A three-dimensional rapid lead arc forming method and device

A lead, three-dimensional technology, applied in the field of three-dimensional fast lead arc forming methods and devices, can solve the problems of low production efficiency, waste of time, and decrease in chip yield, so as to improve efficiency, simplify complex motion, and avoid lead damage and breakage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

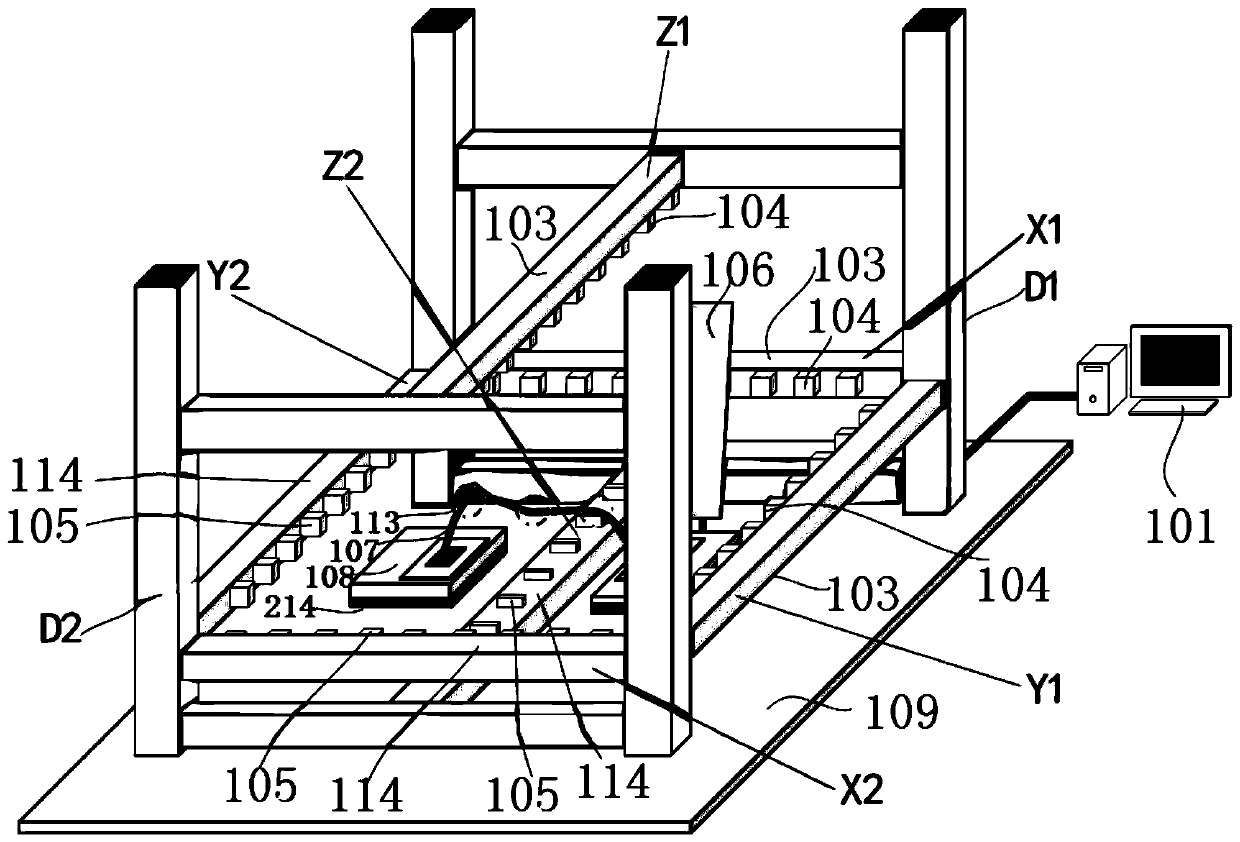

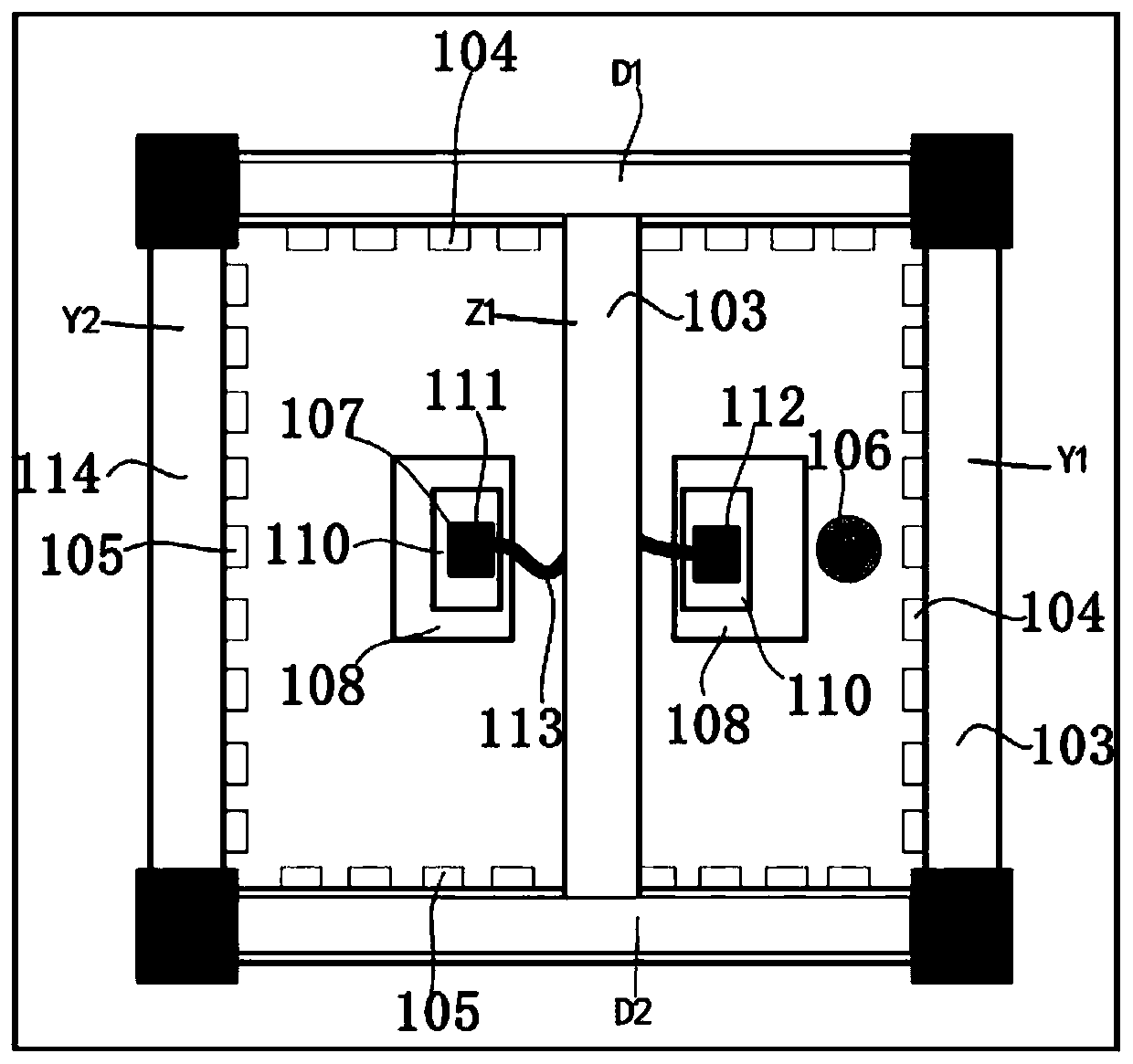

[0035] A three-dimensional rapid lead arc forming method, such as Figure 1-3 shown, including the following steps:

[0036] Step S1: After forming the first solder joint on the first pad 111, the free end of the lead wire 107 is fixed by the rivet 106, and the ultrasonic sounding unit 103 emits ultrasonic waves through the radiating end 104 of the ultrasonic transducer, and at the radiating end 104 of the ultrasonic transducer A sound pressure node is formed in the resonant space between the reflecting unit 105;

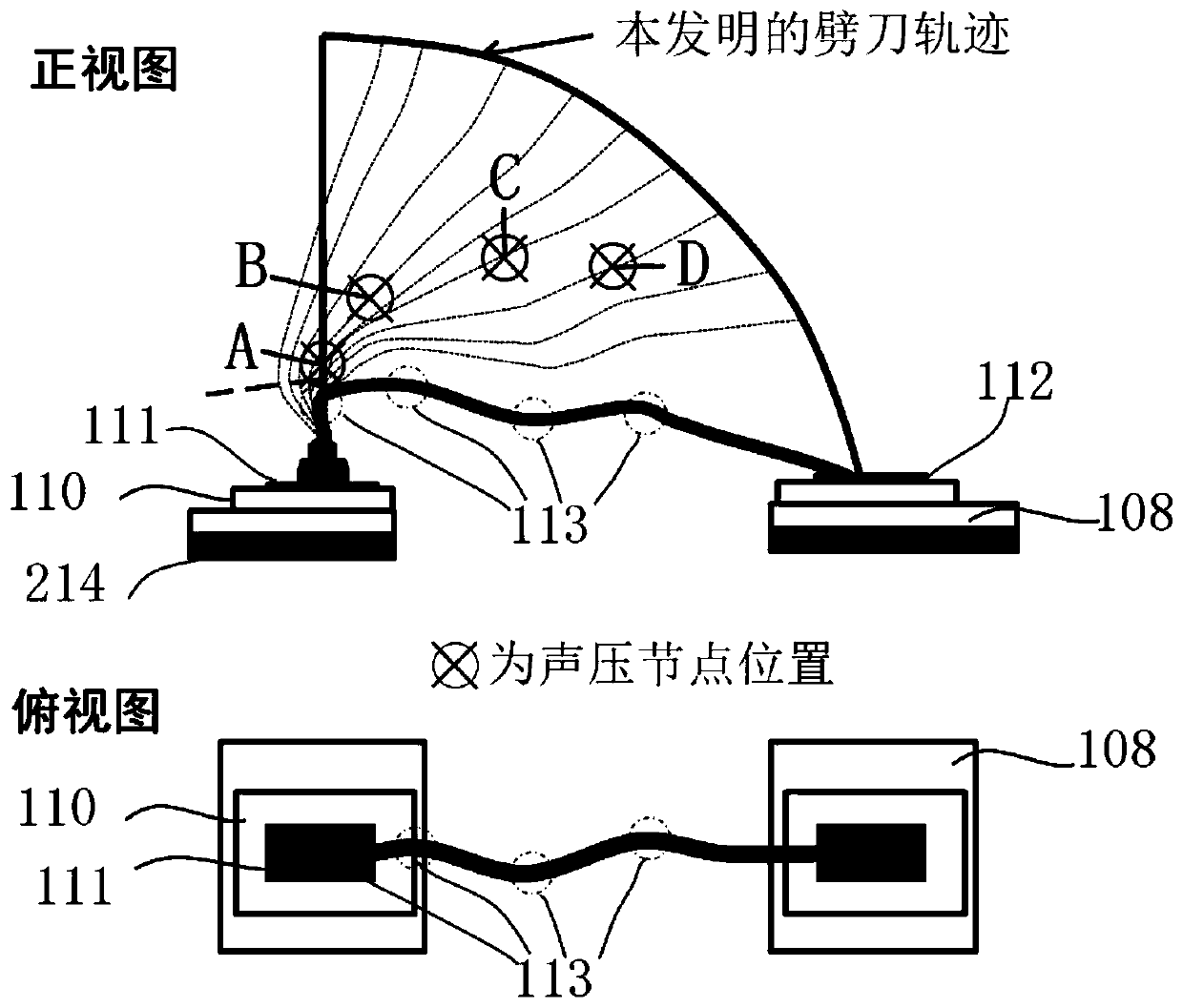

[0037] Step S2: During the movement of the hacker 106 according to the pre-designed three-dimensional trajectory of the computer program, use the spatial fine-tuning of the radiation end 104 of the ultrasonic transducer and the corresponding reflection unit 105 in the space to make the sound pressure node in the resonance space at Move freely within a certain range, and use the sound field radiation force at the sound pressure node to bend the lead 107, thereby pre...

Embodiment 2

[0054] Such as Figure 4-6 As shown, the device can also realize two-dimensional lead arcing, and the steps are:

[0055] Step S21: After forming the first solder joint on the first pad 111, the ultrasonic sounding unit 103 emits ultrasonic waves through the ultrasonic transducer radiating end 104, in the resonance space between the ultrasonic transducer radiating end 104 and the reflecting unit 105 A sound pressure node is formed.

[0056] Step S22: During the rising process of the chopper 106, use the spatial fine-tuning of the radiation end 104 of the ultrasonic transducer located in the space and the corresponding reflection unit 105 to make the sound pressure node in the resonance space move freely within a certain range, and use the sound pressure The radiation force of the sound field at the node bends the lead 107 , thereby precisely controlling the location and angle of the inflection point 113 on the lead 107 .

[0057] Step S23: before the rivet 106 rises to the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com