Micromechanical component and method for manufacturing a micromechanical component

A micro-mechanical and micro-mechanical structure technology, which is applied in the direction of electrical components, manufacturing micro-structural devices, micro-structural technology, etc., can solve the problems of increased manufacturing costs such as scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In different figures, the same reference numerals designate the same elements, and are therefore generally named or mentioned only once in each case.

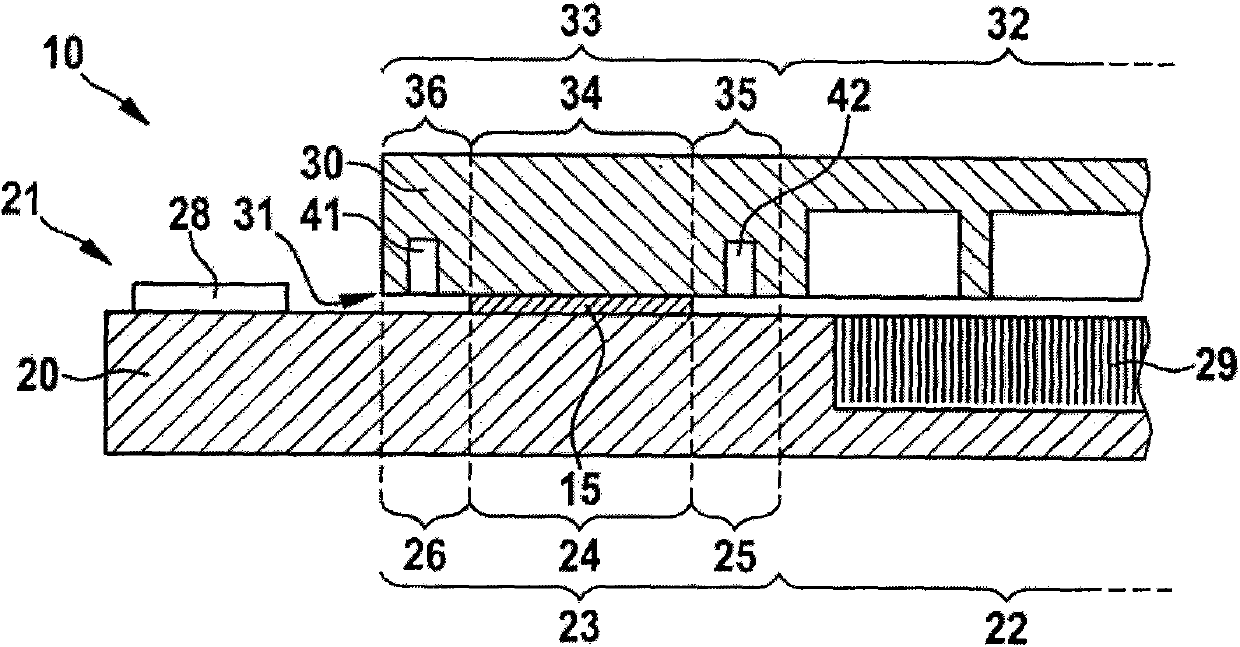

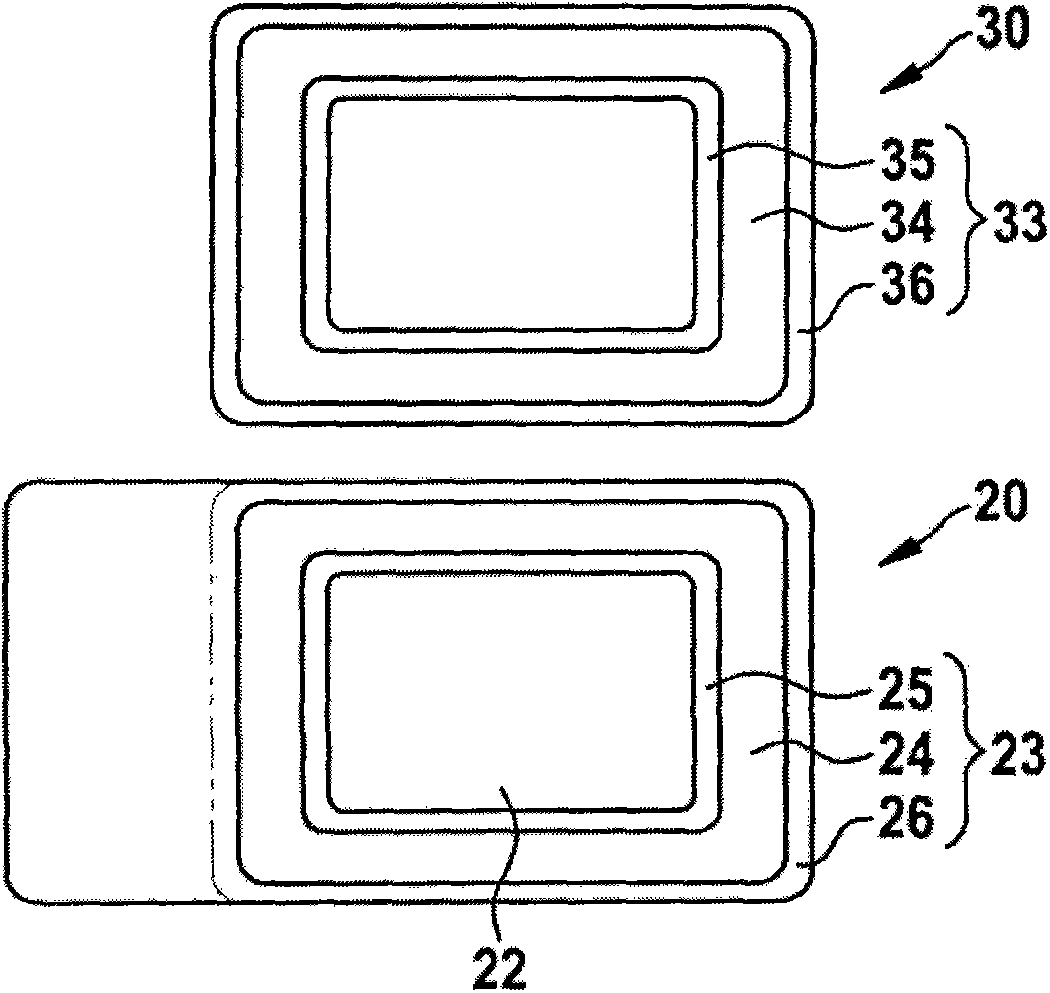

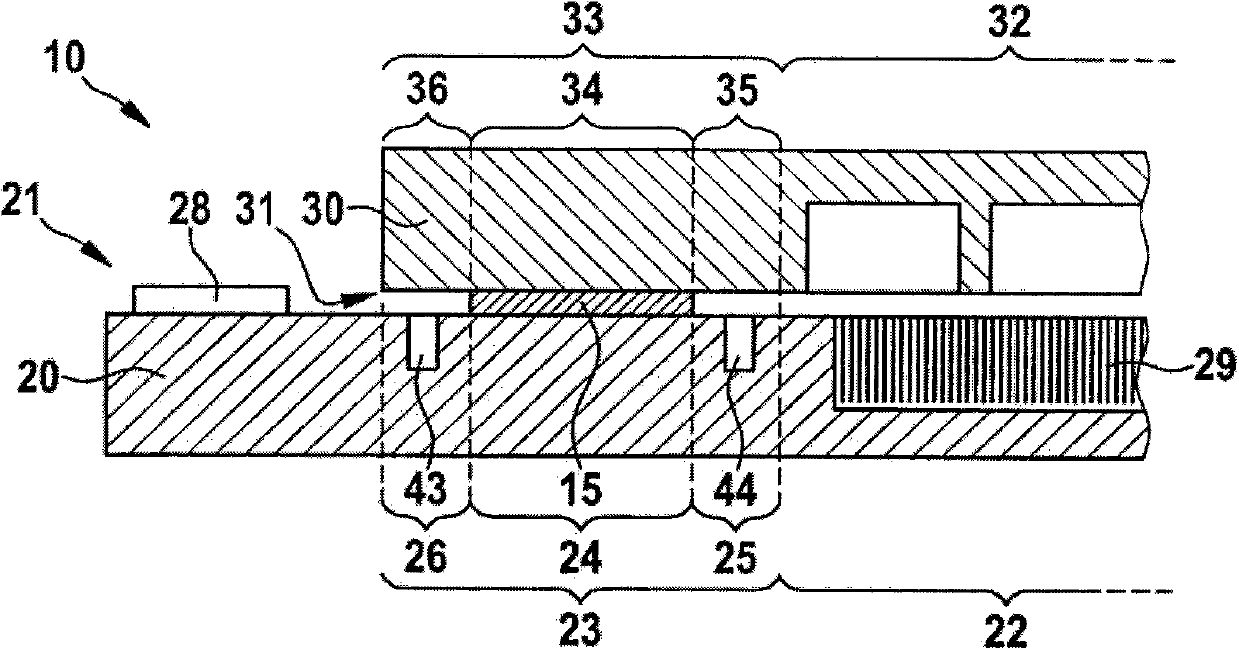

[0025] figure 1, 3, 4, 5, 6 and 7 respectively show a part of a micromechanical component 10 according to the invention in a schematic cross-sectional view, wherein the micromechanical component 10 comprises a carrier substrate 20 and a cap substrate 30 . The carrier substrate 20 has a first connection side 21 and the cap substrate 30 has a second connection side 31, wherein the carrier substrate and the cap substrate 20, 30 face each other with their respective connection sides 21, 31 Connection wherein, according to the invention, eutectic bonding (or soldering) is provided in the edge regions of carrier substrate and cap substrate 20 , 30 . The carrier substrate 20 has a first structure region 22 and a first edge region 23 , wherein, according to the invention, the first edge region 23 has at least a first connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com