Additional device with A and B-axis oscillating structure and manufacturing method thereof

A technology of additional devices and shaft structures, applied in the directions of drive devices, manufacturing tools, metal processing, etc., can solve problems such as delays in equipment procurement, lack of procurement, and impacts on scientific research and production tasks of aircraft manufacturers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

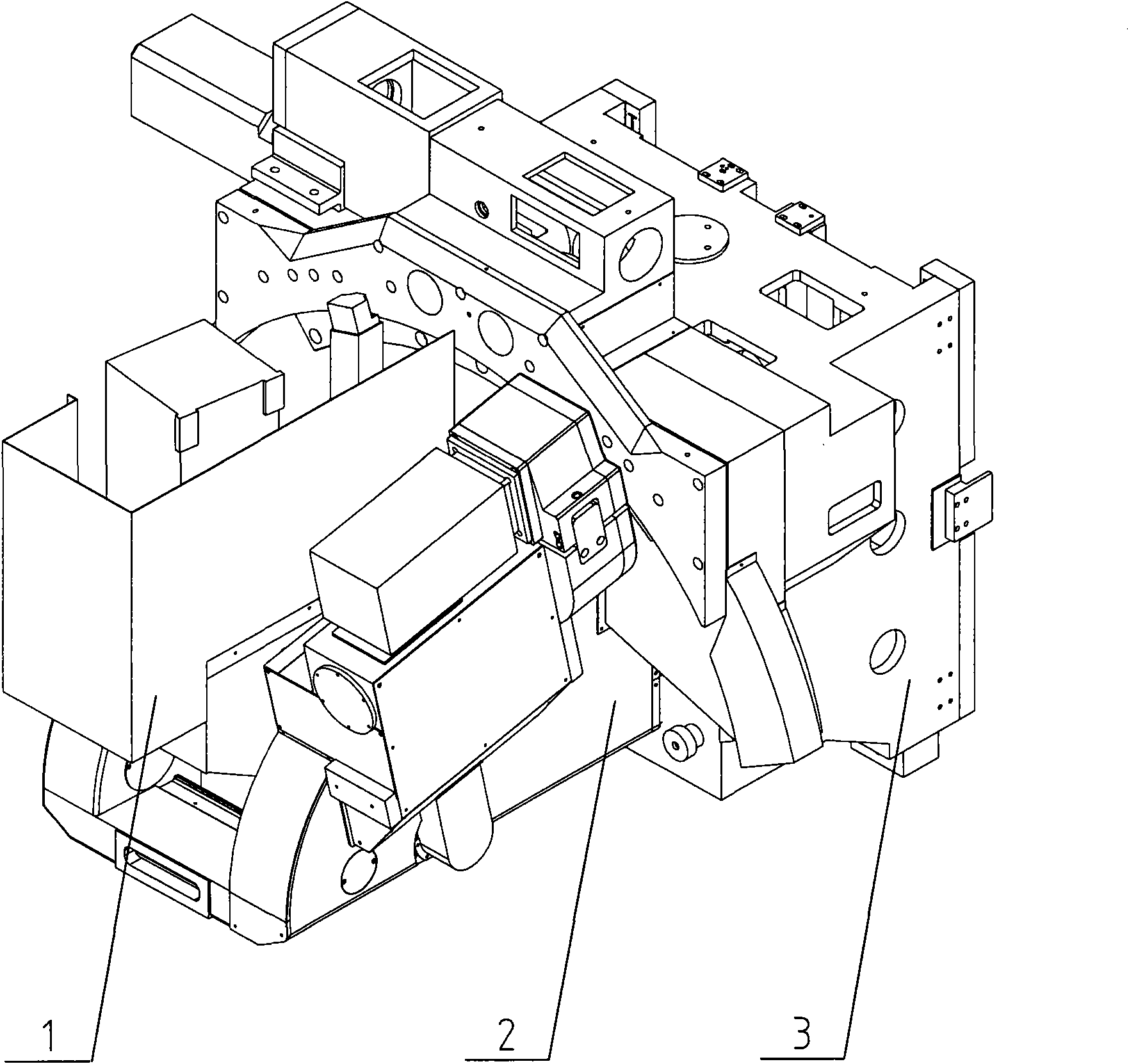

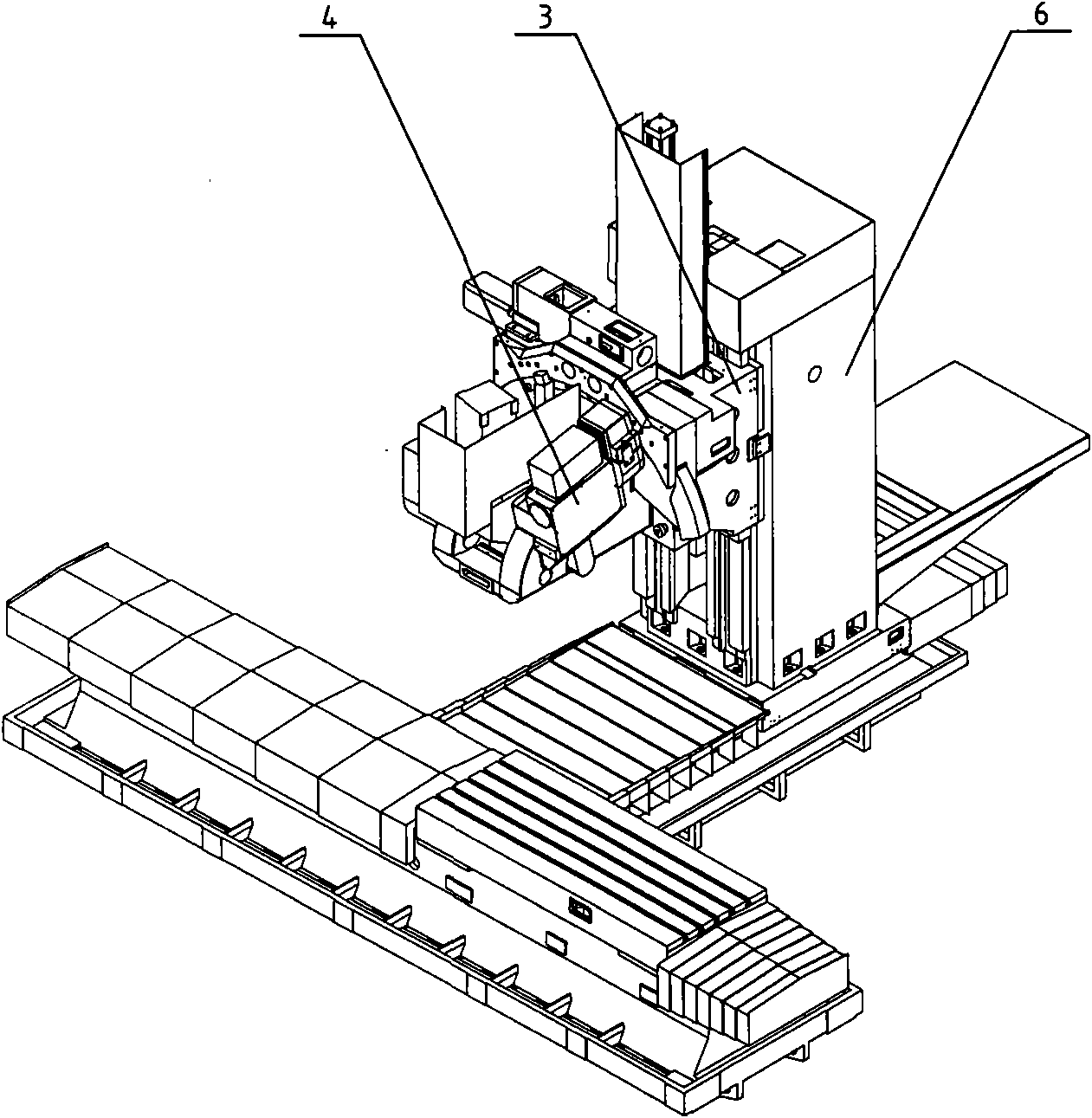

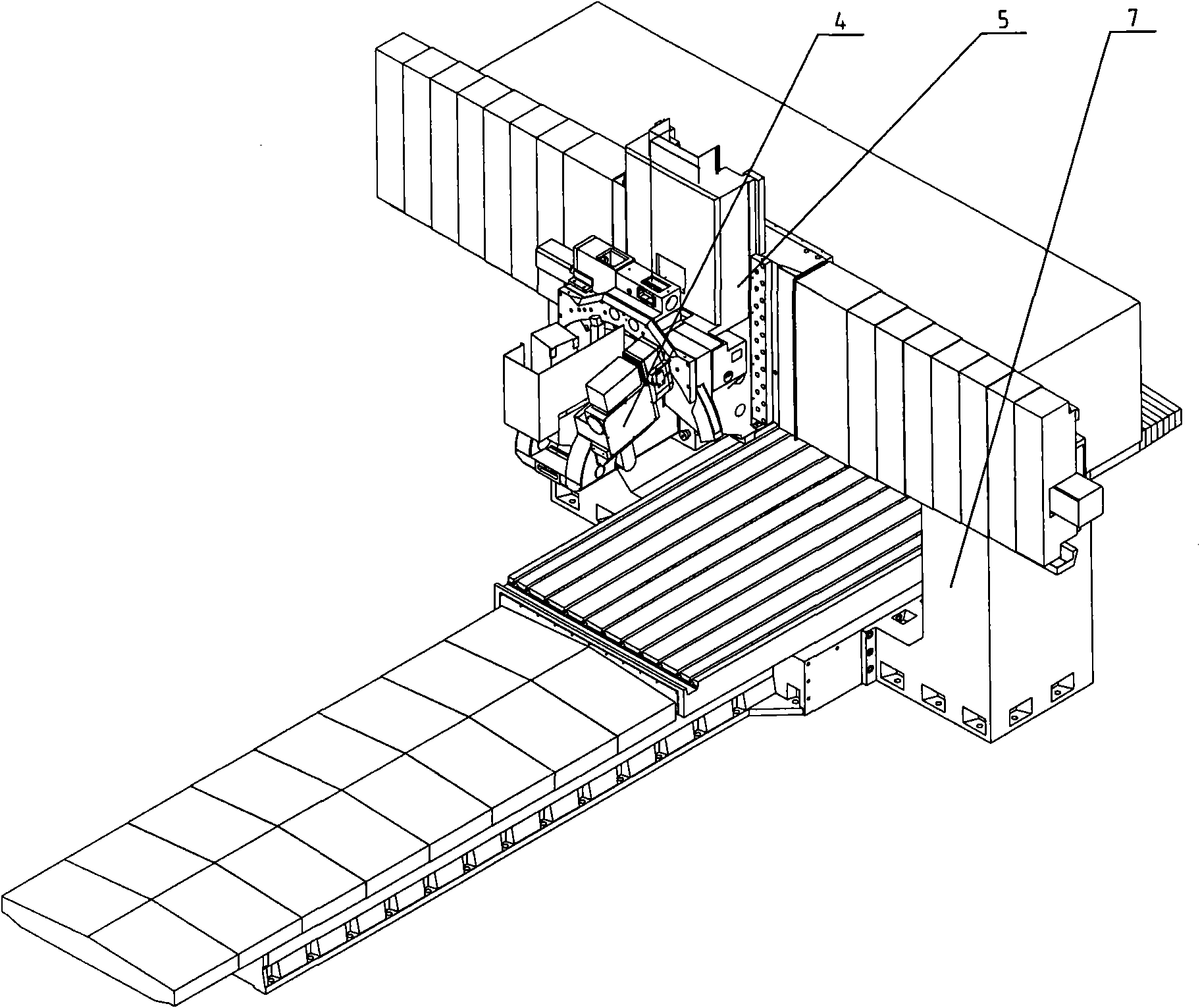

[0018] A, B-axis swing head structure additional device, see figure 1 , including A-axis structure, B-axis structure, spindle box and slide plate, installed on a three-axis CNC machine tool, can be used to install on a vertical CNC machine tool or a gantry CNC machine tool to realize vertical five-axis machining center or gantry five-axis machining The central machine tool is characterized in that the B-axis structure is fixed on the upper side of the slide plate 3, the B-axis large ring gear 25 is fixed to the B-axis support 2, and the swing shaft 34 is fixed on the slide plate 3 by screws. The B-axis bracket 2 rotates around the swing shaft 34 as a B-axis. The A-axis structure is fixed on the right side of the B-axis bracket, the A-axis large ring gear 45 is fixed to the headstock 1, the headstock 1 is fixed between the two arms of the B-axis bracket 2, and the left rotary shaft 50 and the right rotary shaft 52 are respectively Axially fixed on the headstock 1 horizontally....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com