Material receiving unit for weaving production line

An assembly line and material storage technology, applied in thin material handling, strip winding, transportation and packaging, etc., can solve the problems of manual cleaning, cloth backlog, equipment damage, etc., and achieve the effect of avoiding cloth backlog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Specific embodiments of the present invention will be further described in detail below.

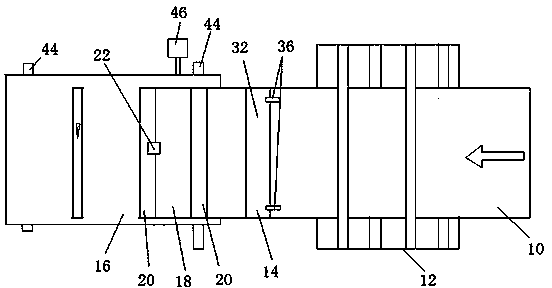

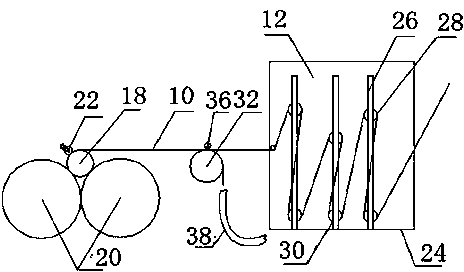

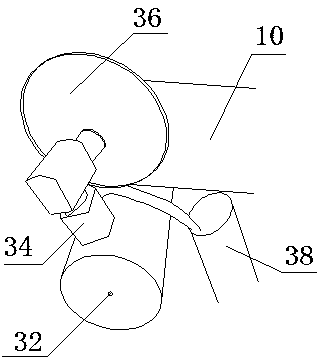

[0016] Such as Figure 1 to Figure 3 As shown, a material receiving unit for a weaving assembly line of the present invention is provided with a material storage mechanism 12 , an edge trimming recovery mechanism 14 and a material receiving frame 16 in sequence along the traveling direction of the produced cloth 10 .

[0017] A receiving rotating shaft 18 for winding the cloth 10 and a first driving mechanism (not shown) for driving the receiving rotating shaft 18 to rotate around its own axis are arranged horizontally on the receiving frame 16 . The first driving mechanism (not shown) adopts a surface contact structure, avoiding the use of a center contact structure (that is, driving the rewinding shaft 18 to rotate to achieve rewinding), resulting in excessive edge speed of the cloth 10 rolled into a roll, which is easy to cause Winding accident. Its specific structure include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com