High-speed coupling lens

A coupling lens, high-speed technology, used in the coupling of optical waveguides, light guides, optics, etc., can solve the problems of high-precision lens concentricity, difficult to accurately guarantee lens concentricity, and difficult to high-quality coating. Difficulty, easy to process, the effect of reducing reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

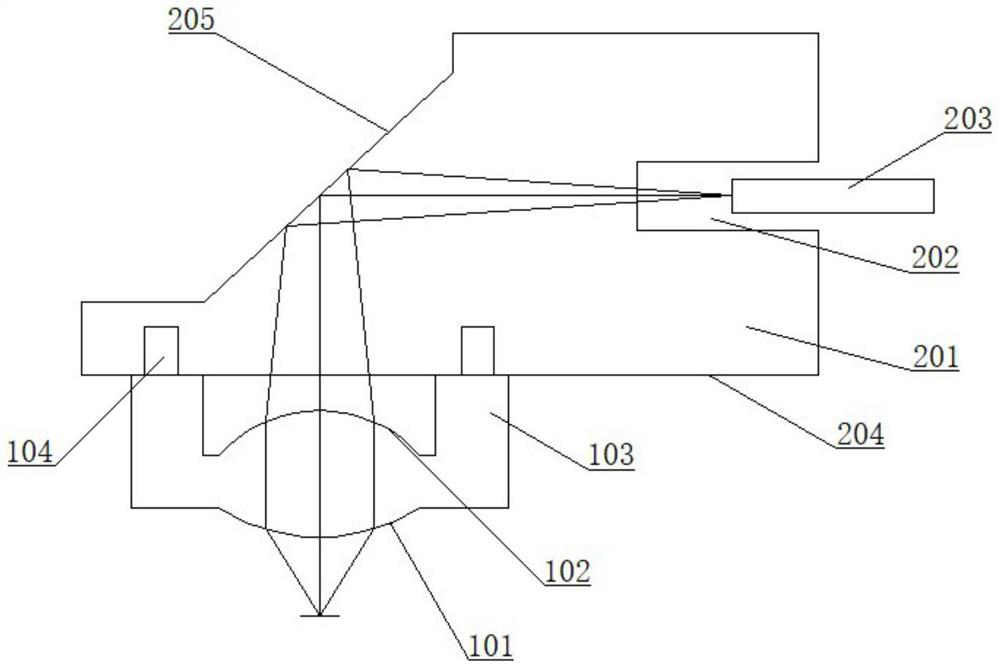

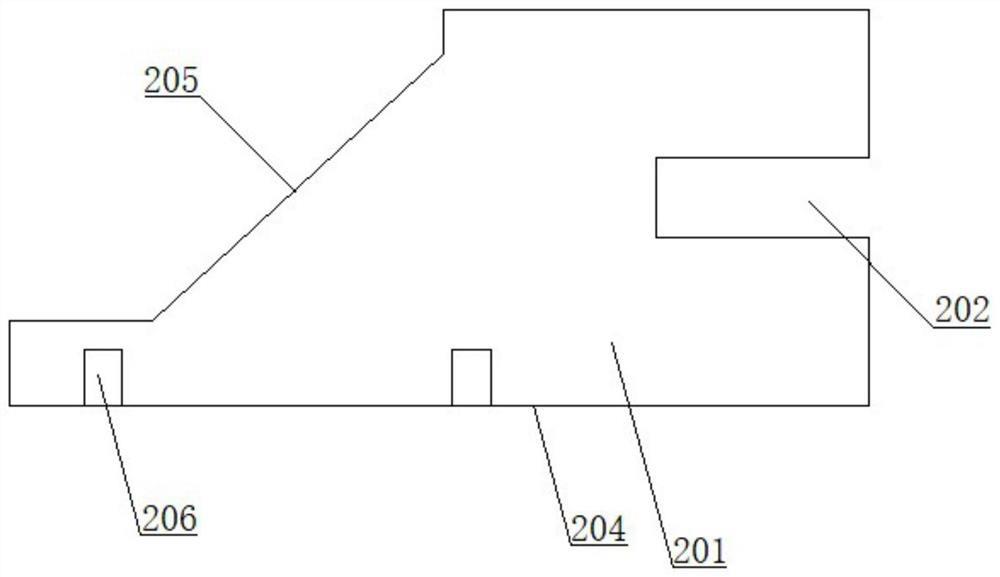

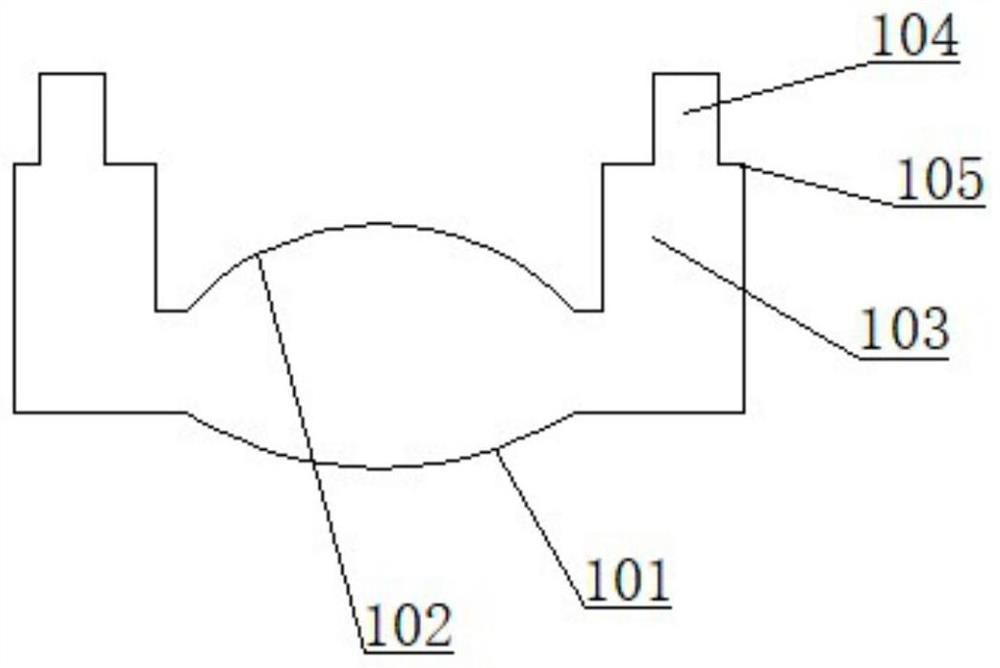

[0019] As shown in the figure, a high-speed coupling lens includes a reflective element 201, a lens, an optical fiber 203 and a light source, wherein the light source is a VCSEL light source, and the lens is provided with an aspheric surface 101 and an aspheric surface 2 102, an aspheric surface 101 and an aspheric surface The surface parameters of the second 102 can be made the same or different according to the needs of use. The lens is installed on one side of the reflective element 201, and the aspheric surface 101 and the aspheric surface 2 102 are all placed on one side of the reflective element, so that the concentricity of the two surfaces can be guaranteed when the lens is made. In addition, the two surfaces When testing or coating, it will not receive interference from other optical surfaces, and it is easy to realize coating and testing.

[0020] The reflective element 201 is provided with a reflective surface 205 corresponding to the first aspheric surface 101 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com