High-efficiency milling and beveling machine for pipes

A beveling machine and pipe technology, applied in milling machine equipment, details of milling machine equipment, metal processing machinery parts, etc., can solve the problems of narrow pipe diameter and wall thickness range, difficult tool feed control, complex mechanical structure, etc. To achieve the effect of convenient control, low noise and less auxiliary time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

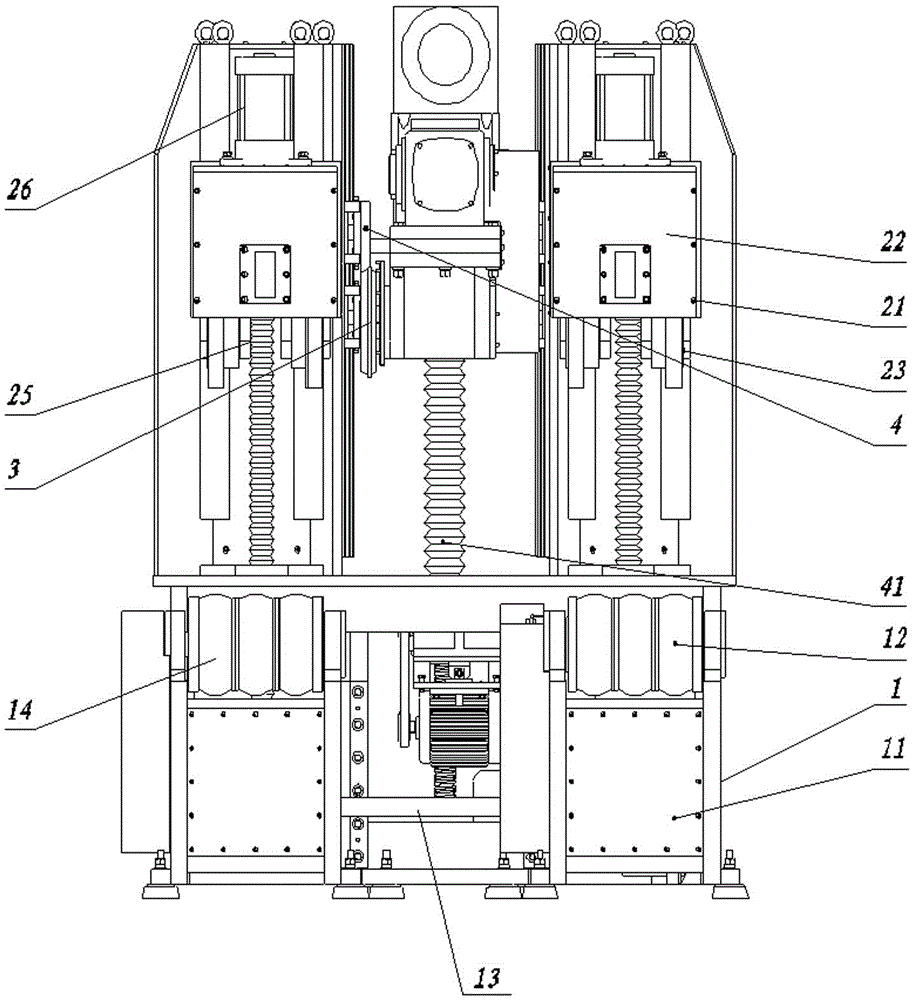

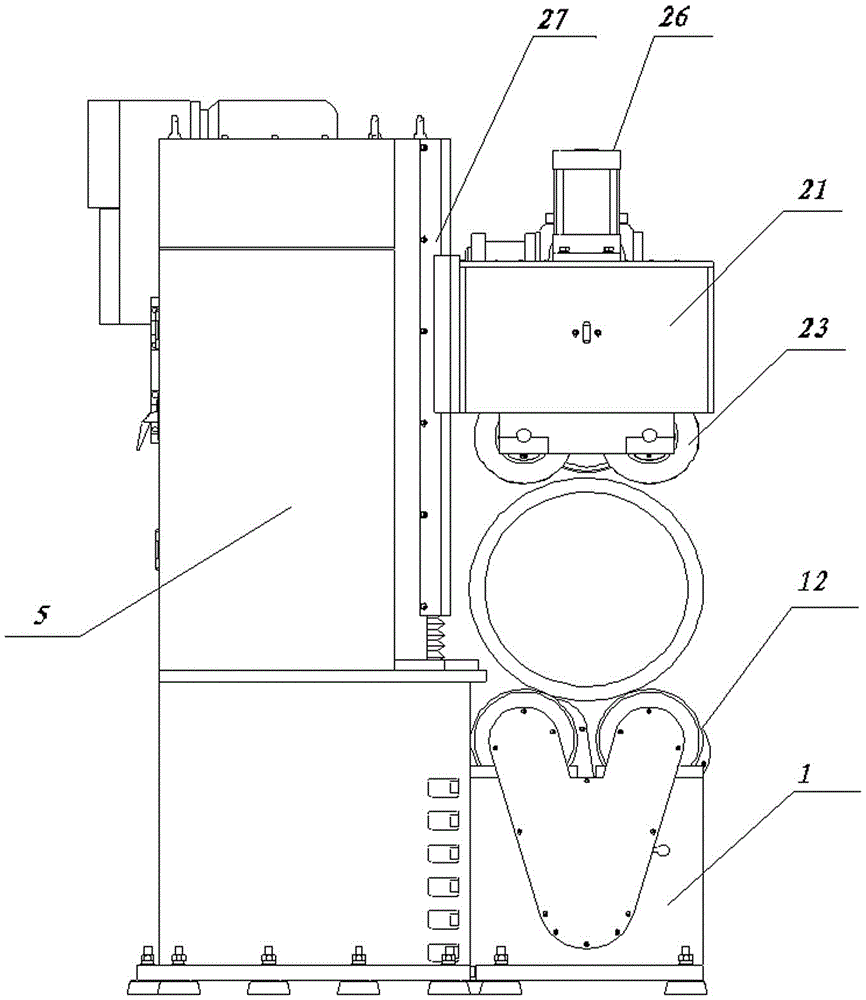

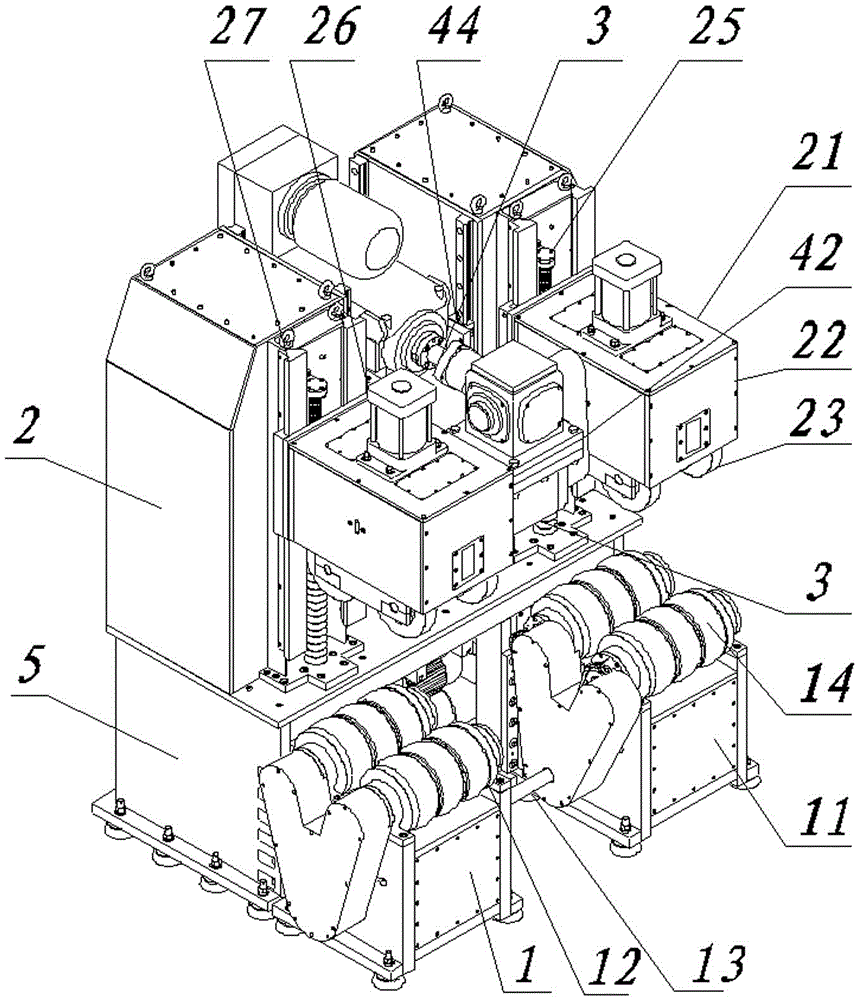

[0022] Such as Figure 1-Figure 3 As shown, the present invention includes a groove milling device 3, a tool lifting system 4, a pipeline delivery system, an electrical control system and a support platform 5; the support platform 5 is provided with a tool lifting system 4, a groove milling device 3, and the The groove milling device 3 is fixed on the tool lifting system 4, and the two ends of the support table 5 are also provided with a pipeline delivery system, and the groove milling device 3, the tool lifting system 4, and the pipeline delivery system are all electrically connected to the electrical control system , the present invention also includes a rotary drive system 1 and a pipeline compression system 2, the pipeline compression system 2 is located on both sides of the tool lifting system 4, the rotation drive system 1 is provided below the pipeline compression system 2, and the pipeline compression system 2 And the rotary drive system 1 is electrically connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com