Patents

Literature

30results about How to "Concentricity is easy to guarantee" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

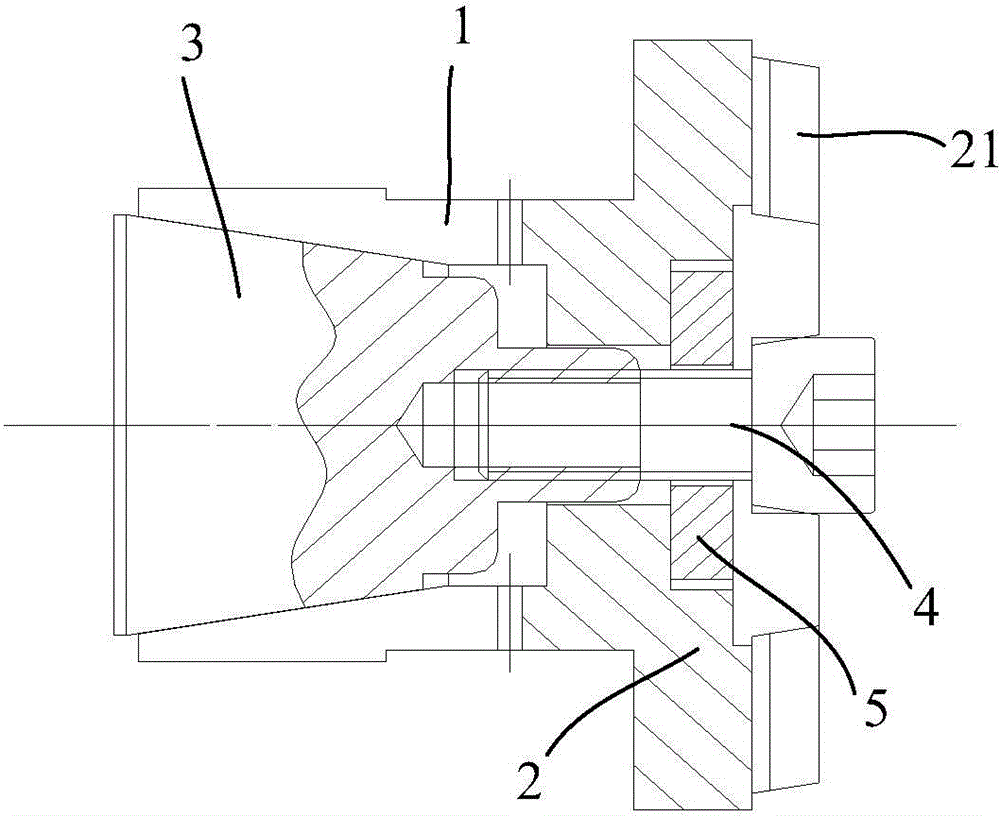

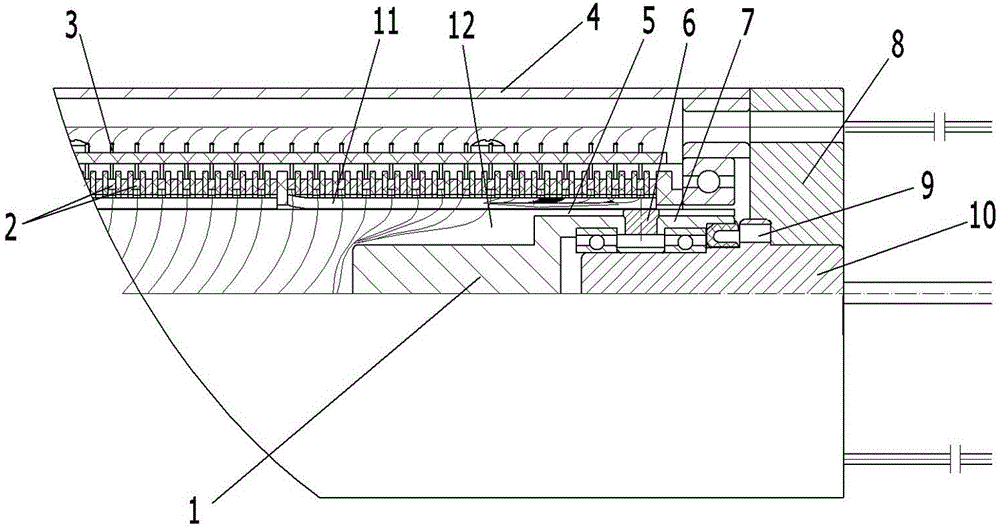

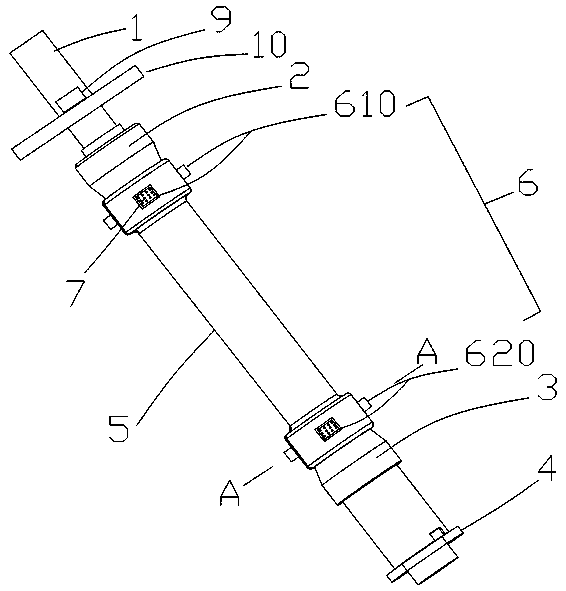

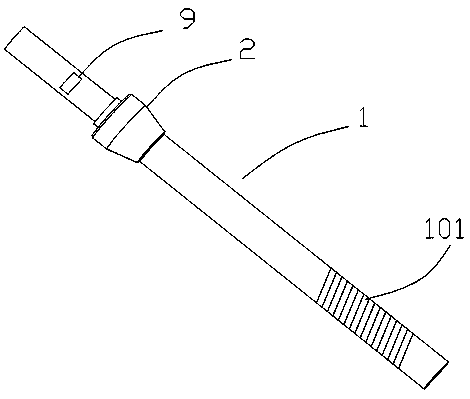

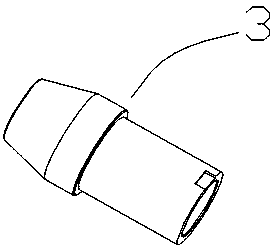

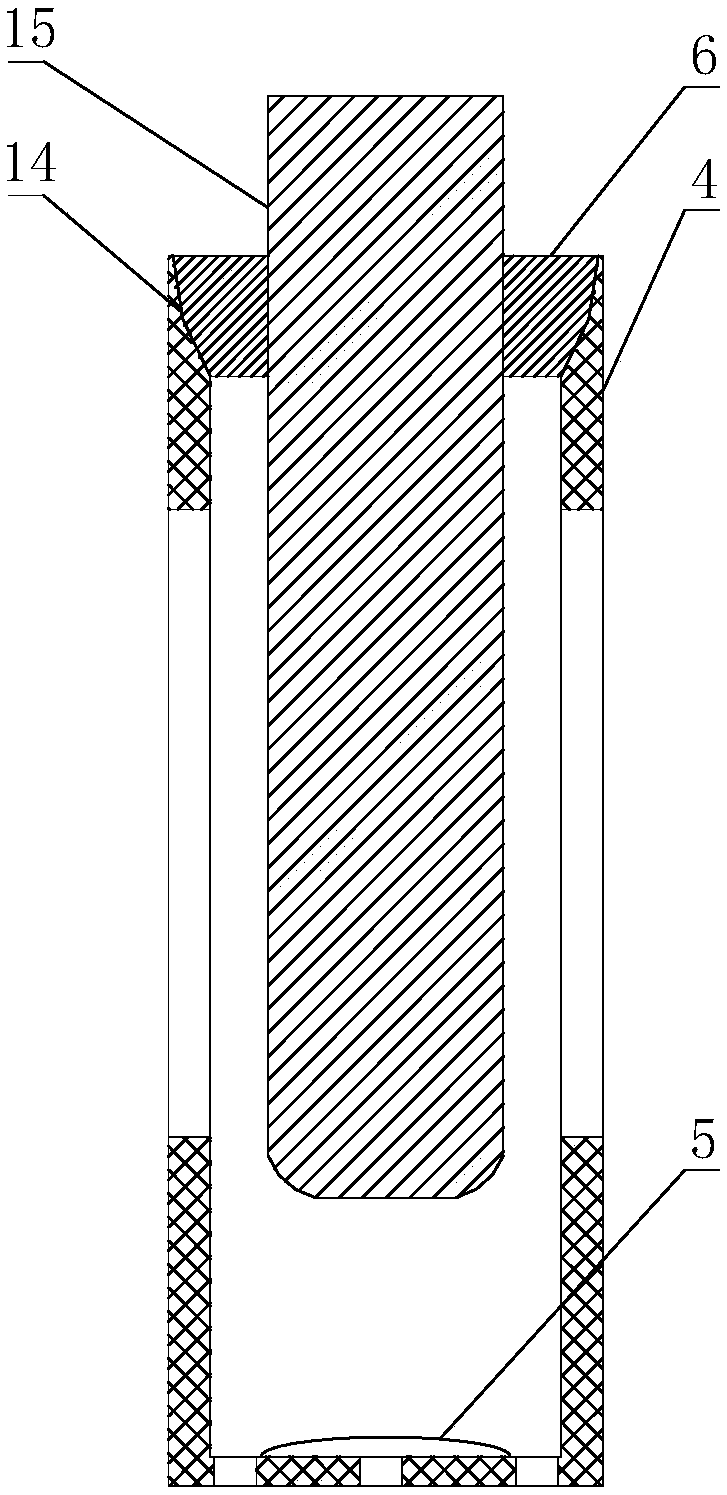

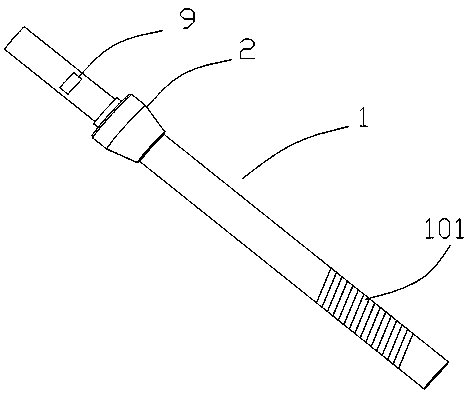

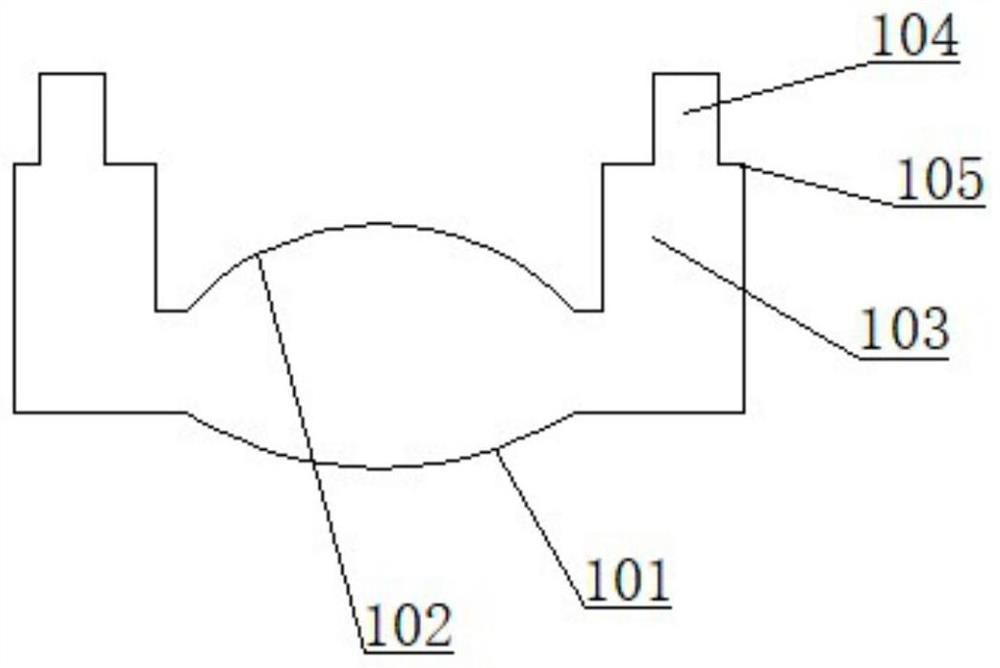

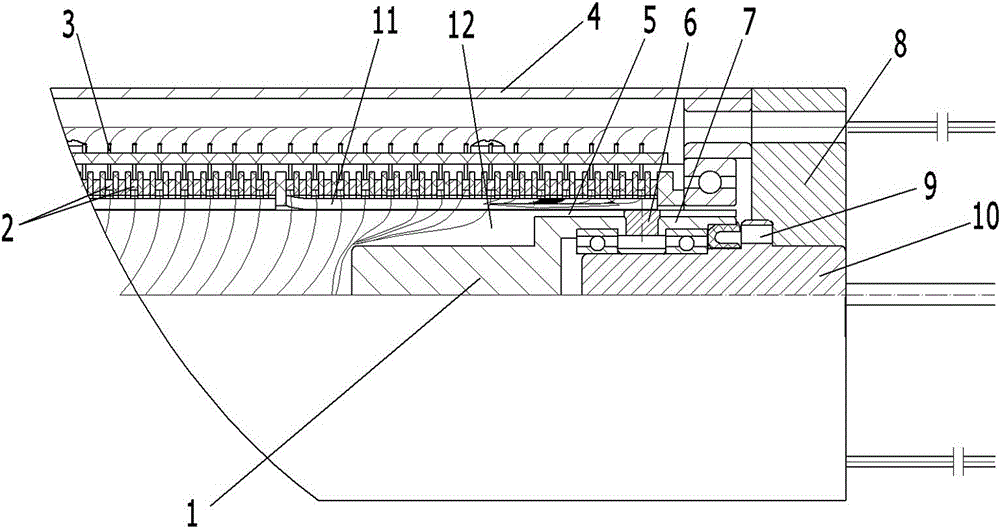

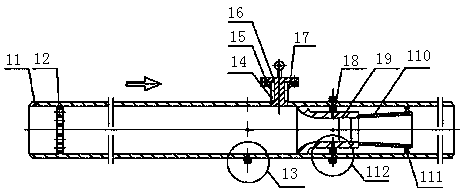

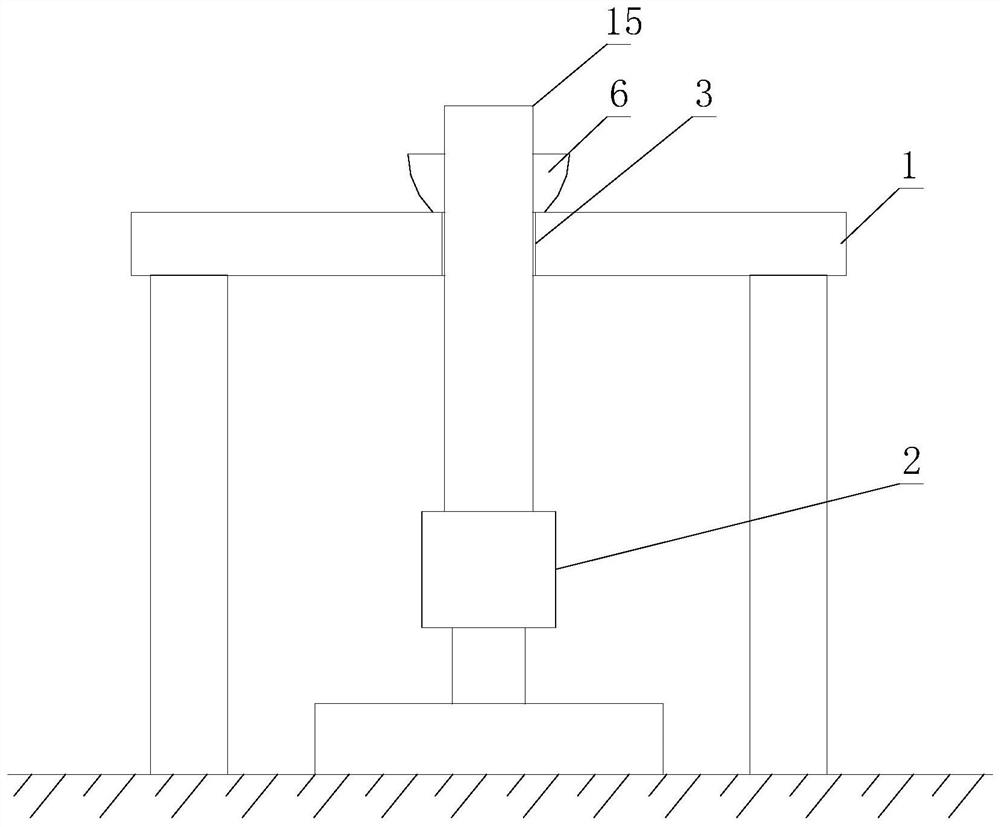

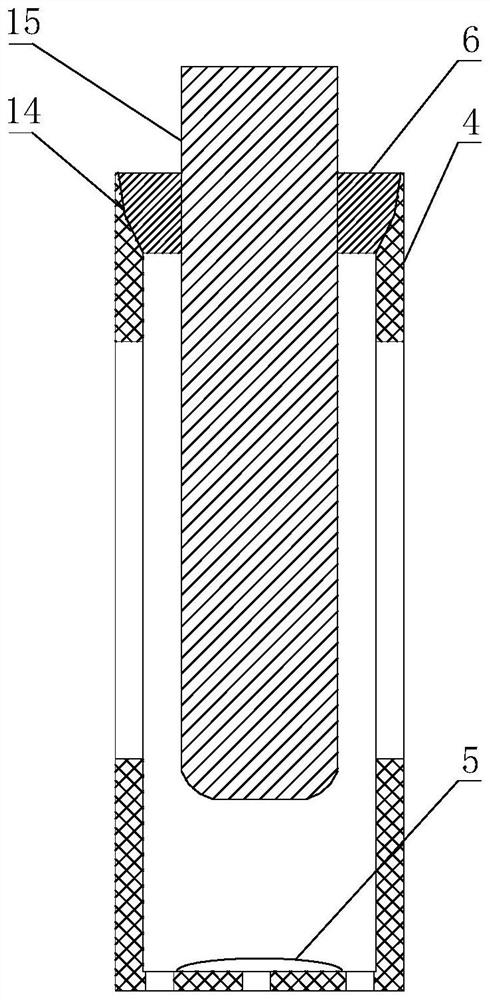

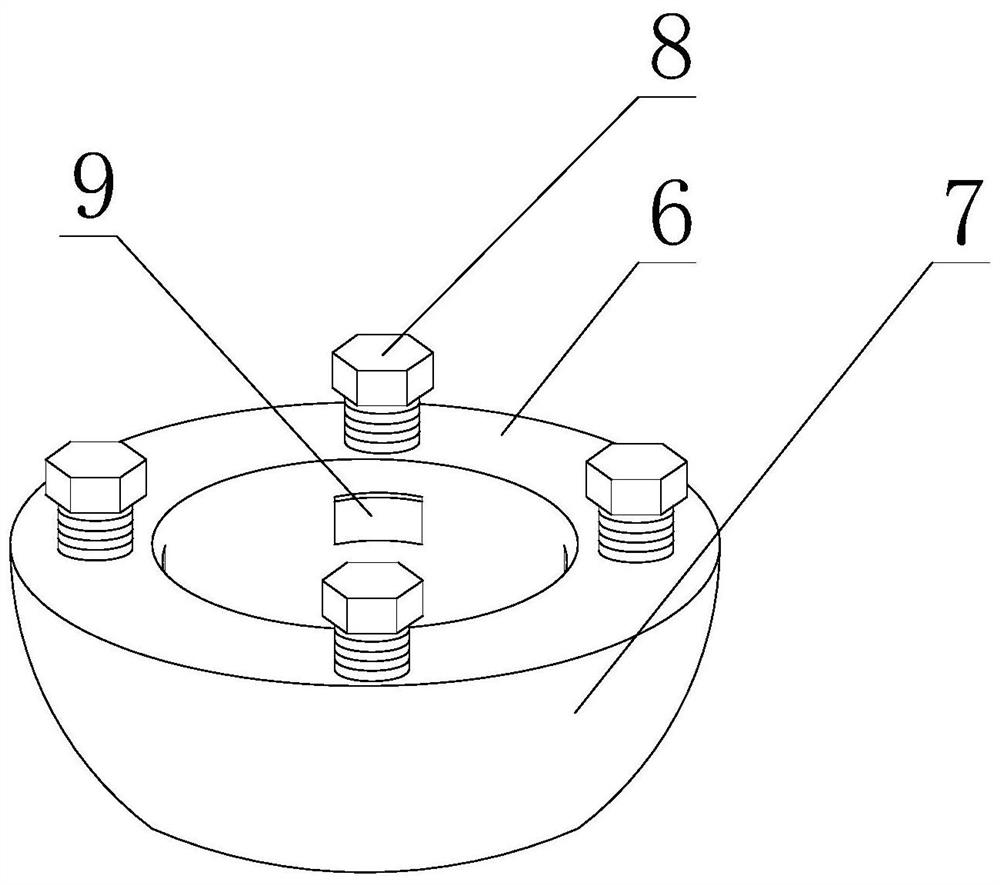

Expansion clamping device

InactiveCN104439363AConcentricity is easy to guaranteeStable structureExpansion mandrelsEngineeringConical surface

The invention provides an expansion clamping device which comprises an expansion sleeve and a chuck connected to one end of the expansion sleeve, wherein a plurality of expansion gaps are axially formed in the expansion sleeve; a core rod is mounted in the expansion sleeve; the side surface of the core rod is conical; the inner wall of the expansion sleeve is a conical surface matched with the core rod; the small-diameter end of the core rod faces to the chuck; a bolt penetrates through the chuck to be in threaded connection with the small-diameter end of the core rod to tightly pull the core rod and the expansion sleeve; chuck teeth are arranged on the chuck. According to the expansion clamping device, a bottom barrel can be quickly tightened by expansion and dismounted, and the chuck is matched with a processing tool of the bottom barrel through the chuck teeth, so that the bottom barrel can be firmly fixed and prevented from rotating during processing; an expansion mechanism is convenient to mount and dismount, the bottom barrel cannot be damaged, and the clamping efficiency is high.

Owner:CHONGQING YAOYONG SHOCK ABSORBER

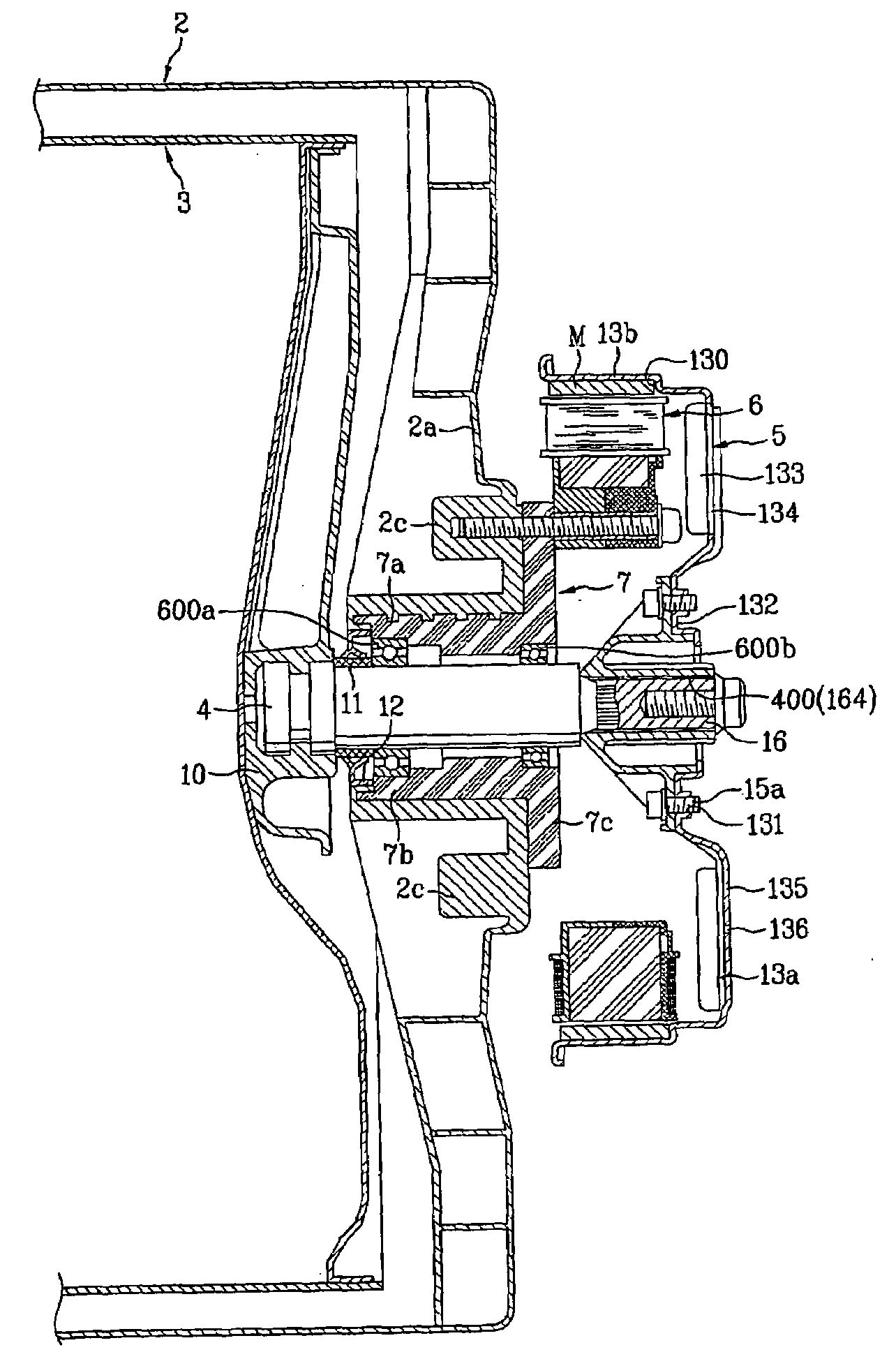

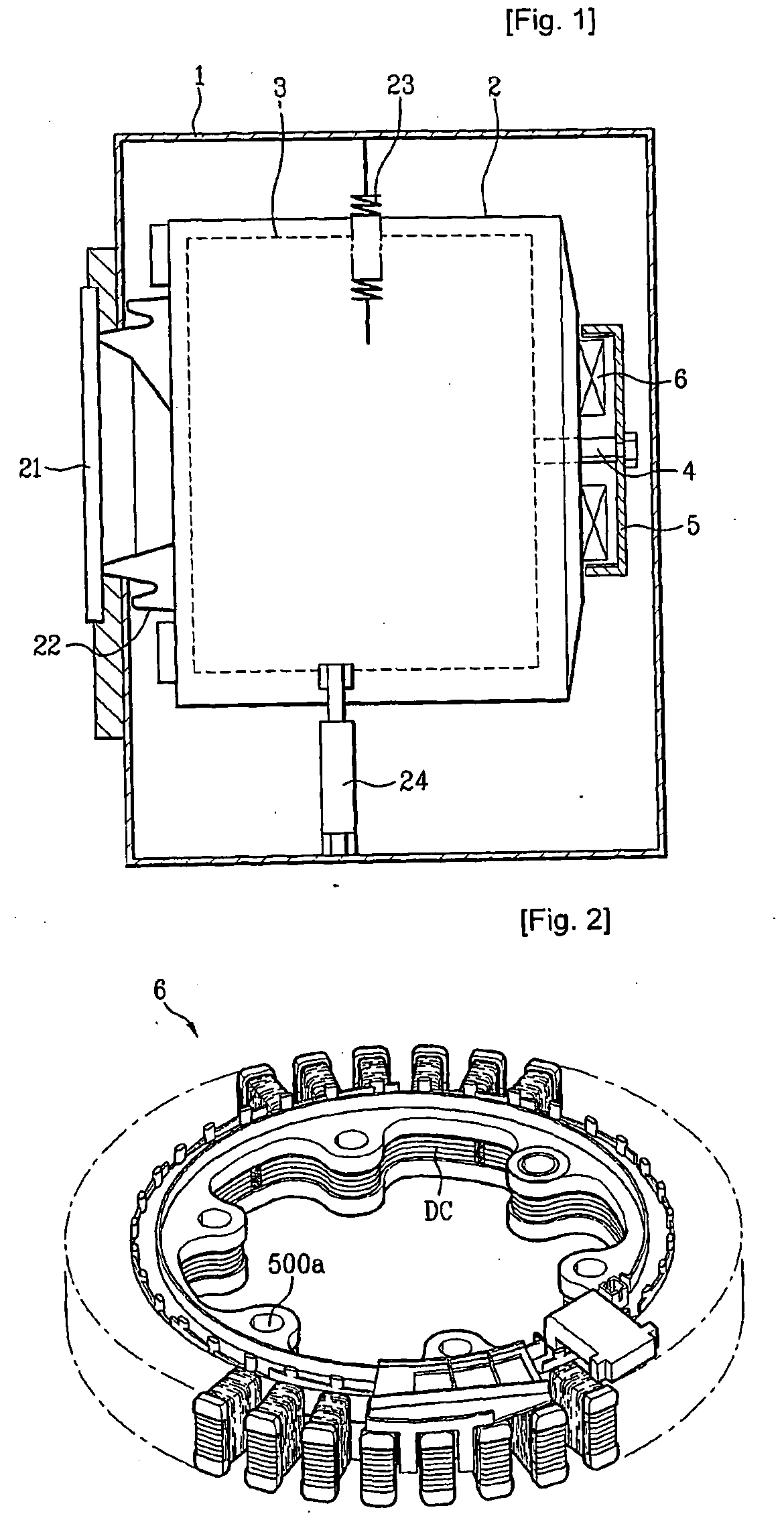

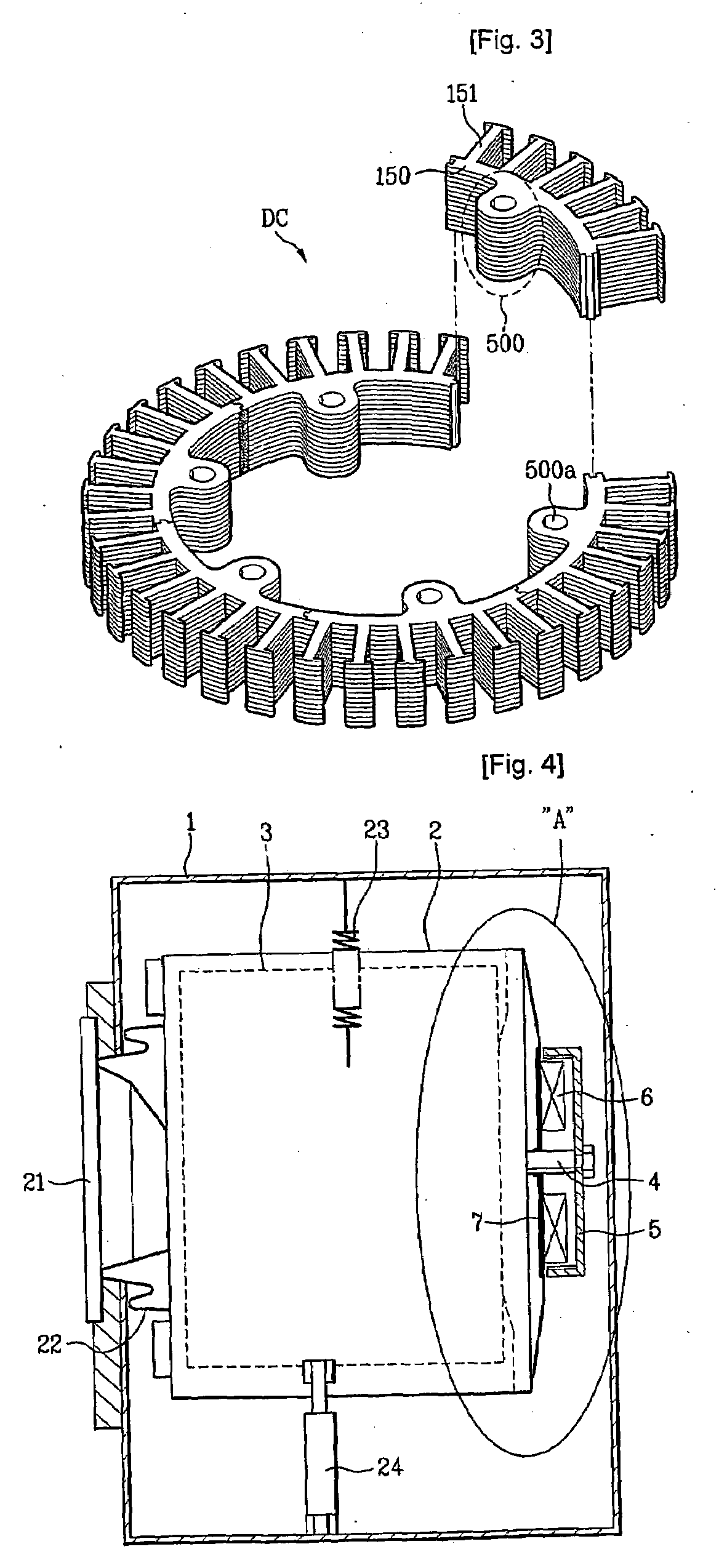

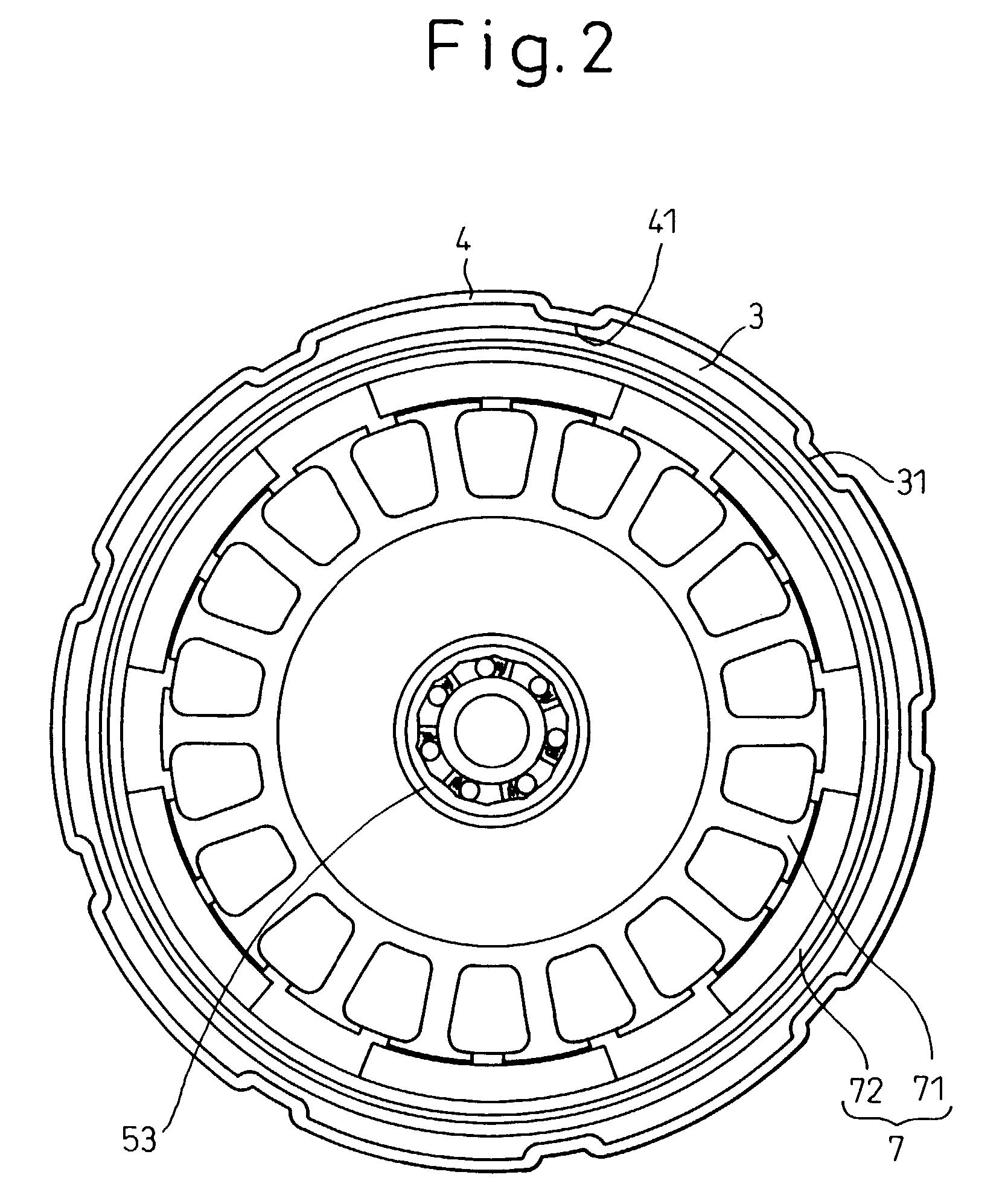

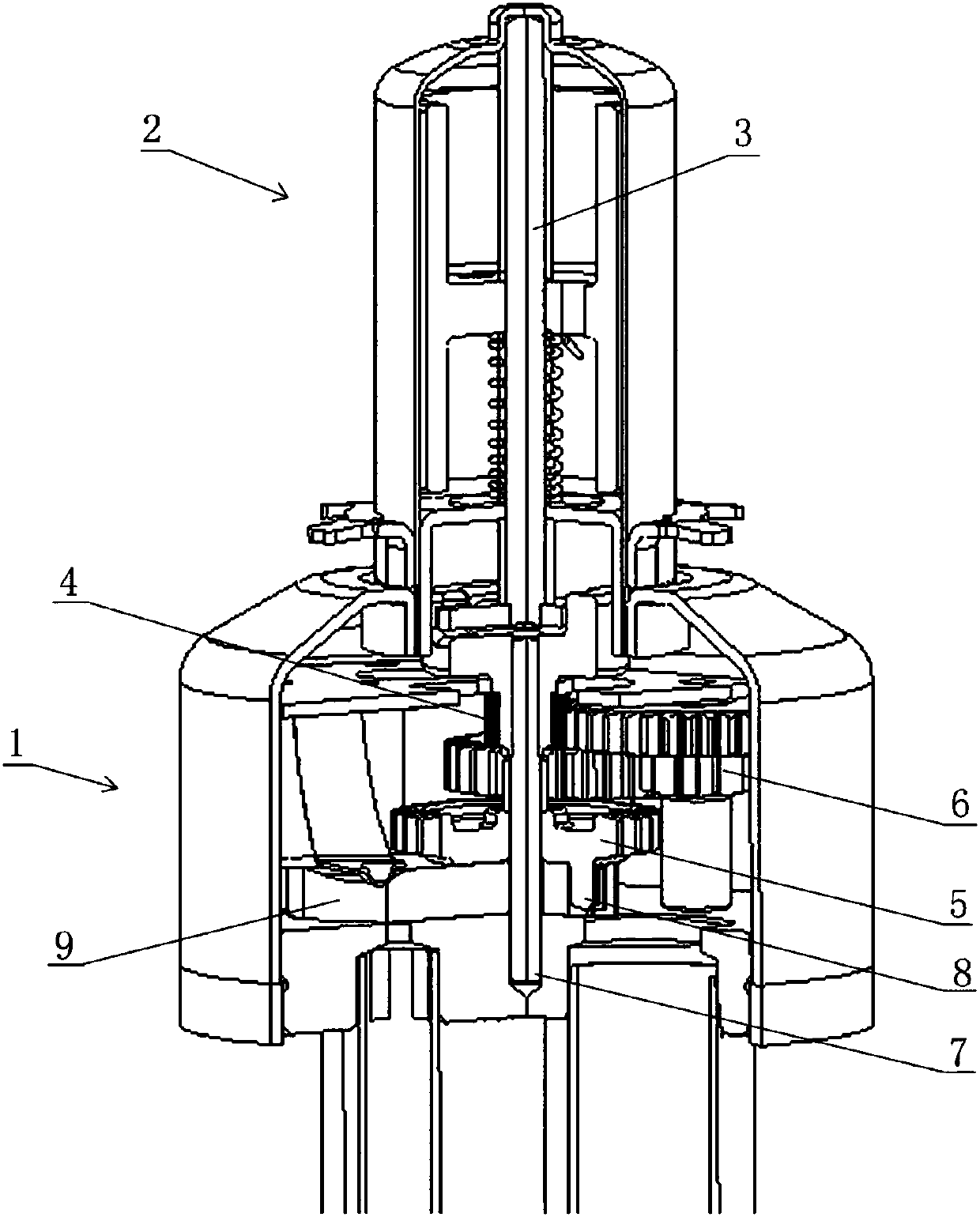

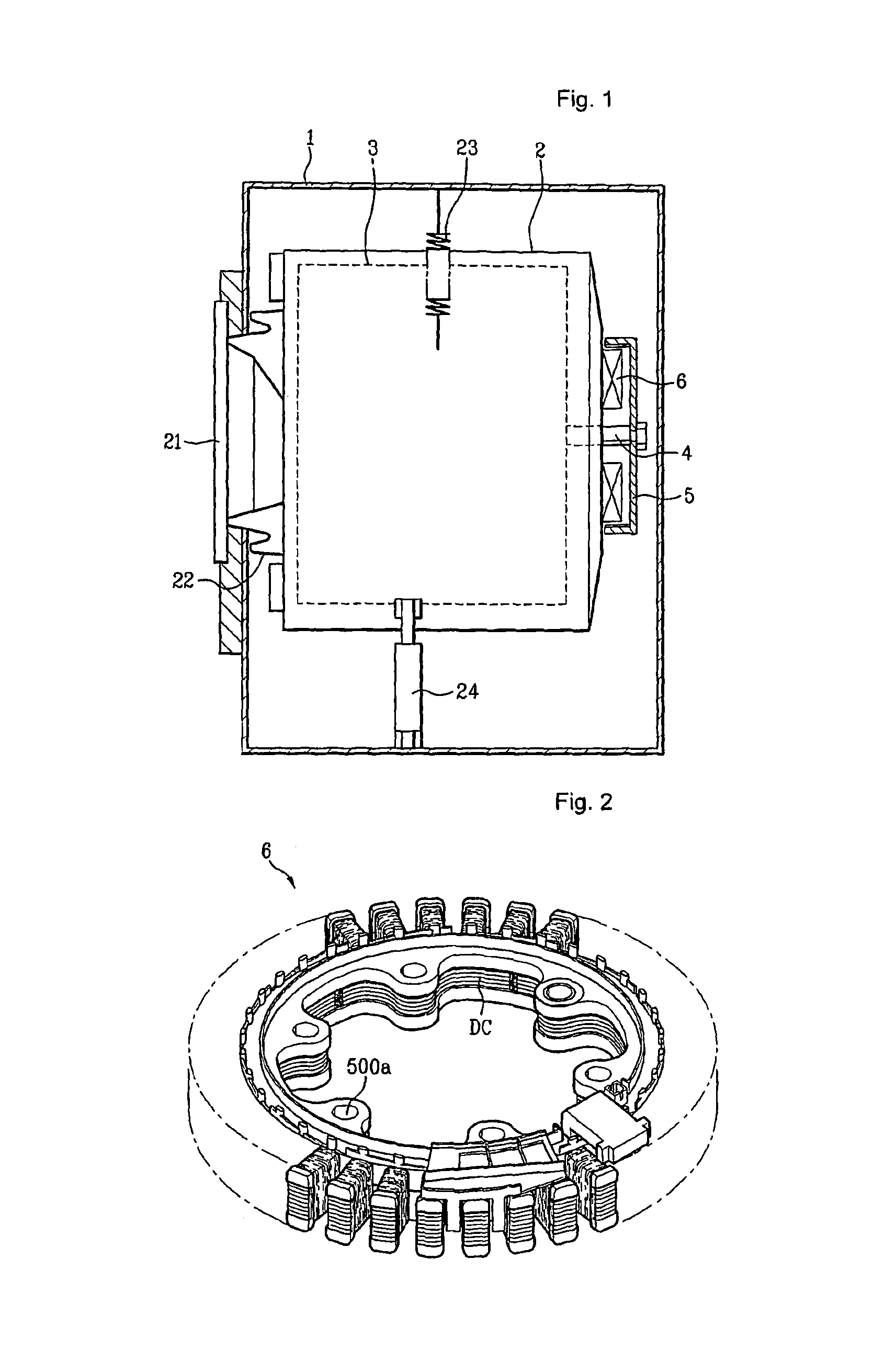

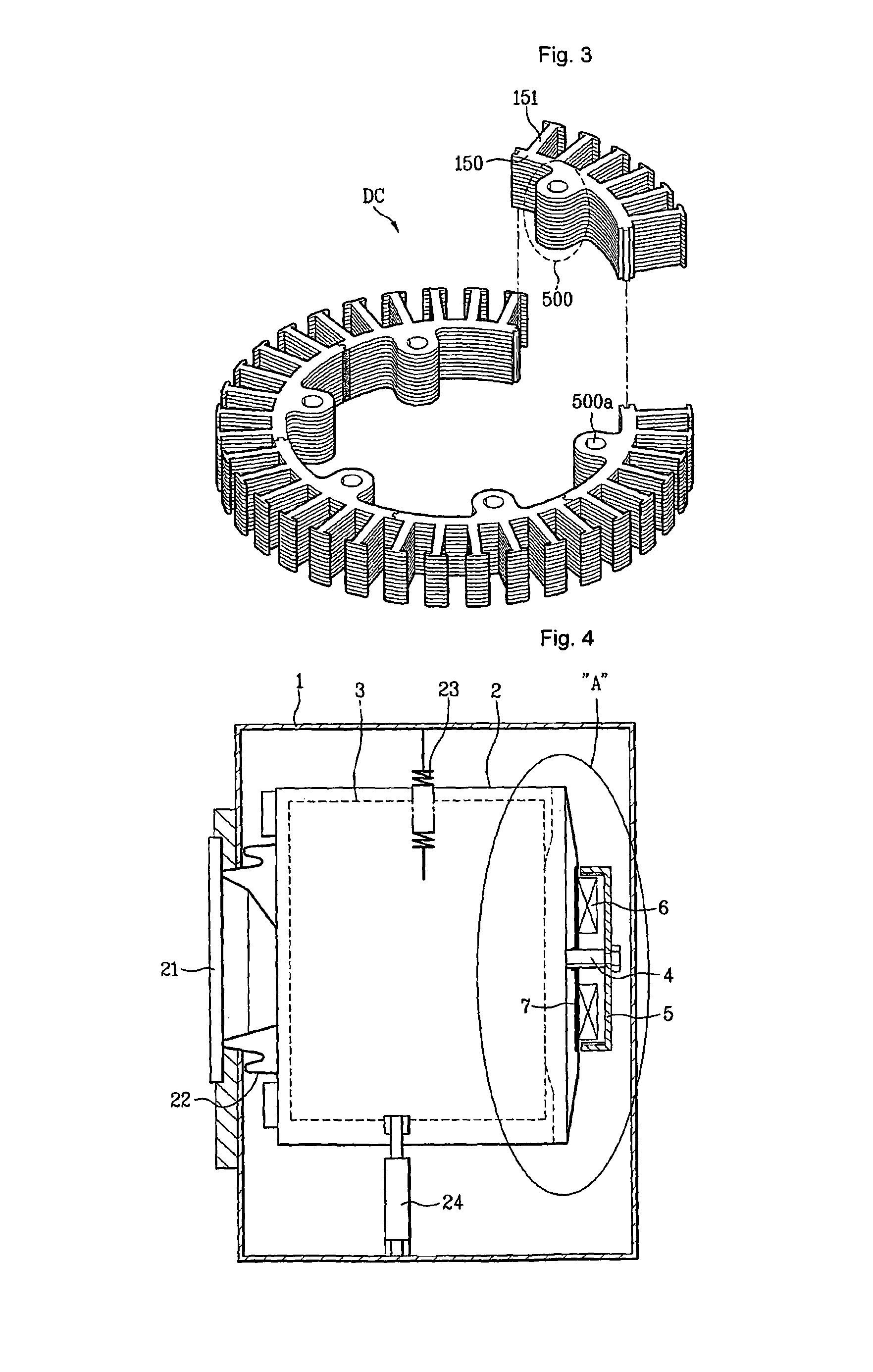

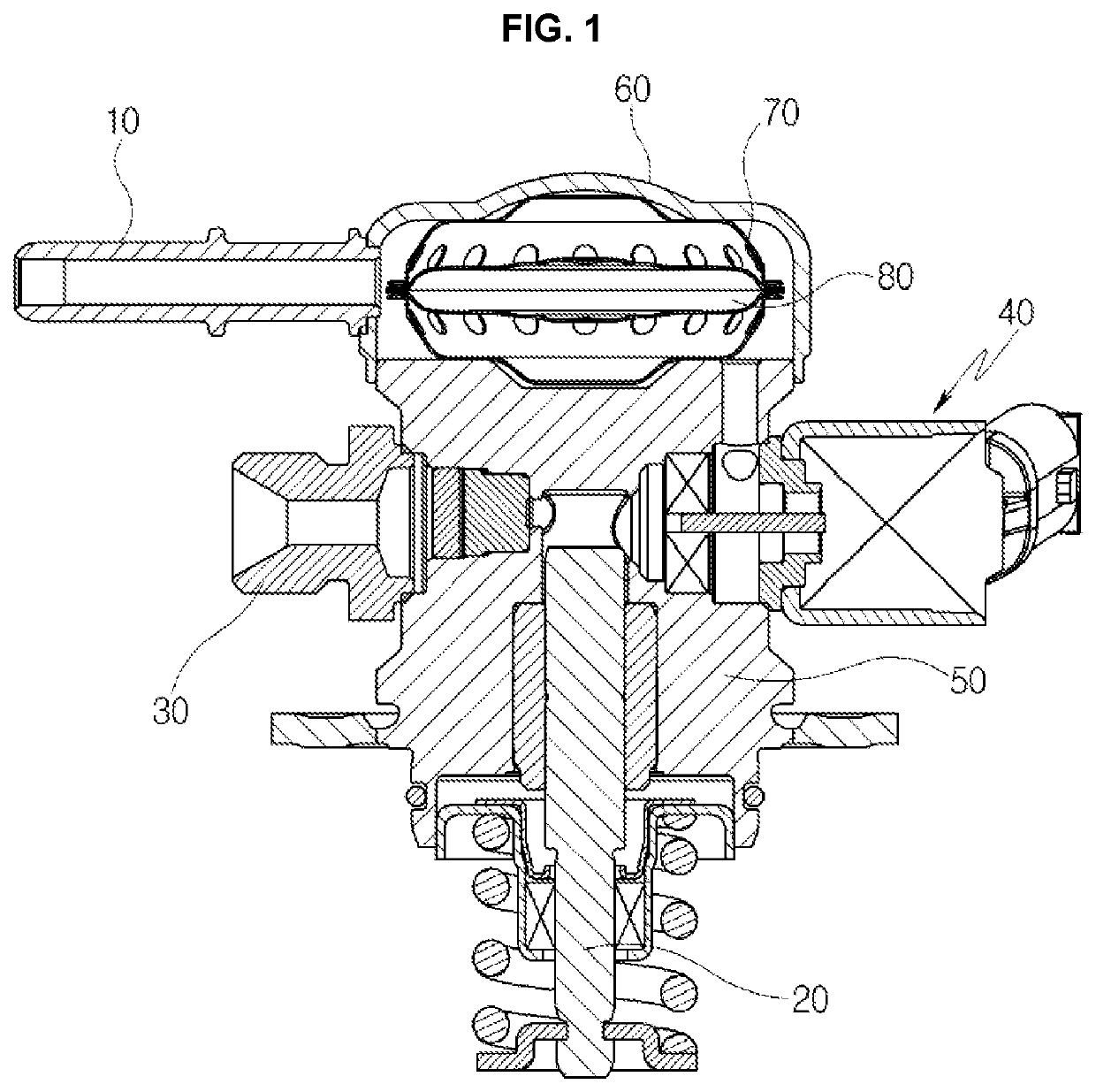

Drum type laundry machine

ActiveUS20090211312A1Reduce weightEasy to installOther washing machinesWashing machine with receptaclesWash waterEngineering

A drum washing machine includes a tub installed in a housing to receive wash water therein, a drum rotatably installed in the tub, a rotor having a rotating shaft connected to the drum, a bearing housing having at least one bearing for supporting the rotating shaft of the rotor, the bearing housing being located at the tub, and a stator spaced apart from the rotor by a predetermined distance and directly connected to the tub.

Owner:LG ELECTRONICS INC

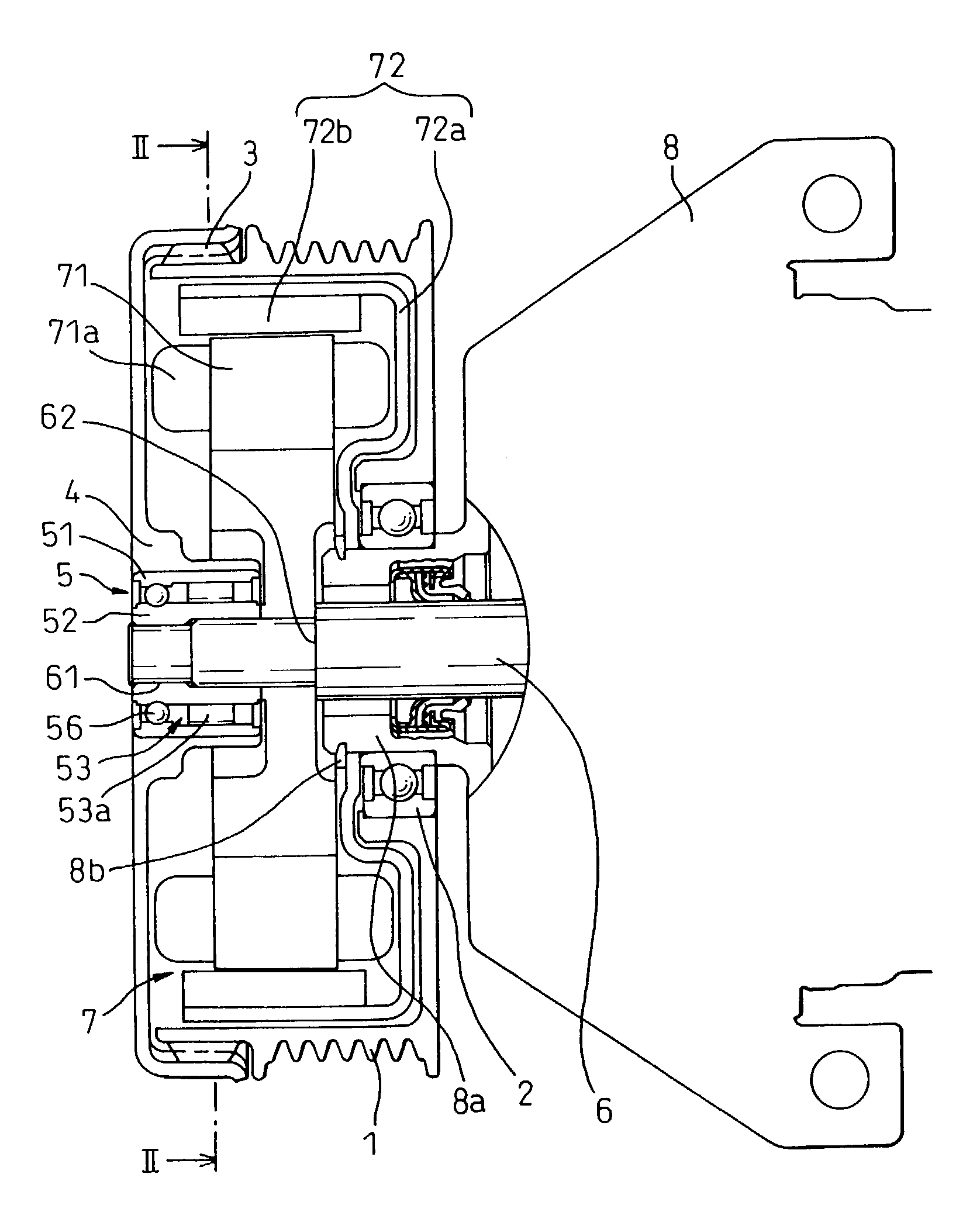

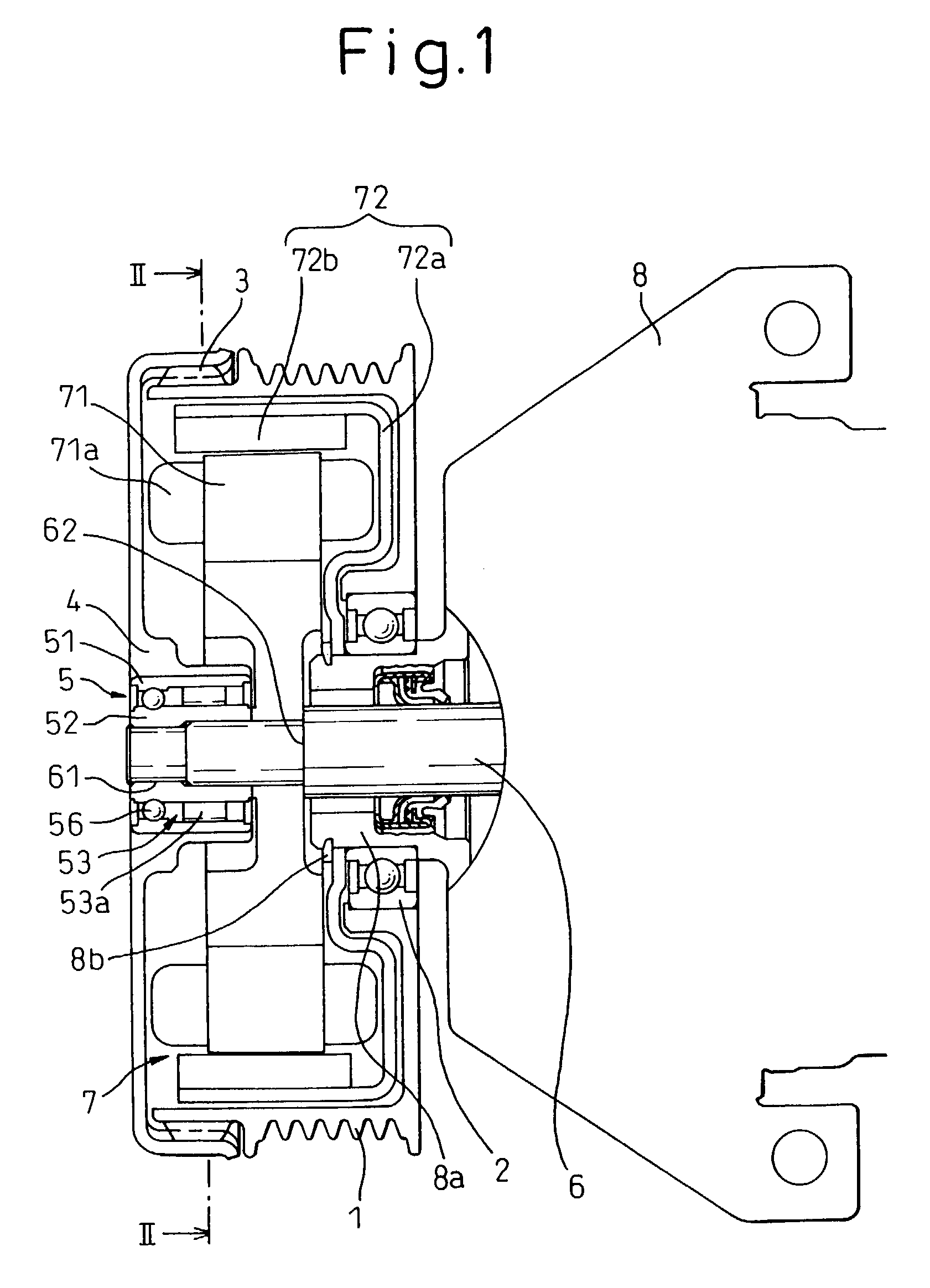

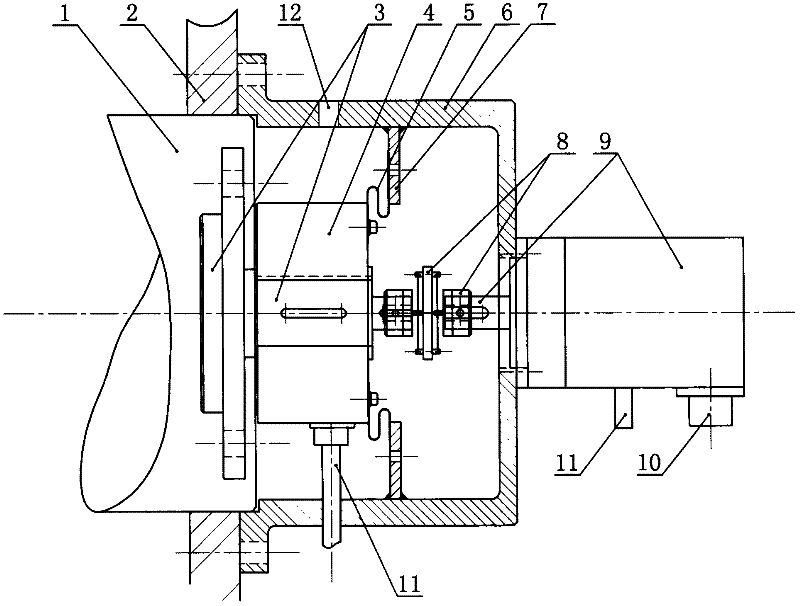

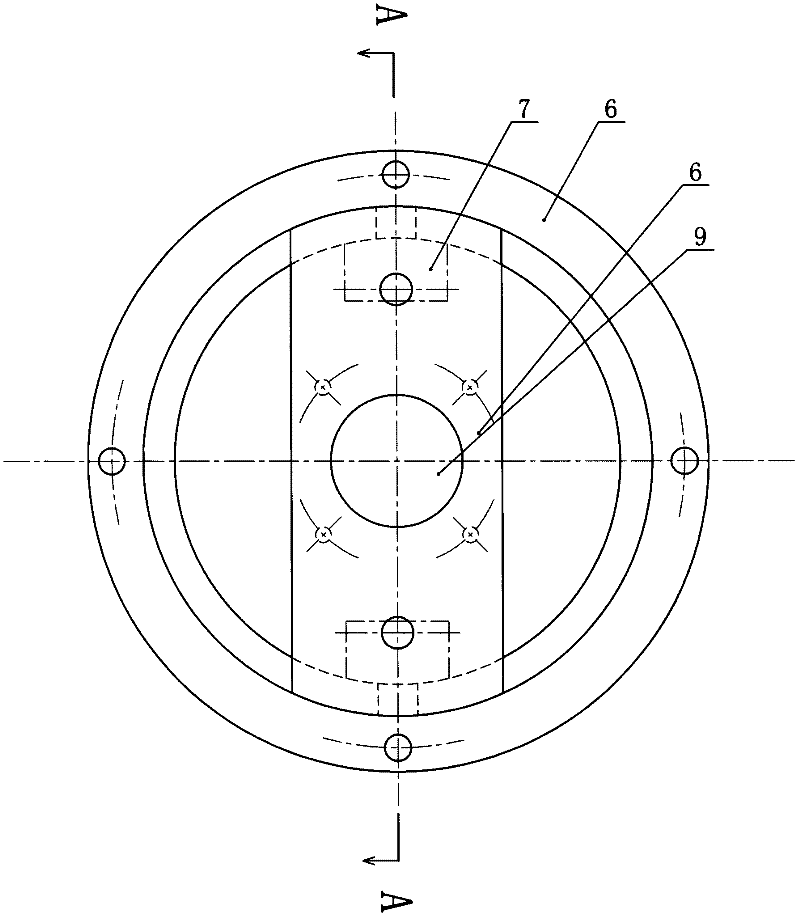

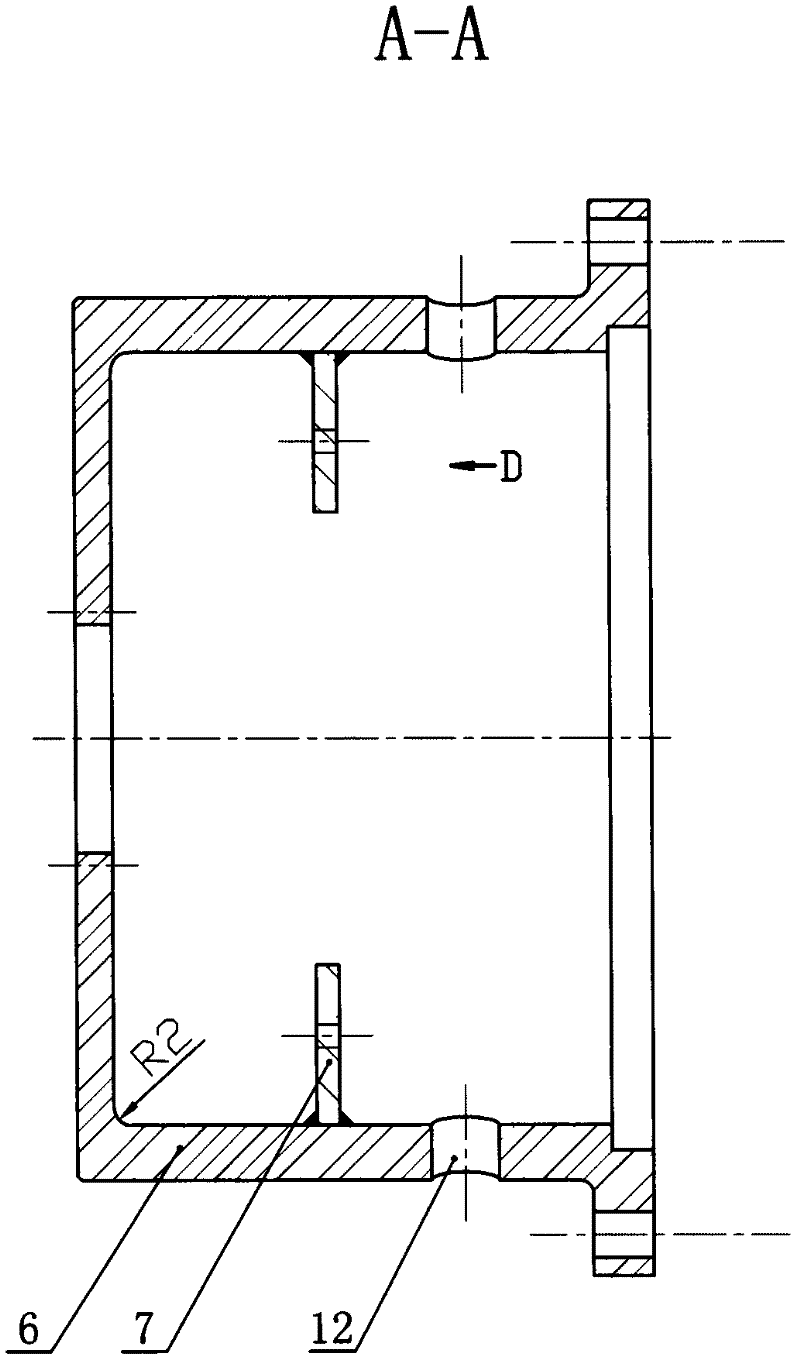

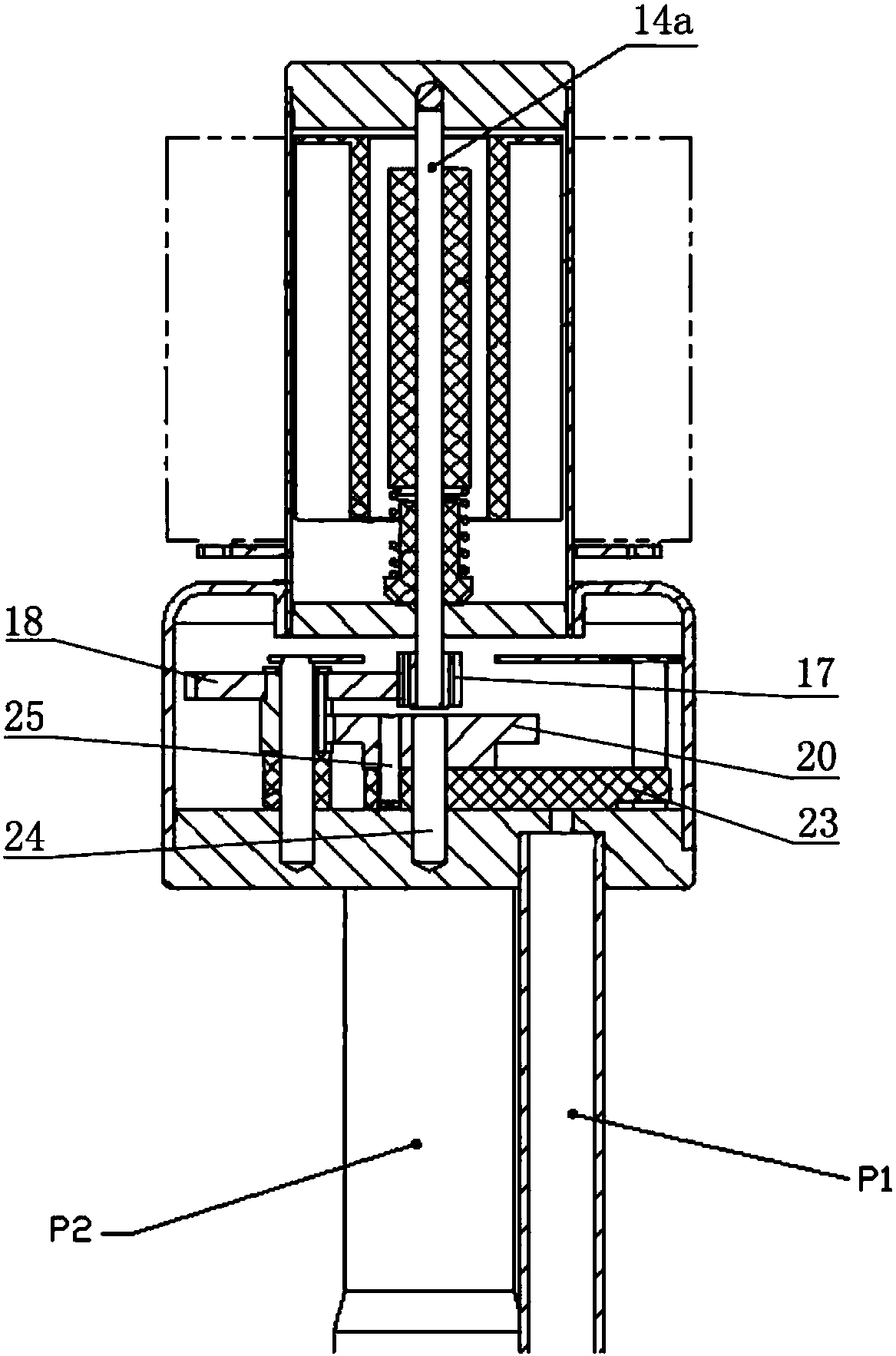

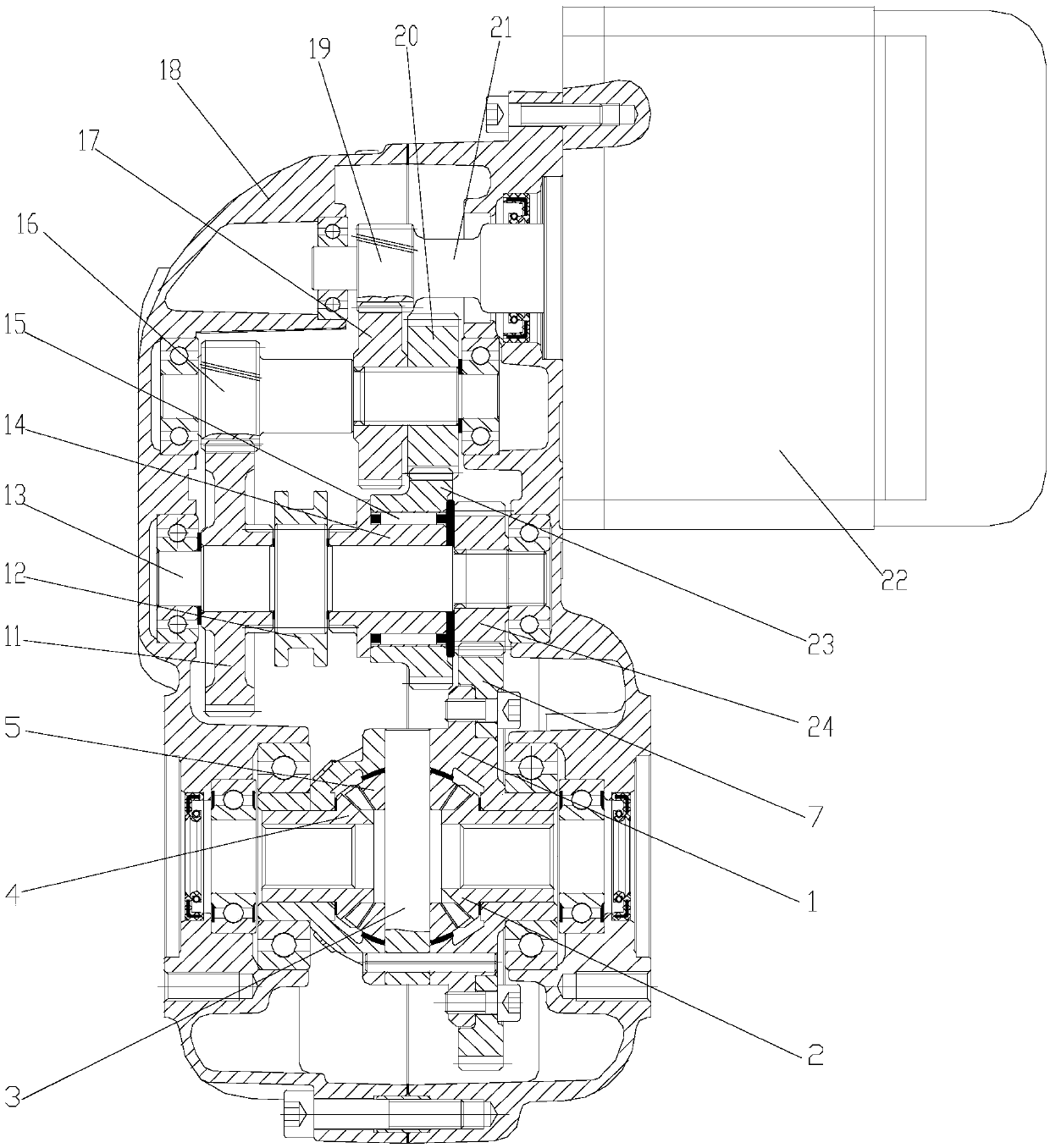

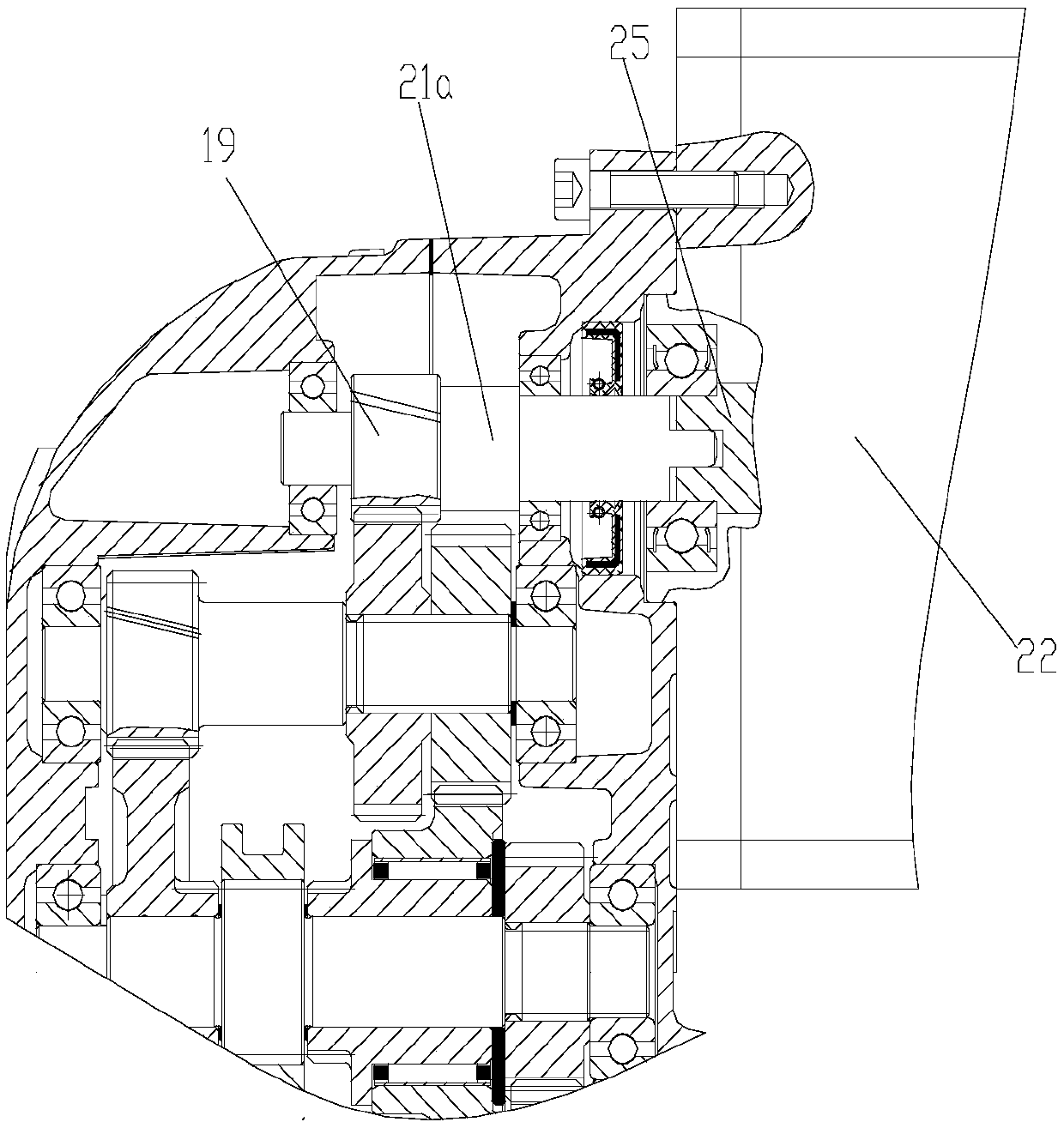

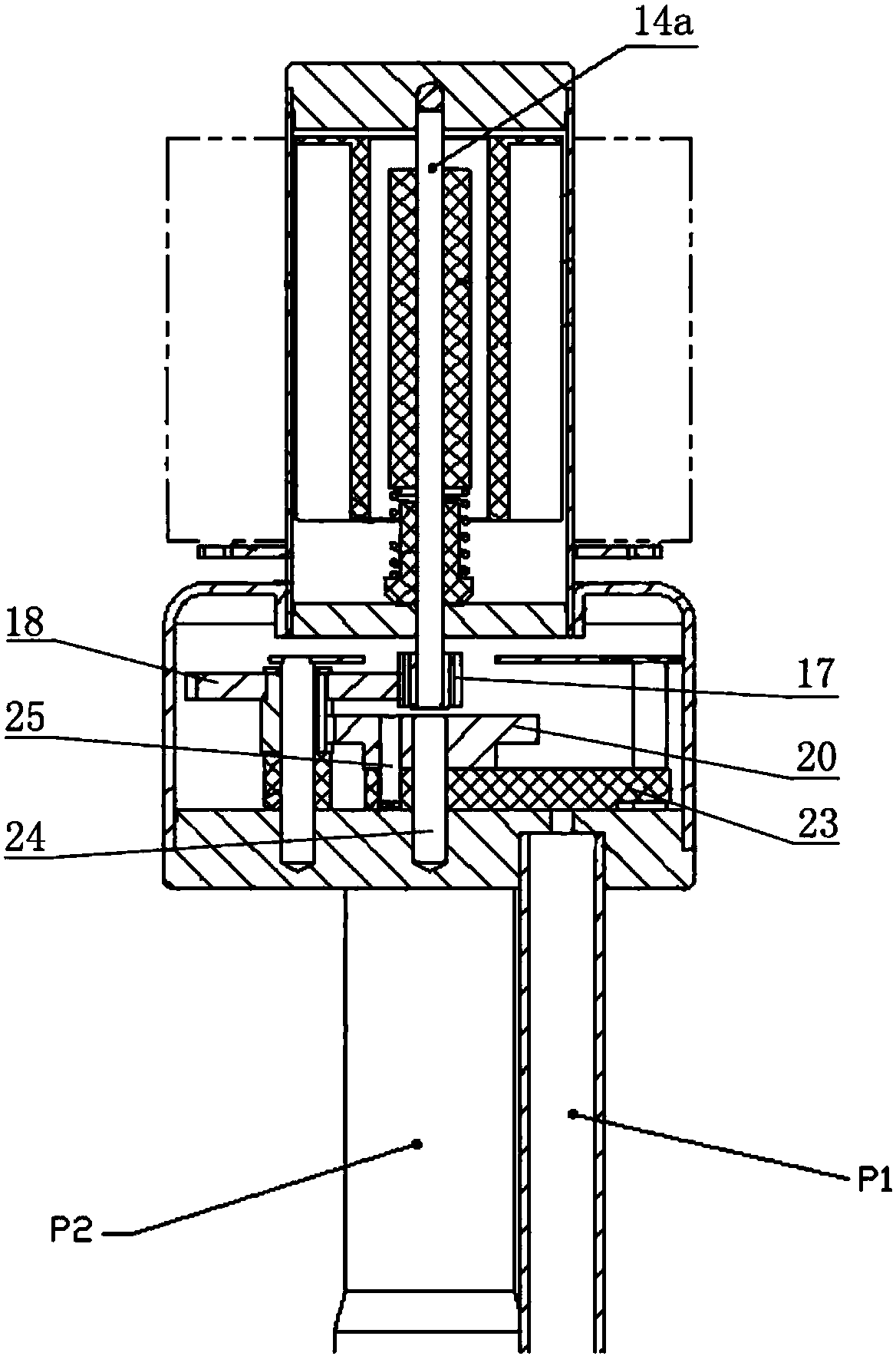

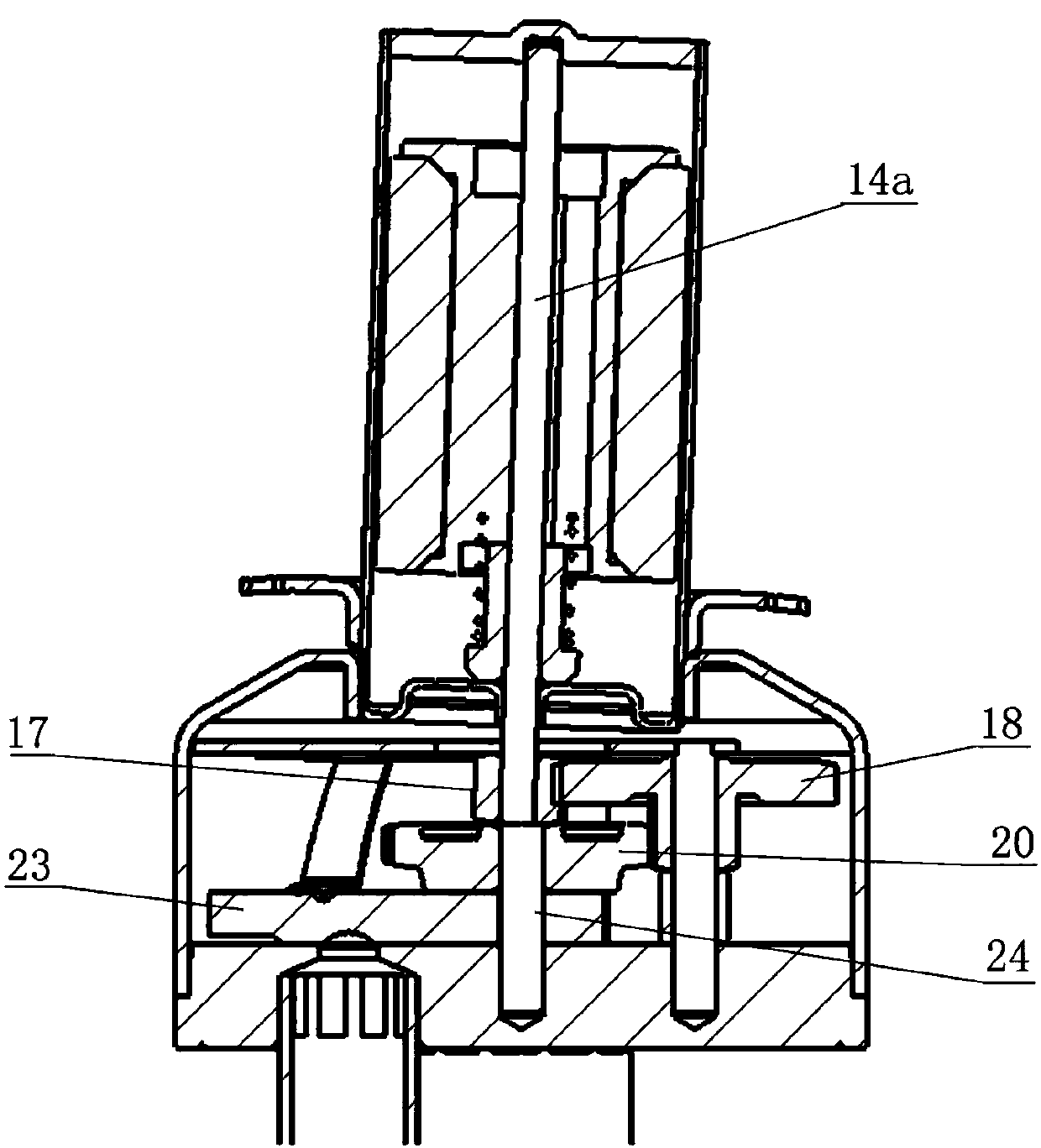

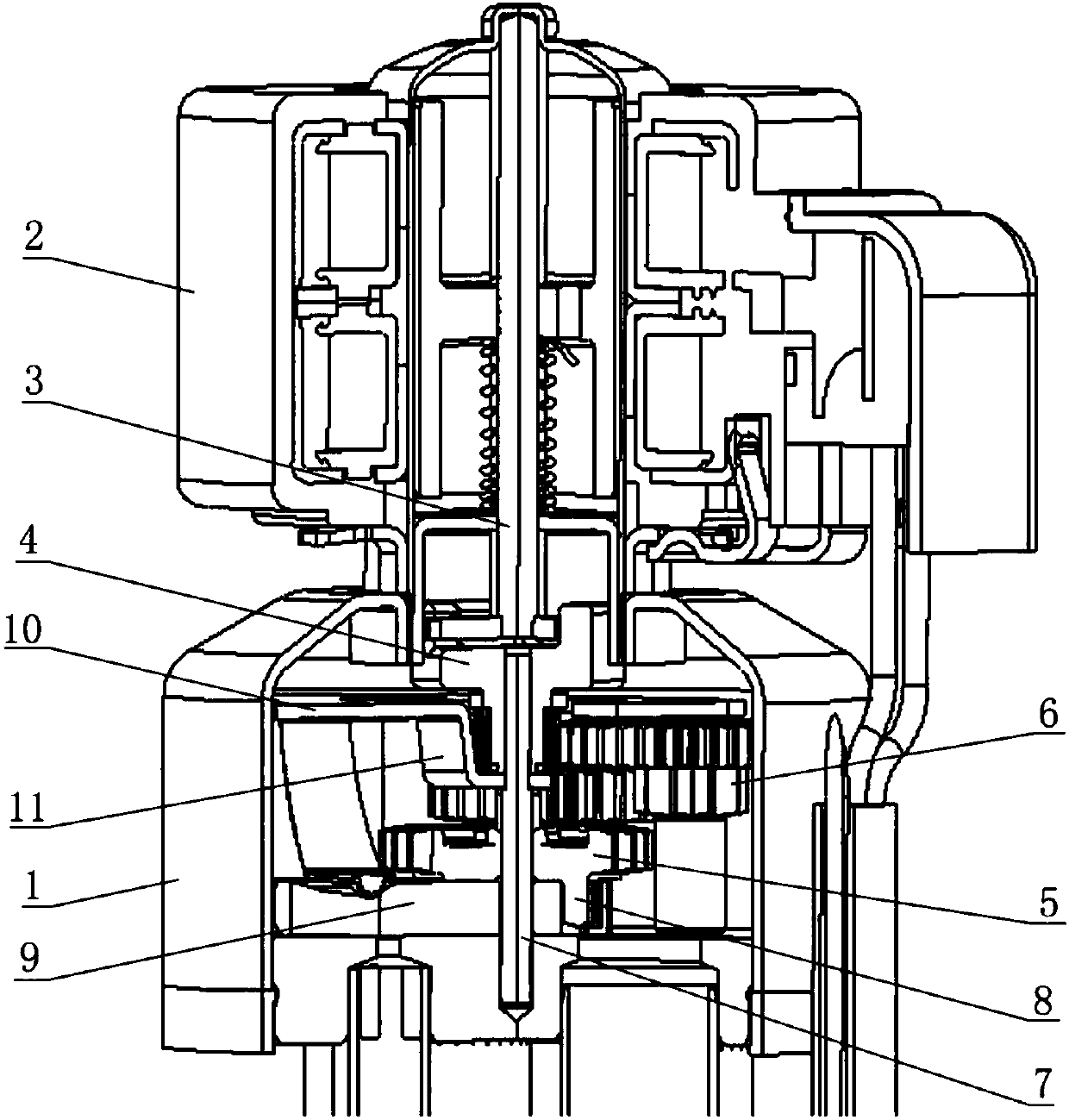

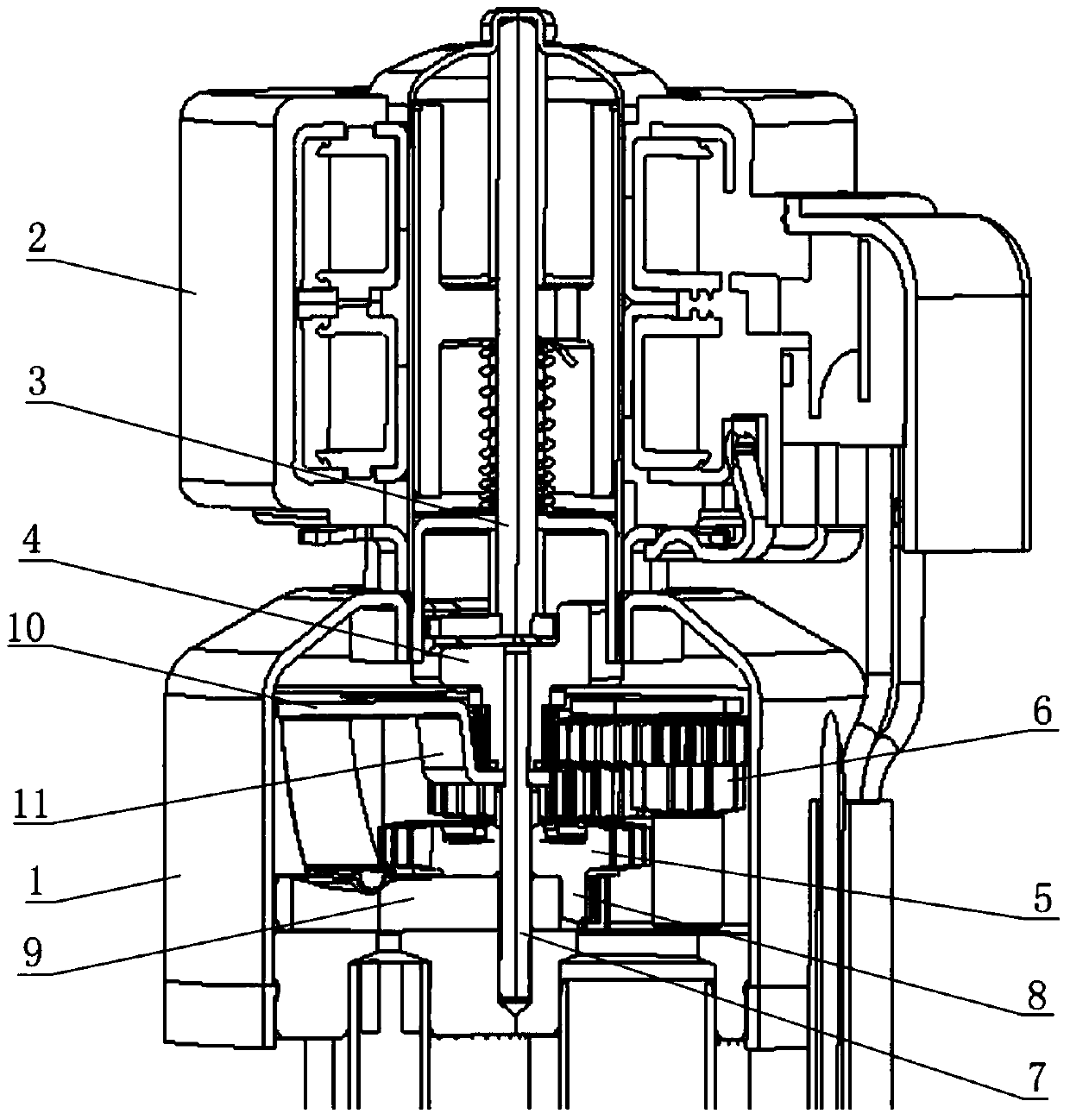

Compressor provided with torque limiter

ActiveUS7040871B2SimplifyEfficient powerCouplings with disconnecting safety membersPump controlInternal combustion engineTorque limiter

A compressor provided with a torque limiter constructed such that, in view of possible occurrence of accidental locking of the compressor, in the case where a one-way clutch is used in place of an electromagnetic clutch in order to permit a refrigerant compressor for a vehicle air-conditioning system to be driven by an electric motor instead of an internal combustion engine, when an excessive torque is to be transmitted by the one-way clutch, rollers ride over wedge surfaces and fall into pocket sections, or sprags are reversed to roll-over.

Owner:DENSO CORP +1

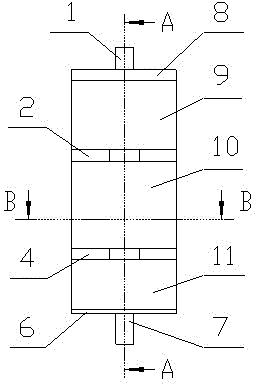

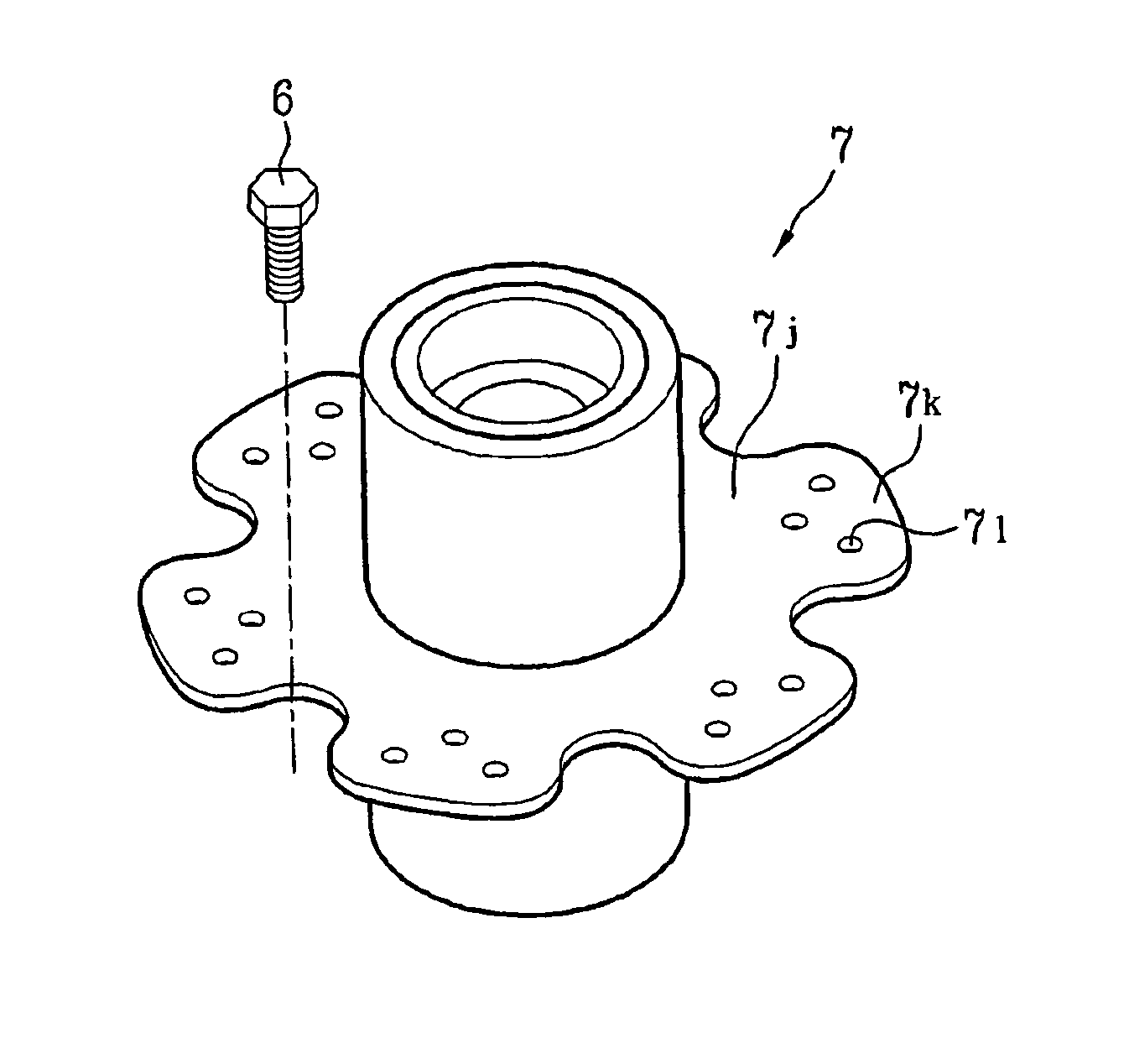

Double-coding mounting bracket for directly-connected low-speed lifter and transmission shafts

The invention discloses a double-coding mounting bracket for a directly-connected low-speed lifter and transmission shafts. The double-coding mounting bracket comprises a roller big shaft, a speed measurement encoder and a depth encoder; the mounting bracket is fixed on an end cover of a bearing by a bolt; the roller big shaft is sleeved on a hole of the mounting bracket; one end of each transmission shaft is fixed on the roller big shaft by a bolt; the speed measurement encoder is sleeved between the transmission shafts; two symmetrical connecting elastic sheets are arranged on the speed measurement encoder and are respectively installed on a connecting plate; a data line passes through a data line through hole and is connected with the speed measurement encoder; the other end of the speed measurement encoder is connected with one end of an elastic coupler; the other end of the elastic coupler is connected with the depth encoder; and the depth encoder is fixed on the mounting bracket by a bolt and is connected with the data line. The double-coding mounting bracket has the advantages that the service life of each encoder is prolonged, the volume is small, the appearance is attractive and elegant, and the reliability is high. With the adoption of the double-coding mounting bracket, the economic cost is reduced, and the good benefice benefit is obtained.

Owner:枣庄矿业(集团)付村煤业有限公司

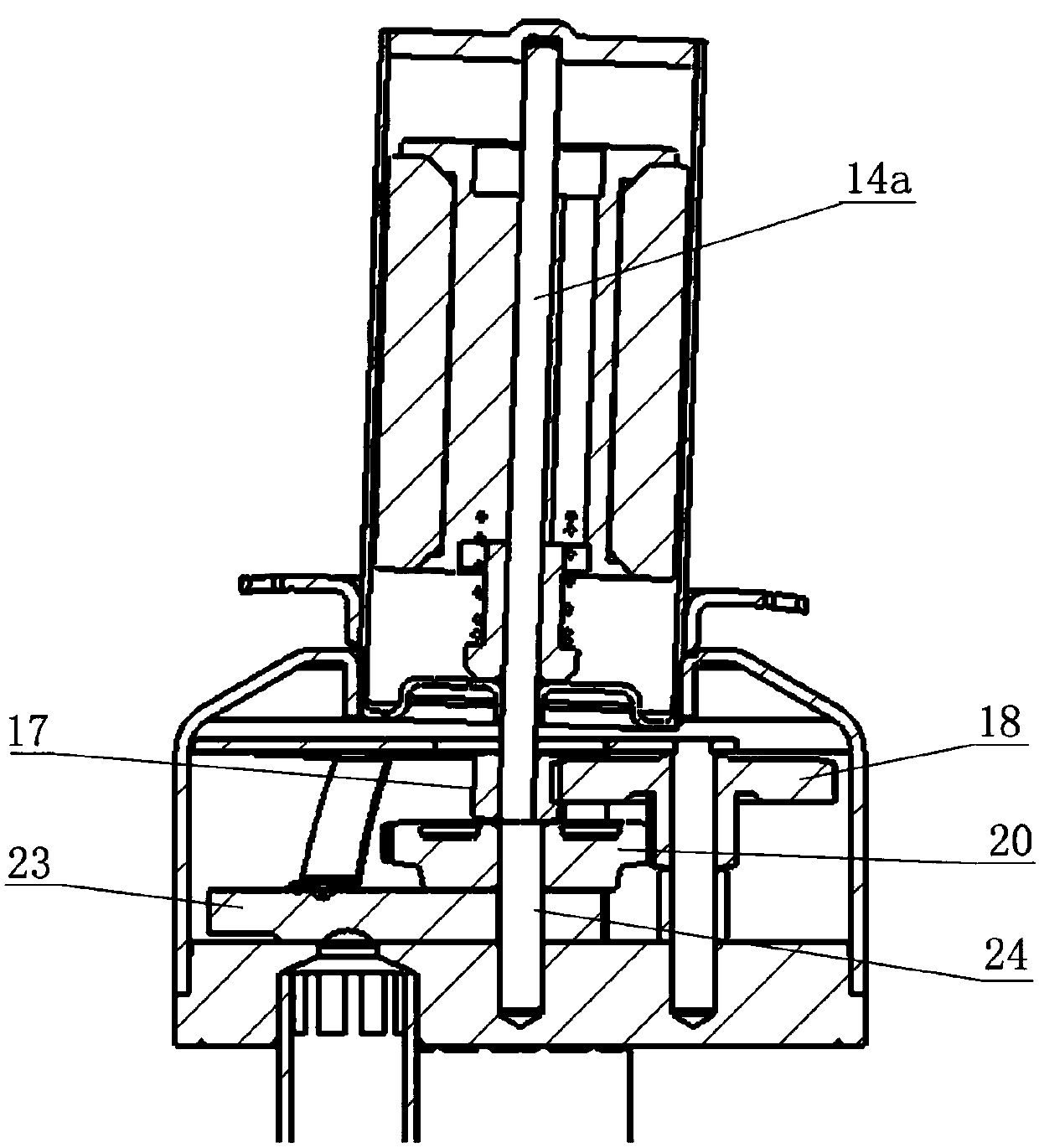

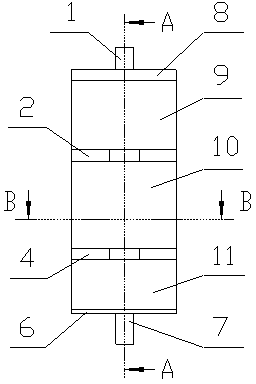

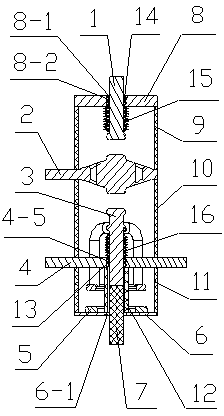

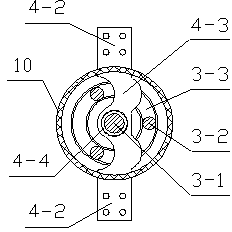

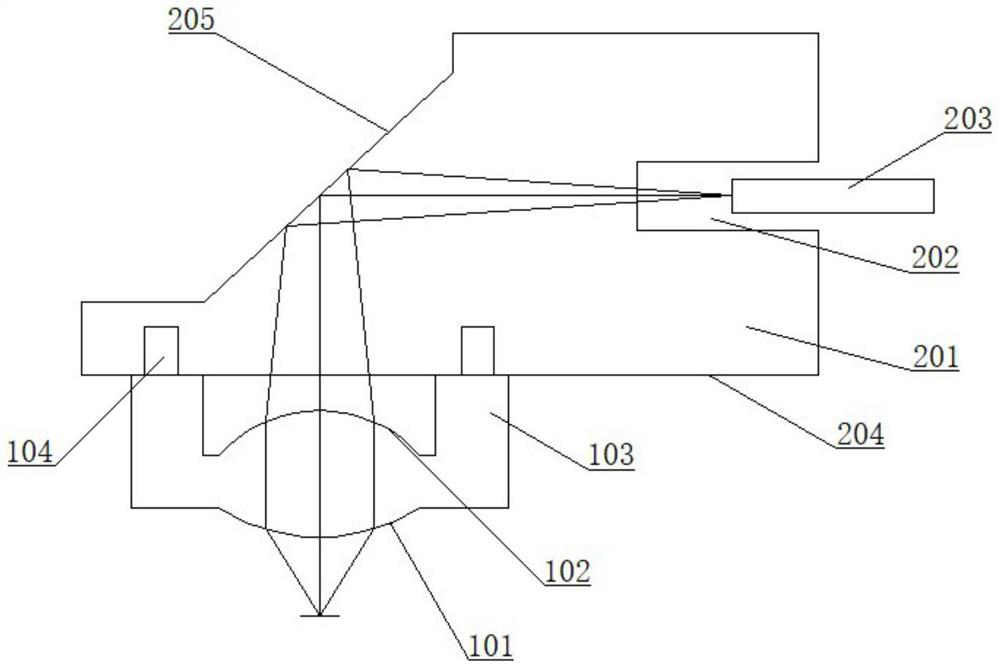

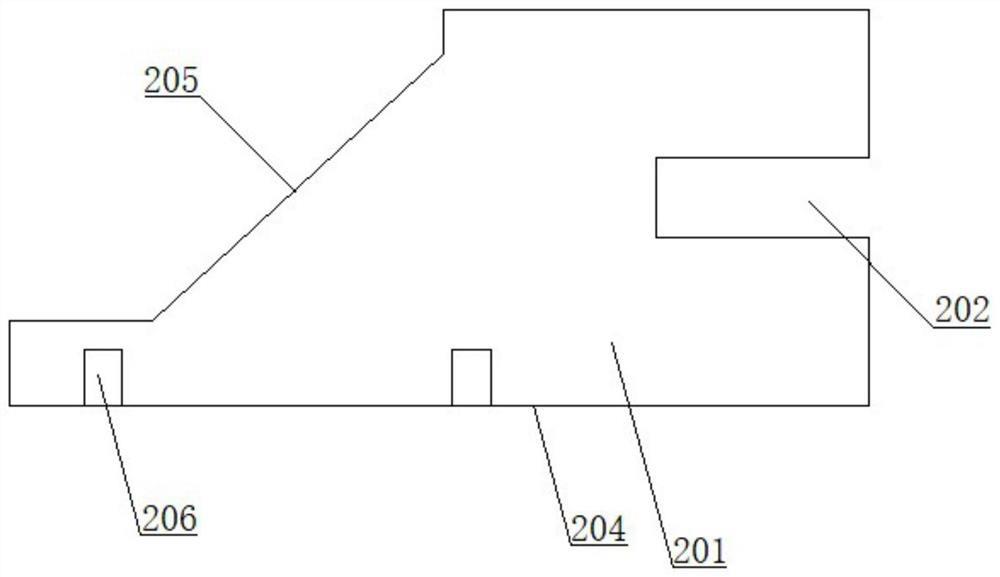

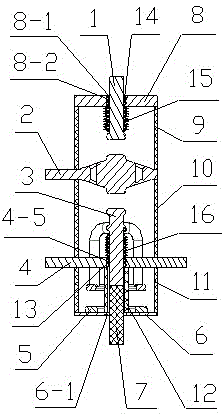

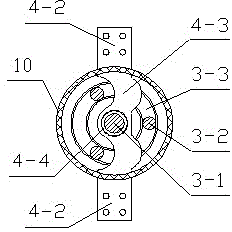

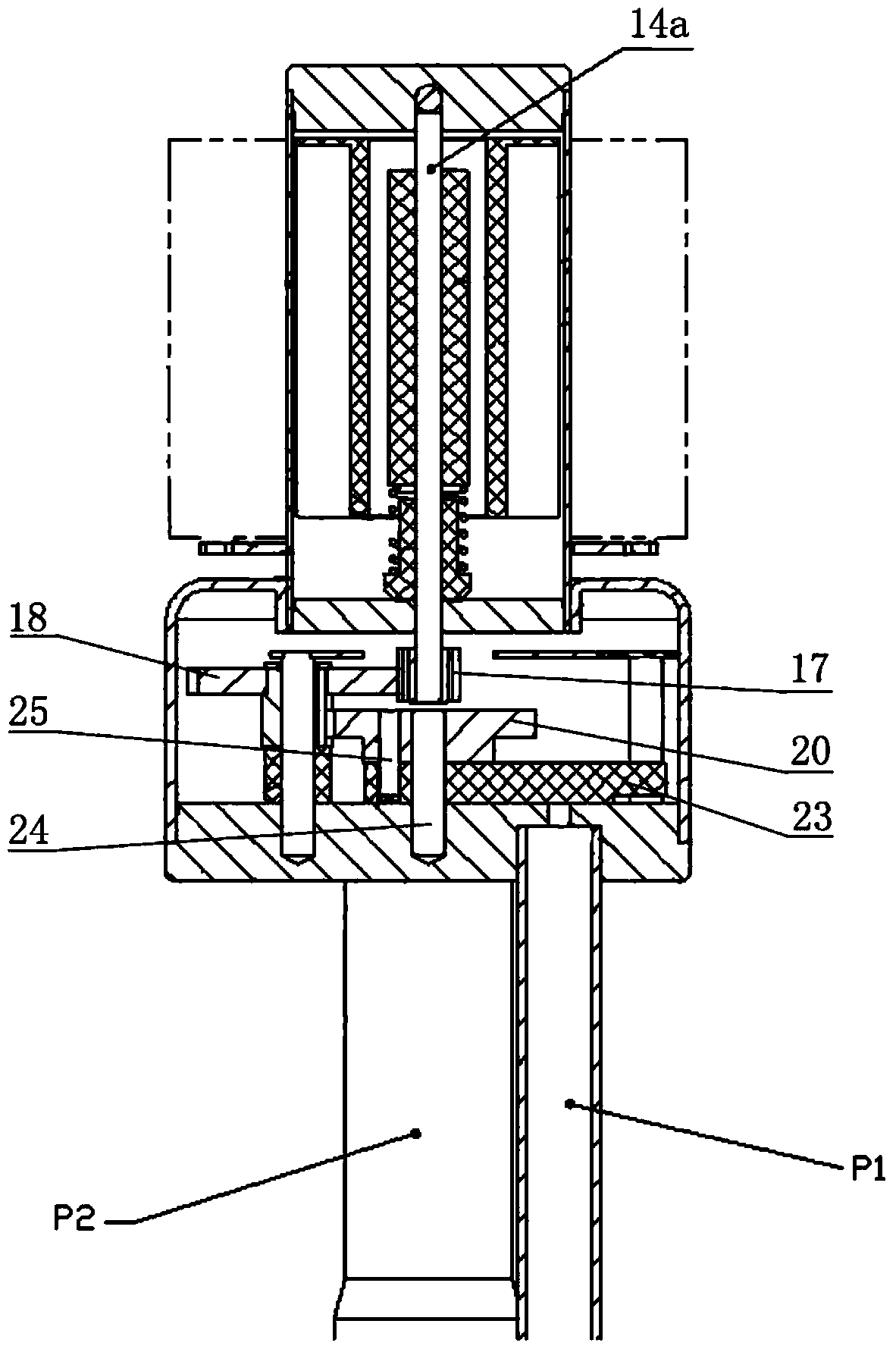

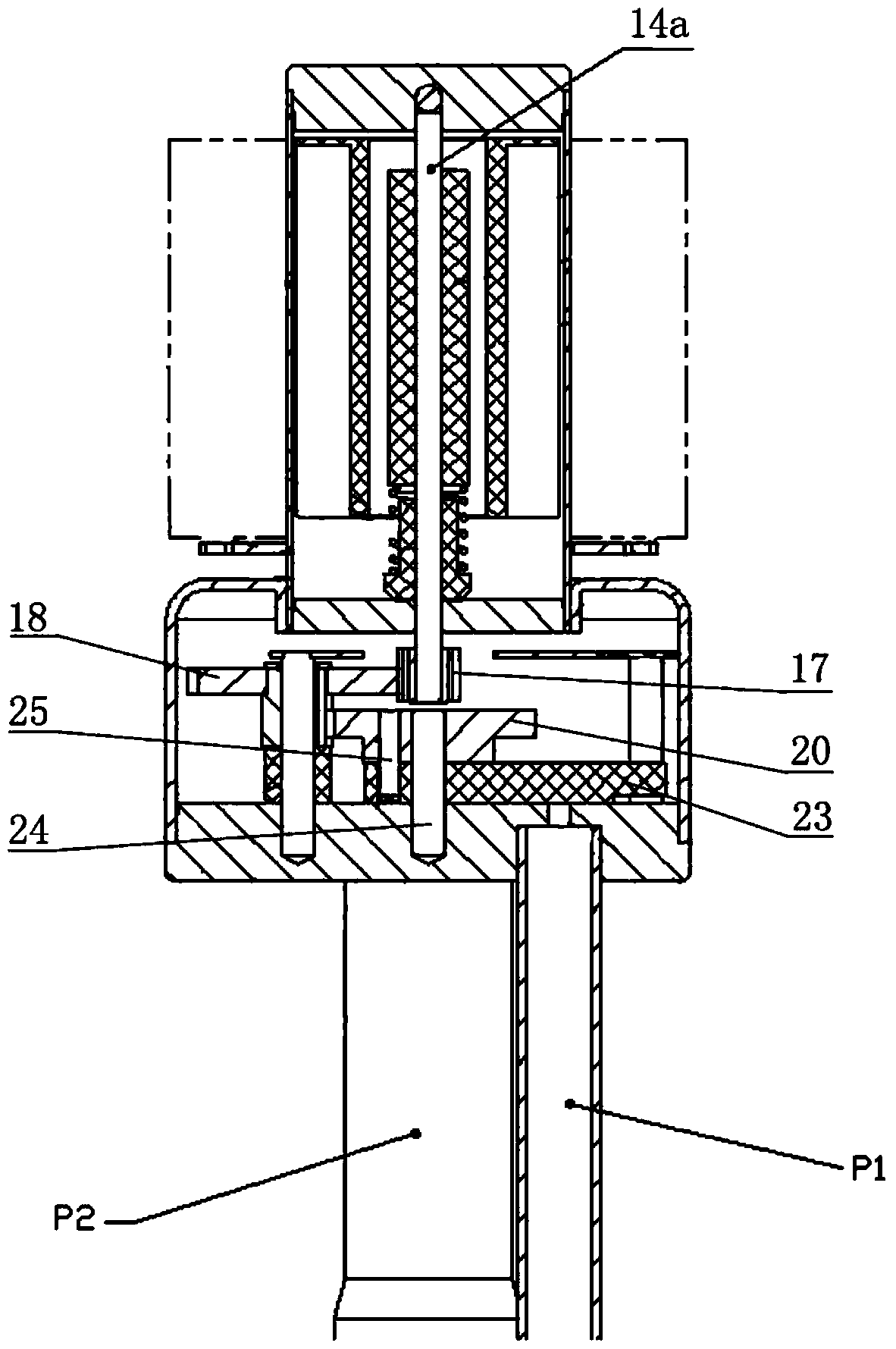

Photoelectric composite rotary connector

ActiveCN104317014AAchieving concentricity requirementsGuaranteed coaxialityCoupling light guidesEngineeringMechanical engineering

The invention relates to a photoelectric composite rotary connector comprising an optical rotary connector and an electric rotary connector. An electric rotary connector rotor of the electric rotary connector includes a rotating shaft with the axis extending along the front-back direction. The optical rotary connector consists of an optical rotary connector stator and an optical rotary connector rotor, wherein the stator and the rotor are assembled together in a rotating mode by sharing the same axis. A routing hole is formed in the rotating shaft, wherein the routing hole and the rotating shaft shares the same axis. The optical rotary connector rotor has an axial assembling segment; and the axial assembling segment is fixedly assembled in the routing hole in a matched mode, so that the optical rotary connector rotor and the rotating shaft share the same axis. The optical rotary connector stator and the electric rotary connector rotor of the electric rotary connector are fixedly connected. According to the photoelectric composite rotary connector, coaxiality of the optical rotary connector and the electric rotary connector can be guaranteed easily.

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

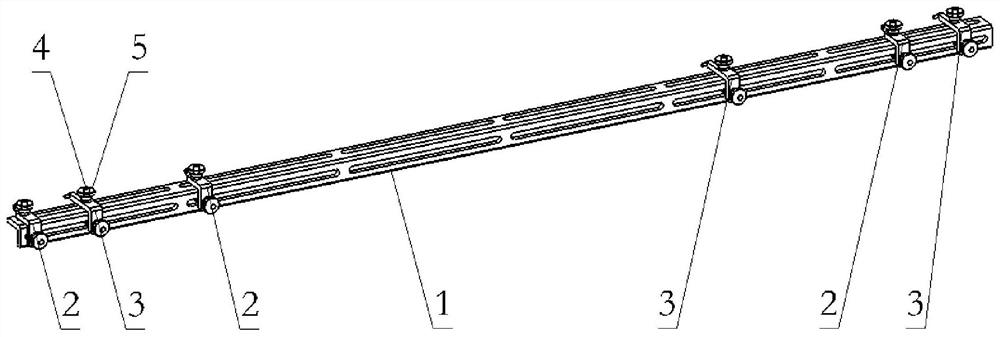

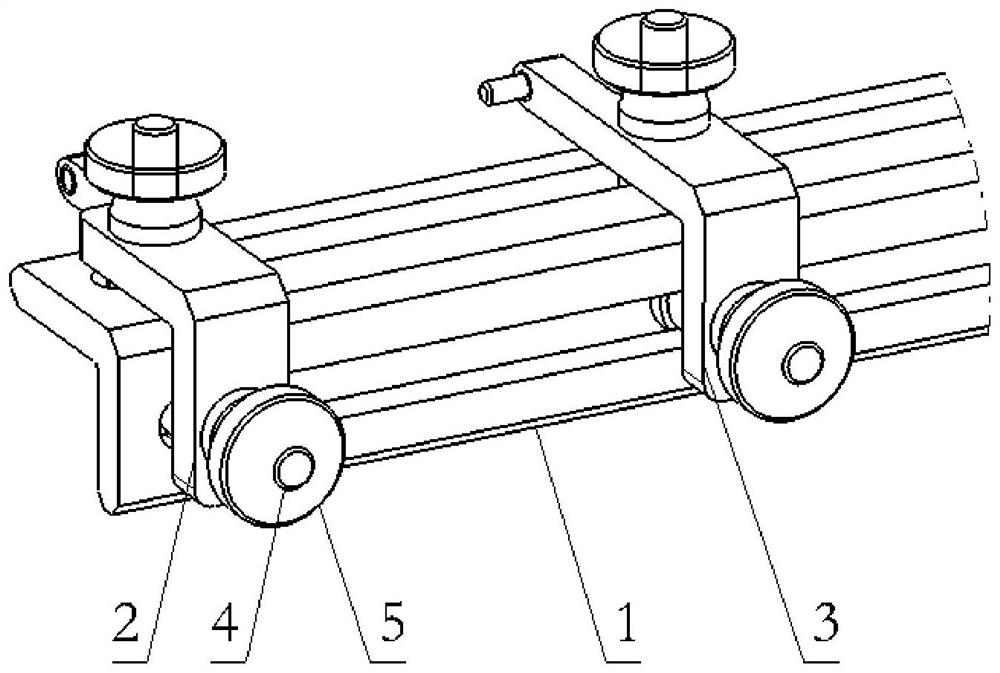

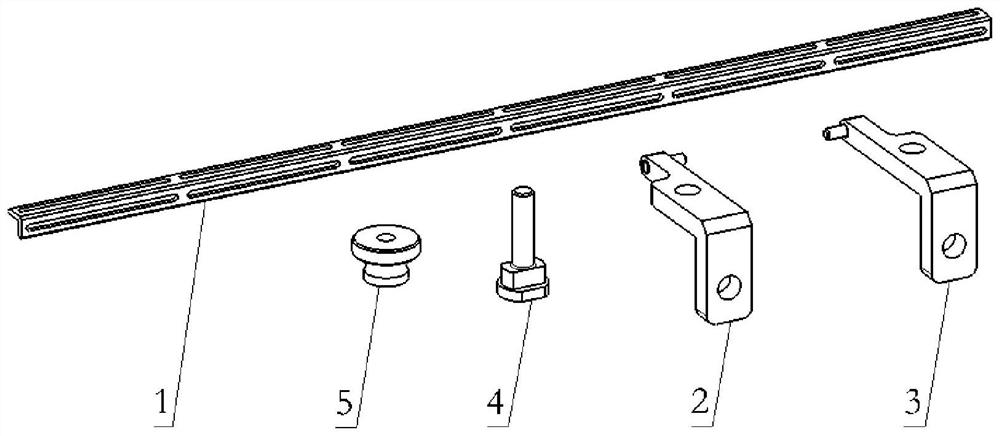

Mounting and positioning device for repairing segmented long hinge of helicopter

ActiveCN114212273ASimple structureEasy to operateWeight reductionAircraft maintainanceProcess equipmentStructural engineering

The invention belongs to the field of helicopter process equipment design, and particularly relates to a mounting and positioning device for repairing a segmented long hinge of a helicopter. The device takes an L-shaped positioning slide rail as a main body, a plurality of left positioning slide blocks and right positioning slide blocks are arranged on the L-shaped positioning slide rail, and each positioning slide block can position one hinge tooth of a hinge; the left positioning sliding blocks and the right positioning sliding blocks are combined in pairs, so that one hinge is positioned; the hinge teeth of each section of hinge are respectively positioned through the combination of a plurality of groups of left and right positioning sliding blocks, and one group of left and right positioning sliding blocks is selected for a newly added hinge to realize positioning; and all the hinges are ensured to be positioned on the same axis after replacement.

Owner:JIANGXI CHANGHE AVIATION IND

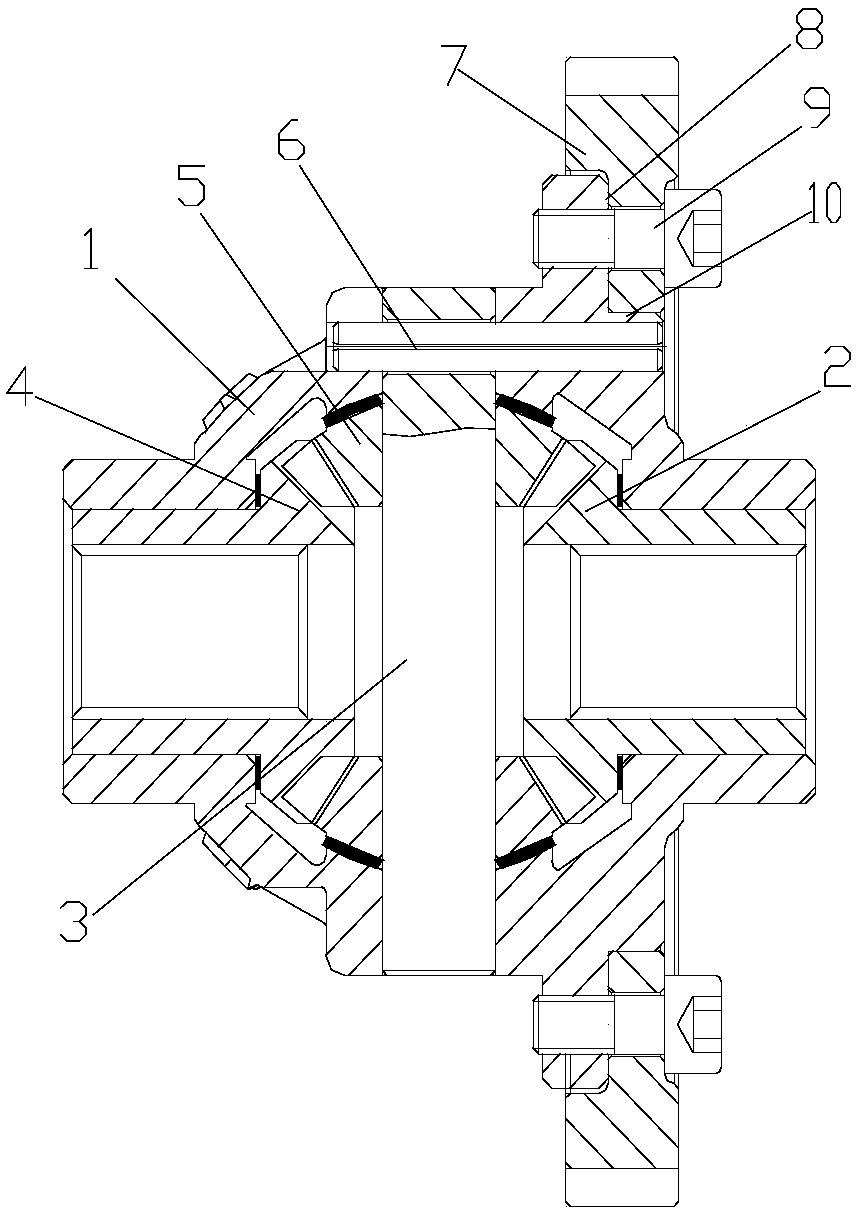

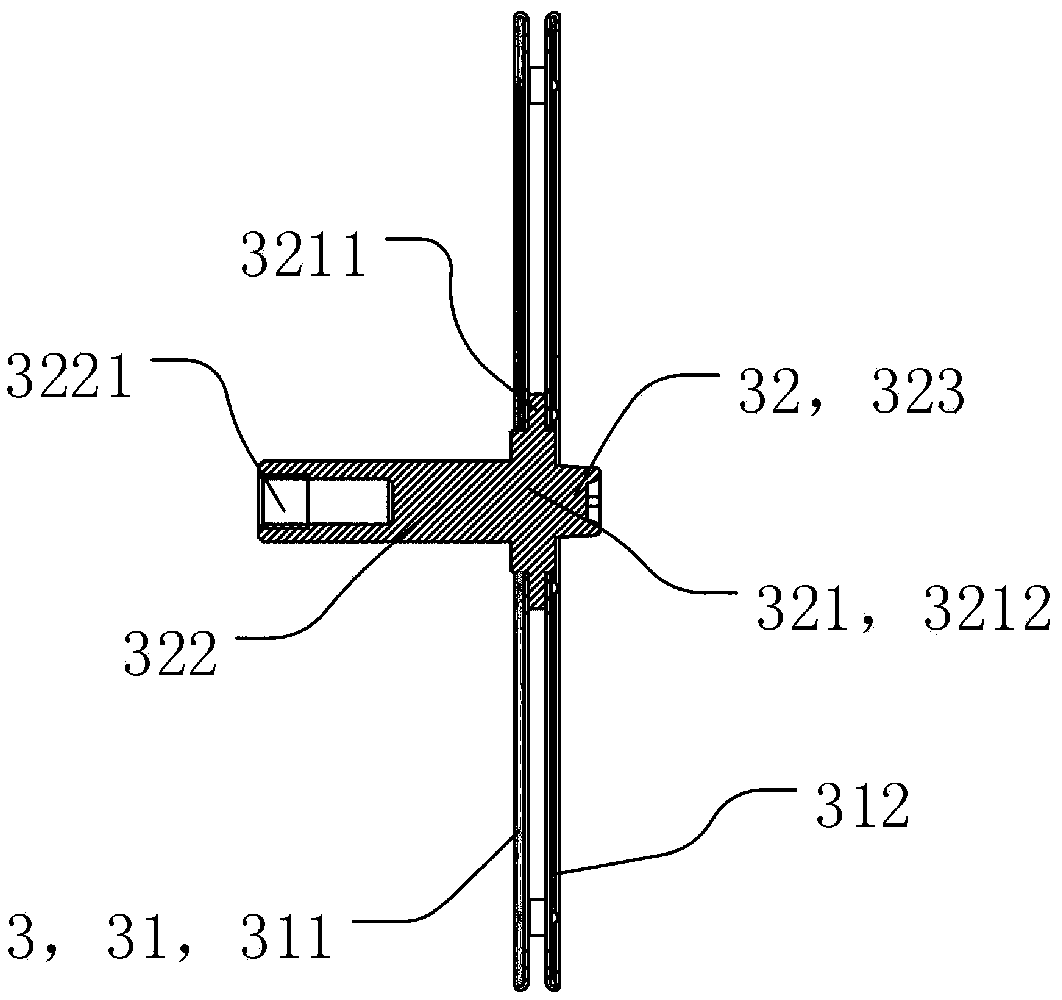

Core-expanding fixture for workpiece with gullies in inner wall and using method thereof

The invention discloses a core-expanding fixture for a workpiece with gullies in the inner wall. The core-expanding fixture comprises a concentric shaft, a limiting taper end head sleeving one side ofthe concentric shaft and a movable taper end head sleeving the other side of the concentric shaft, wherein one side, close to the movable taper end head, of the concentric shaft is provided with external threads; the external thread section of the concentric shaft is provided with a locking nut; the concentric shaft between the limiting taper end head and the movable taper end head is sleeved with a tubular expanding core; a plurality of through holes are evenly formed in the circumferences of the two sides of the expanding core; radial slide blocks are arranged in the through holes; the upper surfaces of the radial slide blocks are provided with a plurality of blind holes; and a movable block is arranged in each blind hole. The core-expanding fixture is convenient to clamp, so that the core-expanding fixture capable of clamping the workpiece quickly is especially suitable for the high-precision machining of the workpiece with the gullies, stripes, small grooves and the like on the inner walls of an aerial bomb body and the like; and in the process of clamping the expanding core, the damage to the gullies and the like on the inner wall of the aerial bomb body is small, so that theimprovement of the product qualification rate and production efficiency is facilitated.

Owner:泰州润骐防务科技有限公司

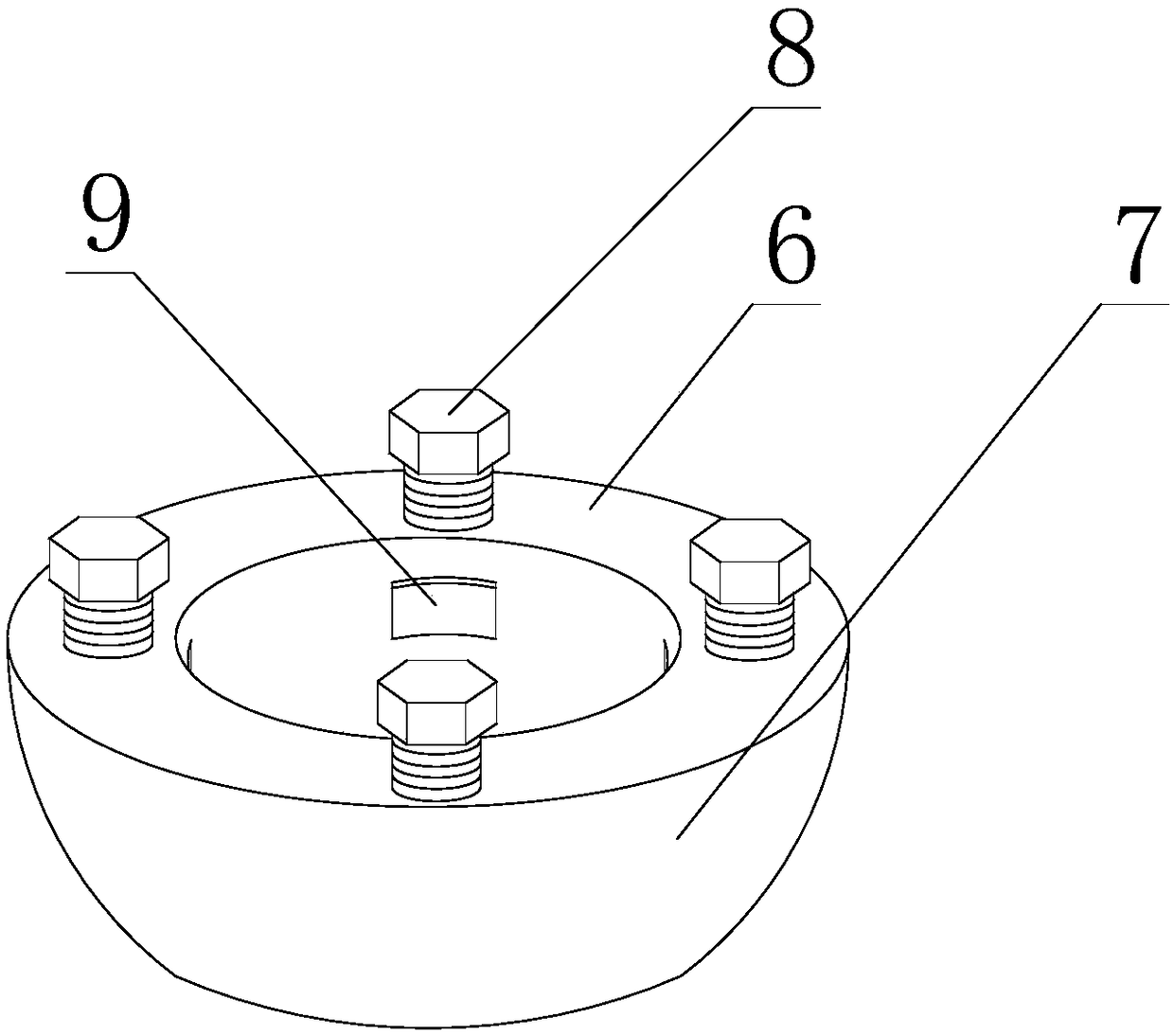

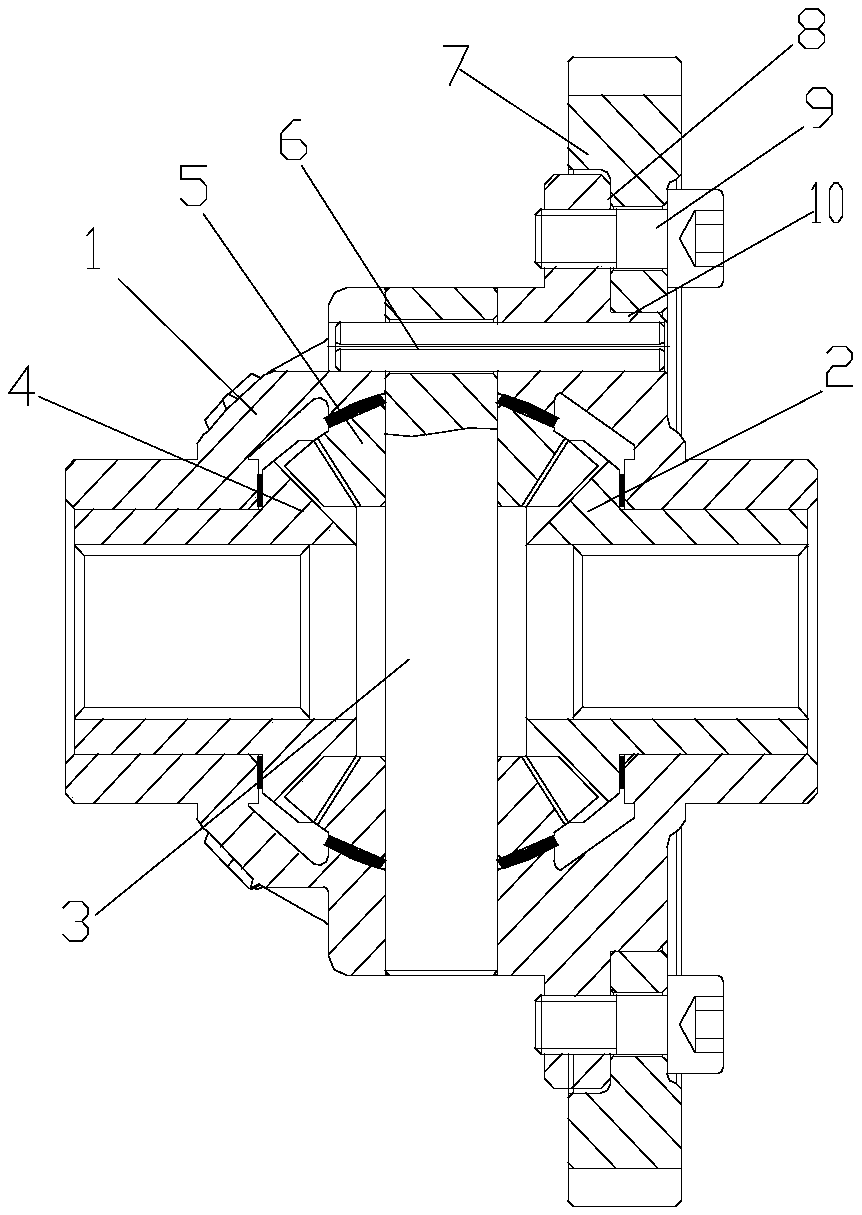

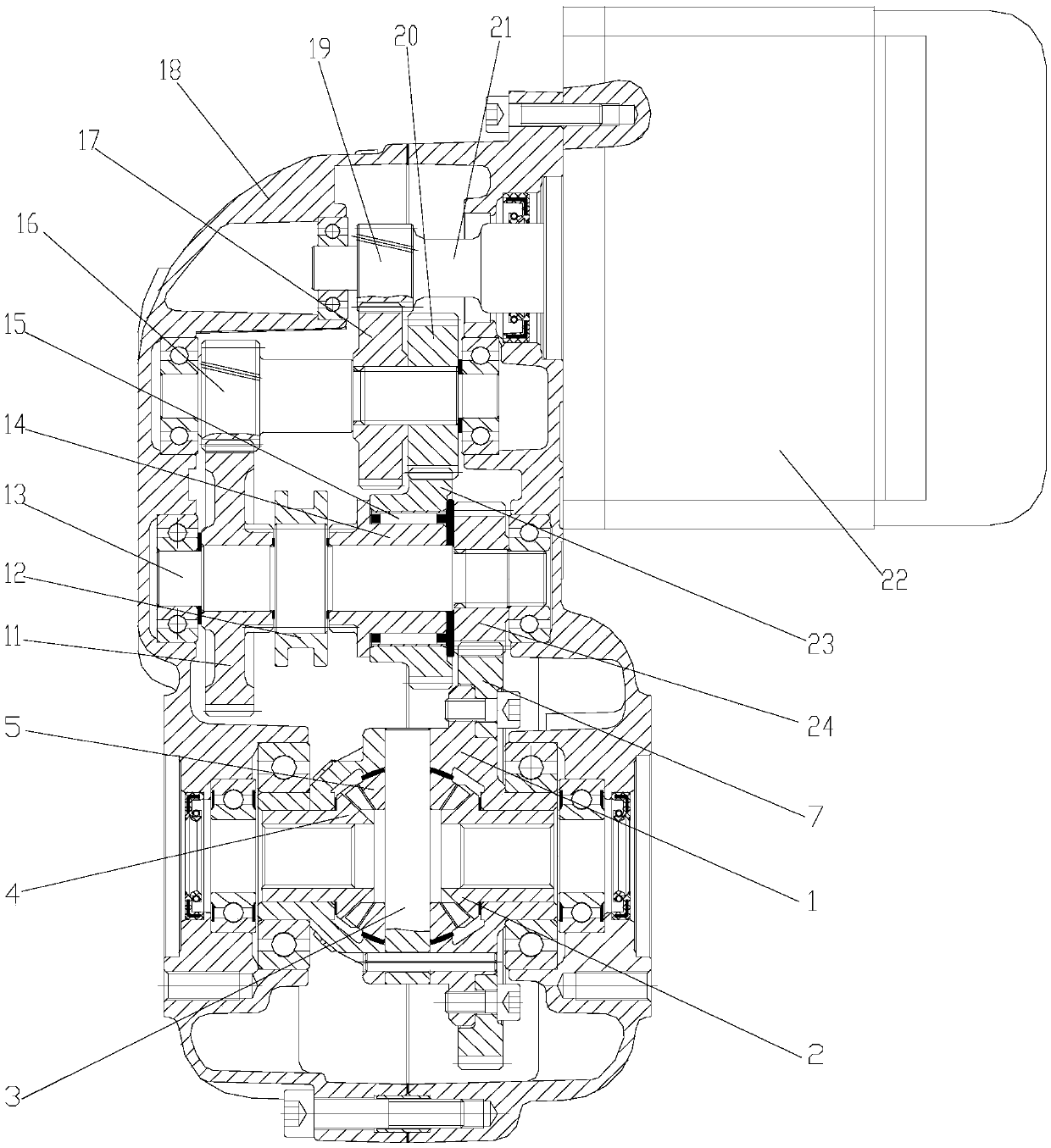

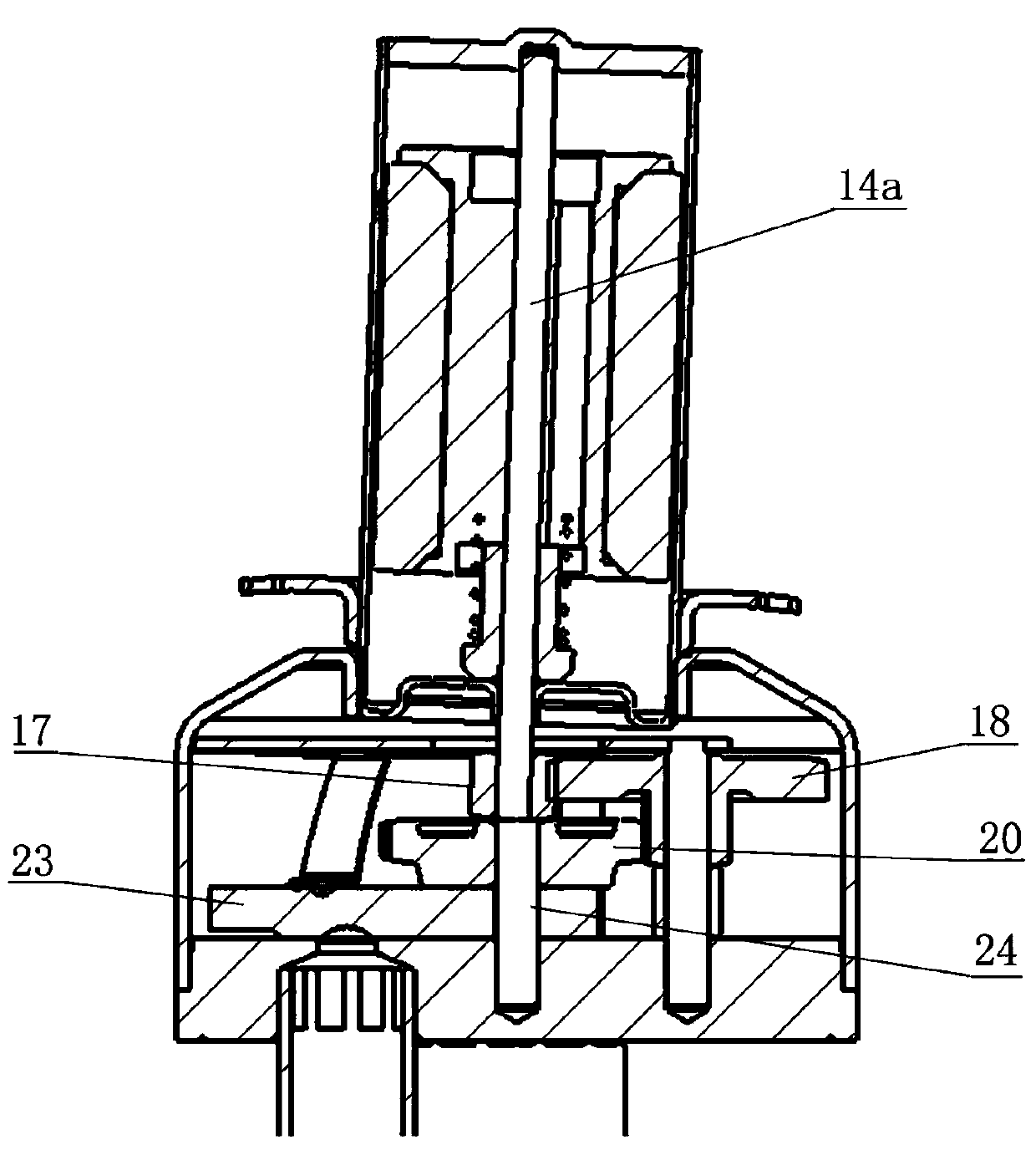

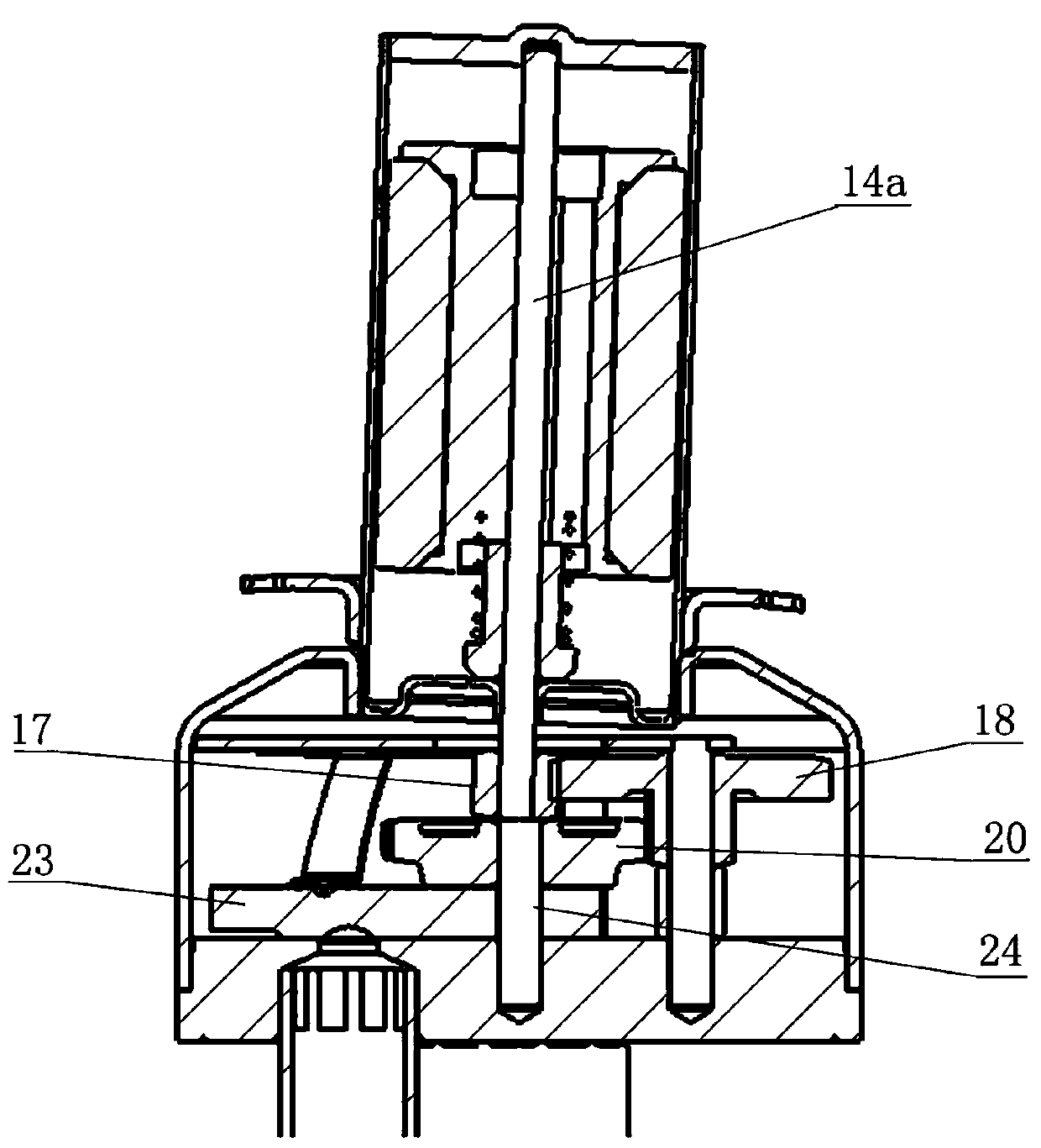

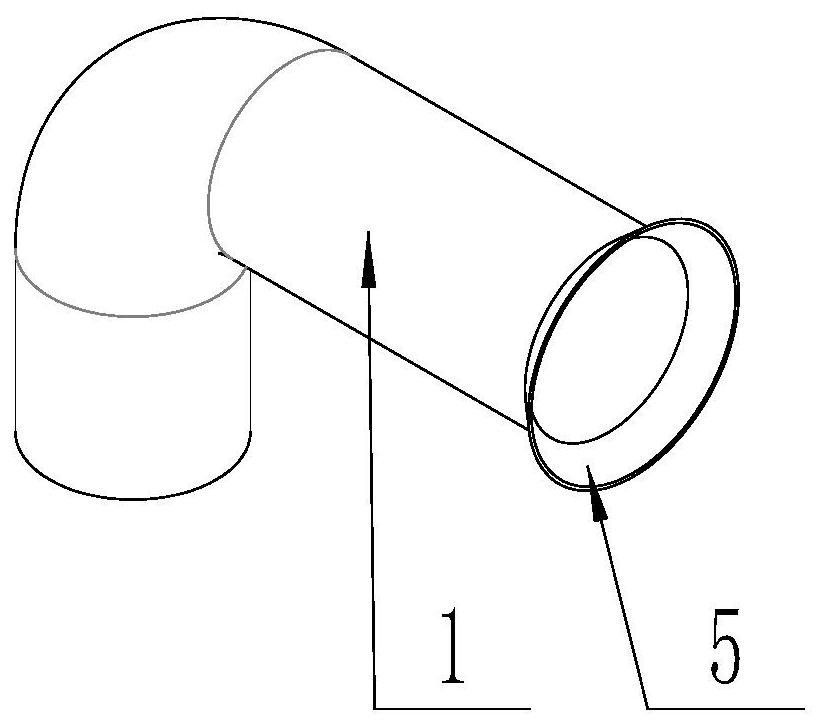

Electric three-way valve and refrigeration equipment

ActiveCN107620813AGuaranteed coaxialityConcentricity is easy to guaranteeOperating means/releasing devices for valvesMultiple way valvesGear wheelPath switching

The invention discloses an electric three-way valve and refrigeration equipment. The electric three-way valve comprises a valve body (1) and a coil (2). A power gear (4) and an execution gear (5) arearranged inside the valve body (1). The power gear (4) is driven by a rotor spindle (3) of the coil (2) and is further in meshing transmission with the execution gear (5) through a reduction gear (6).The execution gear (5) is installed on a center shaft (7) and used for driving a sliding block (9) to achieve flow path switching. The power gear (4) and the execution gear (5) are installed on the center shaft (7) together and are further distributed up and down in a spaced mode. According to the electric three-way valve, the power gear and the execution gear are located on the same center shaftand are further connected through the reduction gear, the gear coaxiality is greatly enhanced in production, and the phenomenon that normal meshing or clamping cannot be conducted due to the poor gear-shaft coaxiality is effectively avoided.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

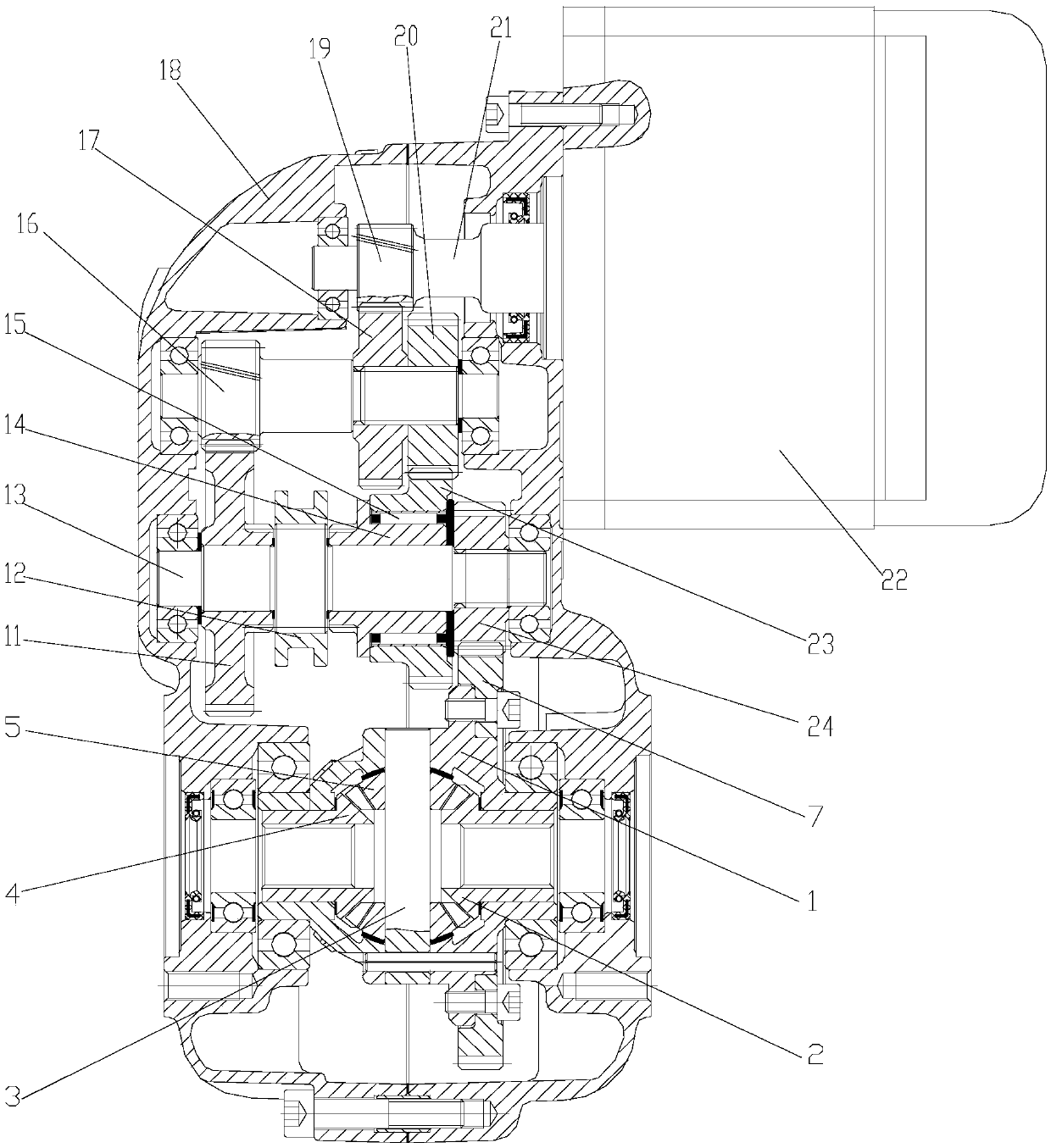

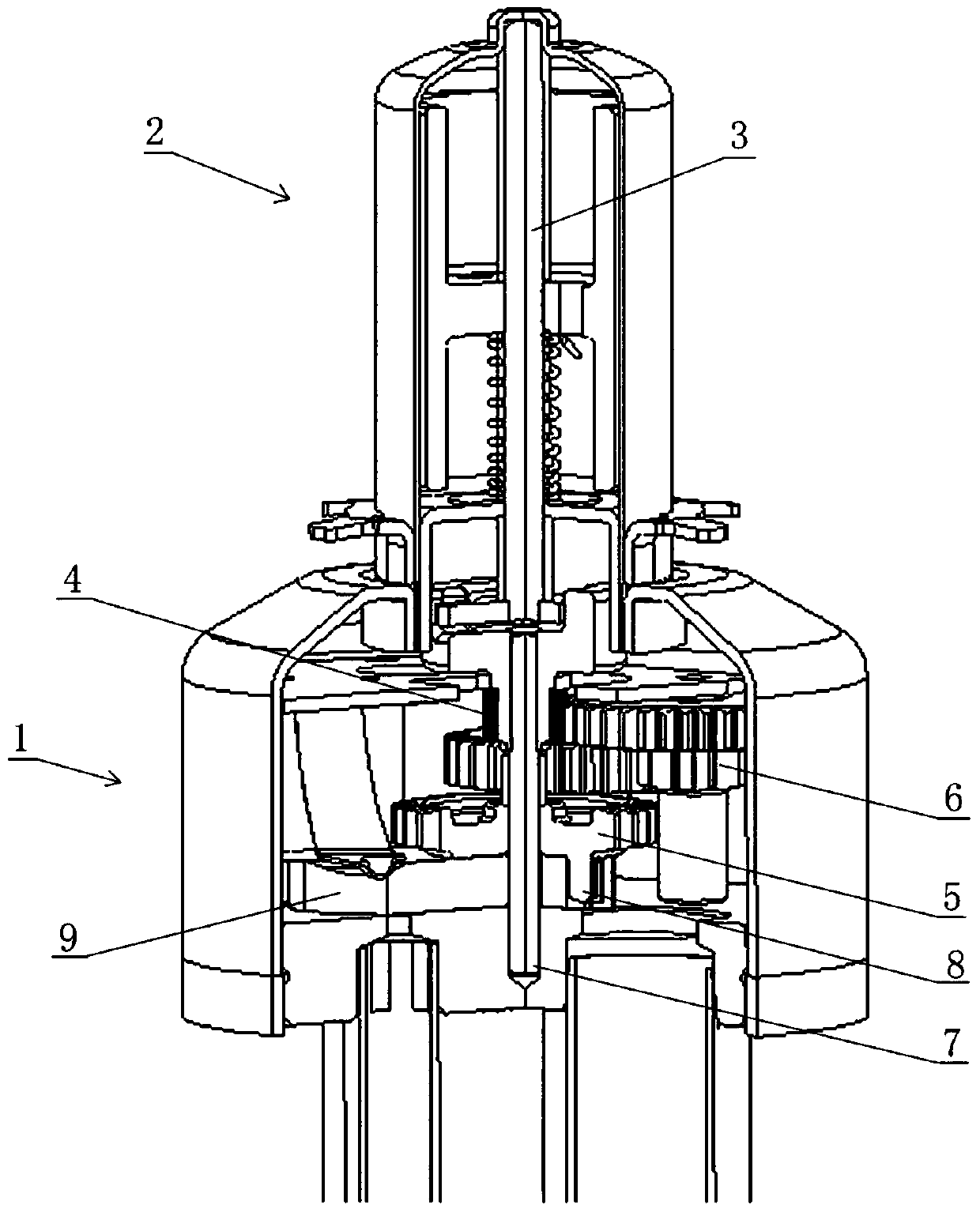

Electric tricycle driving assembly

InactiveCN109910603AIncrease mileageExtended service lifeControl devicesReduction driveElectric machinery

The invention discloses an electric tricycle driving assembly. The electric tricycle driving assembly comprises a power motor, a transmission and a differential, wherein the differential comprises a differential shell and a differential gear assembly; and the differential shell is of an integral structure. The electric tricycle driving assembly adopts a geared transmission system, the differential shell is of the integral structure, and relatively high coaxiality is determined during processing, so that the coaxiality is easy to guarantee in the mounting process, the electric tricycle drivingassembly can be directly mounted, and the mounting efficiency is improved; due to the integral structure, a coaxiality problem is not caused after long-term use and no eccentric wear between kinematic pairs is caused, so that prolonging of the service lives of the differential and a whole speed reducer is facilitated and the using cost is reduced; and due to no existence of the eccentric wear, the using energy consumption is greatly reduced, and thus increase in the mileage of a charged electric vehicle is facilitated.

Owner:重庆轩通机电有限公司

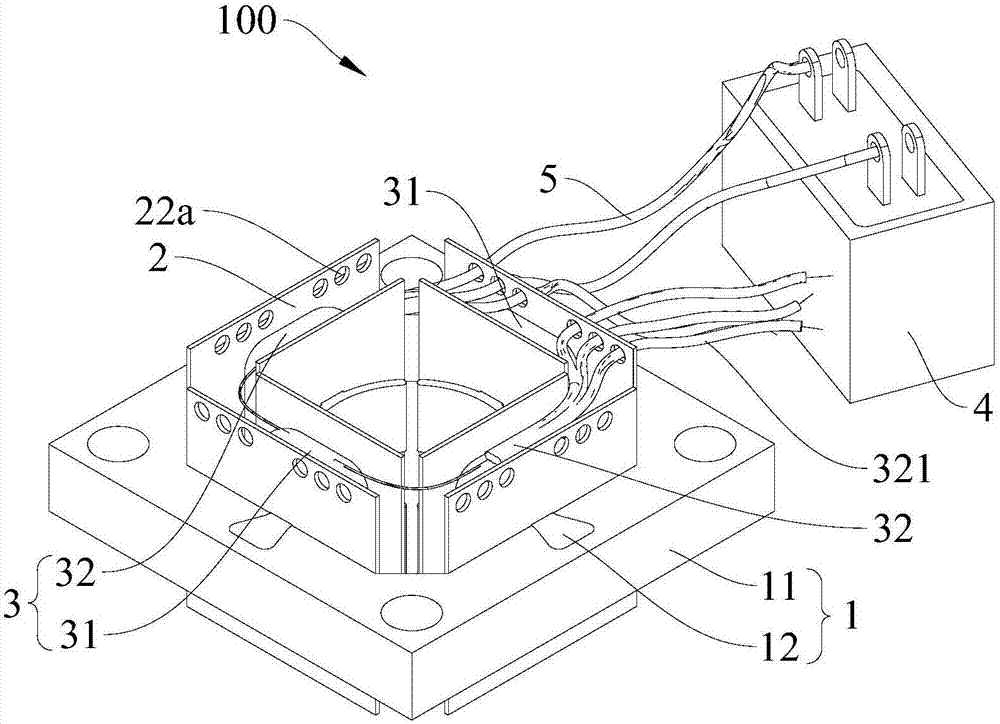

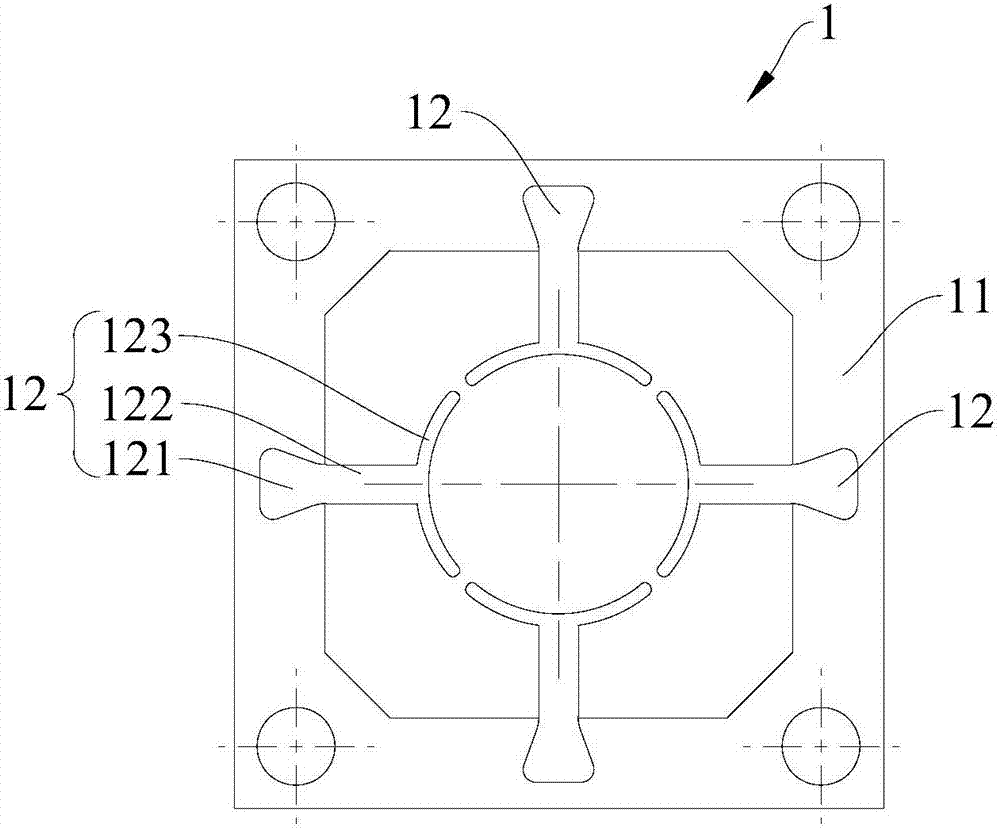

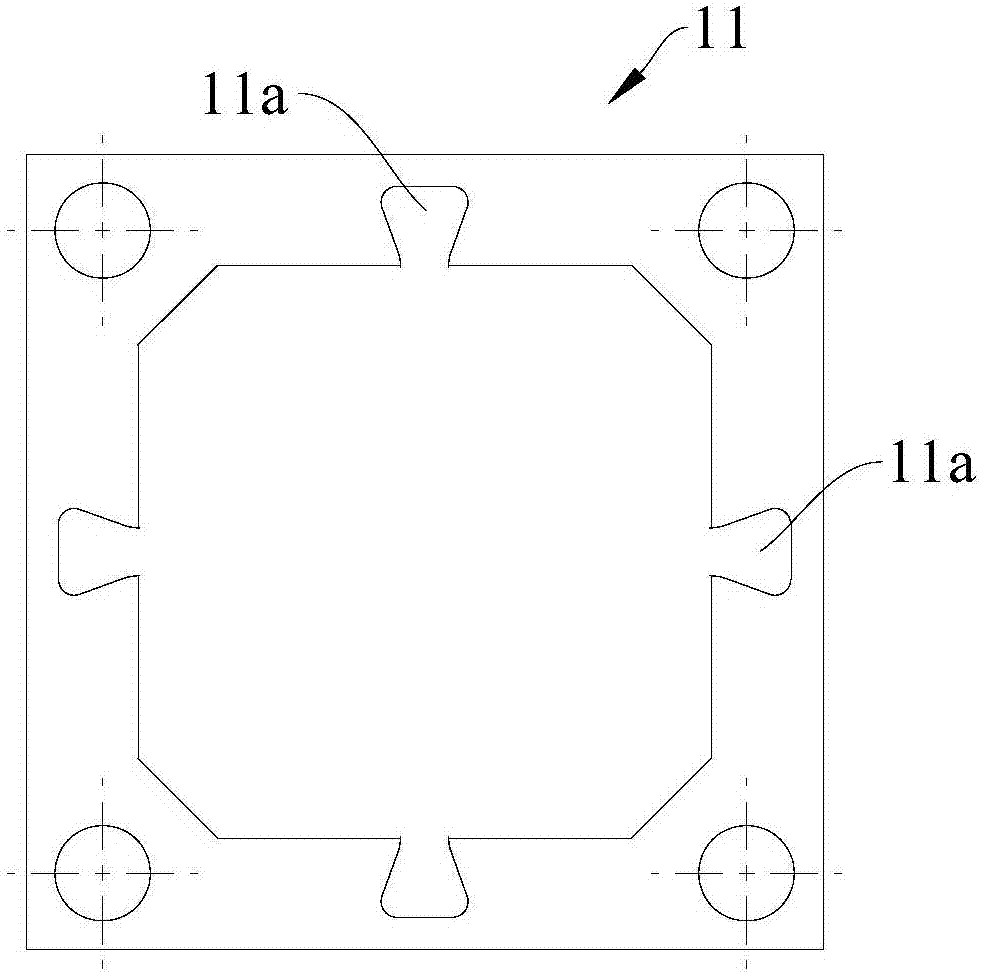

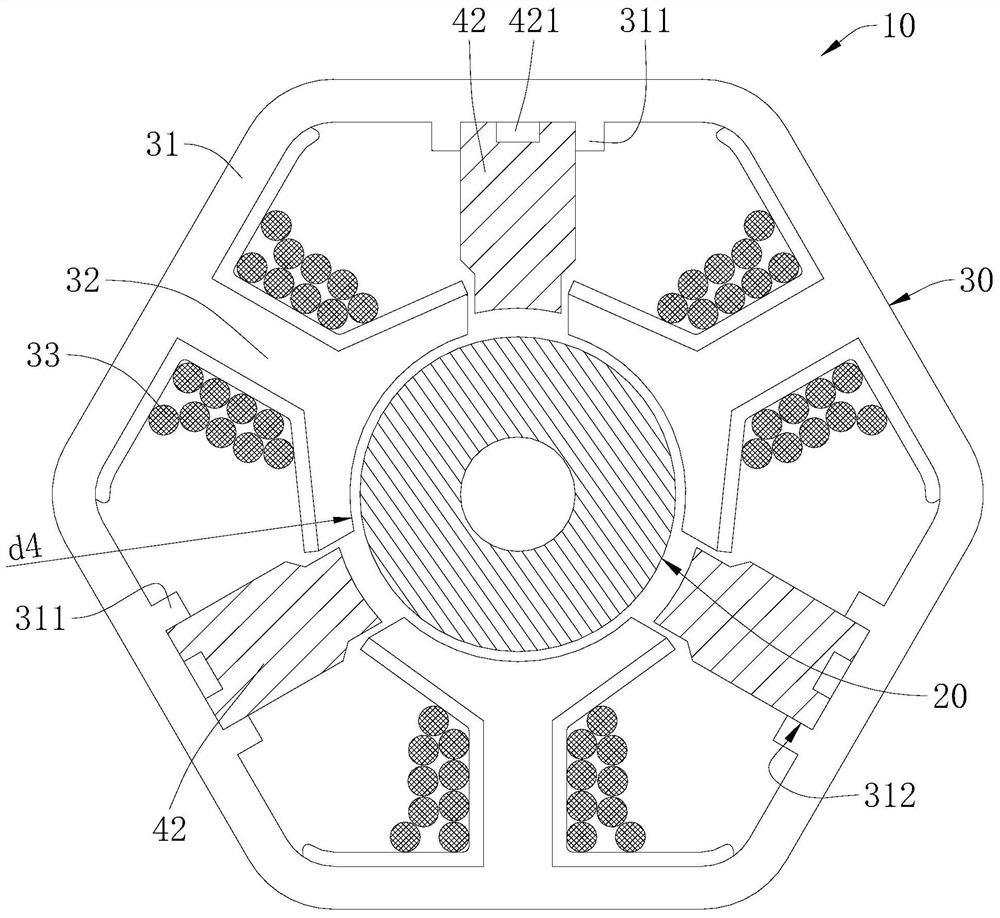

Stator assembly, motor and manufacturing method of stator assembly

PendingCN107294234ASimple structureFacilitate automatic processingWindings insulation shape/form/constructionMagnetic circuit stationary partsCapacitanceElectric machine

The invention discloses a stator assembly, a motor and a manufacturing method of the stator assembly. The stator assembly comprises a stator core, a plurality of insulating frames, a stator winding and a capacitor, wherein the stator core comprises a stator yoke and a plurality of stator teeth, a plurality of grooves are formed in the stator yoke, and a projection matched with the corresponding groove is formed on each stator tooth; the plurality of insulating frames and the plurality of stator teeth are arranged in a one-to-one corresponding manner, and each insulating frame sleeves the corresponding stator tooth along the radial direction of the stator assembly; the stator winding is wound on the plurality of insulating frames, and the stator winding comprises primary windings and auxiliary windings which are alternately distributed in the circumferential direction of the stator core; and one ends of the plurality of primary windings and one ends of the plurality of auxiliary windings are connected with the capacitor. According to the stator assembly disclosed by the invention, the cost is low, the molding efficiency is high, and the realization of automatic machining is facilitated.

Owner:GD MIDEA ENVIRONMENT APPLIANCES MFG

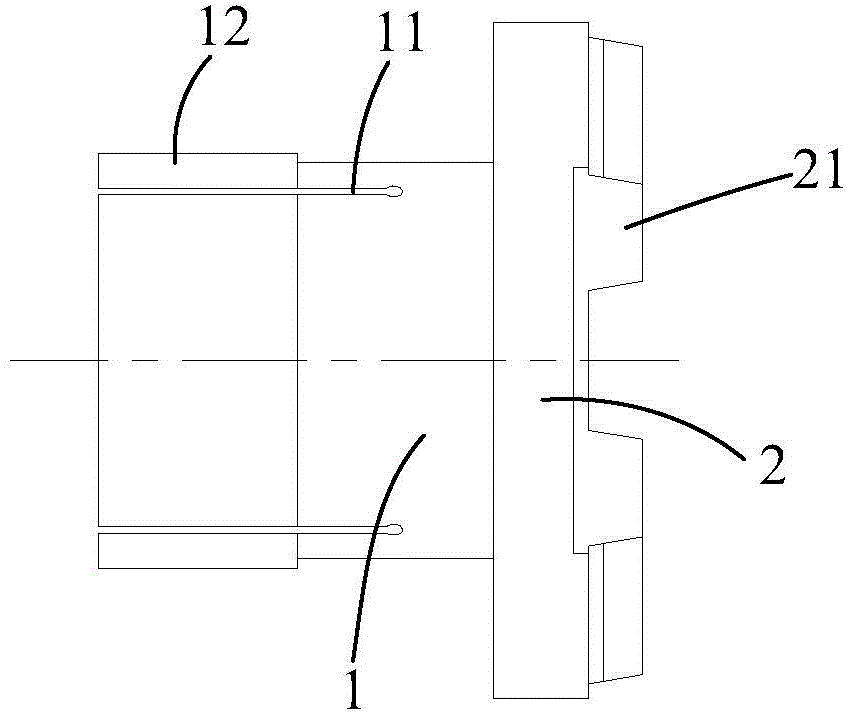

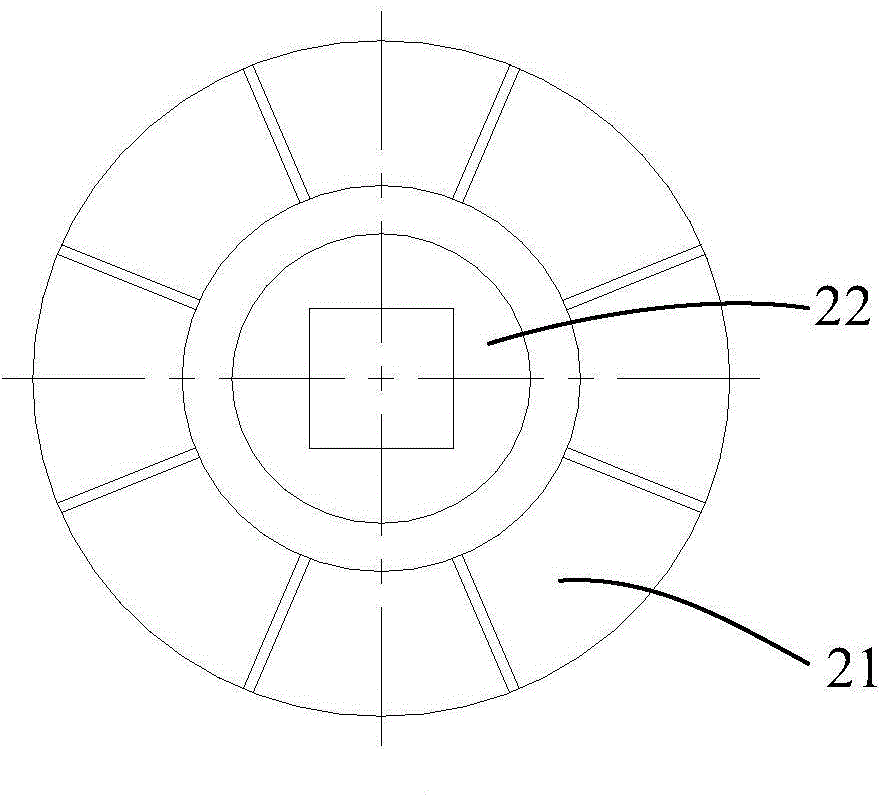

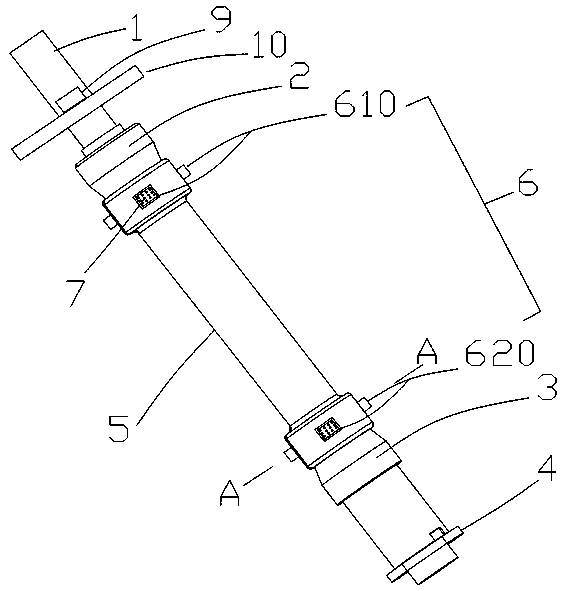

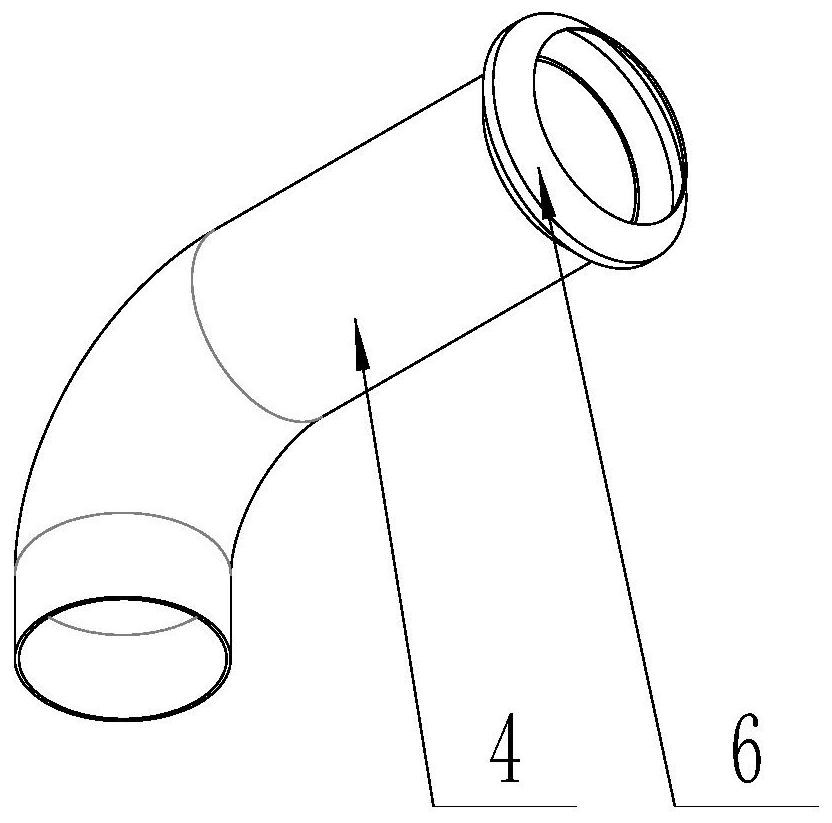

Electric tee valve and refrigeration equipment

ActiveCN107620825AGuaranteed coaxialityConcentricity is easy to guaranteeOperating means/releasing devices for valvesEngineeringRefrigeration

The invention discloses an electric tee valve. The electric tee valve comprises a valve body (1) and a coil (2). A power gear (4), an execution gear (5) and a lining plate (10) are arranged in the valve body (1). The power gear (4) is engaged with the execution gear (5) through a speed reduction gear (6) for transmission, and the power gear (4) and the execution gear (5) are installed on a centershaft (7) together and distributed up and down in a spaced mode. The lining plate (10) is provided with a bent portion (11), and the center shaft (7) is sleeved with the bent portion (11) through a shaft hole (12). The power gear and the execution gear of the tee valve are arranged on the same center shaft, so that the coaxiality of the gears is greatly enhanced, and the phenomenon that gear shafts cannot be normally engaged or clamped to each other due to poor coaxiality is effectively avoided; and in addition, the center shaft is fixed with the lining plate and the both ends of a valve seat,so that the center shaft is more firm and is prevented from bending and disengaging.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

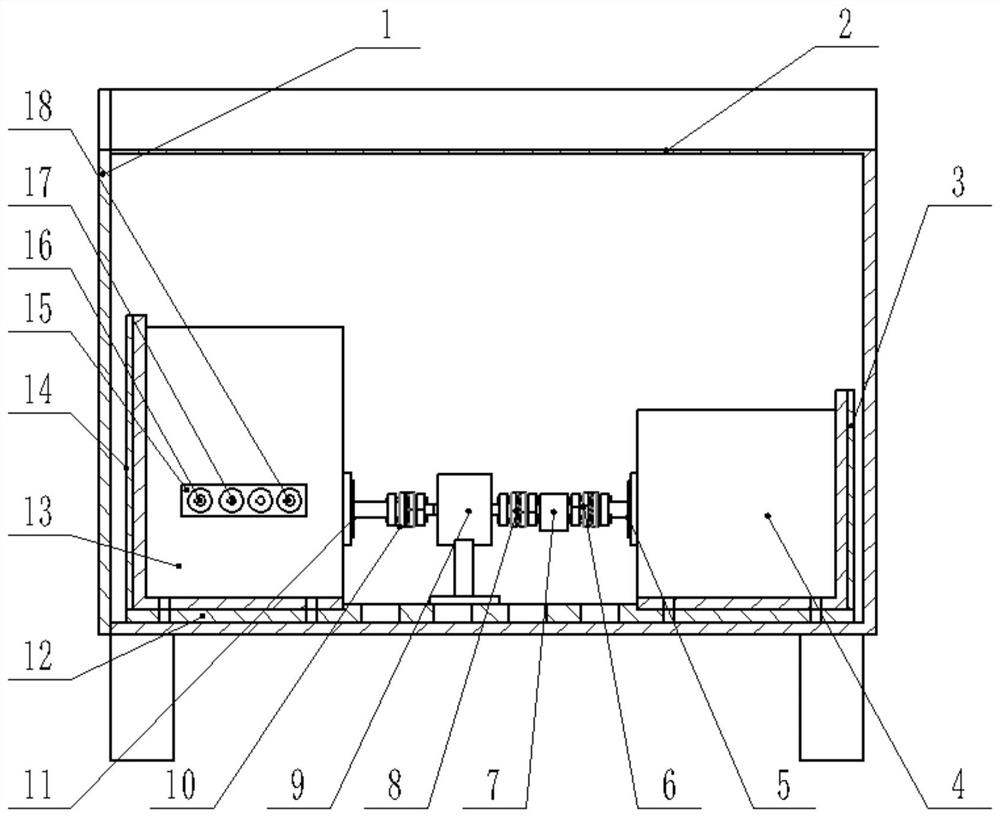

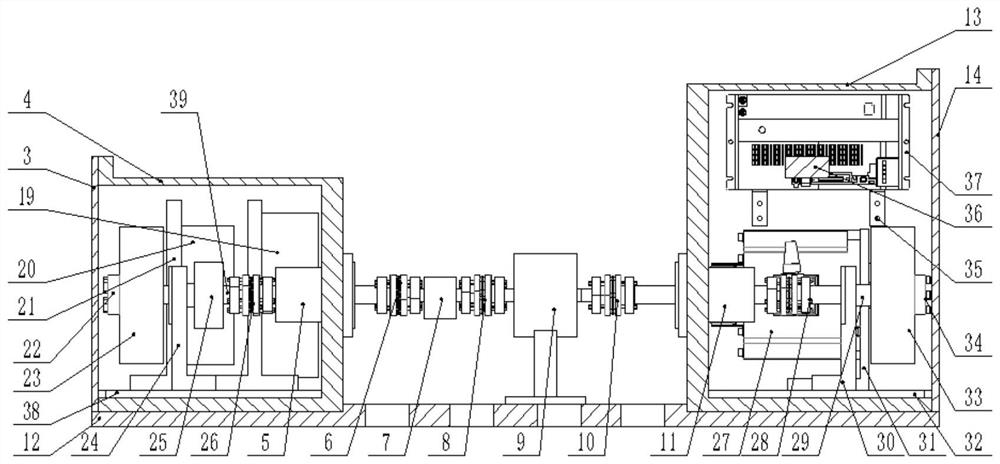

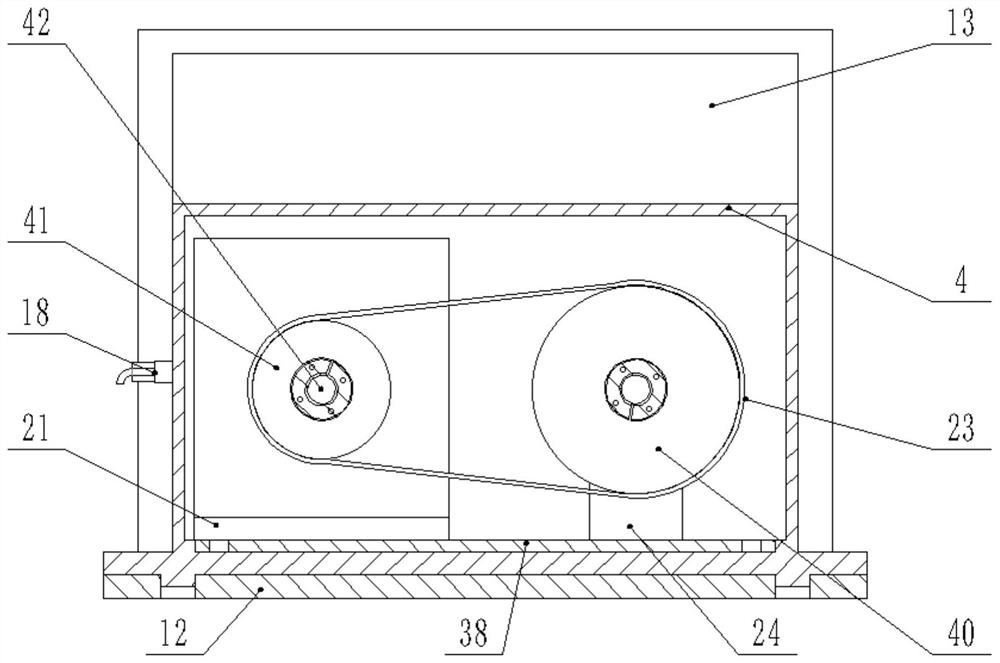

Friction experiment device in thermal vacuum environment

PendingCN112782171AShorten the lengthConcentricity is easy to guaranteeMaterial analysis by optical meansCouplingSpeed test

The invention discloses a friction experiment device in a thermal vacuum environment. The device comprises a temperature-controllable vacuum box, a loading box, a total mounting bottom plate, a loading end magnetofluid sealing shaft, a third heat insulation coupling, a torque sensor, a first heat insulation coupling, a test piece, a second heat insulation coupling, a driving end magnetofluid sealing shaft, a driving end normal temperature and normal pressure box, a driving device and a loading device. According to the invention, a servo motor can be arranged in a normal-temperature and normal-pressure box formed by fixing the open end surface of the normal-temperature and normal-pressure box and a normal-temperature and normal-pressure box end cover 14 through bolts so that under the condition that the large-torque and high-rotating-speed test requirements can be met, driving and loading outside a vacuum tank are not needed; and when the test is completed, a special vacuum tank does not need to be customized, only the mounting platform needs to be put down, the length of a transmission chain is greatly shortened, and the coaxiality is easy to guarantee.

Owner:ZHEJIANG UNIV OF TECH

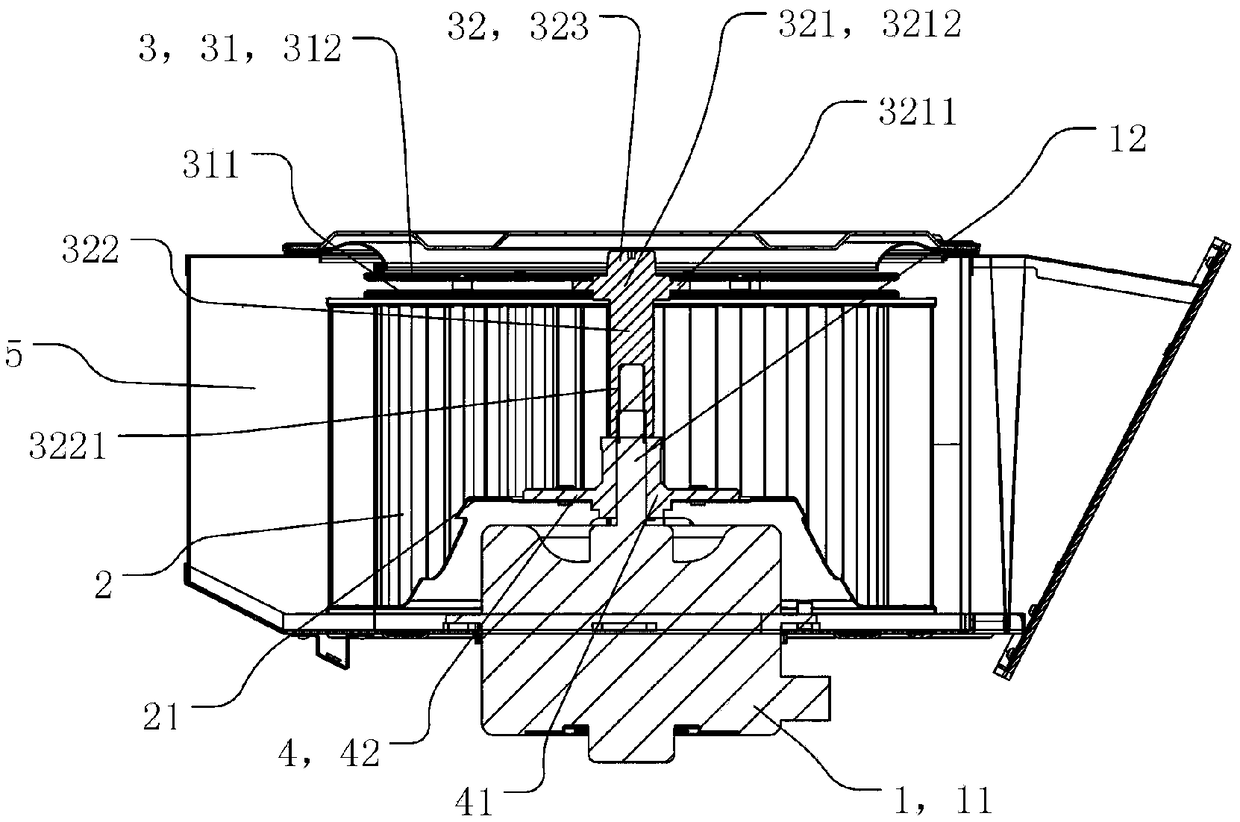

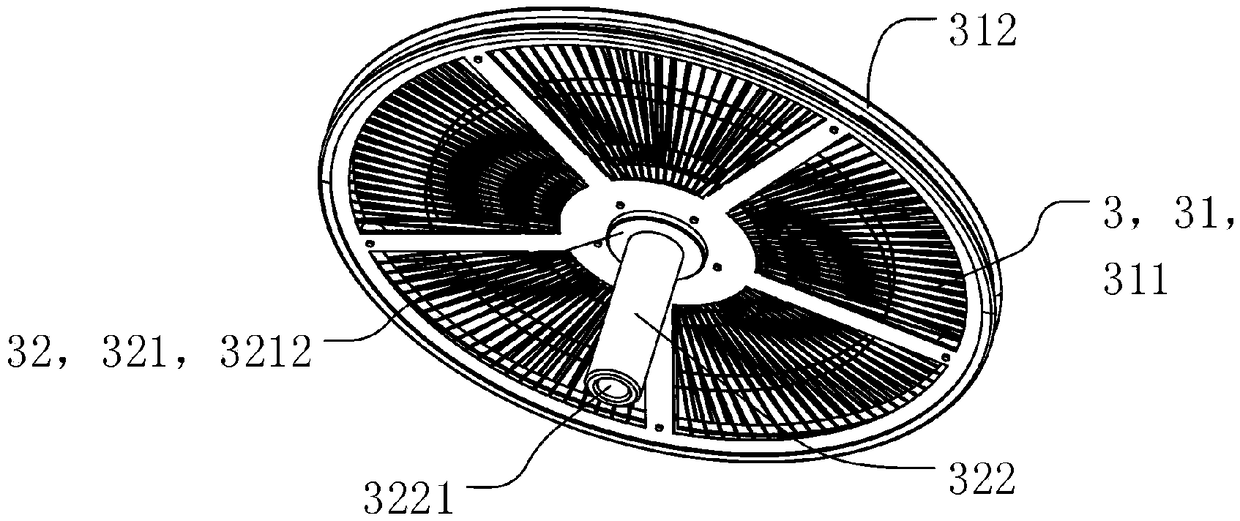

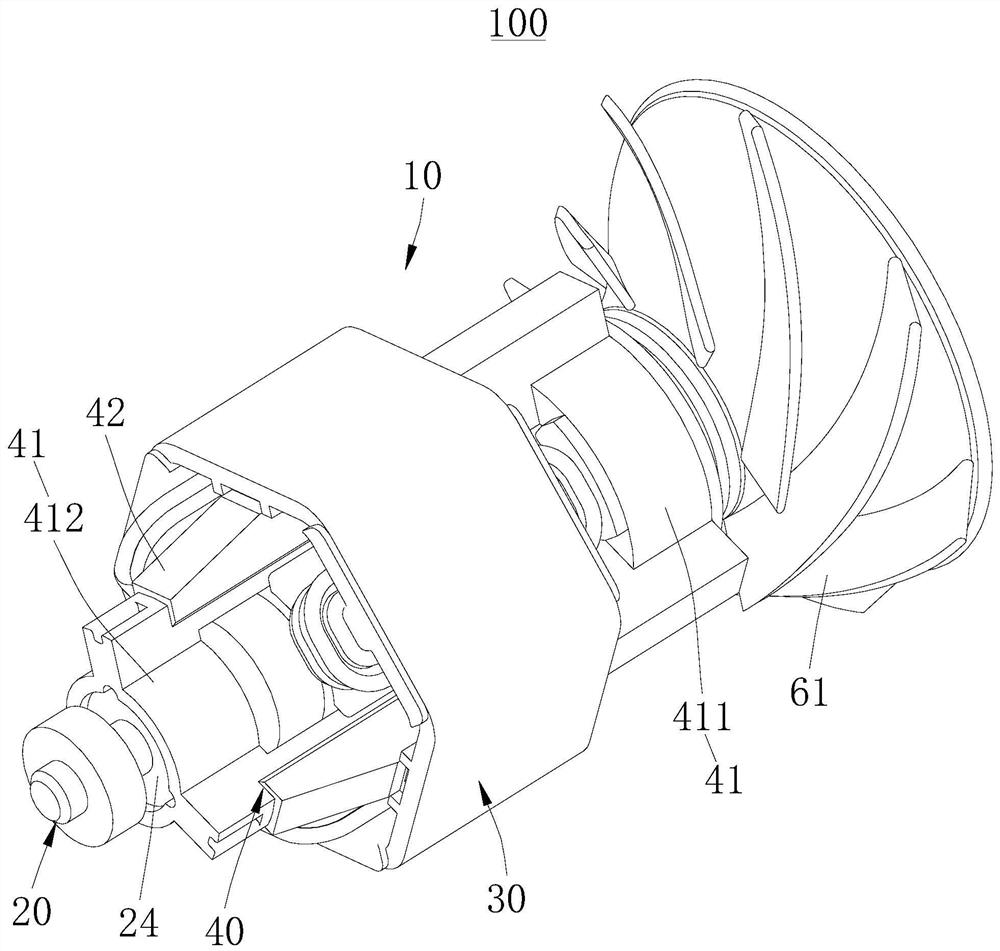

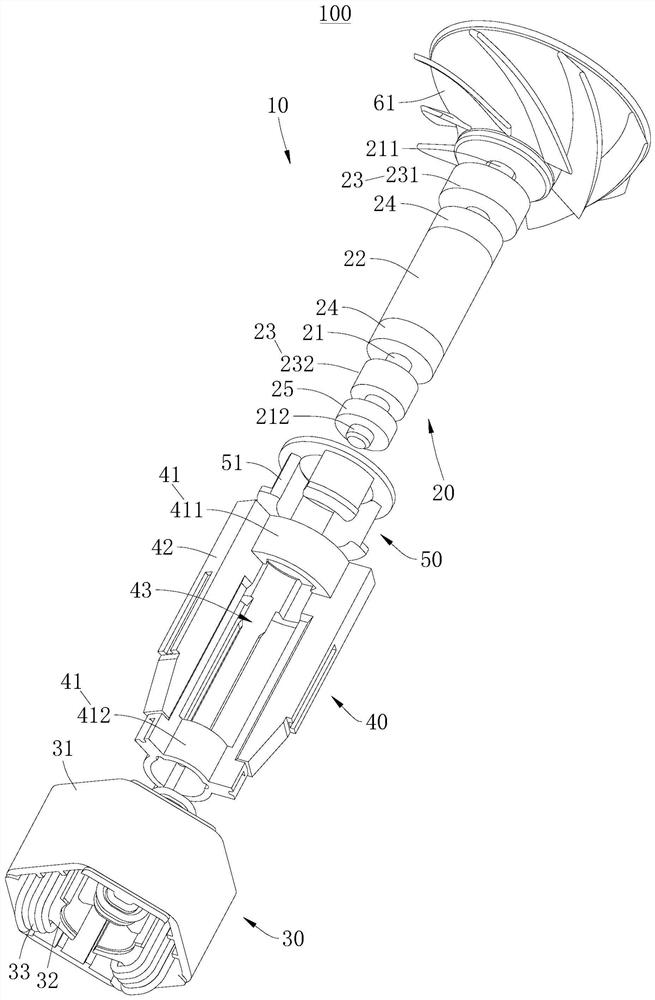

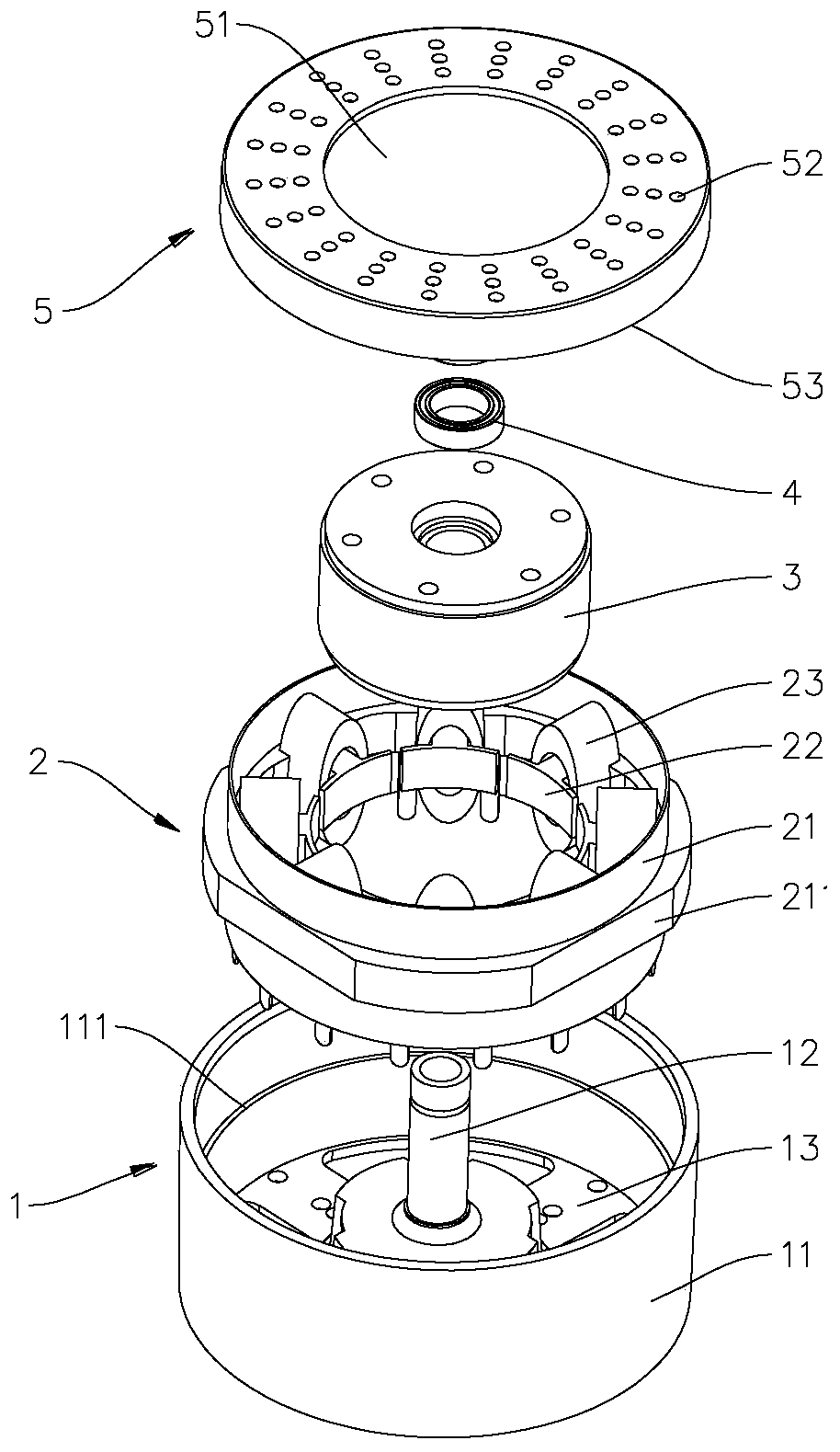

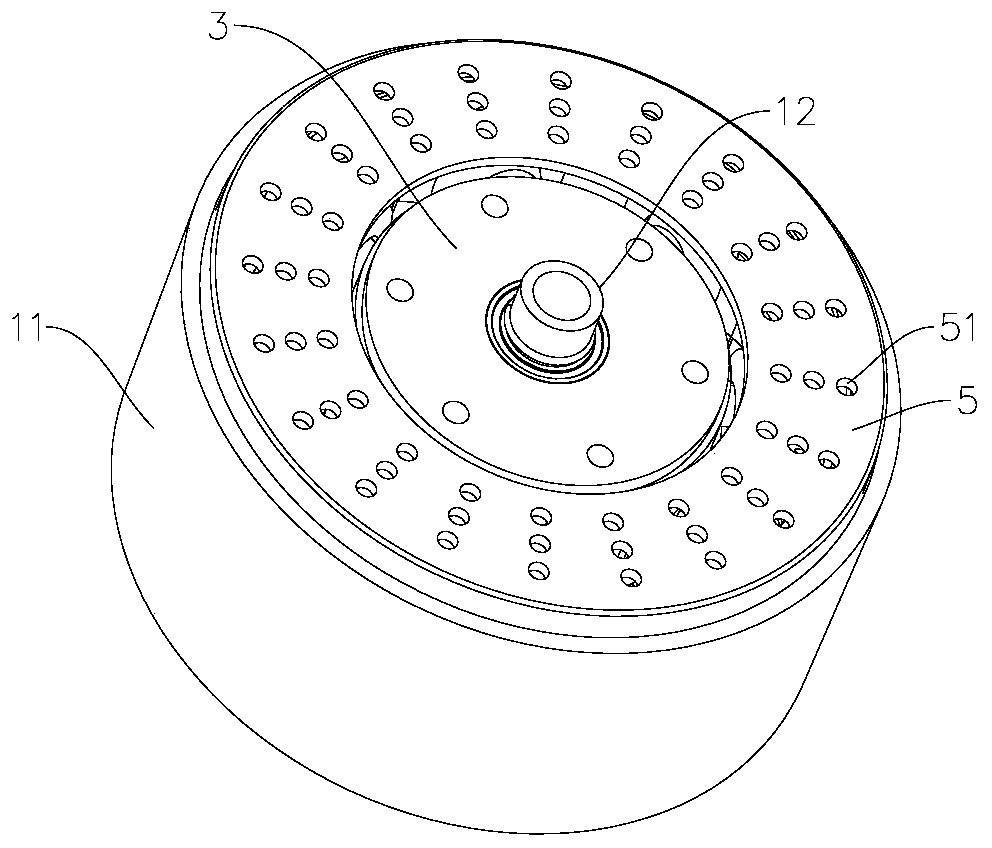

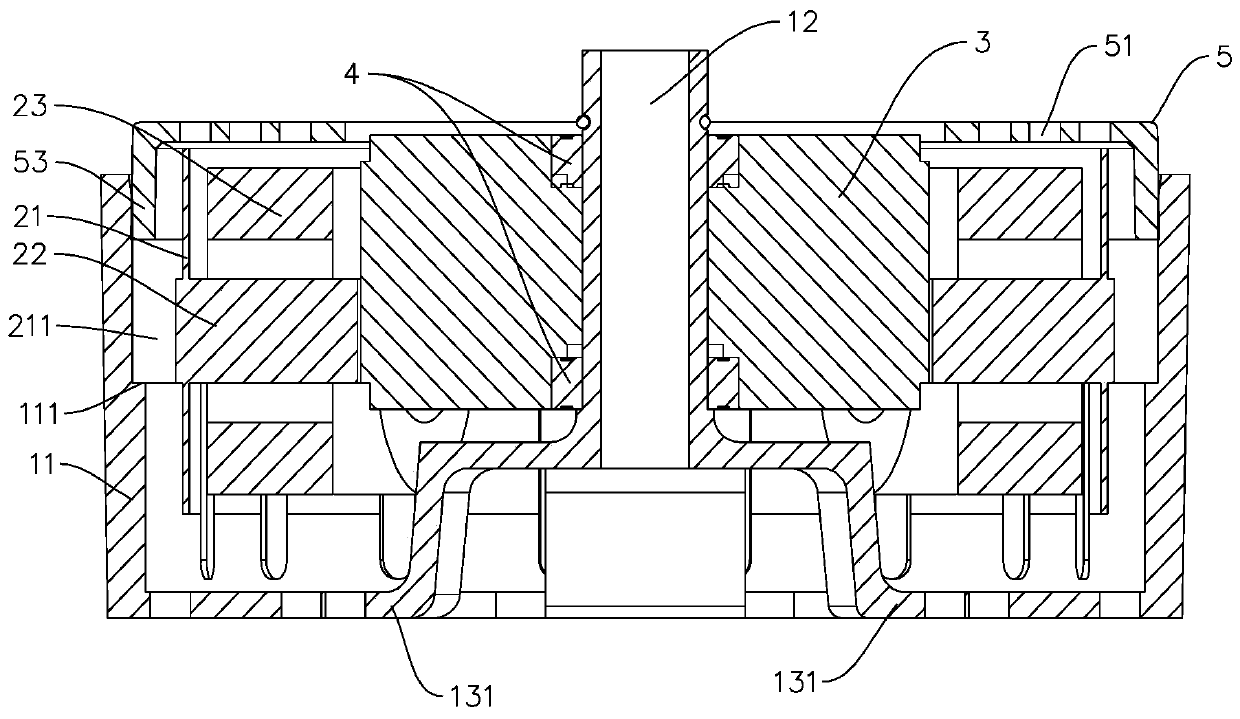

Fan assembly, oil smoke separating net and range hood

PendingCN109237570AReduce processing difficultyGuaranteed structural strengthDomestic stoves or rangesLighting and heating apparatusDrive shaftPulp and paper industry

The invention discloses a fan assembly, an oil smoke separating net and a range hood. The fan assembly comprises a drive device, a wind wheel and the oil smoke separating net, wherein the drive devicecomprises a body and a drive shaft; the wind wheel is fixedly connected with the drive shaft; the oil smoke separating net comprises a net body and a mounting part connected with the net body; at least part of the mounting part is positioned inside the wind wheel; and the part, positioned in the wind wheel, of the mounting part is fixedly connected with the drive shaft. According to the fan assembly disclosed by the invention, the mounting part of the oil smoke separating net extends into the wind wheel, and is fixedly connected with the drive shaft, so that the drive shaft is reduced, processing difficulty of the drive shaft is reduced, and structural strength of the drive shaft is guaranteed; and meanwhile, coaxiality of the drive shaft and the oil smoke separating net is guaranteed more easily.

Owner:GREE ELECTRIC APPLIANCES INC

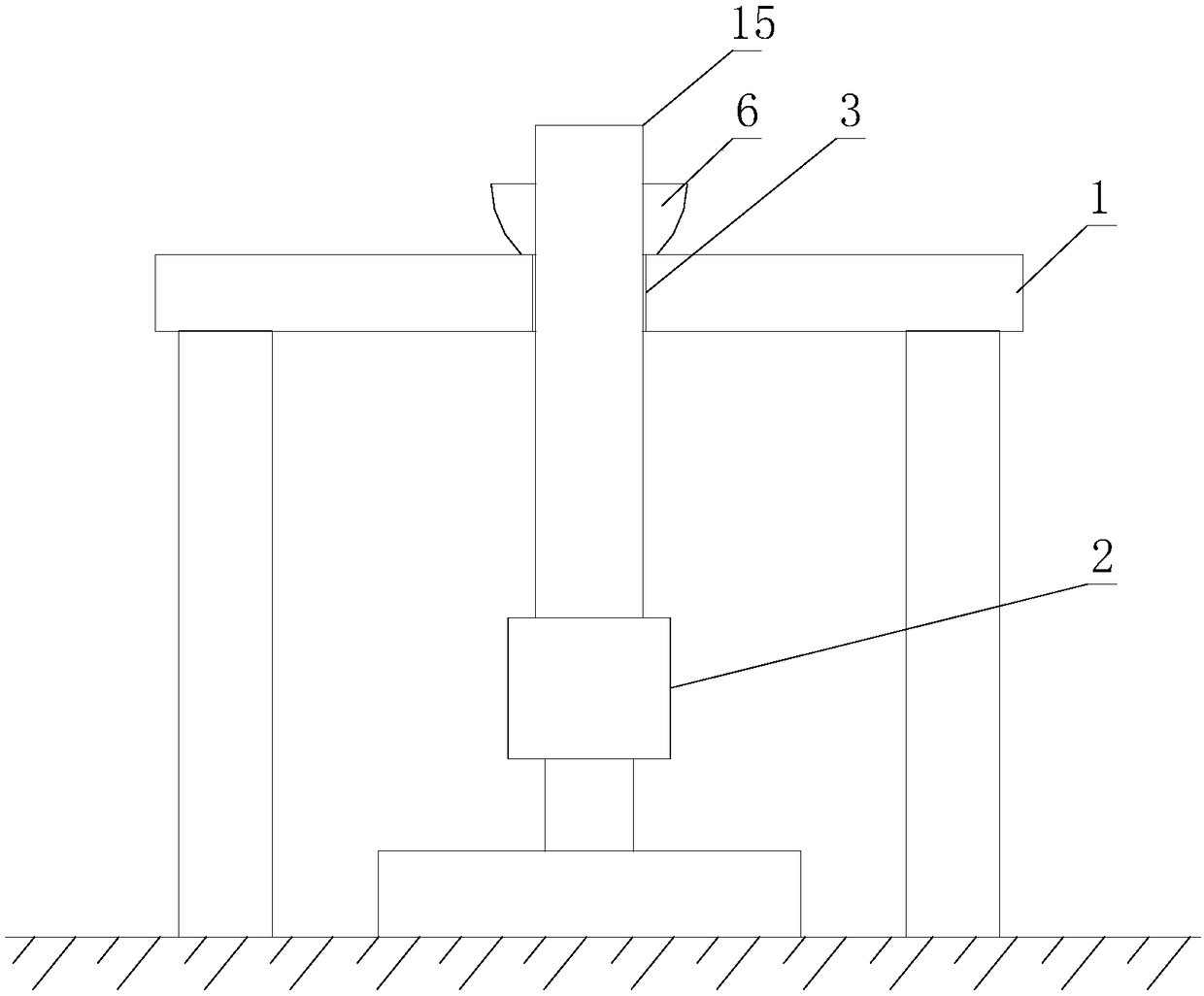

Constraint device of engine shaft part

ActiveCN109176074AConcentricity is easy to guaranteeConvenient high-precision processingPositioning apparatusMetal-working holdersConvex sideEngineering

Owner:CHENGDU ZHIRONG ZHICHUANG INTPROP MANAGEMENT CO LTD

Vacuum three-position switch with rapid earth switch

InactiveCN103441028AAvoid scratchingReduce processing difficultyHigh-tension/heavy-dress switchesAir-break switchesEngineeringElectrical conductor

A vacuum three-position switch with a rapid earth switch overcomes the defects that in the prior art, an existing switch is complex in structure, large in size, high in cost, incomplete in function and poor in safety. The vacuum three-position switch with the rapid earth switch is characterized in that a rapid earth switch electric conductor is arranged in a central hole of an upper cover plate which is welded to the top end of an upper insulating cylinder, an isolation electric conductor is welded between the upper insulating cylinder and a middle insulating cylinder, an outgoing line electric conductor is welded to the middle insulating cylinder and a lower insulating cylinder through an annular connecting body of the outgoing line electric conductor, a movable electric conductor which is fixedly connected with an insulating pull rod is arranged in a hollow guide sleeve welded to the upper side of a central hole of a lower cover plate, and the axis of the rapid earth switch electric conductor, the axis of the insulating electric conductor, the axis of the movable electric conductor, the axis of the outgoing line electric conductor, the axis of an earth electric conductor, the axis of the upper insulating cylinder, the axis of the middle insulating cylinder and the axis of the lower insulating cylinder are in the same line. The vacuum three-position switch with the rapid earth switch has the advantages that due to the fact that the movable electric conductor moves perpendicularly, a crank is omitted, the concentricity of the movable electric conductor, the insulating electric conductor and the earth electric conductor can be easily guaranteed, the machining difficulty of the guide sleeve is lowered, and the vacuum three-position switch with the rapid earth switch is simple in structure, small in size, low in cost, complete in function and high in safety.

Owner:沈阳华德海泰电子有限公司

Electric tricycle transmission system

InactiveCN109915552AIncrease mileageExtended service lifeToothed gearingsGearing controlElectric power transmissionReduction drive

The invention discloses an electric tricycle transmission system. The electric tricycle transmission system comprises a transmission; a differential shell is arranged and is in transmission match witha power output end of the transmission; the differential shell is of an integral structure; a shift differential system is adopted; the differential shell is of the integral structure, so that bettercoaxiality can be determined during machining, so that coaxiality is ensured during the assembly process; assembly can be performed directly; assembly efficiency is improved; the integral structureis adopted, so that the coaxiality problem does not occur after long-time use; eccentric wear cannot happen between motion pairs; the service lives of the differential and a whole reducer are favorably prolonged; the using cost is lowered; the using energy consumption is greatly lowered since the eccentric abrasion does not exist; and the travel distance after charging of an electric tricycle is favorably increased.

Owner:重庆轩通机电有限公司

Rotating motor and fan

ActiveCN113675985AGuaranteed stabilityGuaranteed reliabilityWind energy generationMechanical energy handlingRadial stressElectric machine

The invention provides a rotating motor and a fan. According to the rotating motor provided by the invention, a plurality of accommodating grooves are formed in the radial inner surface of at least one bearing seat of a supporting frame at intervals, and soft arc-shaped petals are arranged in the accommodating grooves, so that the inner diameters of the soft arc-shaped petals are smaller than the inner diameters of the corresponding bearing seats, and the soft arc-shaped petals elastically abut against the corresponding bearings; therefore, a certain binding force is formed between each soft arc-shaped petal and the corresponding bearing, the axial and radial stress of the bearing can be improved, the service life of the bearing is prolonged, the relative position of the inner ring and the outer ring of the bearing can be adjusted during high-speed rotation, and a certain self-adaptive aligning effect is achieved; and the area between the two adjacent accommodating grooves in the bearing seat provided with the soft arc-shaped petals can be well connected with the corresponding bearing, so that the bearing can be more stably mounted in the corresponding bearing seat, and the operation stability and the reliability of the rotating motor are ensured.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

Expanding core fixture for workpiece with gully on inner wall and using method thereof

The invention discloses a core-expanding fixture for a workpiece with gullies in the inner wall. The core-expanding fixture comprises a concentric shaft, a limiting taper end head sleeving one side ofthe concentric shaft and a movable taper end head sleeving the other side of the concentric shaft, wherein one side, close to the movable taper end head, of the concentric shaft is provided with external threads; the external thread section of the concentric shaft is provided with a locking nut; the concentric shaft between the limiting taper end head and the movable taper end head is sleeved with a tubular expanding core; a plurality of through holes are evenly formed in the circumferences of the two sides of the expanding core; radial slide blocks are arranged in the through holes; the upper surfaces of the radial slide blocks are provided with a plurality of blind holes; and a movable block is arranged in each blind hole. The core-expanding fixture is convenient to clamp, so that the core-expanding fixture capable of clamping the workpiece quickly is especially suitable for the high-precision machining of the workpiece with the gullies, stripes, small grooves and the like on the inner walls of an aerial bomb body and the like; and in the process of clamping the expanding core, the damage to the gullies and the like on the inner wall of the aerial bomb body is small, so that theimprovement of the product qualification rate and production efficiency is facilitated.

Owner:泰州润骐防务科技有限公司

High-speed coupling lens

PendingCN114236710ASolve the real problemSuppress light intensityCoupling light guidesInterference (communication)Light beam

The invention belongs to the technical field of optical fiber communication, and particularly relates to a high-speed coupling lens which comprises a lens arranged on one side of a reflecting element. The lens is provided with an aspheric surface I and an aspheric surface II; and the reflecting element is provided with reflecting surfaces corresponding to the aspheric surface I and the aspheric surface II. According to the invention, the problems of the conventional coupling lens can be effectively solved, the process difficulty is reduced, and the transmission rate is improved; no other optical surface is arranged between the first aspheric surface and the second aspheric surface to play an interference role, the concentricity of the two surfaces is easily guaranteed, in addition, detection and film coating of the two aspheric surfaces are not interfered by other surfaces, and film coating and detection are easily achieved; the aspheric surface II is independently arranged instead of being arranged in the optical fiber jack, so that the lens does not need to be coated in the jack, and the processing is convenient; by arranging the microstructure, the light intensity of the central area of the VCSEL light beam can be inhibited, the reflection of the whole system is reduced, and the transmission bandwidth is improved.

Owner:无锡鑫巨宏智能科技有限公司

A vacuum three-position switch with quick grounding knife

InactiveCN103441028BReduce processing difficultyAchieve vertical movementHigh-tension/heavy-dress switchesAir-break switchesState of artElectrical conductor

A vacuum three-position switch with a rapid earth switch overcomes the defects that in the prior art, an existing switch is complex in structure, large in size, high in cost, incomplete in function and poor in safety. The vacuum three-position switch with the rapid earth switch is characterized in that a rapid earth switch electric conductor is arranged in a central hole of an upper cover plate which is welded to the top end of an upper insulating cylinder, an isolation electric conductor is welded between the upper insulating cylinder and a middle insulating cylinder, an outgoing line electric conductor is welded to the middle insulating cylinder and a lower insulating cylinder through an annular connecting body of the outgoing line electric conductor, a movable electric conductor which is fixedly connected with an insulating pull rod is arranged in a hollow guide sleeve welded to the upper side of a central hole of a lower cover plate, and the axis of the rapid earth switch electric conductor, the axis of the insulating electric conductor, the axis of the movable electric conductor, the axis of the outgoing line electric conductor, the axis of an earth electric conductor, the axis of the upper insulating cylinder, the axis of the middle insulating cylinder and the axis of the lower insulating cylinder are in the same line. The vacuum three-position switch with the rapid earth switch has the advantages that due to the fact that the movable electric conductor moves perpendicularly, a crank is omitted, the concentricity of the movable electric conductor, the insulating electric conductor and the earth electric conductor can be easily guaranteed, the machining difficulty of the guide sleeve is lowered, and the vacuum three-position switch with the rapid earth switch is simple in structure, small in size, low in cost, complete in function and high in safety.

Owner:沈阳华德海泰电子有限公司

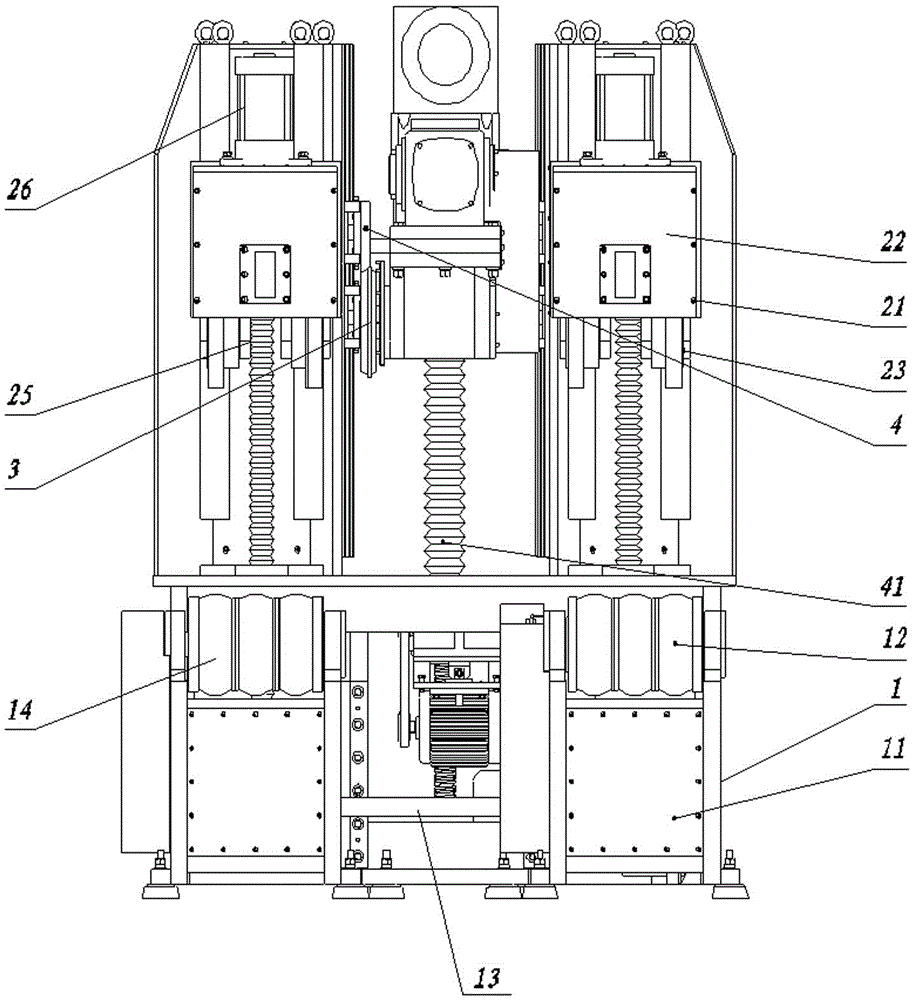

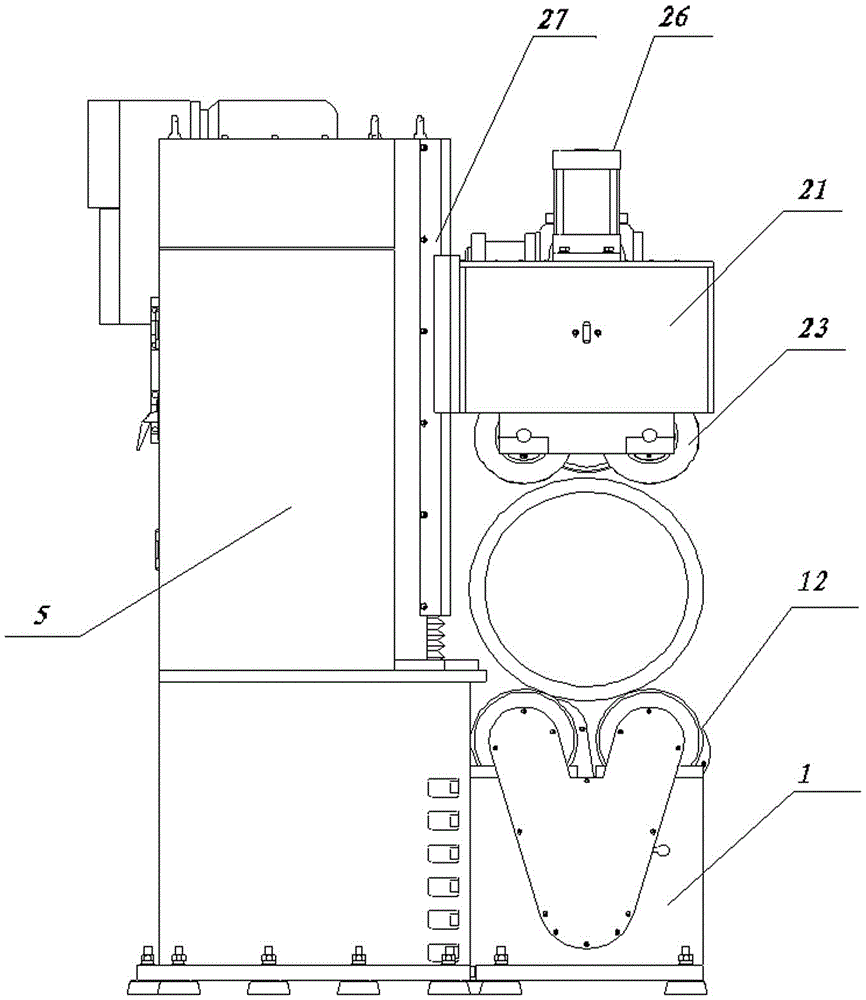

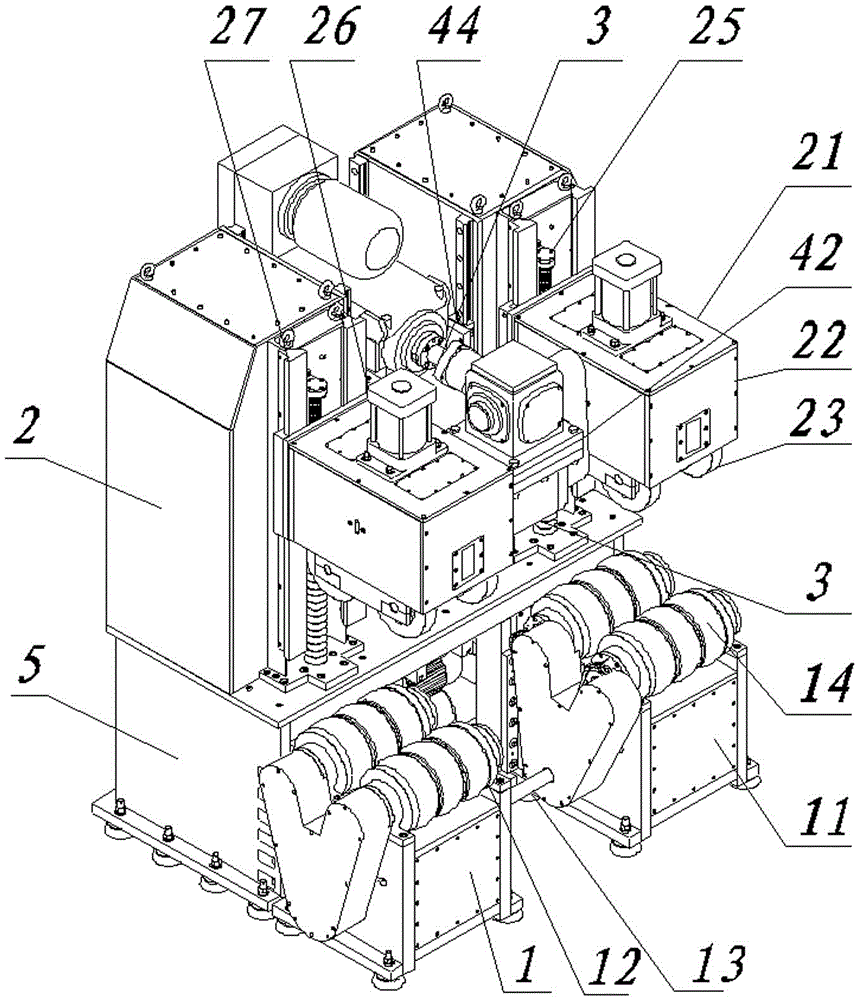

High-efficiency milling and beveling machine for pipes

InactiveCN103286362BConcentricity is easy to guaranteeEasy to controlMilling equipment detailsMetal working apparatusControl systemElectrical control

Owner:上海前山管道技术有限公司

Drum type laundry machine

ActiveUS8499591B2Reduce weightEasy to installOther washing machinesWashing machine with receptaclesWash waterEngineering

A drum washing machine includes a tub installed in a housing to receive wash water therein, a drum rotatably installed in the tub, a rotor having a rotating shaft connected to the drum, a bearing housing having at least one bearing for supporting the rotating shaft of the rotor, the bearing housing being located at the tub, and a stator spaced apart from the rotor by a predetermined distance and directly connected to the tub.

Owner:LG ELECTRONICS INC

Photoelectric composite rotary connector

ActiveCN104317014BAchieving concentricity requirementsGuaranteed coaxialityCoupling light guidesEngineeringElectrical connector

Owner:CHINA AVIATION OPTICAL-ELECTRICAL TECH CO LTD

An electric three-way valve and refrigeration equipment

ActiveCN107620825BGuaranteed coaxialityConcentricity is easy to guaranteeOperating means/releasing devices for valvesEngineeringRefrigeration

The invention discloses an electric tee valve. The electric tee valve comprises a valve body (1) and a coil (2). A power gear (4), an execution gear (5) and a lining plate (10) are arranged in the valve body (1). The power gear (4) is engaged with the execution gear (5) through a speed reduction gear (6) for transmission, and the power gear (4) and the execution gear (5) are installed on a centershaft (7) together and distributed up and down in a spaced mode. The lining plate (10) is provided with a bent portion (11), and the center shaft (7) is sleeved with the bent portion (11) through a shaft hole (12). The power gear and the execution gear of the tee valve are arranged on the same center shaft, so that the coaxiality of the gears is greatly enhanced, and the phenomenon that gear shafts cannot be normally engaged or clamped to each other due to poor coaxiality is effectively avoided; and in addition, the center shaft is fixed with the lining plate and the both ends of a valve seat,so that the center shaft is more firm and is prevented from bending and disengaging.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

Throat pressure tapping nozzle and device using same

PendingCN109060049AMachining with high geometric precisionSimple processVolume/mass flow by differential pressureWater flowSpray nozzle

The invention provides a throat pressure tapping nozzle and a device using the same. The throat pressure tapping nozzle is characterized in that a nozzle body, the throat and a rear expanding sectionare of an overall structure; and the throat is provided with a pressure tapping hole, and the pressure tapping hole of the throat is perpendicular to the axis of the nozzle body and conducts straighthole pressure tapping. The throat pressure tapping nozzle is applied to the measuring device for measuring the water flow of a steam turbine, machining can be facilitated, the structure and the technology are simplified, using reliability and safety are improved, the verifying pass percent is increased, and the measuring precision is improved.

Owner:KAIFENG INSTR

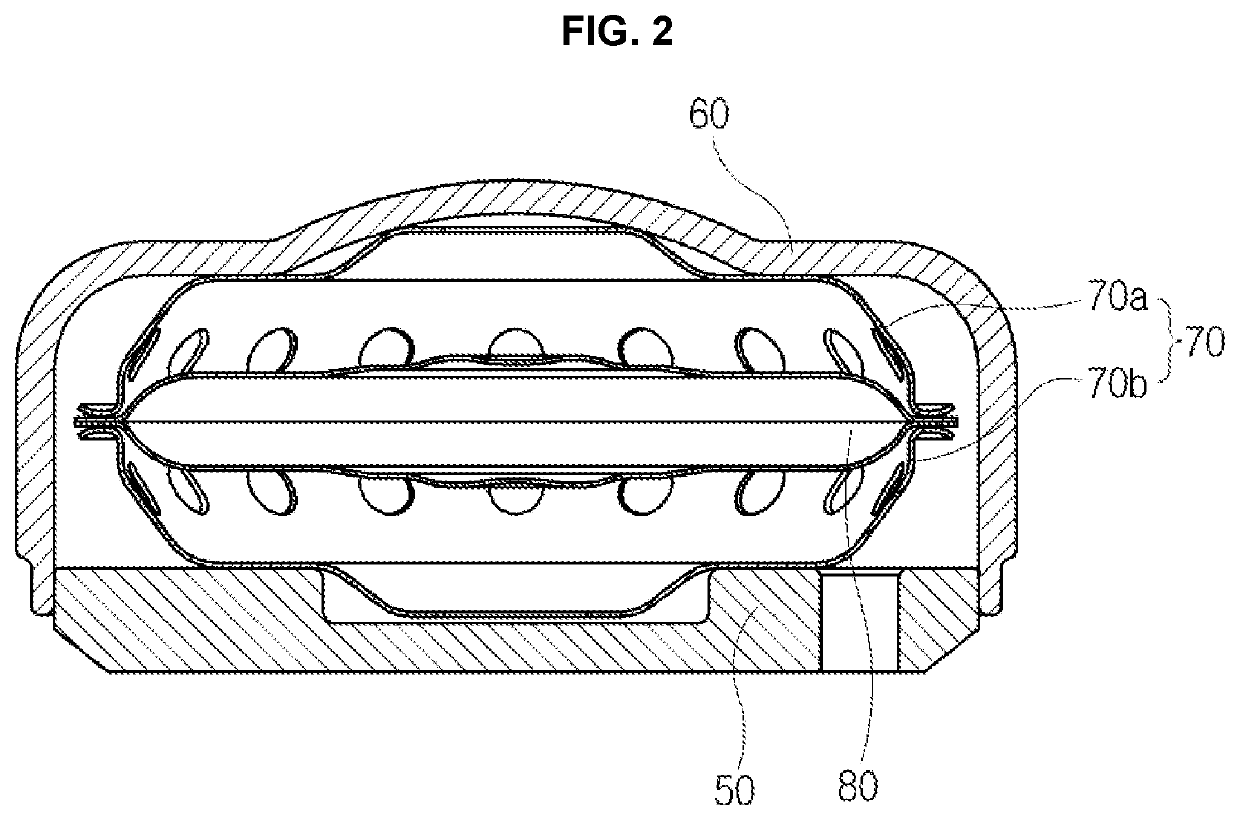

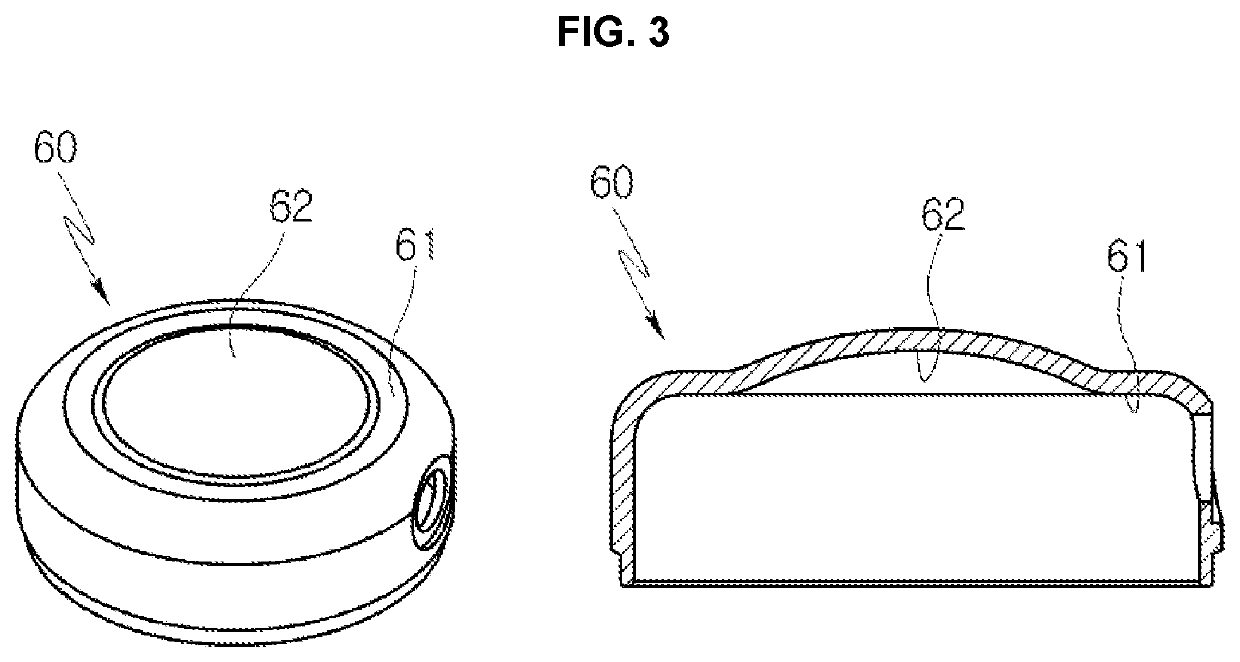

Damper spring structure for reducing radiation noise of high-pressure fuel-pump

ActiveUS20220145838A1Improve structural rigidityReduce noise radiationPositive displacement pump componentsEngine fuctionsEngineeringDamper

A damper spring structure of a high-pressure fuel pump includes: a housing of the high-pressure fuel pump in which a flow path for fuel is formed; a lid coupled to the housing and having an accommodation space between the housing and the lid; a damper spring installed in the accommodation space between the housing and the lid; and a damper installed in the damper spring so as to be supported by the damper spring, in which the damper spring is seated and supported on the lid and the housing in the accommodation space by contact points, and the lid is supported at a plurality of contact points.

Owner:HYUNDAI KEFICO CORP

A restraint device for engine shaft parts

ActiveCN109176074BConcentricity is easy to guaranteeConvenient high-precision processingPositioning apparatusMetal-working holdersStructural engineeringMechanical engineering

Owner:CHENGDU ZHIRONG ZHICHUANG INTPROP MANAGEMENT CO LTD

Fan motor and eccentric fan

PendingCN110224518AFew partsEasy assemblyMagnetic circuit rotating partsPump componentsAgricultural engineeringStator

The invention discloses a fan motor. The fan motor comprises a fixed seat, a rotor and a stator assembly, wherein the fixed seat comprises an annular shell, a rotor shaft and a connection part, wherein the rotor shaft is coaxially arranged in the annular shell, the connection part is connected to one end of the annular shell and one end of the rotor shaft and is used for fixing the rotor shaft, the rotor is coaxially arranged on the rotor shaft by a bearing, the stator assembly is arranged in a way encircling the periphery of the rotor and is fixed on an inner circumferential wall of the annular shell. By the fan motor, the problems that an existing fan motor is trouble to assemble and is poor in assembly accuracy, poor in running stability and large in running noise are solved. The invention also discloses an eccentric fan comprising the fan motor.

Owner:宋振明

An electric three-way valve and refrigeration equipment

ActiveCN107620813BGuaranteed coaxialityConcentricity is easy to guaranteeOperating means/releasing devices for valvesMultiple way valvesGear wheelPath switching

The invention discloses an electric three-way valve and refrigeration equipment. The electric three-way valve comprises a valve body (1) and a coil (2). A power gear (4) and an execution gear (5) arearranged inside the valve body (1). The power gear (4) is driven by a rotor spindle (3) of the coil (2) and is further in meshing transmission with the execution gear (5) through a reduction gear (6).The execution gear (5) is installed on a center shaft (7) and used for driving a sliding block (9) to achieve flow path switching. The power gear (4) and the execution gear (5) are installed on the center shaft (7) together and are further distributed up and down in a spaced mode. According to the electric three-way valve, the power gear and the execution gear are located on the same center shaftand are further connected through the reduction gear, the gear coaxiality is greatly enhanced in production, and the phenomenon that normal meshing or clamping cannot be conducted due to the poor gear-shaft coaxiality is effectively avoided.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

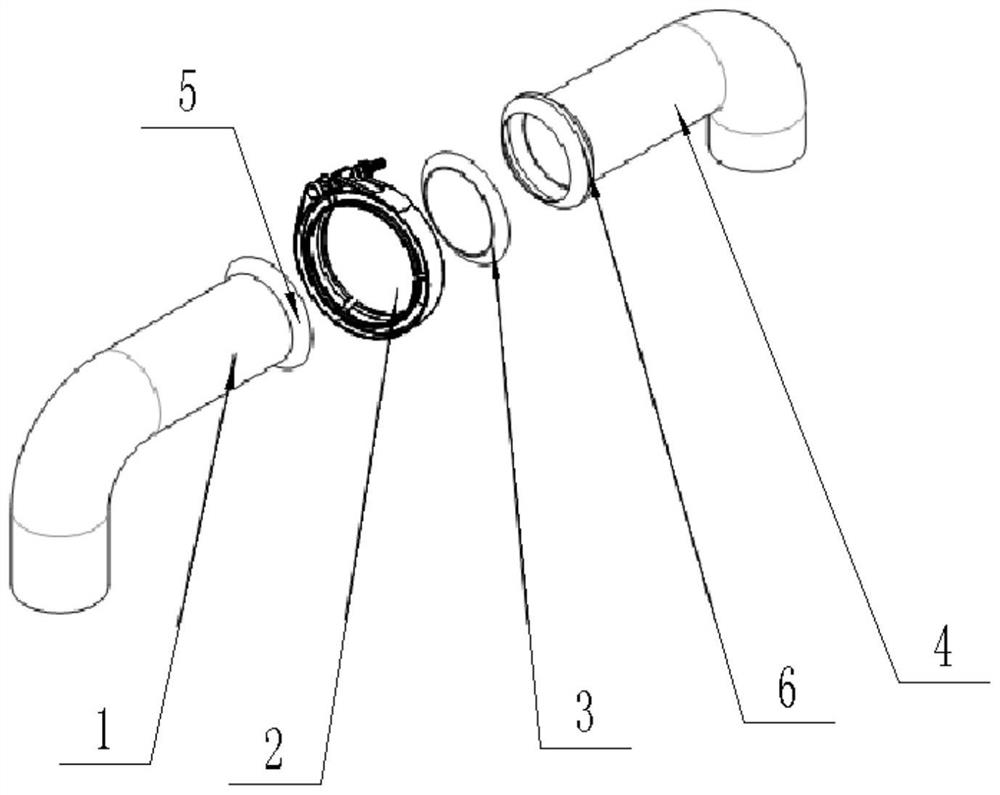

Exhaust pipe assembly method

The invention discloses an exhaust pipe assembly method. The method comprises the following steps of 1) detecting a conical surface inclination angle of an upstream exhaust pipe by using a flanging detection tool, and detecting a conical surface inclination angle of a downstream exhaust pipe by using a bulged pipe detection tool; selecting an upstream exhaust pipe and a downstream exhaust pipe which reach the standard; 2) fitting the inner wall of a conical sealing gasket into a sealing gasket tool, and then tearing off a white protective film on the gluing surface of the outer wall of the conical sealing gasket; (3) clamping the sealing gasket tool on a flanged pipe opening of the upstream exhaust pipe; (4) pulling the sealing gasket tool out, and inserting a bulged pipe opening into the flanged pipe opening for concentric assembly; and (5) mounting a V-shaped clamp at the joint of the flanged pipe opening and the bulged pipe opening, and using a constant-torque electric gun for tightening. The qualified upstream exhaust pipe and the qualified downstream exhaust pipe are screened through the flanging detection tool and the flanging detection tool, the conical sealing gasket is fitted into the sealing gasket tool, the concentricity of the conical sealing gasket and the upstream exhaust pipe is guaranteed, and the problem of smoke leakage at the assembly position after the upstream exhaust pipe and the downstream exhaust pipe are assembled is solved.

Owner:SINO TRUK JINAN POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com