Automatic arc forming equipment for pipe fittings and arc forming method thereof

A pipe fitting and arc forming technology, which is used in metal processing equipment, grinding/polishing equipment, grinding drive devices, etc. Effect of Arc Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

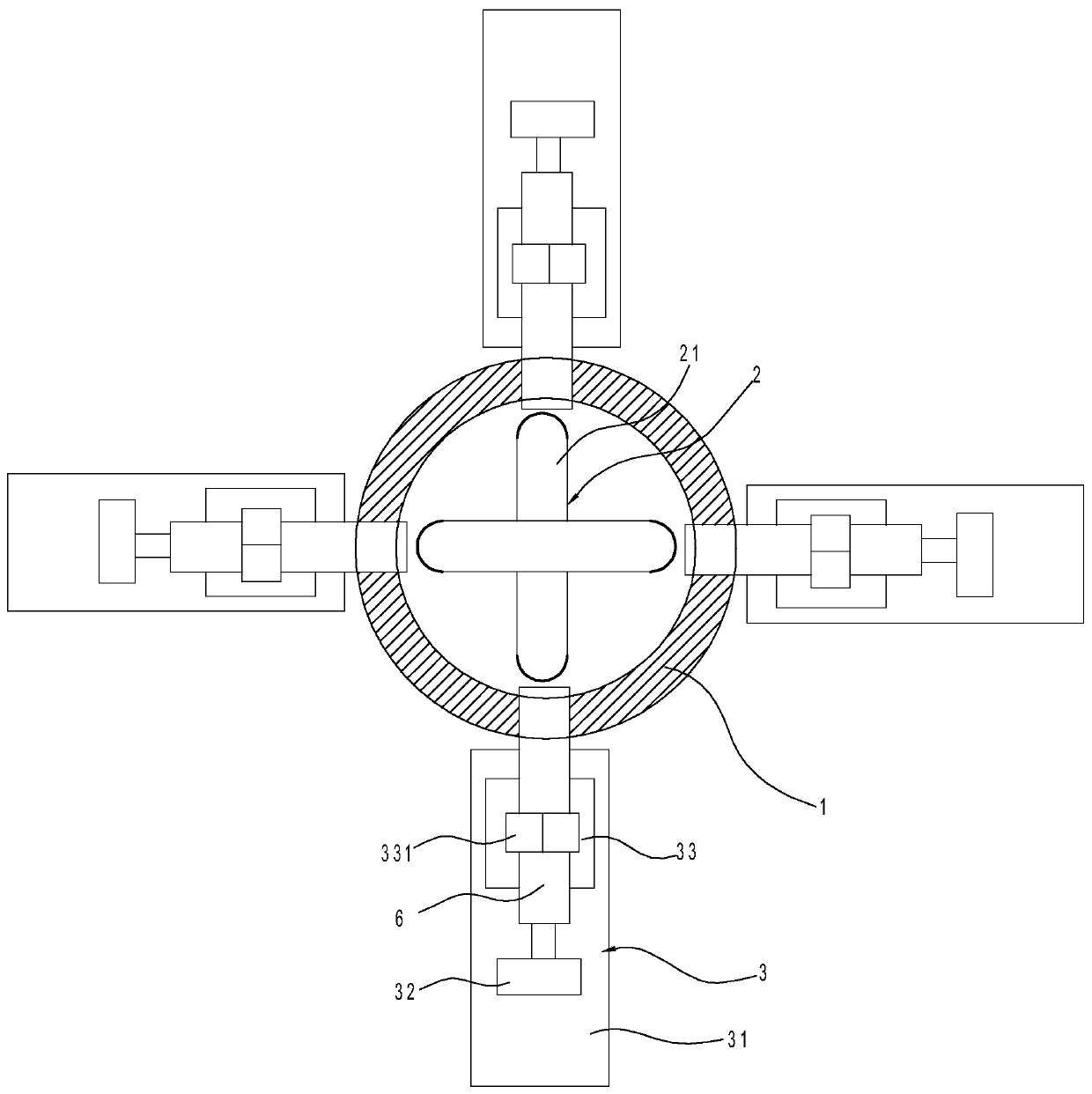

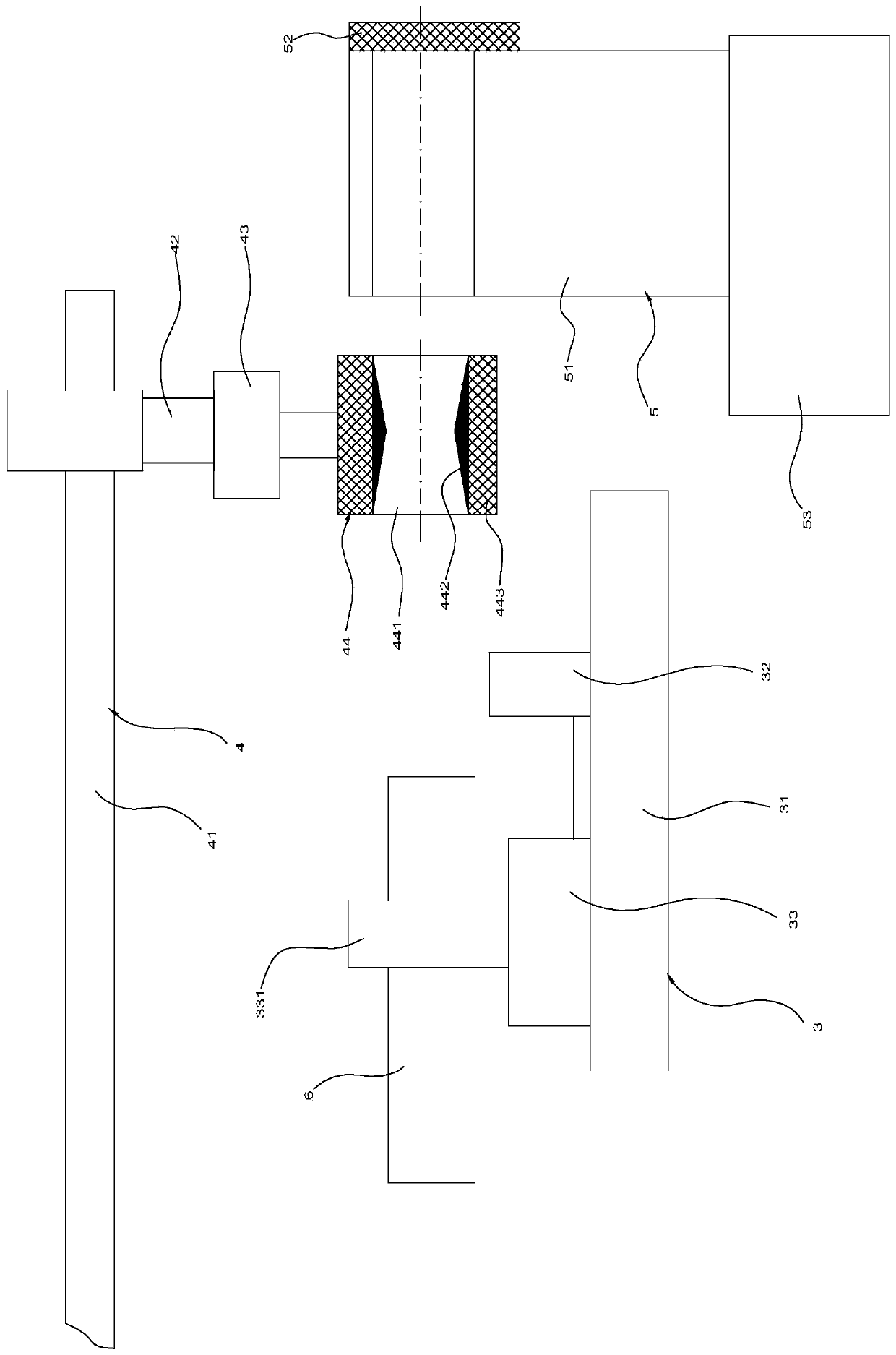

[0022] Such as Figures 1 to 3 As shown, the automatic arc forming equipment for pipe fittings in this implementation includes a fixed ring 1 and a plurality of arc forming mechanisms.

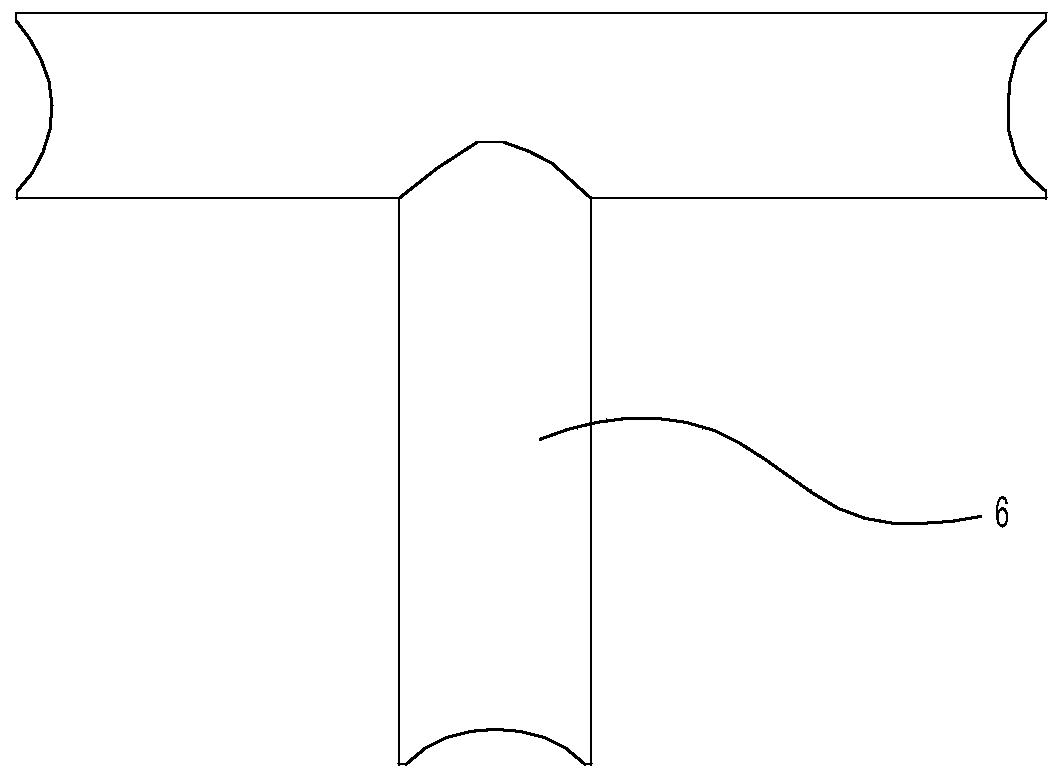

[0023] Wherein, a plurality of arc-forming mechanisms are arranged circumferentially outside the fixed ring 1, and corresponding to each arc-forming mechanism on the fixed ring 1, there is a limit hole for the end of the pipe fitting 6 to pass through. The arc grinding head 2, the arc grinding head 2 includes two staggered turning bars 21, the width of the turning bars 21 is smaller than the diameter of the pipe fitting 6, and the two ends of each turning bar 21 form a radian after arcing with the pipe fitting 6 For the matching arc surface, a grinding layer is formed on the surface of the arc surface. Further, the structure of the grinding layer is that an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com