An arc bending machine used for arc bending and forming of door frame flat iron

A flat iron and arc bending technology is applied in the field of door frame production and processing equipment, which can solve the problems of increased flat iron production and processing costs, affecting the production efficiency of manufacturers, unable to guarantee the production quality of flat iron, etc., so as to improve the flat iron bending and arc forming. Efficiency, improving the efficiency of bending arc forming, the effect of good versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with specific embodiments:

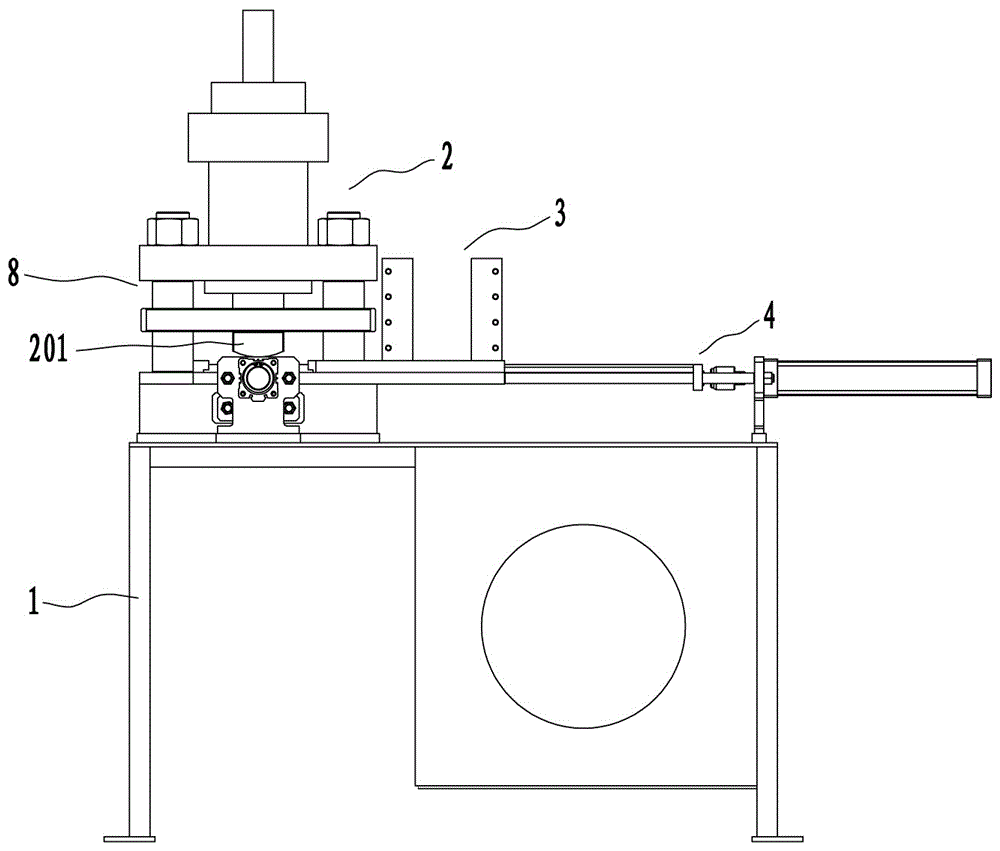

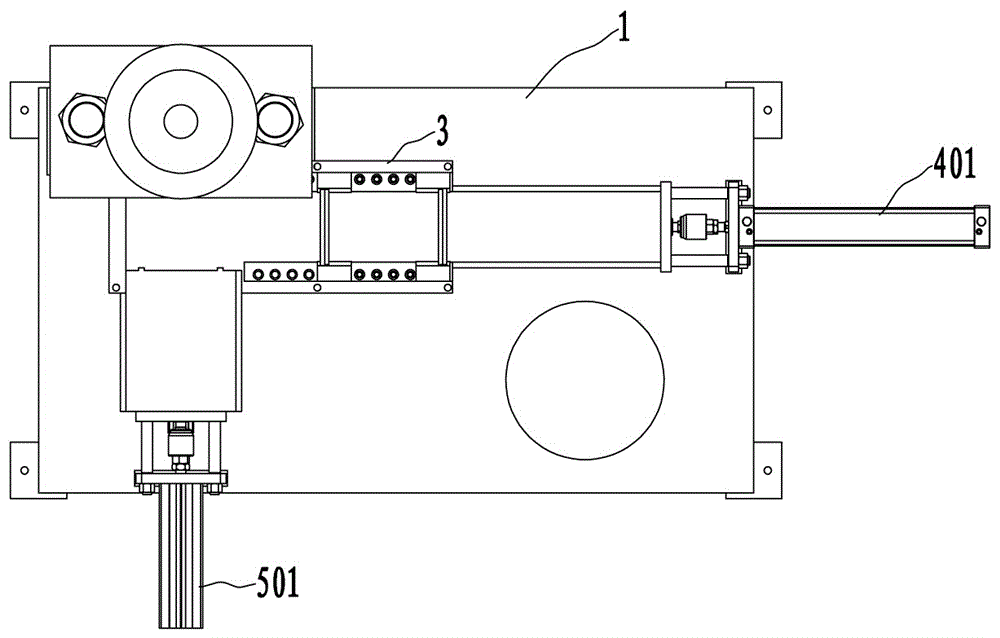

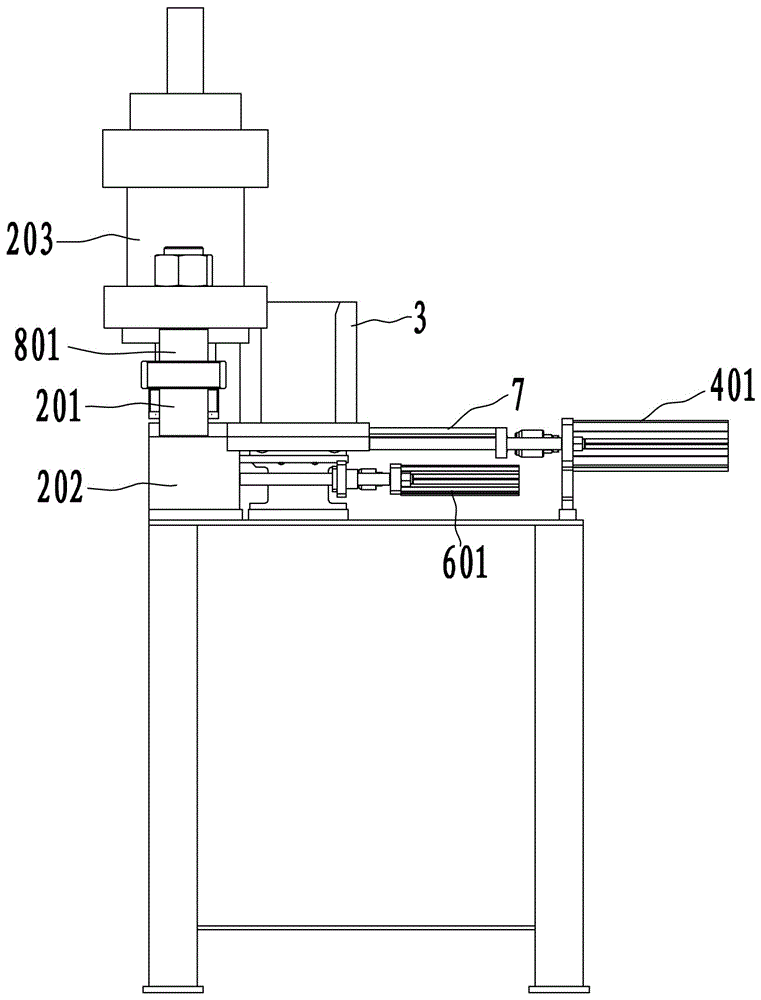

[0017] See attached figure 1 Attached Figure 4 As shown, the arc bending machine used for bending and forming door frame flat iron according to this embodiment includes a frame 1, a pusher assembly 4 arranged in sequence along the longitudinal direction of the frame 1, and The silo 3 for storing flat irons and the flat iron bending assembly 2, wherein the pushing assembly 4 is used to push the flat irons in the silo 3 into the flat iron bending assembly 2 for arc forming. At the same time, a side adjacent to the flat iron bending assembly 2 is also provided with a feeding assembly 5 for feeding the flat iron pushed out of the silo 3 into the flat iron bending assembly 4 by the pushing assembly 4. In addition, this solution also includes a discharging assembly 6 for pushing out the flat iron after the arc forming in the flat iron bending assembly 2.

[0018] In order to furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com