Optical angle reflection target ball and manufacturing method thereof

A manufacturing method and corner reflection technology, which is applied in optics, optical components, instruments, etc., can solve the problems that the concentricity of the glass reflector is difficult to achieve high precision, the installation process of the three reflecting surfaces is complicated, and the manufacturing cost of the glass reflector is high. Achieve the effects of improving structural firmness and drop resistance, simple structure, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

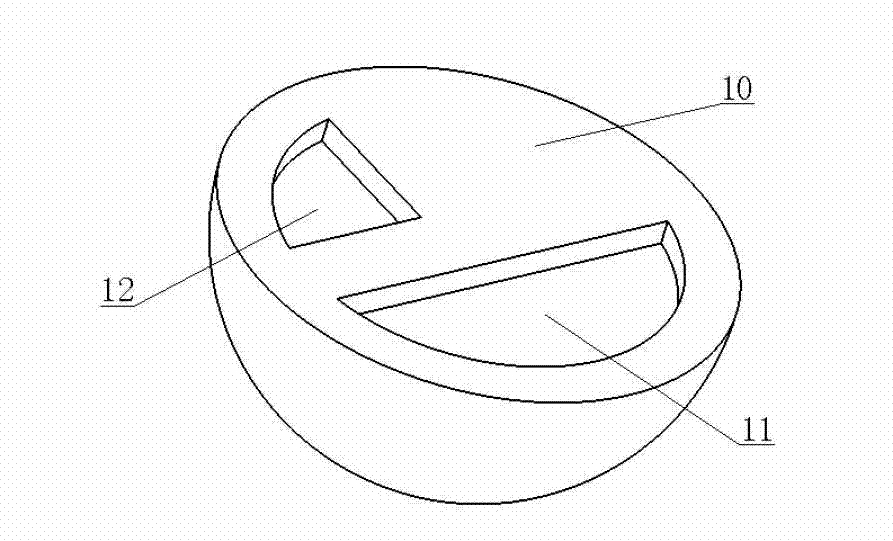

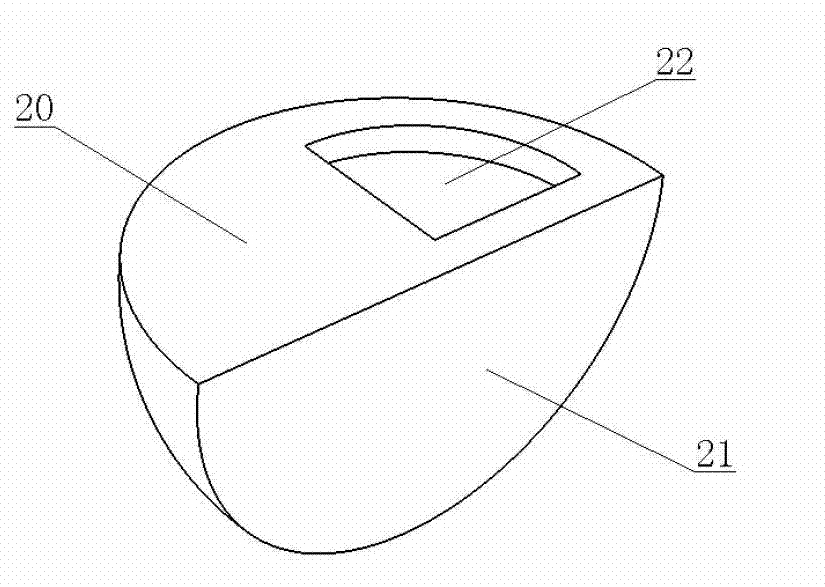

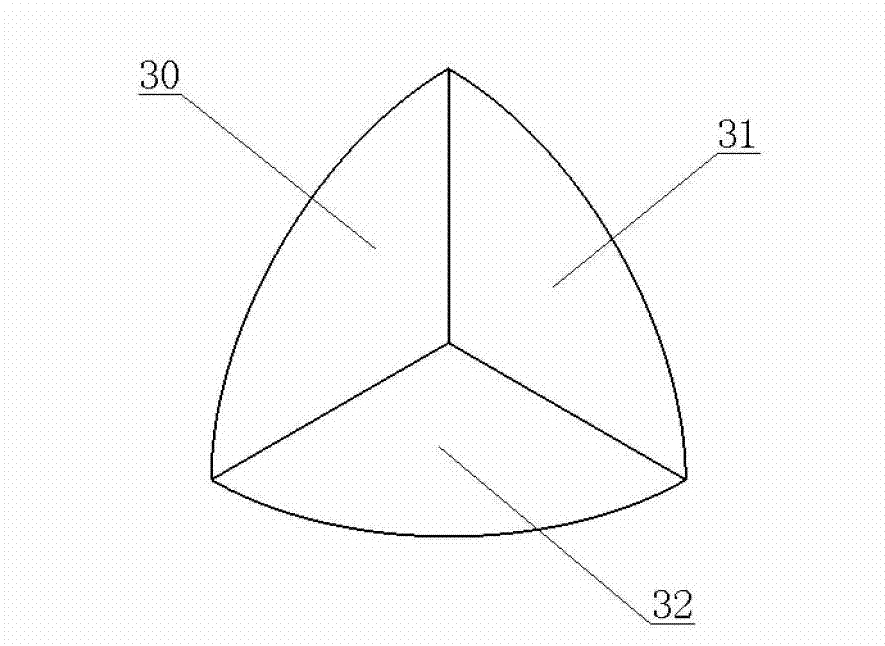

[0034] A processing method of the optical angle reflective target ball of the present invention is introduced below, and the specific steps of the method are as follows. First take a solid metal sphere, cut it in half three times in turn, and get a 1 / 2 metal sphere respectively (such as figure 1 shown), a 1 / 4 metal sphere (as figure 2 shown) and two 1 / 8 metal spheres (as image 3 shown), a 1 / 8 sphere is discarded. Such as figure 1 , 2 , 3, in the 1 / 2 metal sphere, 1 / 4 metal sphere, and 1 / 8 metal sphere, three reflective surfaces 10, 20, 30 are formed; three groups of corresponding bonding surfaces are also formed: bonding Surface 11 and bonding surface 21; bonding surface 12 and bonding surface 31; bonding surface 22 and bonding surface 32. Next, dig grooves on one of the two faces of each group of corresponding joint surfaces and apply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com