Liquid observation mirror

A technology of sight glass and mirror body, which is applied in the field of sight glass, can solve the problems of complicated press-fitting process and high processing cost, and achieve the effects of controlling processing cost, simple structure, and improving assembly manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The core of the present invention is to provide a sight glass with an optimized structure. By improving the connection structure between the glass lens and the mirror body, the assembly process can be simplified and the assembly precision can be improved, thereby effectively controlling the processing cost of the product. The present embodiment will be described in detail below in conjunction with the accompanying drawings.

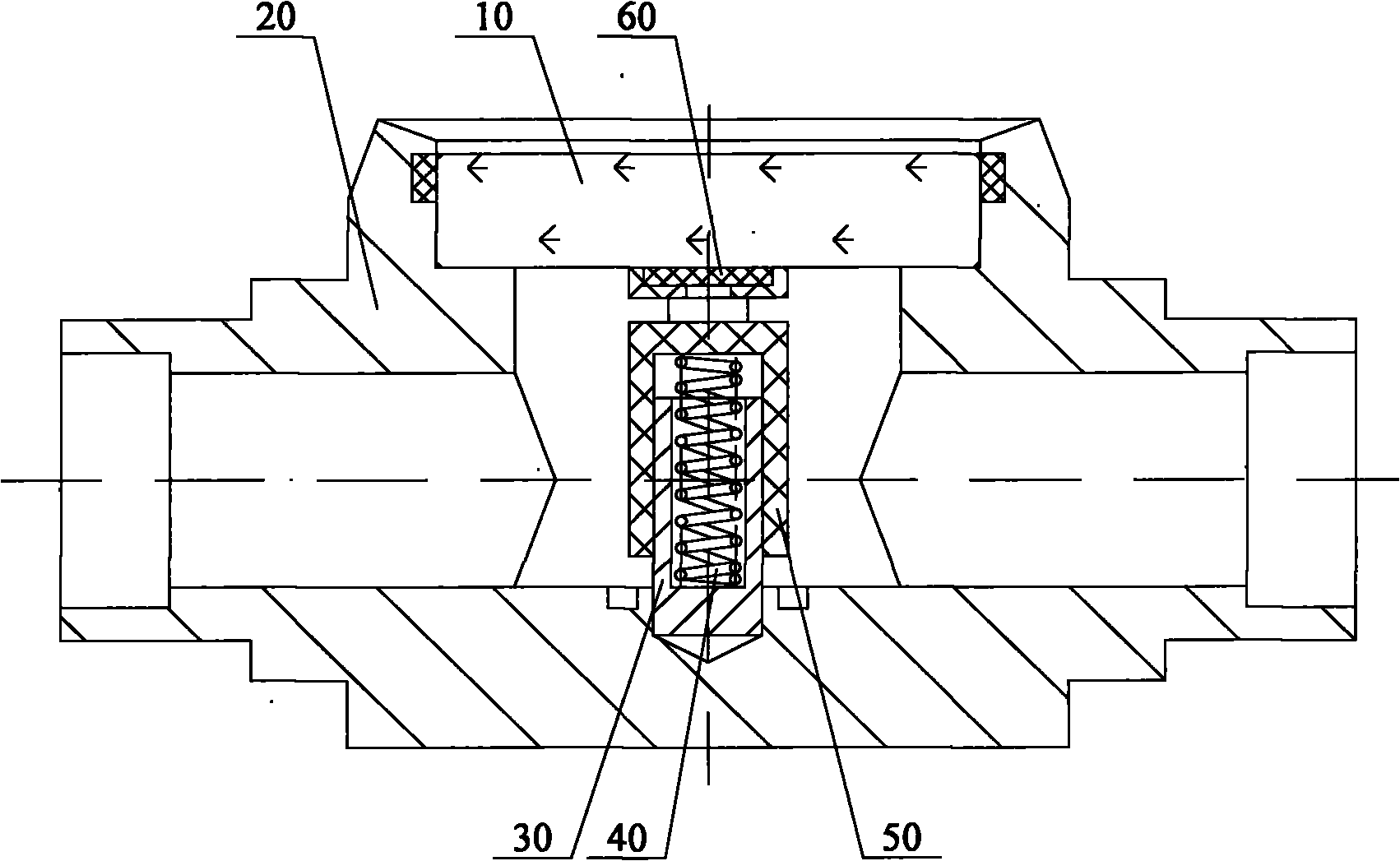

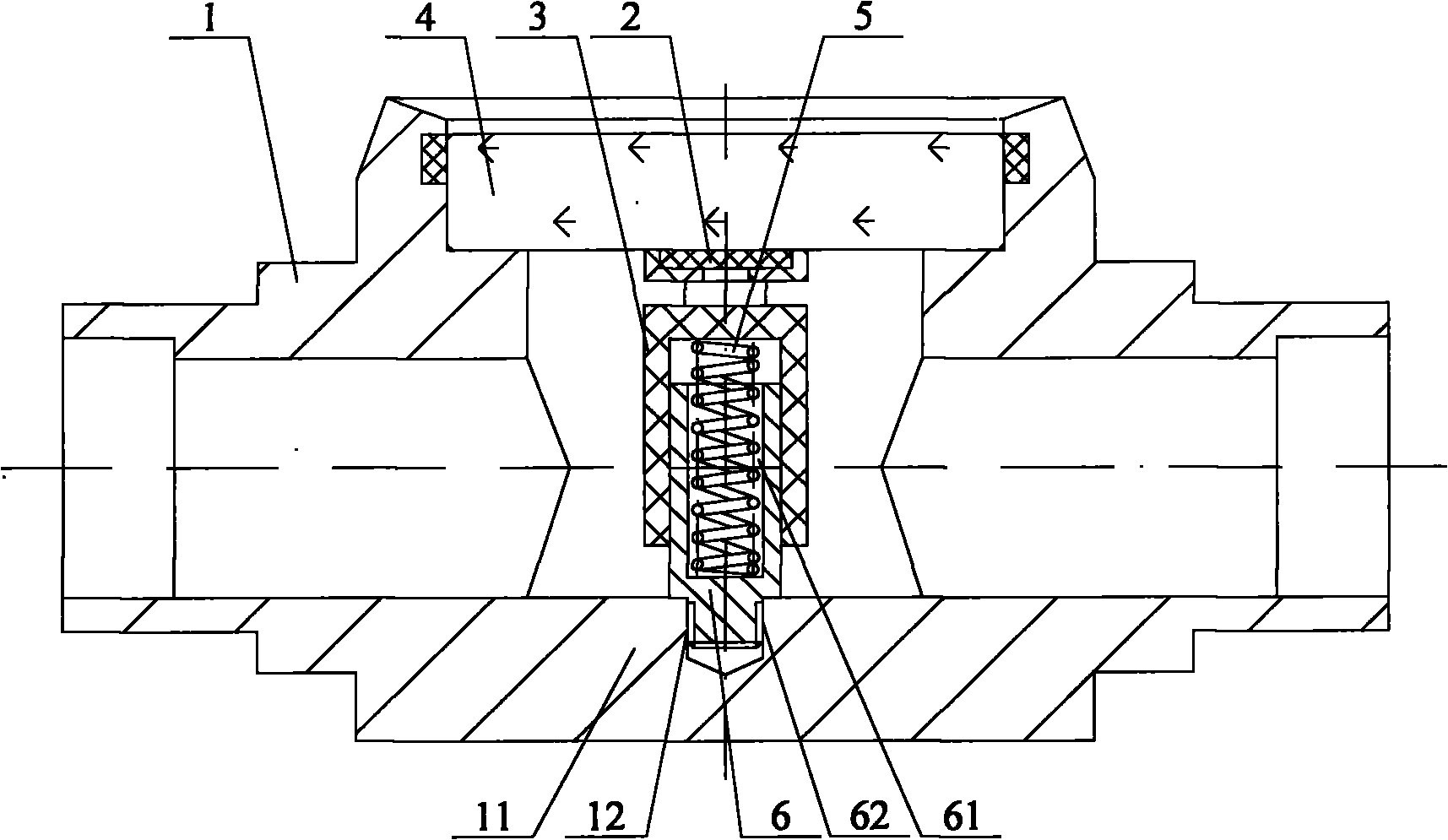

[0026] See figure 2 , which is a schematic diagram of the overall structure of a sight glass.

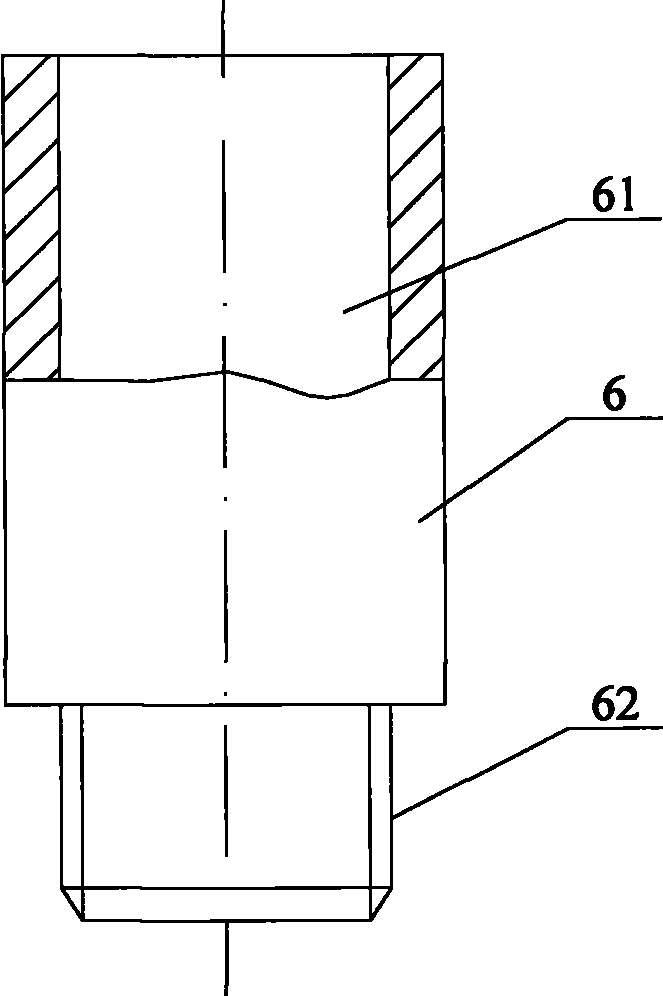

[0027] Such as figure 2 As shown, the sight glass mainly includes a mirror body 1, an indicator 2, an indicator holder 3 for installing the indicator 2, a glass lens 4, a spring 5, a mandrel 6 and other components.

[0028] The mirror body 1 has two interfaces communicating with its internal cavity, which are respectively communicated with the pipeline of the application system, so that the corresponding liquid enters its internal cavity; the indicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com