A method for slow wave welding test of traveling wave tube

A technology of traveling wave tube and slow wave structure, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as manual assembly instability, save assembly time, reduce welding risk, and improve testing The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

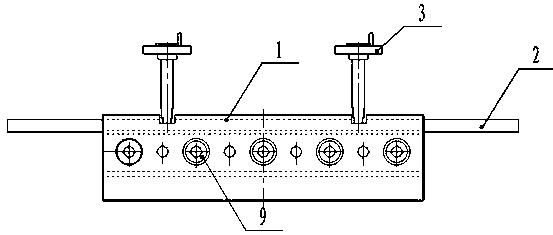

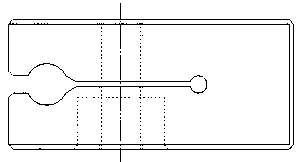

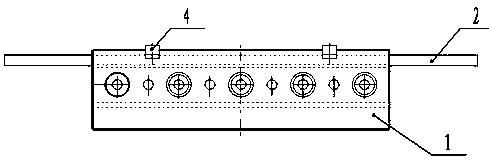

[0032] Such as Figure 1 to Figure 4 As shown, a method for slow-wave welding testing of traveling wave tubes, including: a slow-wave fixture base, which is provided with a cylindrical hole for ensuring the coaxiality of the slow-wave structure, and is equipped with a fastening slow-wave Screws for structural parts; thimbles, used to ensure the parallelism of the end faces of slow-wave structural parts; test dummy windows with waveguide transmission channels, which can be used for cold testing of slow-wave structures after connecting with slow-wave parts; stoppers, used for slow-wave structural parts When the wave structure is welded, the input and output ports are covered; the slow wave structure parts are clamped in the base of the slow wave fixture, and the thimble is used to adjust the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com