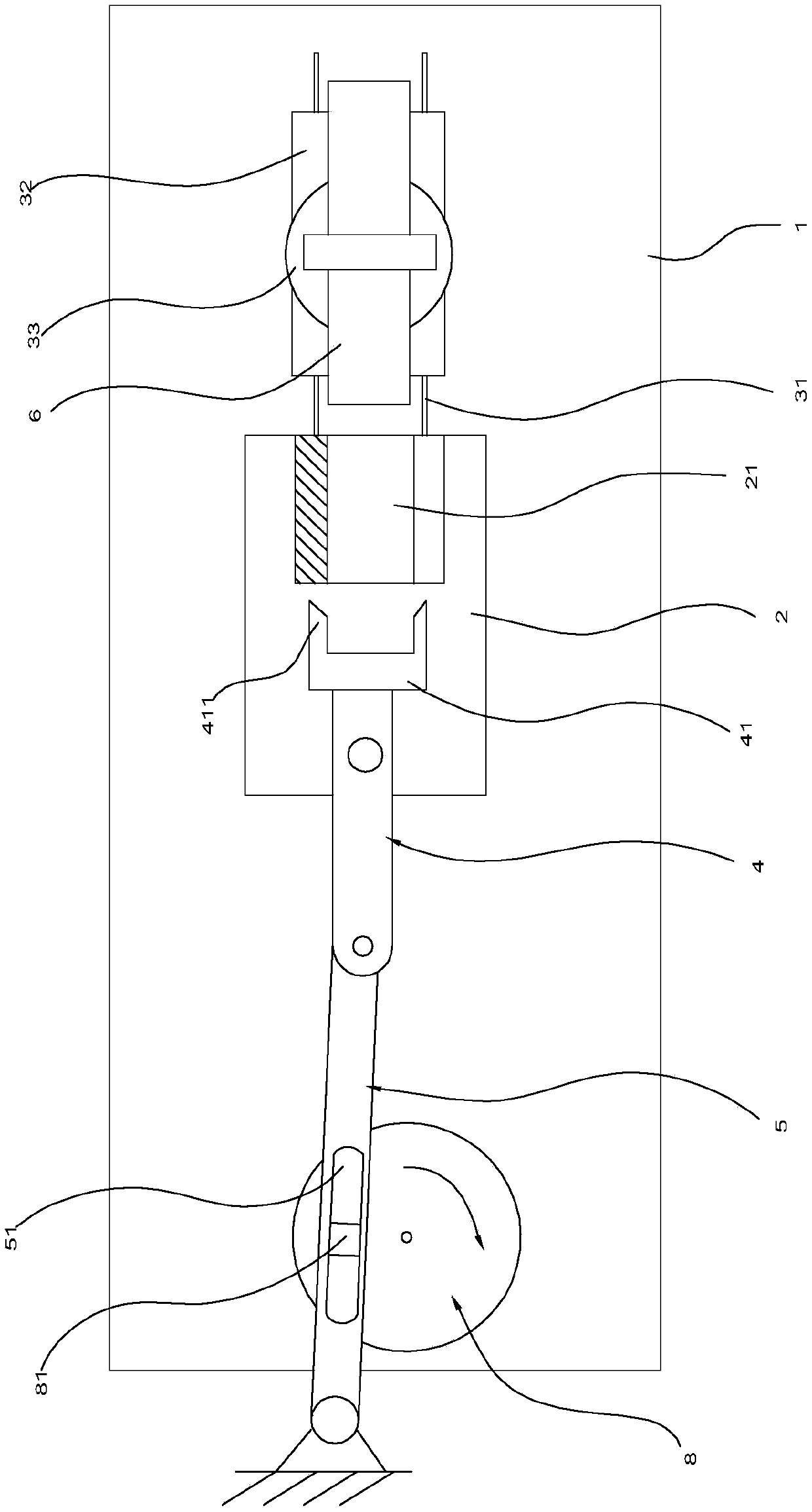

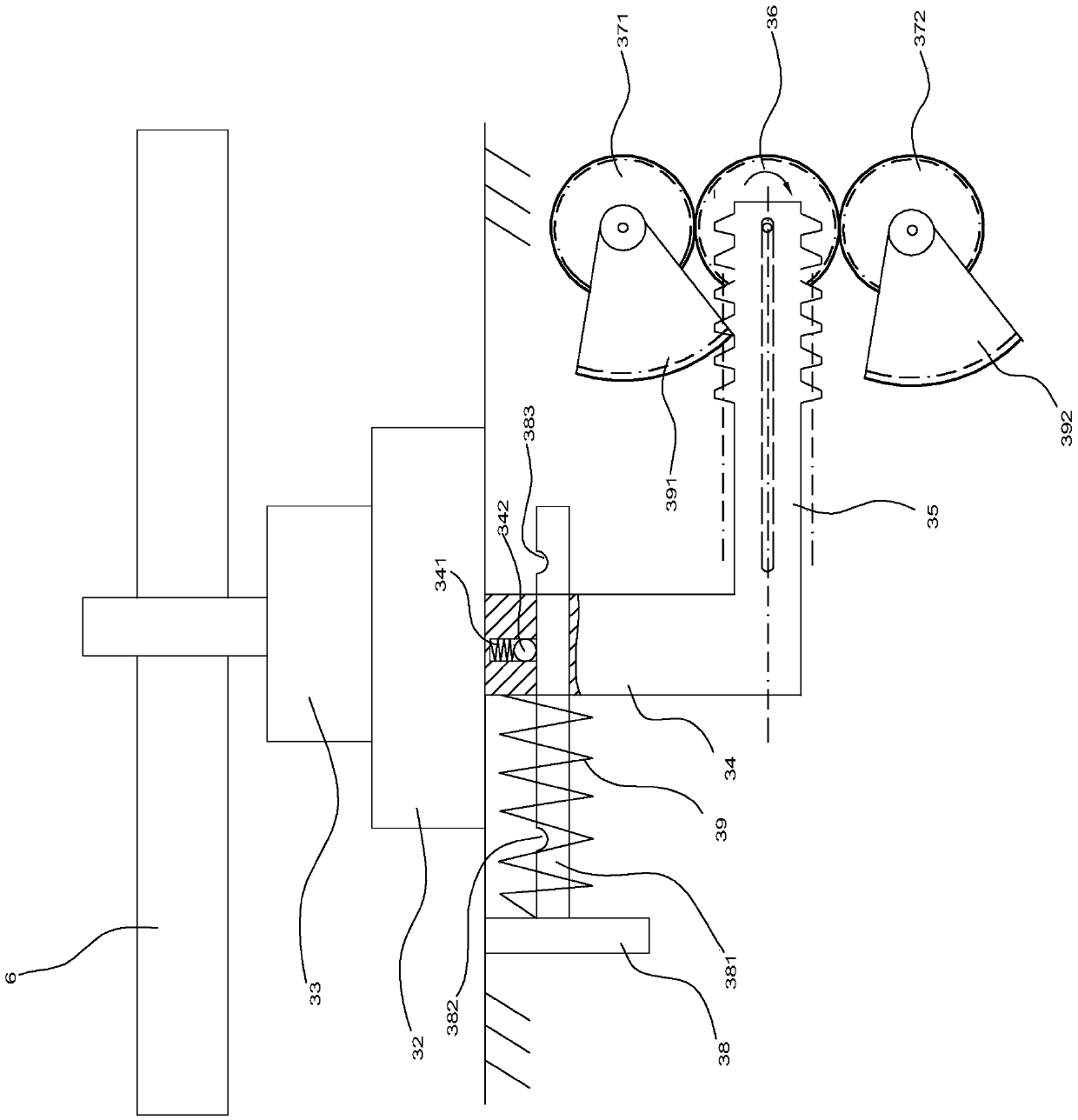

Arc punching device for both ends of circular tube and arc punching method thereof

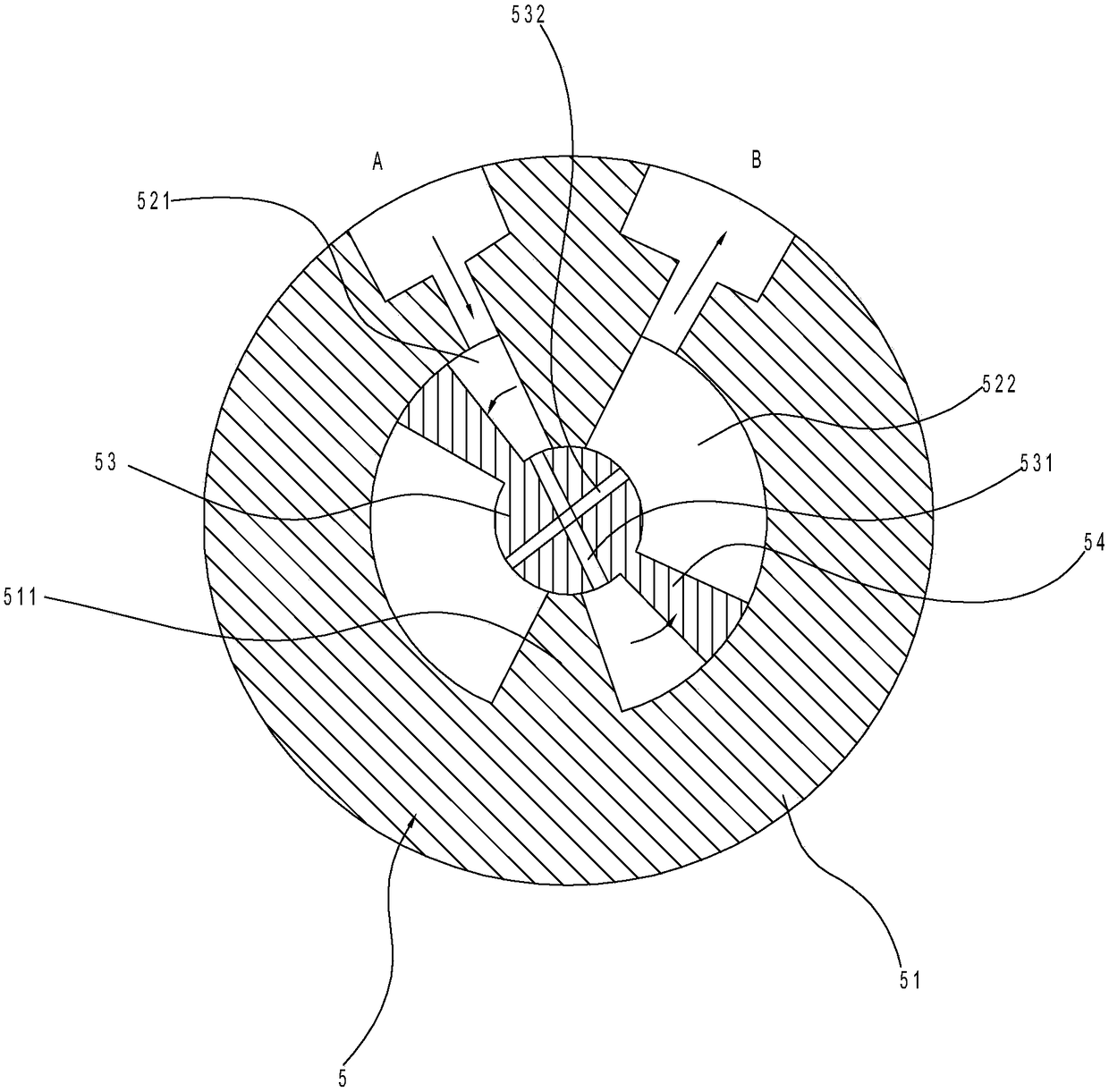

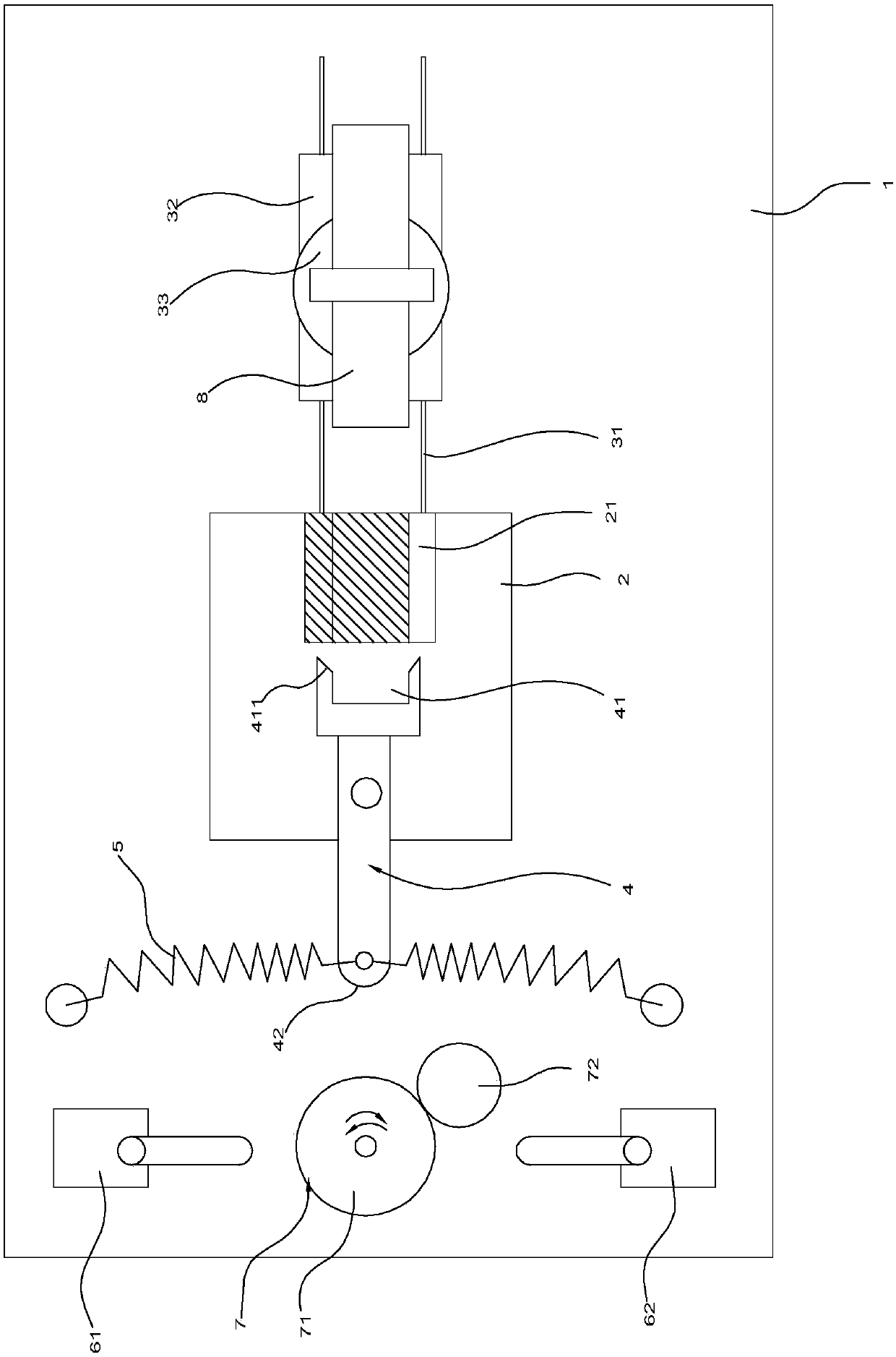

ActiveCN108080484ARealize automatic arc punching and blanking operationReduce labor intensityMetal-working feeding devicesPositioning devicesWorm driveCam

The invention discloses an arc punching device for both ends of a circular tube and an arc punching method thereof. The arc punching device comprises an arc punching seat, a feeding rotating mechanism, and a pulling arc-punching mechanism; and a limiting sleeve is arranged in the arc punching seat, the feeding rotating mechanism comprises a base, a rotating cylinder, a connecting block, a roller,a spring, and a rotating cam, the pulling arc-punching mechanism comprises a cylinder body, an arc punching rod rotatably arranged in the arc punching seat, and a rotor and blades are arranged in thecylinder body. The arc punching method comprises the following steps that a pipe fitting is clamped and limited in a clamping mechanism, the rotating cam rotates, and one end of the pipe fitting is inserted into the limiting sleeve of the arc punching seat; the cylinder body is fed with oil, the rotor drives the arc punching rod to swing, and one side of one end of the pipe fitting is arc-punchedby cutters; the cylinder body is fed with oil in the backward direction, and the other side of one end of the pipe fitting is arc-punched by the cutters; and the feeding rotating mechanism exits, a rotating motor dives a worm to rotate, the worm drives a turbine ring to rotate by 90 degrees, the rotating cylinder drives the pipe fitting to overturn by 180 degrees, and the other end of the pipe fitting is arc-punched.

Owner:雷磊

Liquid observation mirror

ActiveCN102236144BSimple structureStable structureMaterial analysis by observing effect on chemical indicatorMountingsEngineeringCentral spindle

Owner:ZHEJIANG SANHUA COMMERCIAL REFRIGERATION CONTROLS CO LTD SHAOXING CITY

Welding device for axial flow machine shell

PendingCN111468878AQuality improvementExtended service lifeWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachine

The invention discloses a welding device for an axial flow machine shell. The welding device is characterized in that a clamping module is fixed to the surface of a workbench, and the clamping modulecomprises a supporting rod, a limiting frame and a bidirectional adjusting mechanism; the supporting rod is vertically fixed to the surface of the workbench; a limiting frame is mounted on the supporting rod; the two output ends of the bidirectional adjusting mechanism face the inner side of the limiting frame; the machine shell fixing plate is arranged on the surface of the workbench, machine shell supporting plates are fixed to the two ends of the machine shell fixing plate, the top ends of the machine shell supporting plates are located between the output end of the bidirectional adjustingmechanism and the limiting frame, and when the bidirectional adjusting mechanism acts, the output end of the bidirectional adjusting mechanism extends out and clamps the machine shell supporting plates to the inner side of the limiting frame, and the machine shell supporting plates and the machine shell fixing plate are perpendicular to each other. According to the welding device for the axial flow machine shell, the problem that a machine shell supporting module is loosened due to vibration is solved, the axial flow machine shell to be machined does not move in the machining process, errors are reduced, and therefore the quality of the axial flow machine shell is improved.

Owner:FOSHAN CITY NANHAI POPULA FAN

Manufacturing method of semiconductor fin ray, manufacturing method of finfet device

ActiveCN103413758BGuaranteed to be perpendicular to each otherReduce roughnessSemiconductor/solid-state device manufacturingSemiconductor devicesRegioselectivityGate oxide

Owner:浙江海宁经编产业园区开发有限公司

Fluxgate with single iron core and three-axis fluxgate sensor

InactiveCN102129049BEnsure consistencyEasy processing and windingMagnitude/direction of magnetic fieldsEngineeringWire wrap

The invention discloses a fluxgate with a single iron core and a three-axis fluxgate sensor, solving the technical problem of processing difficulty of a traditional three-axis fluxgate sensor. The invention adopts the technical scheme that the iron core of the fluxgate is of a strip shape, is more convenient to process and wind, and can better ensure consistency between a measuring shaft and a mounting shaft and decrease the manufacture cost. The three-axis fluxgate sensor adopting the strip iron core fluxgate is of a separation structure of the fluxgate and a sensor base, thus, the complexity for processing, winding and assembling of the iron core the coil is lessened, the three single-axis fluxgates are ensured to be mutually perpendicular and convenient to fix, and the reliability and the maintainability of the three-axis fluxgate sensor are improved.

Owner:JIANGSU ZHONGHAI HEAVY MACHINE TOOL +1

Automatic pipe arc-forming device and arc-forming method thereof

The invention discloses an automatic pipe arc-forming device and an arc-forming method of the automatic pipe arc-forming device. The automatic pipe arc-forming device comprises an arc-forming seat, afeeding rotating mechanism and a shifting arc-forming mechanism. A limiting sleeve is arranged in the arc-forming seat. The feeding rotating mechanism comprises a base, a rotating cylinder, a rack, asector-shaped plate, a connecting rod and a rotating drum. The shifting arc-forming mechanism comprises a driving piece, triggers arranged on the two sides of the driving piece, an arc-forming rod rotationally arranged in the arc-forming seat and springs. The arc-forming method comprises the following steps that a pipe is clamped and limited in the clamping mechanism, the rotating drum rotates, one end of the pipe is inserted into the limiting sleeve in the arc-forming seat, a shifting disc drives the arc-forming rod to swing, one side of one end of the pipe is subjected to arc-forming processing by a cutter, the shifting disc rotates reversely, the other side of one end of the pipe is subjected to arc-forming processing by the cutter, the rotating drum drives the feeding rotating mechanism to retreat, a rotating motor drives a worm to rotate, the worm drives a turbine ring to rotate by 90 degrees, the rotating cylinder drives the pipe to turn over by 180 degrees, and the other end ofthe pipe is subjected to arc-forming processing

Owner:XINCHANG HAODI REFRIGERATION CO LTD

Grinding machine corner corrector

ActiveCN102152181BHigh precisionGuaranteed to be perpendicular to each otherPlane surface grinding machinesEngineeringMechanical engineering

The invention discloses a grinding machine corner corrector, which comprises a corner correction baffle and a force clamp. The corner correction baffle comprises a first working surface and a second working surface which are mutually vertical; a groove corner is arranged at the intersection part between the first working surface and the second working surface; the corner correction baffle also comprises a first fixing surface and a second fixing surface which are mutually vertical; and moreover, the first fixing surface is parallel with the second working surface, and the second fixing surface is parallel with the second working surface.

Owner:KUNSHAN XINTAILI PRECISION COMPONENTS CO LTD

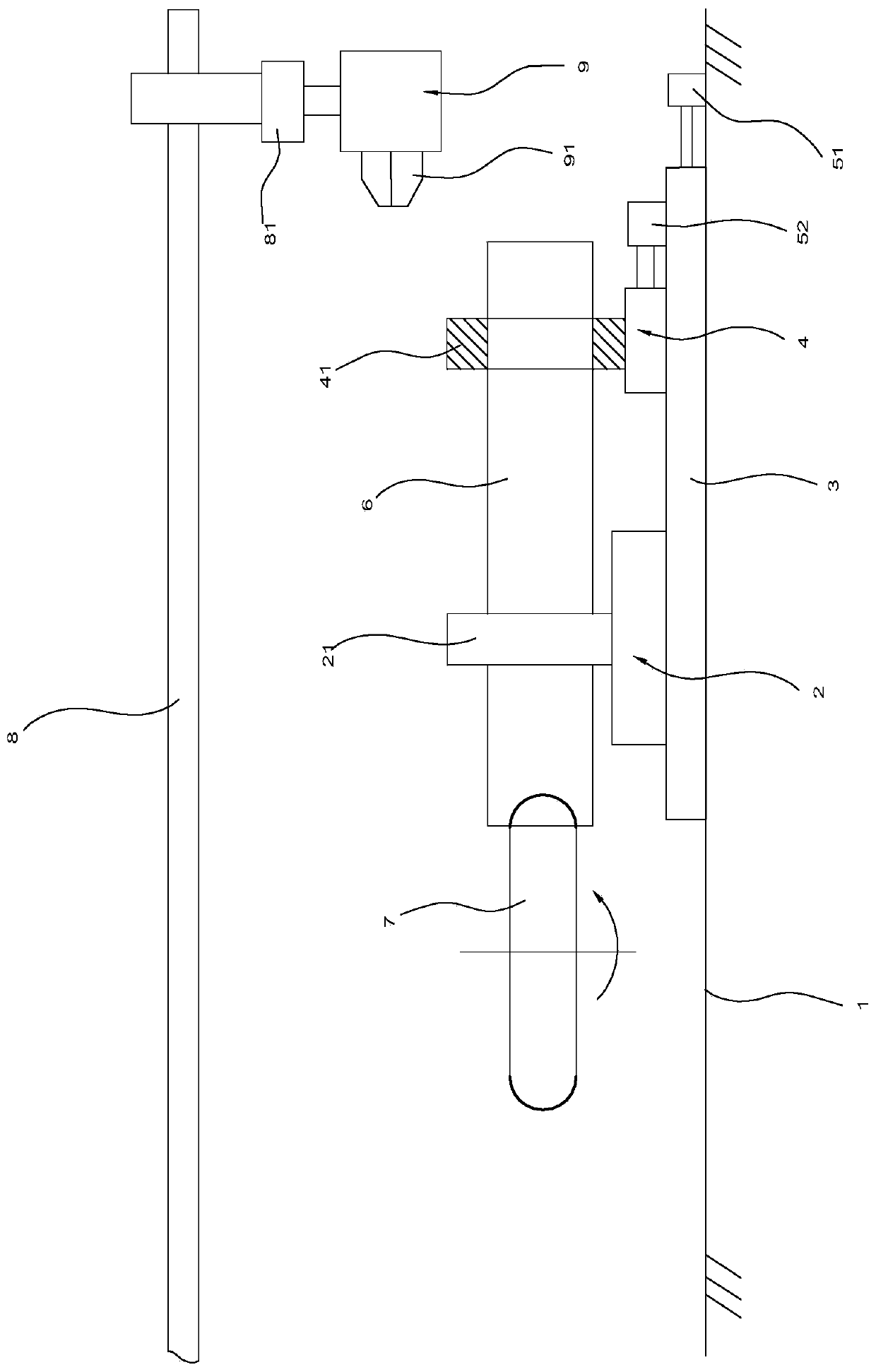

An on-site automatic cutting device for adhesive strength samples of facing bricks

ActiveCN107139342BGuaranteed to be perpendicular to each otherImprove cut qualityPreparing sample for investigationWorking accessoriesBrickCoupling

The invention belongs to the technical field of building material product detection, and particularly relates to a tapestry brick bonding strength sample cutting device. The tapestry brick bonding strength sample cutting device comprises a cutting saw. The cutting saw is fixedly connected with the left end of a telescopic shaft of a horizontal telescopic shaft motor A through a bolt. A coupling is fixed to the right end of a shell of the horizontal telescopic shaft motor A. The right end of the coupling is connected with a pressure ring sensor. The pressure ring sensor is mounted at the end of a hollow shaft motor. The lower end of the hollow shaft motor and a vertical telescopic shaft motor are fixedly connected together. The vertical telescopic shaft motor and the other horizontal telescopic shaft motor B are fixedly connected together. The horizontal telescopic shaft motor B is fixed to a support. The support is fixed to a bottom disc of a cage. The cutting saw, the horizontal telescopic shaft motor A, the pressure ring sensor, the hollow shaft motor, the vertical telescopic shaft motor and the horizontal telescopic shaft motor B are all connected with a PLC.

Owner:山东金谷信息技术有限公司

Arc striking device and arc striking method thereof

ActiveCN108176982BGuaranteed to be perpendicular to each otherRealize feedingGrinding carriagesMetal-working feeding devicesEngineeringForm processing

The invention discloses an arc stamping device and an arc stamping method thereof. The arc stamping device comprises a slide table, wherein one end of the slide table is equipped with a rotary cylinder; the other end of the slide table is equipped with a slide block in a sliding mode; a limiting ring is formed on the slide block; one end of the slide table is equipped with a rotary strip; a grinding layer is formed on the arc-shaped surface of the rotary strip; a guide rail is arranged above the slide table; a telescopic cylinder is arranged on the guide rail in the sliding mode; the output end of the telescopic cylinder is arranged on a rotation cylinder; and the output end of the rotation cylinder is equipped with a clamping part. An arc stamping method comprises the following steps of:inserting a tube into a limiting ring on the slide block, locking one end of the tube by a clamping jaw of the rotary cylinder, rotating the rotary strip, performing arc-forming processing on one endof the tube, rotating the rotary cylinder by 180 degrees, rotating the rotation cylinder by 90 degrees, performing arc-forming processing on the other end of the tube, withdrawing the slide table, anddriving the tube to withdraw by the clamping part of the rotation cylinder to unload.

Owner:青岛华运铸造机械有限公司

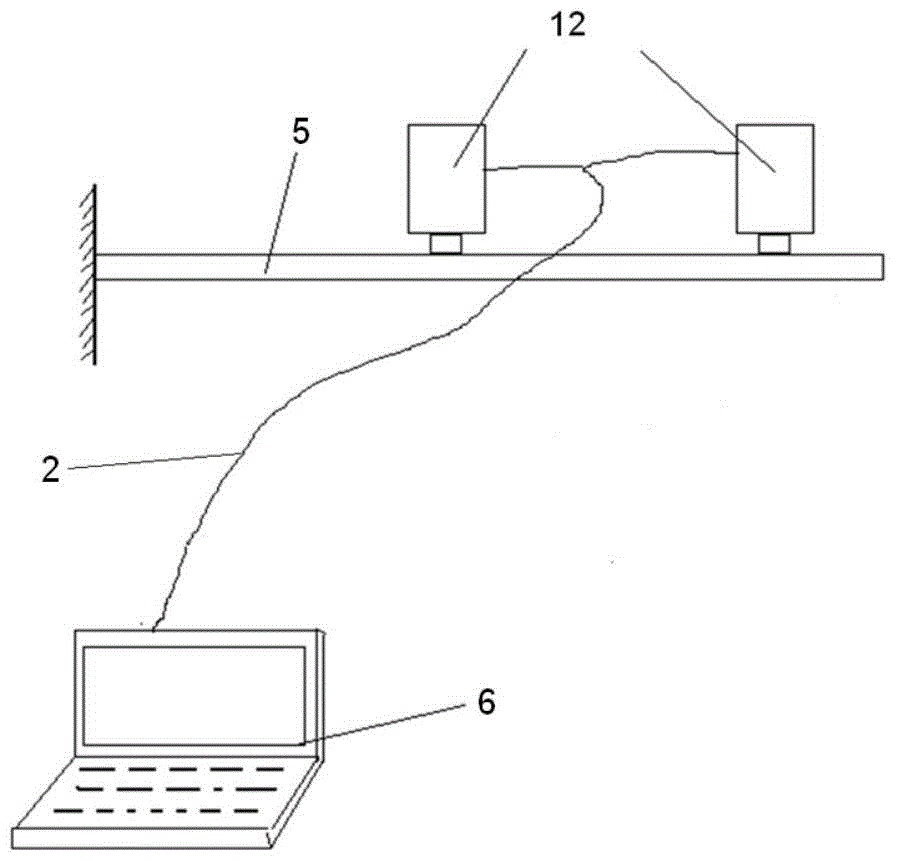

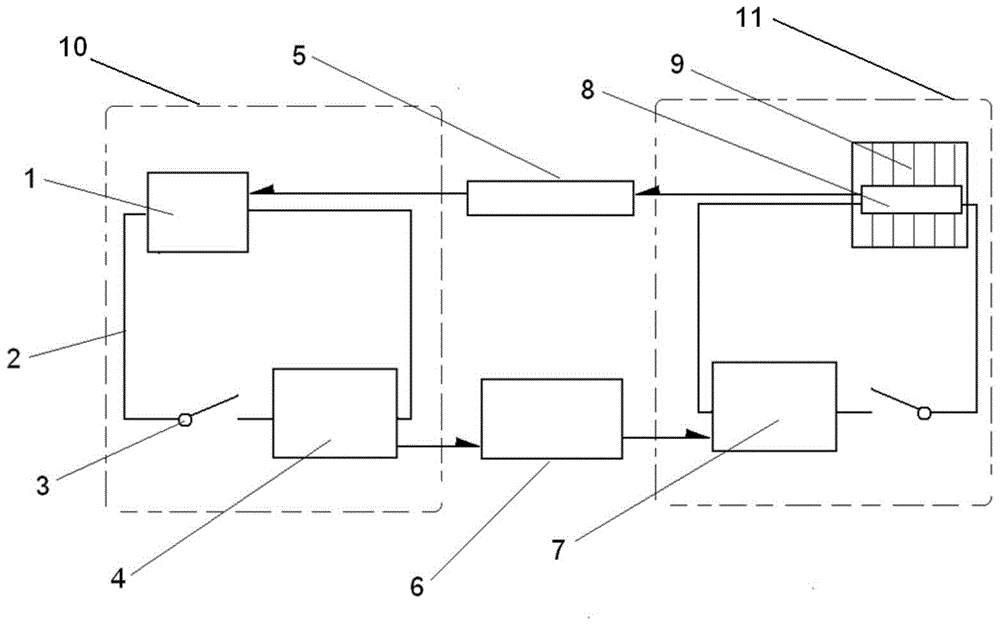

Dry wind tunnel aeroelastic test method

ActiveCN104458188BGuaranteed to be perpendicular to each otherStrong followability of loadingAerodynamic testingStructural deformationPilot system

The invention provides an aeroelasticity testing method for a dry wind tunnel. According to the method, a closed aeroelasticity testing system is utilized to test a testing model. The method comprises the steps that firstly, the closed aeroelasticity testing system is formed by a data acquisition and feedback system and an aerodynamic force generation system through a computer; afterwards, the closed aeroelasticity testing system is utilized to test the testing model; accordingly, the purpose that a simulated aircraft responds under the action of unsteady aerodynamic force is achieved. As a circuit is formed through a signal acquisition / feedback system, the influence on load distribution by structural deformation, namely the aeroelasticity influence, can be effectively simulated. Moreover, as loading equipment does not make contact with a loading model, the errors caused in a traditional ground test can be reduced.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Automatic arc forming equipment for pipe fittings and arc forming method thereof

ActiveCN108177058BImprove arc forming efficiencyAchieve fixationGrinding drivesGrinding machinesPipe fittingEngineering

Owner:JIANGSU FORGED PIPE FITTINGS

Tapestry brick bonding strength sample site automatic cutting device

ActiveCN107139342AGuaranteed to be perpendicular to each otherImprove cut qualityPreparing sample for investigationWorking accessoriesBrickCoupling

The invention belongs to the technical field of building material product detection, and particularly relates to a tapestry brick bonding strength sample cutting device. The tapestry brick bonding strength sample cutting device comprises a cutting saw. The cutting saw is fixedly connected with the left end of a telescopic shaft of a horizontal telescopic shaft motor A through a bolt. A coupling is fixed to the right end of a shell of the horizontal telescopic shaft motor A. The right end of the coupling is connected with a pressure ring sensor. The pressure ring sensor is mounted at the end of a hollow shaft motor. The lower end of the hollow shaft motor and a vertical telescopic shaft motor are fixedly connected together. The vertical telescopic shaft motor and the other horizontal telescopic shaft motor B are fixedly connected together. The horizontal telescopic shaft motor B is fixed to a support. The support is fixed to a bottom disc of a cage. The cutting saw, the horizontal telescopic shaft motor A, the pressure ring sensor, the hollow shaft motor, the vertical telescopic shaft motor and the horizontal telescopic shaft motor B are all connected with a PLC.

Owner:山东金谷信息技术有限公司

Device for testing adhesive force of raw material of photovoltaic module

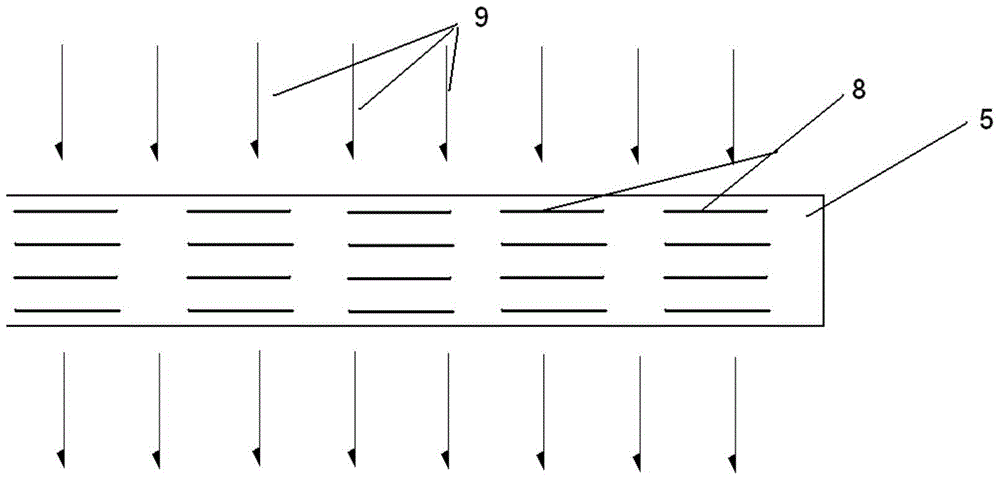

PendingCN112924380AUniform shadeImprove accuracyUsing mechanical meansMaterial analysisDisplay deviceEngineering

The invention discloses a device for testing the adhesive force of a raw material of a photovoltaic module. The device comprises a seat body, a cutter, a display device and at least one pressure sensor. The upper end part of the cutter is connected in the seat body in a sliding manner, and the lower end part of the cutter is provided with at least one cutter tooth suitable for scribing on a workpiece; the pressure sensor is arranged between the upper end part of the cutter and the seat body and is suitable for collecting the acting force of the cutter teeth on the workpiece; and the display device is connected with the output end of the pressure sensor and is suitable for receiving a pressure signal generated by the pressure sensor and correspondingly displaying the pressure signal. According to the device, the uniformity of the scribing depth on the surface of the workpiece can be improved, and the large difference of the scribing depth is avoided.

Owner:常州华阳检验检测技术有限公司

Arc punching device and arc punching method at both ends of a circular tube

ActiveCN108080484BRealize the processing effectEasy to operateMetal-working feeding devicesPositioning devicesPunchingPipe fitting

Owner:雷磊

A Method of Improving the Opening Precision of Split Seat Ring

ActiveCN109909679BGuaranteed to be perpendicular to each otherGuaranteed baseline levelOther workshop equipmentNumerical controlStructural engineering

The invention discloses a method for improving sectioning base ring opening precision. According to different points of the method from a conventional technology, for perpendicularity after sectioningbase ring joint close face machining, a steel wire is hoisted to check various parts of the joint close face, a numerical control program is utilized for correcting joint close face perpendicularitydeviation, and precision of the joint close face is guaranteed; 1 / 2 of a base ring is machined on a boring machine, boring machine stroke precision is utilized, a digital level gage is placed on a boring box, fixed guide vane opening measuring in the whole 1 / 2 base ring stroke is achieved, and precision of base ring 1 / 2 datum lineation is guaranteed; a 360-degree rotation center column is utilizedin the integral base ring for measuring and datum lineation and checking, datum uniformity of the integral base ring is guaranteed, and the datum lineation and checking precision is improved; sectioning base ring datum plane machining and combining are conducted, the sectioning base ring is assembled and combined with the datum plane as the reference, and the assembling and combining precision isimproved. The method has the advantages that the base ring opening size control technology is simple, the machining quality is controllable, and precision is high.

Owner:HARBIN ELECTRIC MASCH CO LTD

An automatic arc forming device for pipe fittings and an arc forming method thereof

The invention discloses an automatic pipe arc-forming device and an arc-forming method of the automatic pipe arc-forming device. The automatic pipe arc-forming device comprises an arc-forming seat, afeeding rotating mechanism and a shifting arc-forming mechanism. A limiting sleeve is arranged in the arc-forming seat. The feeding rotating mechanism comprises a base, a rotating cylinder, a rack, asector-shaped plate, a connecting rod and a rotating drum. The shifting arc-forming mechanism comprises a driving piece, triggers arranged on the two sides of the driving piece, an arc-forming rod rotationally arranged in the arc-forming seat and springs. The arc-forming method comprises the following steps that a pipe is clamped and limited in the clamping mechanism, the rotating drum rotates, one end of the pipe is inserted into the limiting sleeve in the arc-forming seat, a shifting disc drives the arc-forming rod to swing, one side of one end of the pipe is subjected to arc-forming processing by a cutter, the shifting disc rotates reversely, the other side of one end of the pipe is subjected to arc-forming processing by the cutter, the rotating drum drives the feeding rotating mechanism to retreat, a rotating motor drives a worm to rotate, the worm drives a turbine ring to rotate by 90 degrees, the rotating cylinder drives the pipe to turn over by 180 degrees, and the other end ofthe pipe is subjected to arc-forming processing

Owner:XINCHANG HAODI REFRIGERATION CO LTD

Auxiliary tool for vertical installation of internal and external corners of transverse keel and use method of auxiliary tool

PendingCN114197821AWide applicabilityVertically accurateBuilding constructionsFixed angles setting outLight pipeTrackway

The invention discloses a transverse keel internal and external corner vertical installation auxiliary tool and a using method thereof.The transverse keel internal and external corner vertical installation auxiliary tool comprises a vertical testing device, a horizontal testing device, a rail and a connecting structure, the rail is in an L shape, and the vertical testing device is installed on the rail, slides back and forth on the rail and is used for testing the perpendicularity of a transverse keel; the horizontal testing device is horizontally fixed on a track, the connecting structure is used for connecting the track to a transverse keel with internal and external corners, the vertical testing device comprises a vertical light pipe, a laser host and horizontal light pipes, the laser host is installed below the turning center of the track, the horizontal light pipes are installed on the two sides of the laser host, and the vertical light pipes are open in the top and hollow in the interior. An opening is formed in the lower side face, the vertical light pipe penetrates through the through groove of the track, the opening in the lower side face corresponds to and is opposite to the opening of the horizontal light pipe, and a reflector which is obliquely arranged is arranged in the opening in the lower side face and used for reflecting light beams. The device is simple in structure, detachable, convenient to mount and wide in applicability.

Owner:ZHEJIANG YASHA DECORATION

A kind of arc punching equipment and arc punching method at both ends of circular tube

ActiveCN108176759BAchieving stationary positioningGuaranteed to be perpendicular to each otherPunchingGear drive

The invention discloses a device and a method for punching arcs on two ends of a circular pipe. The device comprises an arc punching seat, a feeding and rotating mechanism and a pulling and arc punching mechanism. A limiting sleeve is arranged in the arc punching seat; the feeding and rotating mechanism comprises a base, a rotary cylinder, a connecting block, a guiding pillar, a spring, a connecting rod, a drive gear and two driven gears; the pulling and arc punching mechanism comprises a rotary plate, a slide block, a drive rod, and an arc punching rod rotatably arranged in the arc punching seat; the rotary plate drives the drive rod to swing; and the drive rod drives the arc punching rod to swing. The arc punching method comprises the following steps: a pipe is clamped and limited in a clamping mechanism, the drive gear rotates, one fan-shaped gear drives one end of the pipe to be inserted into the limiting sleeve in the arc punching seat, the rotary plate rotates, the drive rod drives the arc punching rod to swing back and forth, a cutter carries out arc punching processing on two sides of one end of the pipe, the other fan-shaped gear drives the pipe to retreat, a rotary motordrives a worm to rotate, the worm drives a worm wheel to rotate at 90 degrees, the rotary cylinder drives the pipe to turn over at 180 degrees, and the other end of the pipe is subjected to arc punching processing.

Owner:浙江亚奇工艺品股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com