Photoelectric composite rotary connector

A rotary connector and photoelectric composite technology, which is applied in the coupling of optical waveguide, light guide, optics, etc., can solve the problems of different axes, rotary hysteresis of rotary connector, large axial size of photoelectric composite rotary connector, etc., and achieve easy Production and coaxiality are easy to guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

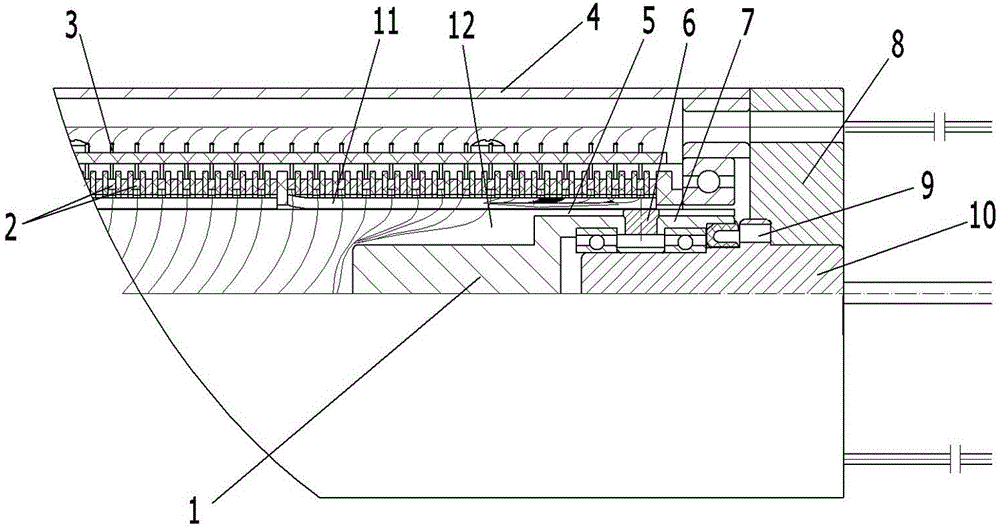

[0013] Examples of optoelectronic composite rotary connectors are figure 1 As shown: it includes an optical rotary connector and an electrical rotary connector. The optical rotary connector includes an optical rotary connector stator 10 and an optical rotary connector rotor 1 that are rotatably assembled with coaxial axes. The optical rotary connector stator 10 and the optical rotary connector are connected The rotor 1 is arranged front and back, and the electric rotary connector includes an electric rotary connector stator and an electric rotary connector rotor assembled together on a coaxial line. The cover 8, the rotor of the electric rotary connector includes a rotating shaft 11 whose axis extends in the front-to-back direction, and a plurality of conductive rings 2 are arranged at intervals along the axial direction on the rotating shaft, and a conductive ring 2 is arranged on the stator of the electric rotary connector to be in contact with the conductive ring. In the br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com