A vacuum three-position switch with quick grounding knife

A grounding knife, three-position technology, used in electrical switches, high-voltage/high-current switches, high-voltage air circuit breakers, etc., can solve the problems of high requirements for guide sleeves, potential safety hazards, complex structures, etc., and achieve low cost and structure. Simple, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Specific embodiments of the present invention are provided below in conjunction with the accompanying drawings.

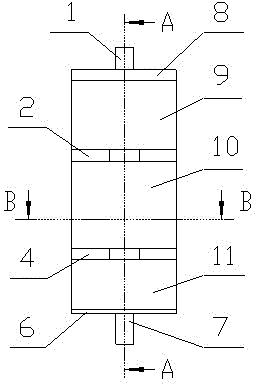

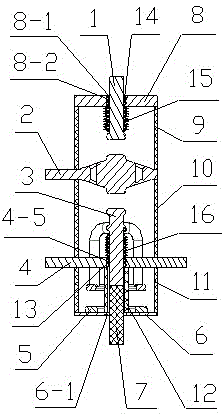

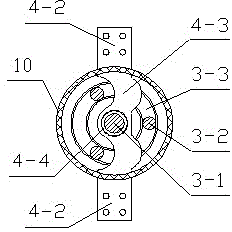

[0039] As shown in the drawings, the present invention includes an upper insulating cylinder 9, a middle insulating cylinder 10 and a lower insulating cylinder 11. An upper cover plate 8 is welded on the top of the upper insulating cylinder 9, and the center of the upper cover plate 8 is processed with a center of the upper cover plate. The hole 8-1 is used as the outlet of the fast grounding knife conductor 1; the fast grounding knife conductor 1 is installed in the center hole 8-1 of the upper cover plate, and the center hole of the upper cover plate is processed on the center hole 8-1 of the upper cover plate Groove 8-2, the second Basel spring 14 is installed at the groove 8-2 in the center hole of the upper cover plate, and the isolated conductor 2 is welded between the upper insulating cylinder 9 and the middle insulating cylinder 10, and the middle ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com