Mounting and positioning device for repairing segmented long hinge of helicopter

A technology for installing positioning and positioning devices, applied in aircraft maintenance and other directions, can solve the problems of inability to guarantee hinge position requirements, inconvenient insertion of hinge strips, low repair accuracy, etc., and achieves easy repair and maintenance, no later maintenance, and universal strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

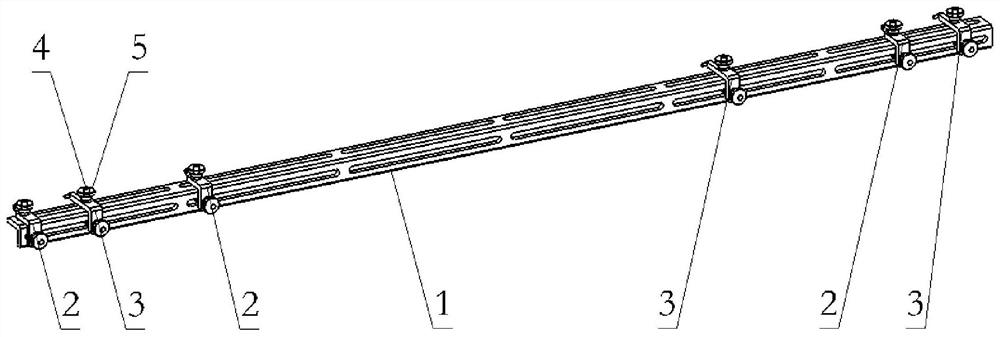

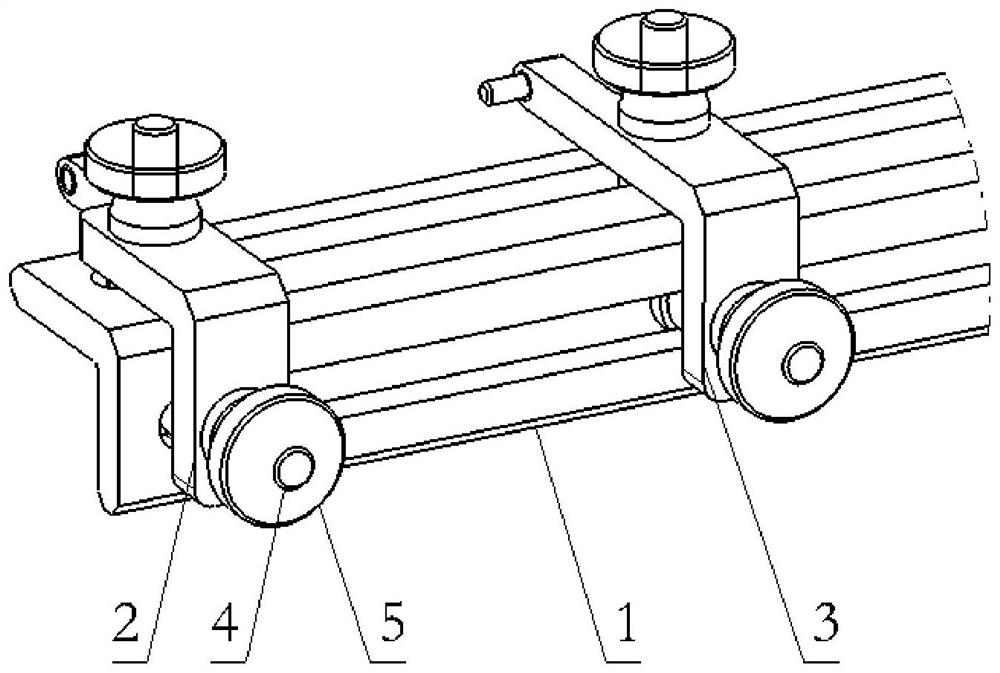

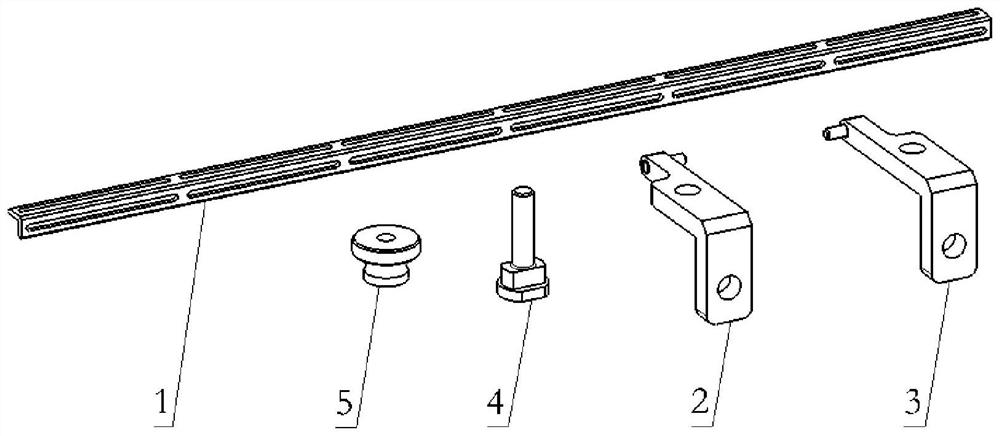

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings; the composition, structure and usage method of the helicopter hinge repair installation and positioning device of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0026] A helicopter hinge repair installation positioning device as attached figure 1 , attached figure 2 And attached image 3 As shown, the device mainly includes a positioning slide rail 1, a left positioning slide block 2, a right positioning slide block 3, a bolt 4 and a nut 5; the positioning slide rail 1 is used as the positioning main structure, and a plurality of left positioning slides used in pairs are installed on it. Slider 2 and right positioning slider 3, each positioning slider can locate a hinge tooth of the hinge; use the combination of left positioning slider 2 and right positioning slider 3 to realize the positioning of a hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com