Double-coding mounting bracket for directly-connected low-speed lifter and transmission shafts

A technology for installing a bracket and a transmission shaft, which is applied in the field of speed measuring machines, can solve the problems of increasing the maintenance workload and cost of the hoist, the constant magnetic speed measuring machine is prone to failure, and the hidden danger of safe operation of auxiliary shafts, etc. The installation process requirements are not high, and the effect of good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

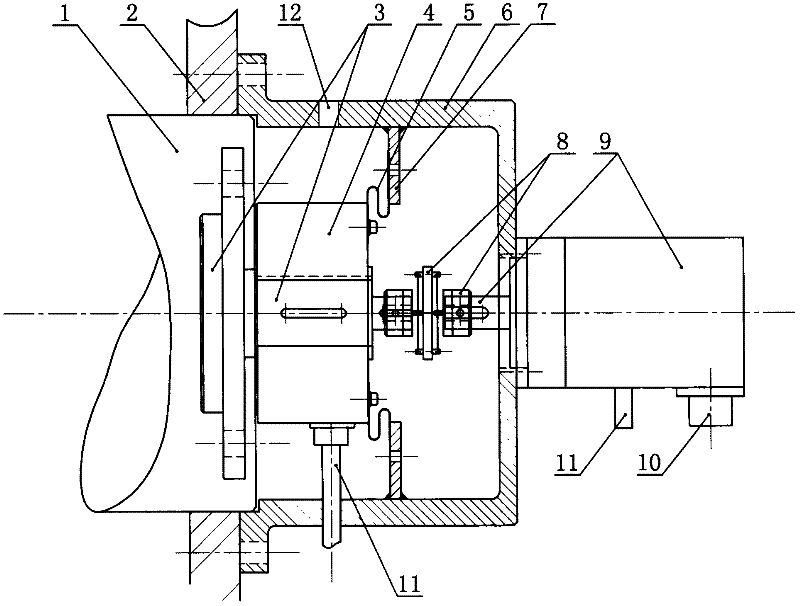

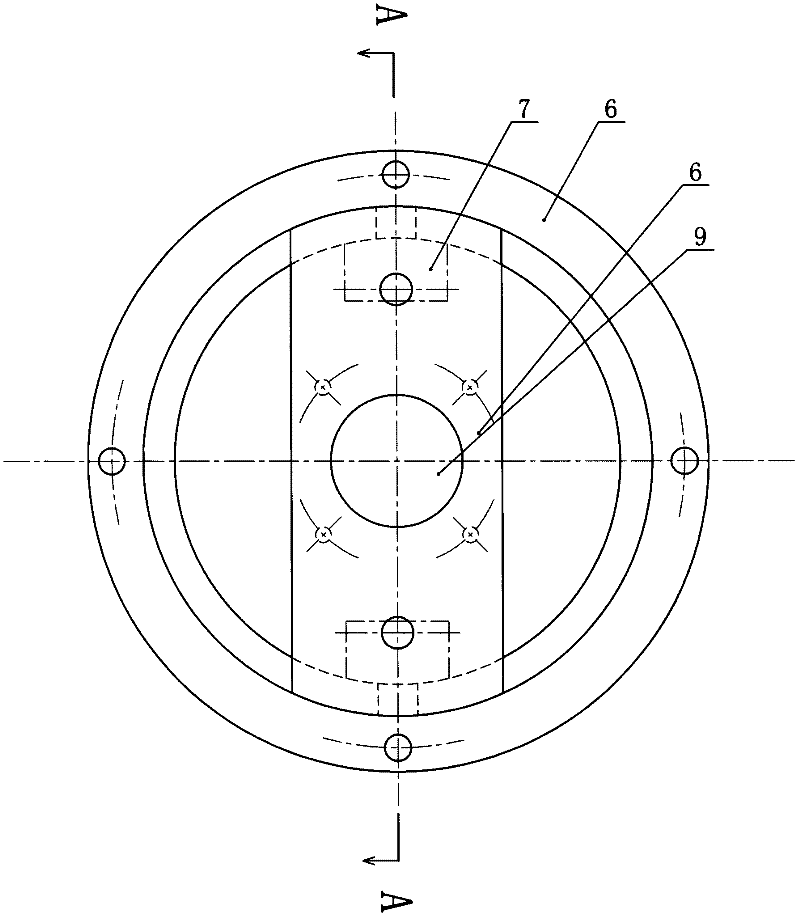

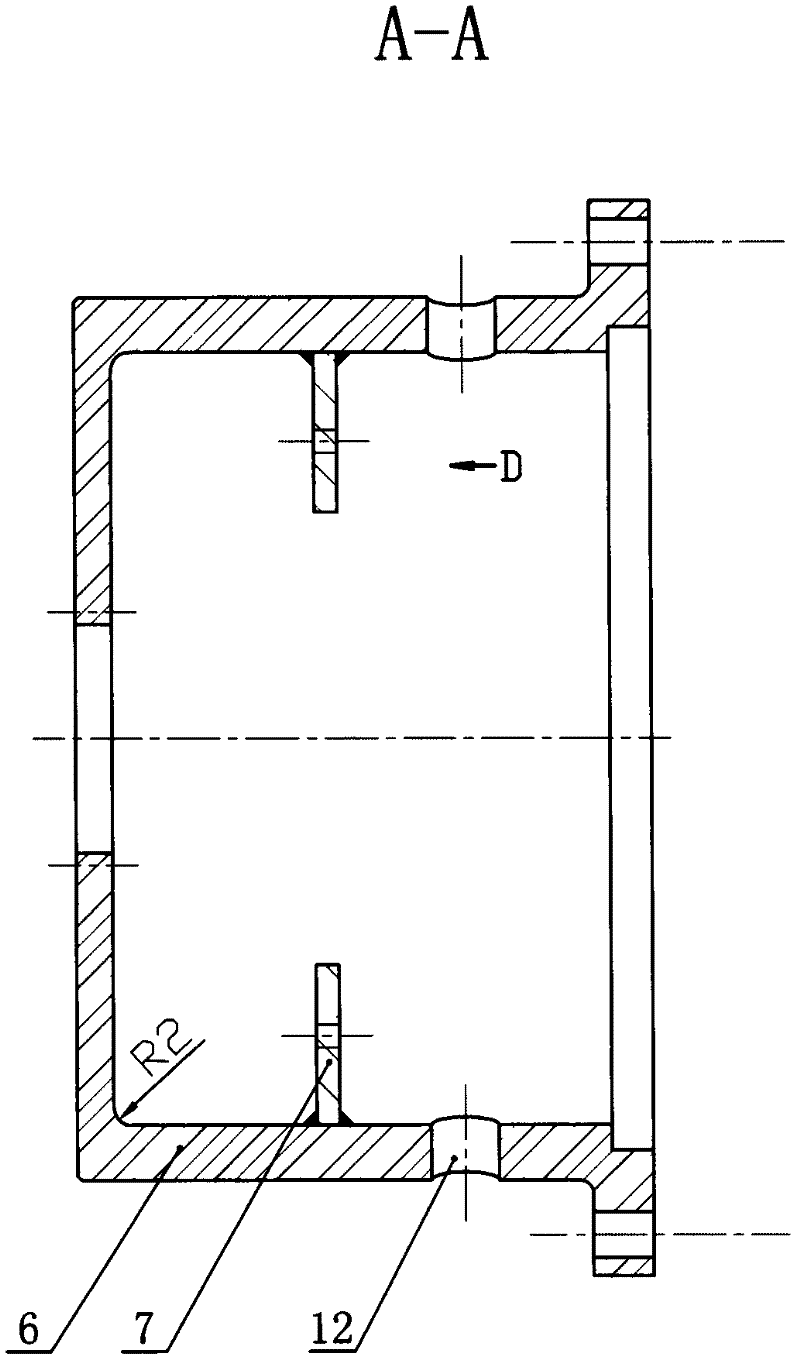

[0023] The structure of the present invention is as figure 1 , 6 As shown, a double-coded mounting bracket and transmission shaft of a low-speed direct-connected hoist, including a large drum shaft 1, a bearing end cover 2, a speed measuring encoder 4, a depth encoder 9, and a data line 11, is characterized in that: a mounting bracket 6 It is fixed on the bearing end cover 2 by screws. There are two symmetrical connecting plates 7 on the inner side of the mounting bracket 6. The data line through-hole 12 is provided on the mounting bracket 6. The large roller shaft 1 is sleeved in the hole of the mounting bracket 6. On the top, one end of the transmission shaft 3 is fixed on the large drum shaft 1 by screws, and the speed measuring encoder 4 is sleeved in the middle of the transmission shaft 3. The speed measuring encoder 4 is provided with two symm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com