Throat pressure tapping nozzle and device using same

A throat and nozzle technology is applied in the field of throat pressure taking nozzles and devices using the nozzles, which can solve the problems of high processing difficulty, influence on flow measurement, influence on flow field, etc. Qualification rate, ensure the effect of coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solution of the present invention will be further described in detail in conjunction with the following drawings.

[0036] like Figure 7 As shown, a throat pressure-taking nozzle is used as a standard measuring instrument for measuring the flow rate of a steam turbine in a power plant, including a nozzle 81, a throat 82 and a rear expansion section 83, and the nozzle 81, the throat 82 and the rear expansion section 83 are integral structures; The throat 81 is provided with a pressure-taking hole 84, which is perpendicular to the axis of the nozzle 81, and the throat pressure-taking hole 84 is a straight hole for pressure-taking.

[0037] Further, a cylindrical surface is provided at the front of the nozzle 81, and the cylindrical surface is used as a positioning cylindrical surface.

[0038]Further, a support ring 85 is provided on the rear expansion section 83 .

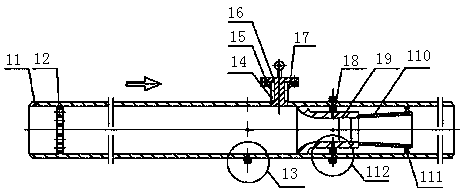

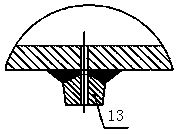

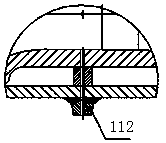

[0039] like Figure 8 , Figure 9 , Figure 10 As shown, a device using a throat press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com