Clamp suitable for testing microhardness at different angles

A technology of microhardness and fixtures, which is applied in the direction of testing material hardness, measuring devices, strength characteristics, etc., can solve problems such as distortion of measured hardness values, increased measurement errors, troublesome sample production, etc., to achieve large clamping force and reduce Effects of Experimental Error, Guaranteed Accuracy, and Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following are preferred embodiments of the present invention. It should be pointed out that for those skilled in the art, without departing from the principle of the present invention, some improvements and modifications can also be made, and these improvements and modifications are also considered as the present invention. protection scope of the invention.

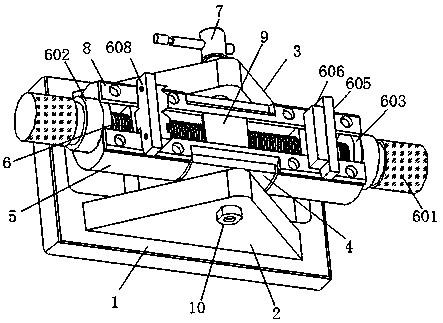

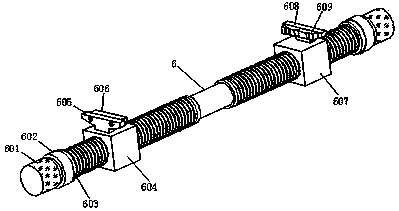

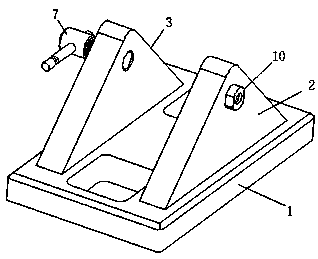

[0028] The invention provides a fixture suitable for microhardness testing at different angles, such as Figure 1-11 As shown, the fixture includes a base 1, and a first support platform 2 and a second support platform 3 are respectively installed on the top of the base 1 at the two sides, and the first support platform 2 and the second support platform 3 An arc sleeve 4 is arranged between them, and an arc clamp seat 5 is arranged inside the sleeve 4, and a driving screw 6 is arranged inside the clamp seat 5; the first support platform 2, the second support platform The table 3 , the sleeve 4 and the clamp s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com