Constraint device of engine shaft part

A technology of engine shaft and restraint device, which is used in metal processing mechanical parts, positioning devices, clamping and other directions to achieve the effect that the coaxiality is easy to ensure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

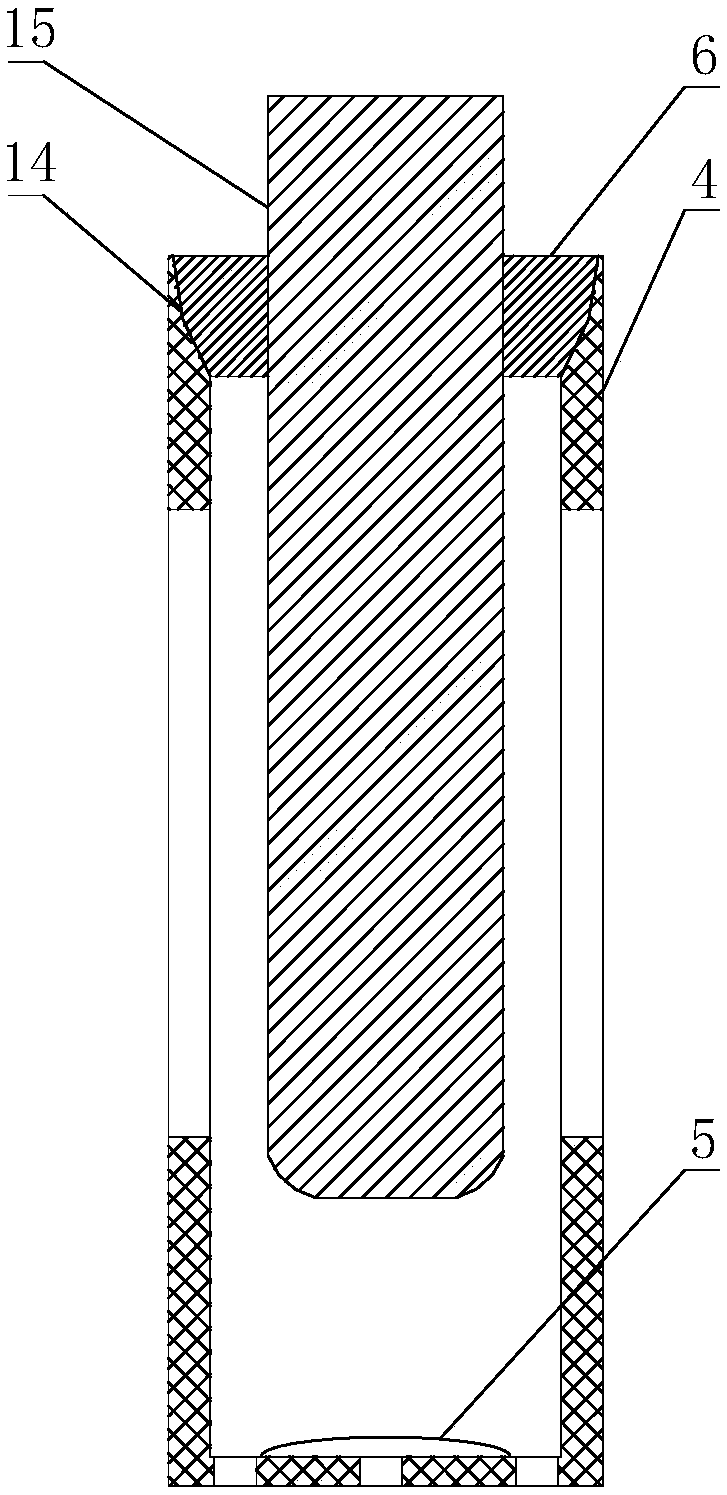

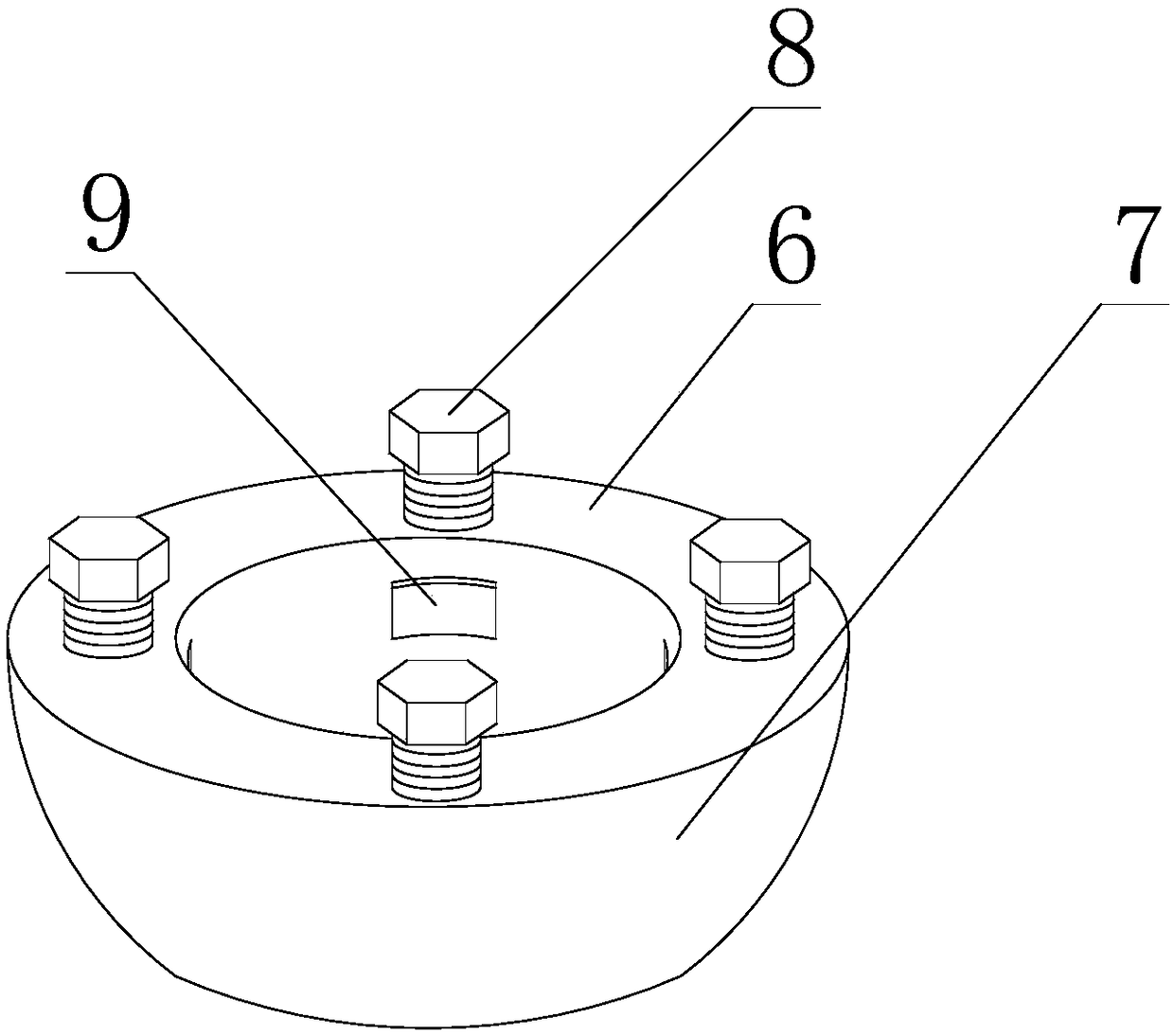

[0036] Such as Figure 1 to Figure 5 , a constraining device for engine shaft parts, including a hoop 6 for clamping shaft parts 15, said hoop 6 is provided with a through hole for clamping shaft parts 15, and one end of said hoop 6 The end face is flat, and a plurality of clamping devices are installed on the hoop 6, and the clamping devices are evenly distributed in a circle relative to the axis of the through hole. 6. The position on the axis of the shaft part 15 is fixed. The clamping device includes a pressure plate 9, a slider 10, an elastic piece 11 and a first bolt 8; part;

[0037] The hoop 6 is provided with a tunnel for installing a clamping device, and the tunnel is connected to the through hole on the hoop 6, and the slider 10 is partially located in the tunnel, and the slider 10 can move along the channel sliding;

[0038] The pressing plate 9 is fixed on one end of the slider 10 close to the through hole, one end of the elastic sheet 11 is fixed on the end of...

Embodiment 2

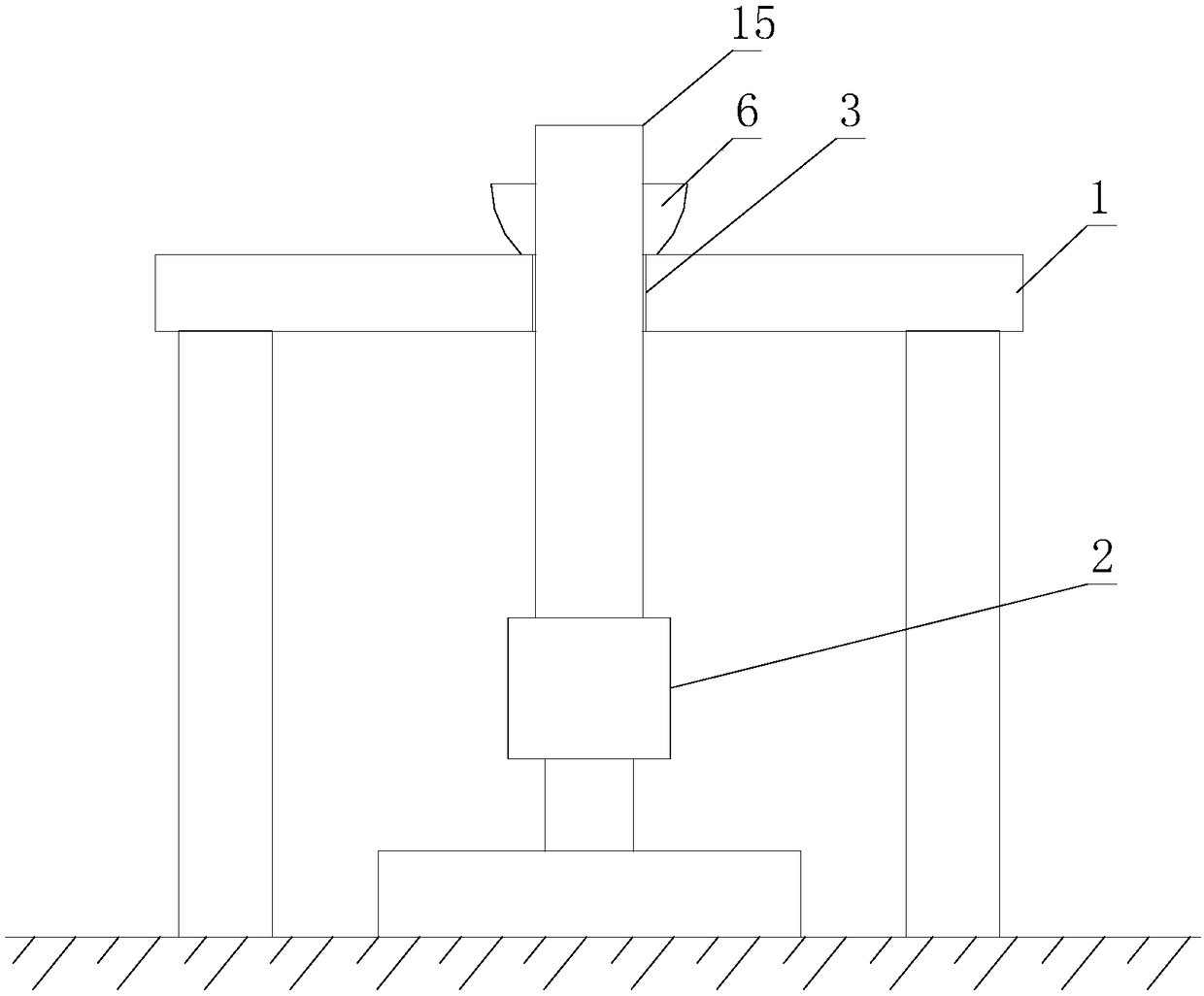

[0043] Such as Figure 1 to Figure 5 , this embodiment is further limited on the basis of Embodiment 1: as an integrated design, it also includes a workbench 1 for completing the connection between the hoop 6 and the shaft parts 15, and the upper surface of the workbench 1 is plane, the workbench 1 is also provided with a through-hole 3 passing through the upper and lower surfaces of the workbench 1, and the axis of the through-hole 3 is perpendicular to the upper surface of the workbench 1;

[0044] It also includes a jacking mechanism 2 arranged on the lower side of the workbench 1 and facing the through hole 3. The top of the jacking mechanism 2 is a supporting surface for supporting shaft parts 15. The height of the supporting surface is adjustable. When this solution is in use, it is set that the plane is installed as a horizontal plane, so that the shaft part 15 can be inserted into the through hole 3 from the upper end of the through hole 3 and the lower end is support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com