Self-lubricating mower blade and method for manufacturing same

A manufacturing method and cutting tool technology, applied in the field of mechanical parts manufacturing, can solve problems such as unsatisfactory lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

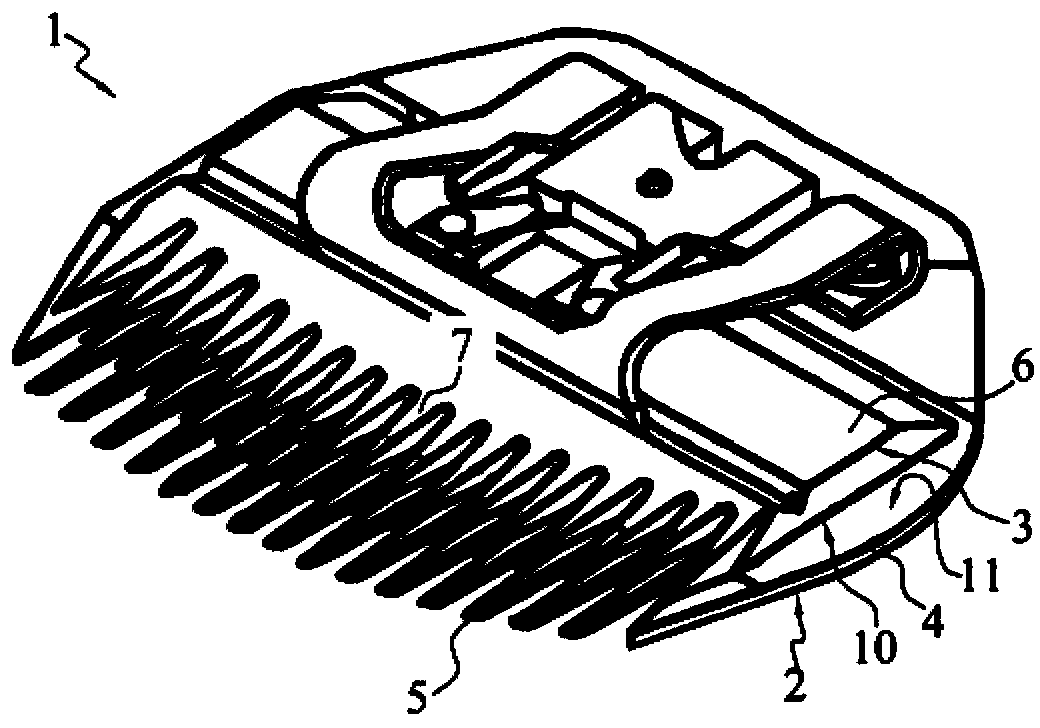

[0102] Such as figure 1 As shown, a cutting module 1 for a hair or hair electric clipper generally includes two knives 2 and 3, which are controlled by an unillustrated and skilled person in an alternating translational movement relative to each other. Well-known mechanism drives. Often the lower cutter 2 is fixed relative to the base of the clipper, while the upper cutter 3 is movable relative to the lower cutter 2 .

[0103] The stationary knife 2 comprises a main body 4 from which extends a set of teeth or blades 5 each having a generally triangular shape, such as figure 1 shown. Likewise, the movable knife 3 comprises a body 6 carrying a set of teeth 7 each also of generally triangular shape. Unlike the blades 5 of the stationary knife 2 , the teeth 7 of the movable knife 3 according to the example each have two sharp edges which form the sides of a corresponding triangle. Of course, the teeth 5 of the stationary knife 2 can also have sharp edges.

[0104] The tooth 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com