Electric tricycle driving assembly

An electric tricycle and drive assembly technology, which is applied to vehicle parts, control devices, transportation and packaging, etc., can solve the problems of wasting drive energy, deviation of coaxiality, prolonging the assembly cycle, etc., so as to prolong the service life and reduce the cost of use , the effect of extending the mileage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

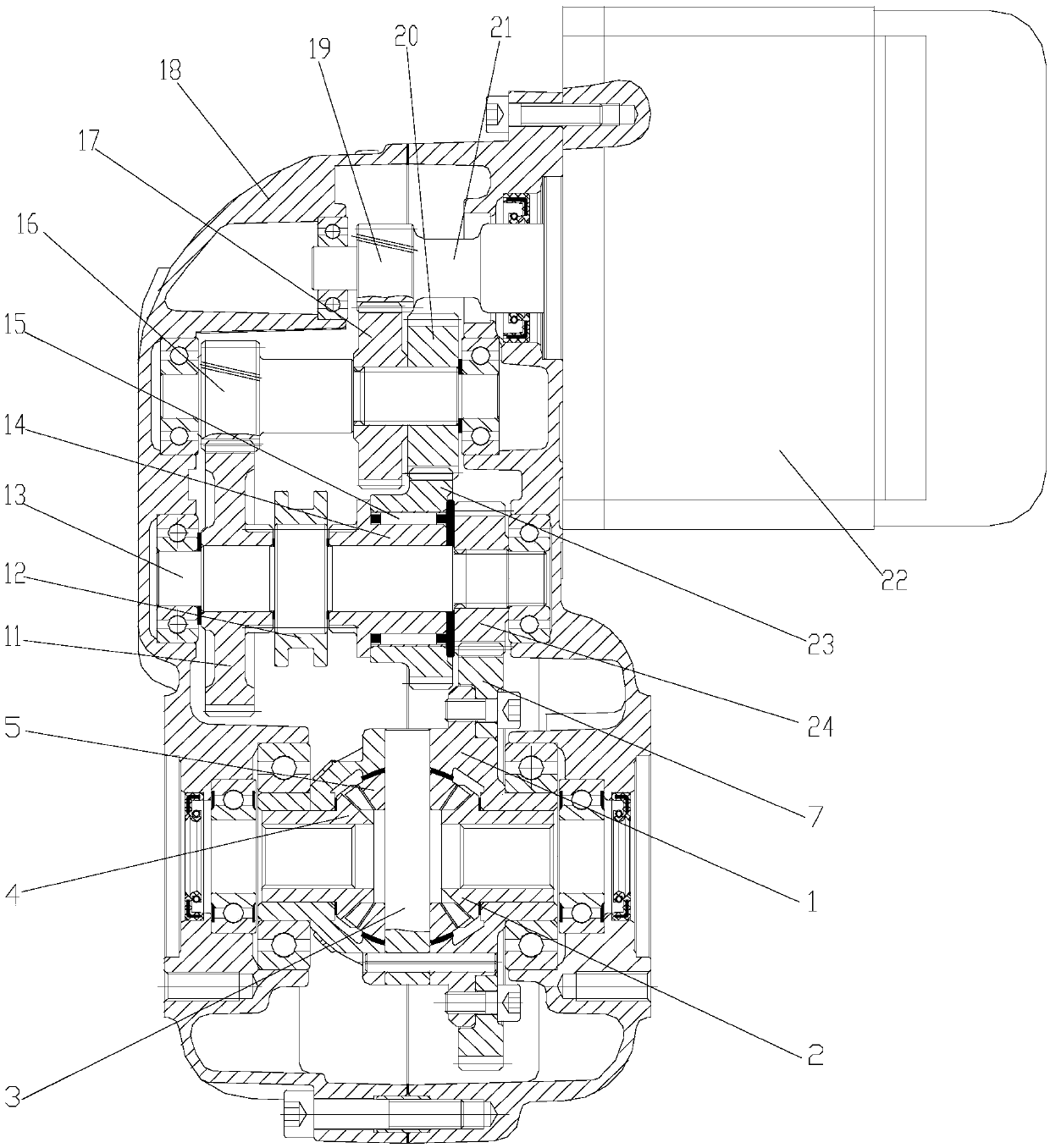

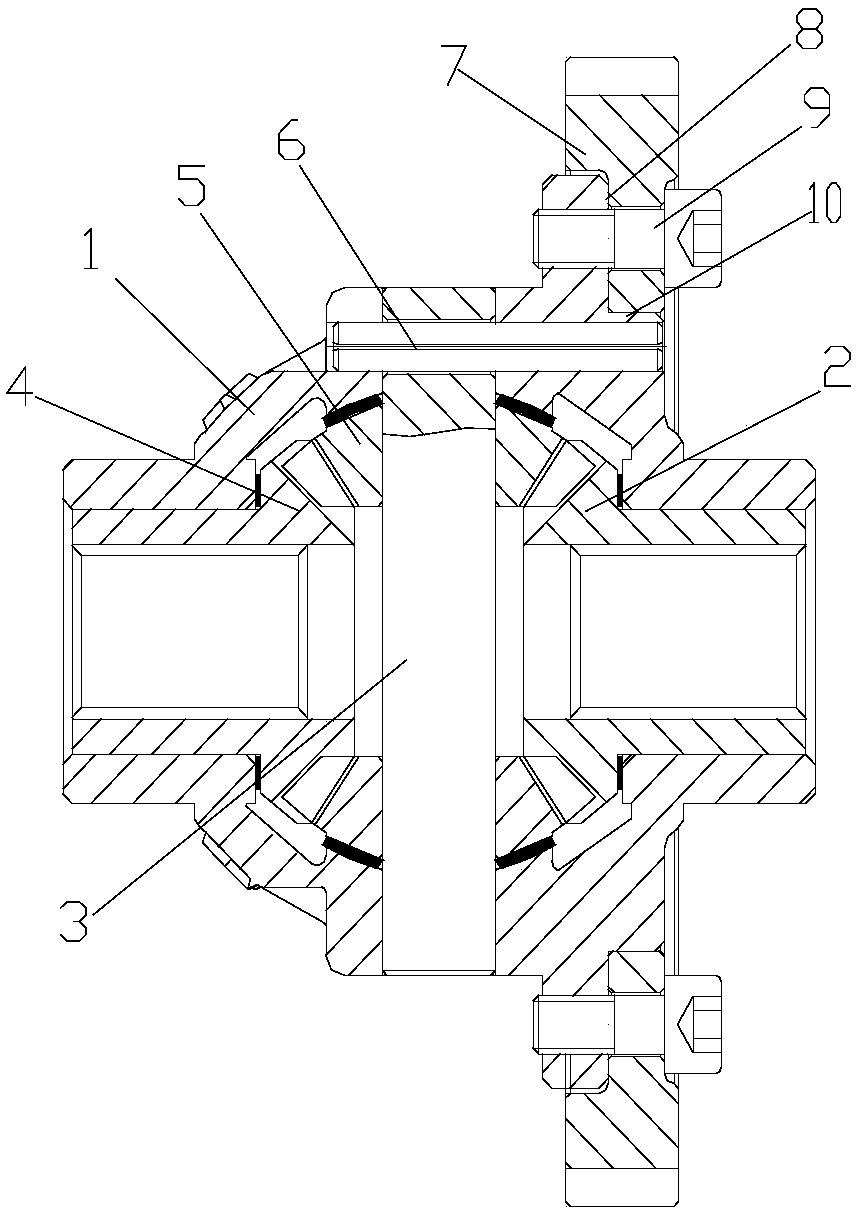

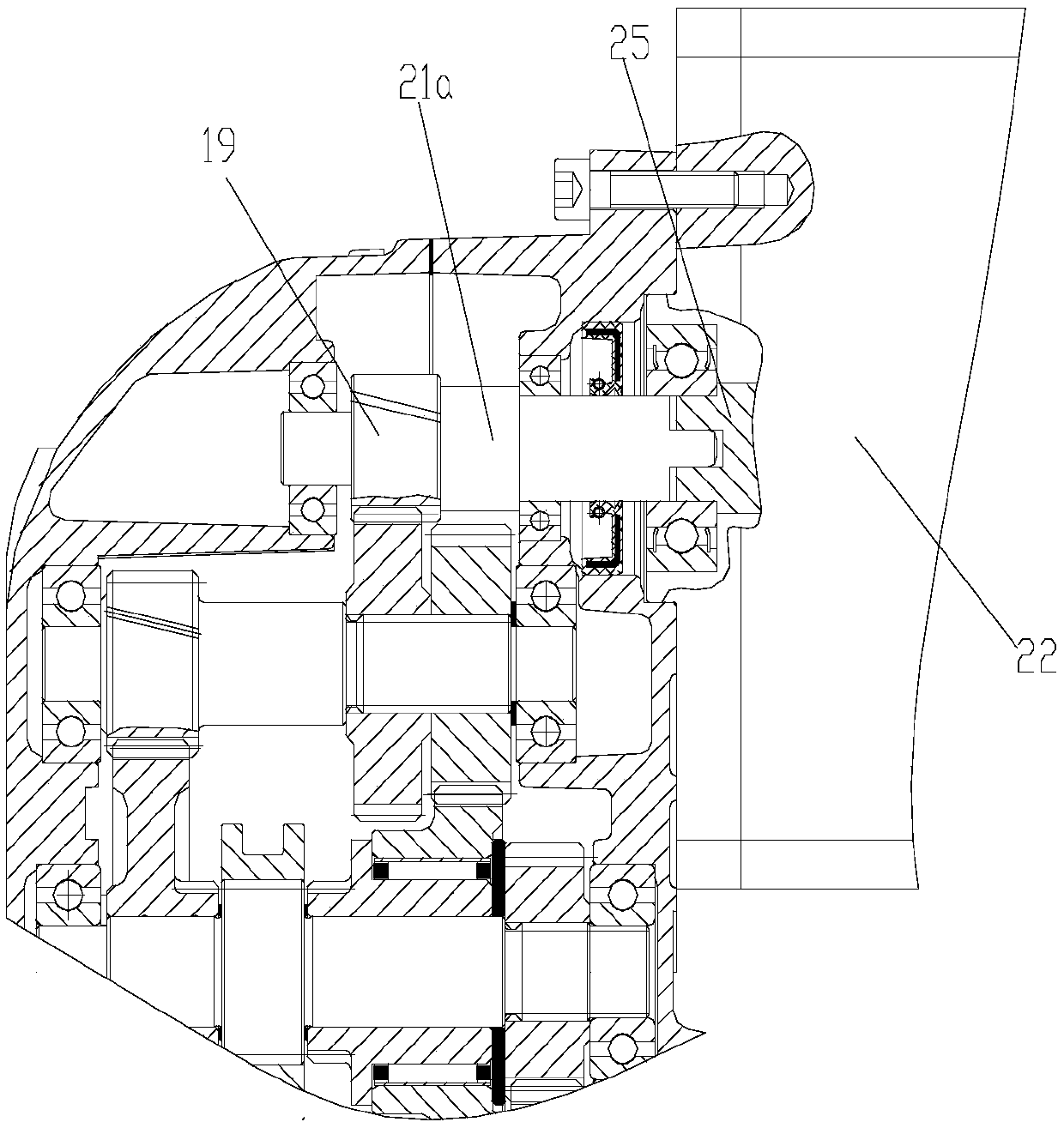

[0022] figure 1 It is a structural schematic diagram of the first embodiment of the present invention, figure 2 It is a structural diagram of a differential, as shown in the figure: the electric tricycle drive assembly of this embodiment includes a power motor 22, a transmission and a differential, and the differential includes a differential housing 1 and a differential gear Assemblies, the differential housing is an integral structure differential gear assembly belongs to the existing structure, including the planetary gear 5, the left side gear 2 and the right side gear 4, which will not be described in detail here; for the convenience of installation , the differential case 1 is provided with installation through holes for the installation of gear assemblies; the transmission case 1 of the integral structure needs to be provided with installation through holes on the side, or adopt an integral frame structure for the installation of planetary gears 5 and side gears (left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com