Dried seaweed packaging compressor

A compressor and kelp technology, applied in presses, manufacturing tools, etc., can solve the problems that dry kelp cannot be sealed and packaged, the labor is heavy, and the number of finished products is small

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Prepare all components, use modern mechanical manufacturing tools, and use technical means to create a "dried product kelp packaging compressor".

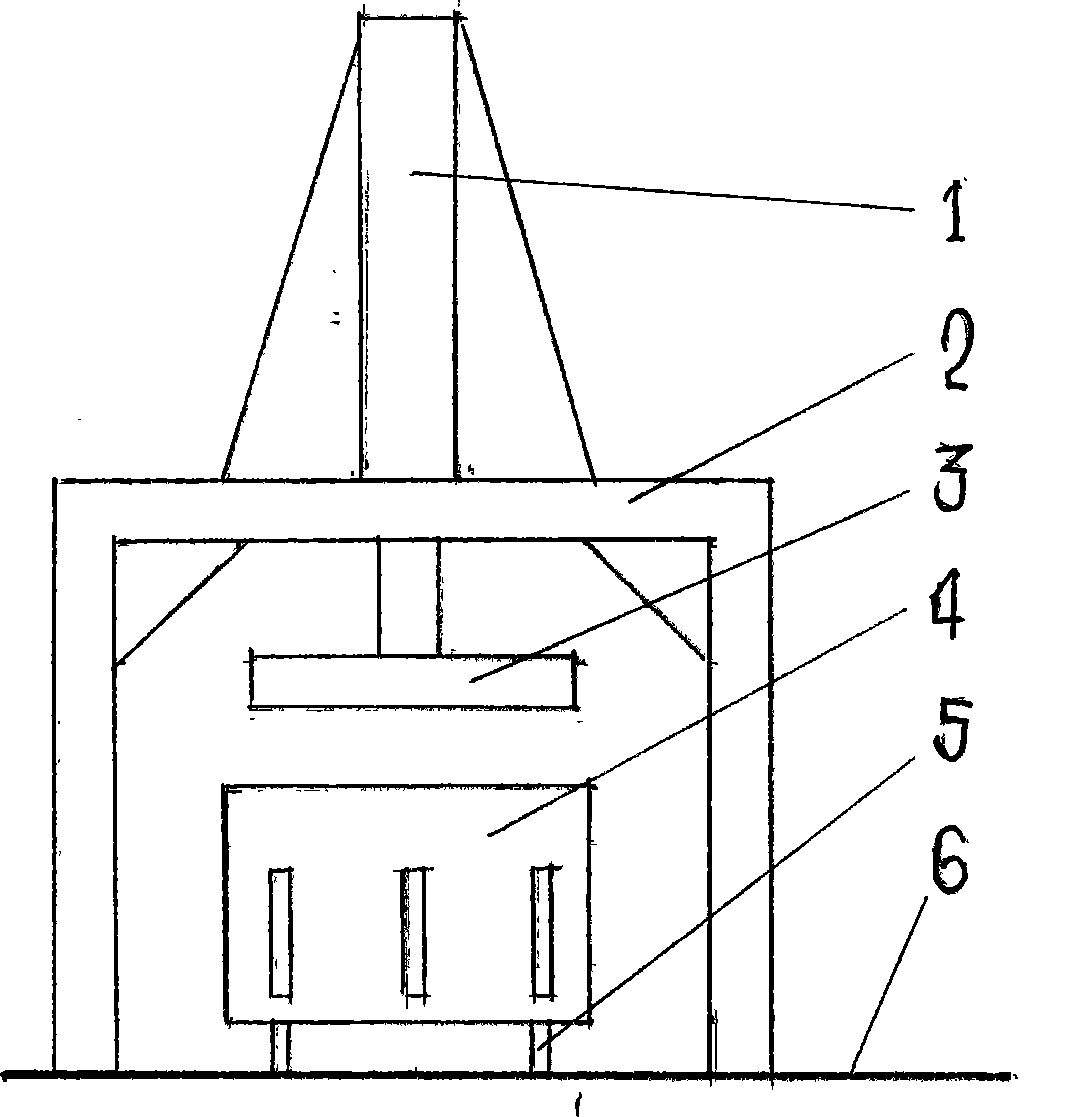

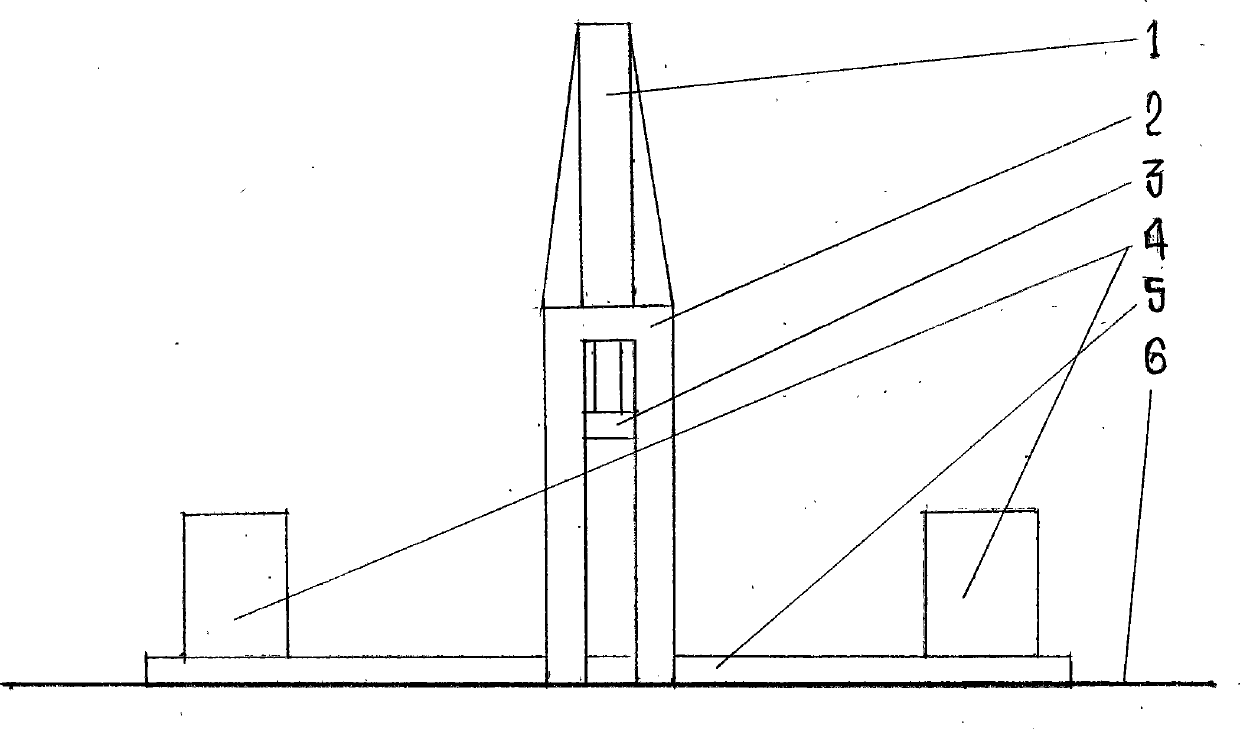

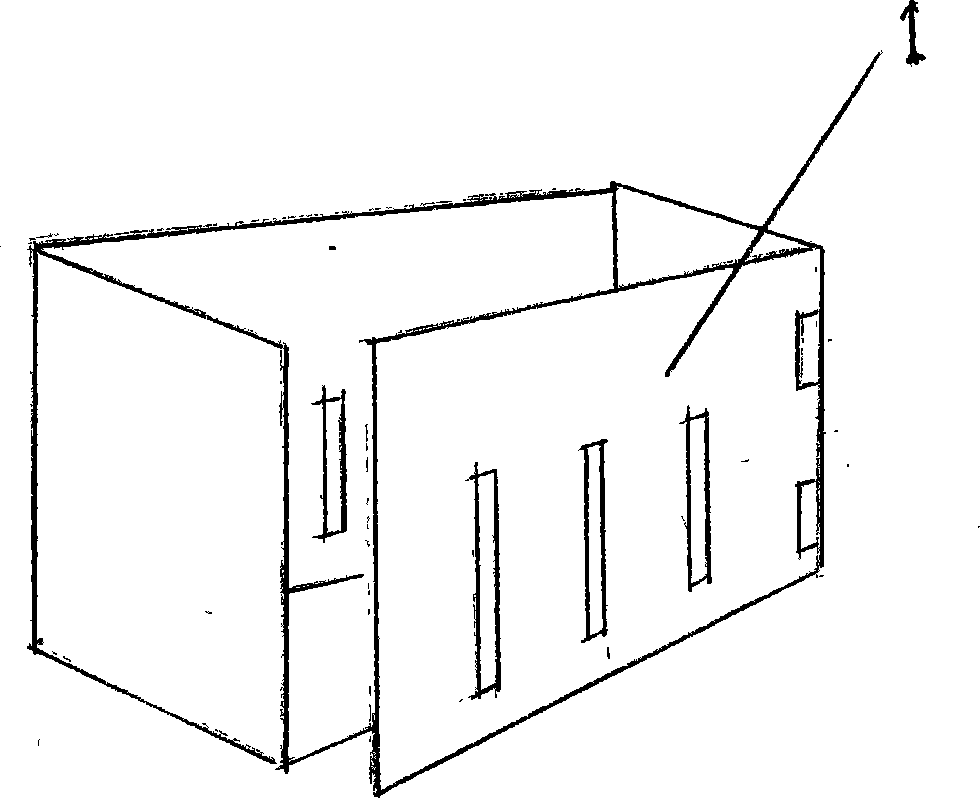

[0050] 1. Manufacture of the steel frame: the first step is to manufacture the workbench first, and select steel pipes with a diameter of less than 200mm, or channel iron with a width of less than 200mm and a thickness of less than 20mm, and choose one of the above materials. Using a cutting machine, cut into 4 pieces each with a length of 1000mm and 800mm; 5 pieces with a length of 500mm, and weld them into Figure 11 shape. Then cut into 4 pieces of 600mm long and 2 pieces of 1000mm, and weld them into Figure 12 shape, and weld a hollow pressed iron plate at the top center position, Figure 12 1, in order to install the hydraulic cylinder.

[0051] Will Figure 12 welded on Figure 11 the upper central position of the Figure 13 . exist Figure 11 A steel plate or plank is laid on the upper part of the machine, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com