The non-rigid support system and the chimney of the horizontal section of the inner tube of the chimney

A non-rigid, horizontal section technology, applied in the field of chimneys, can solve problems such as inability to carry vertical loads and inability to provide vertical displacement capacity, and achieve the effects of avoiding fire safety hazards, easy installation and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

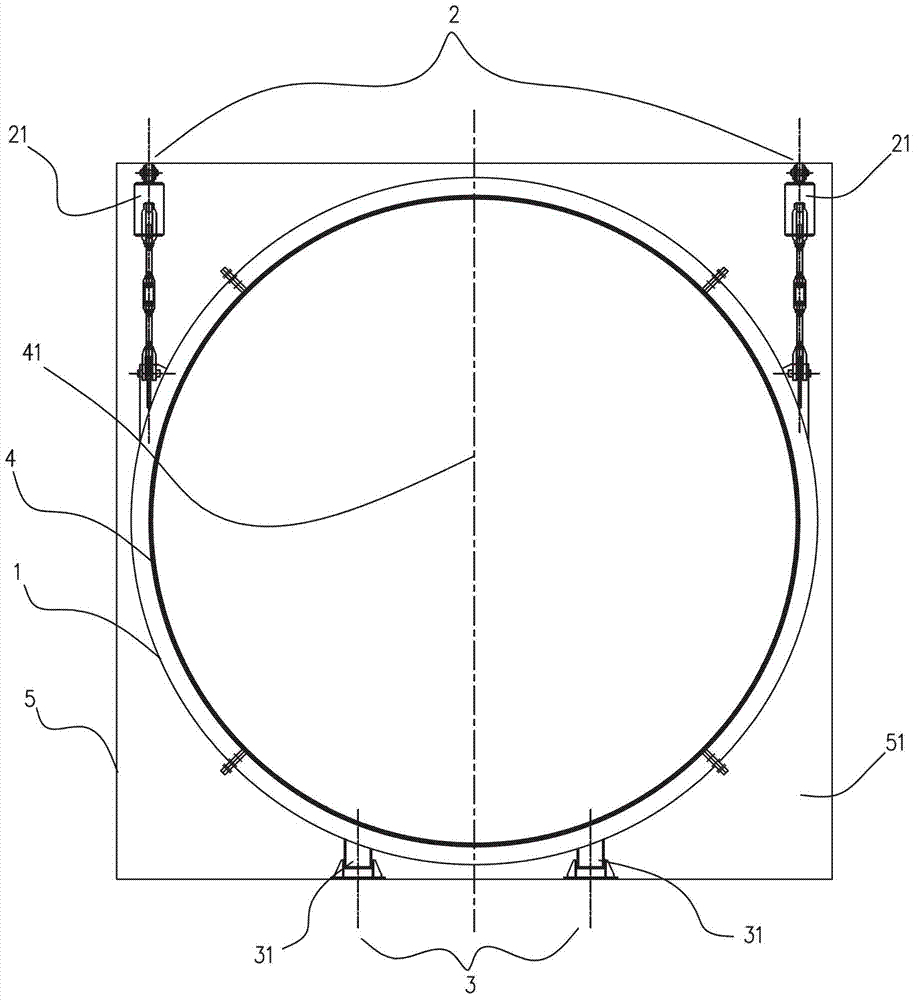

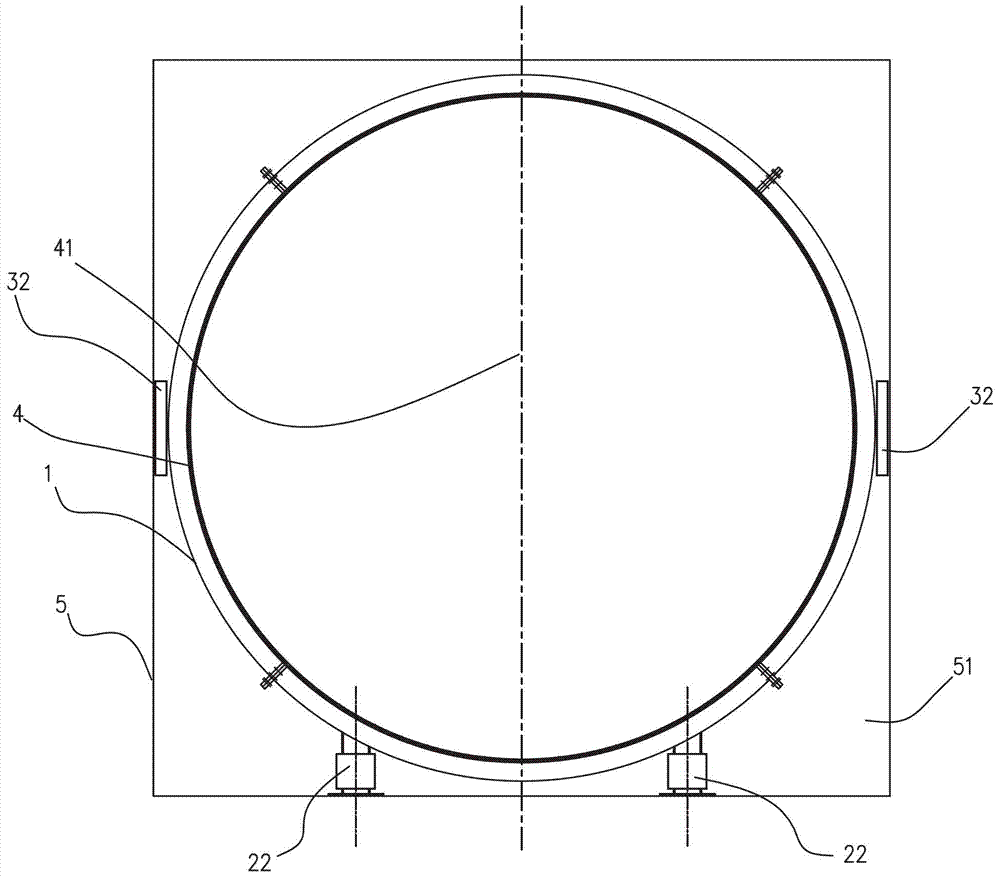

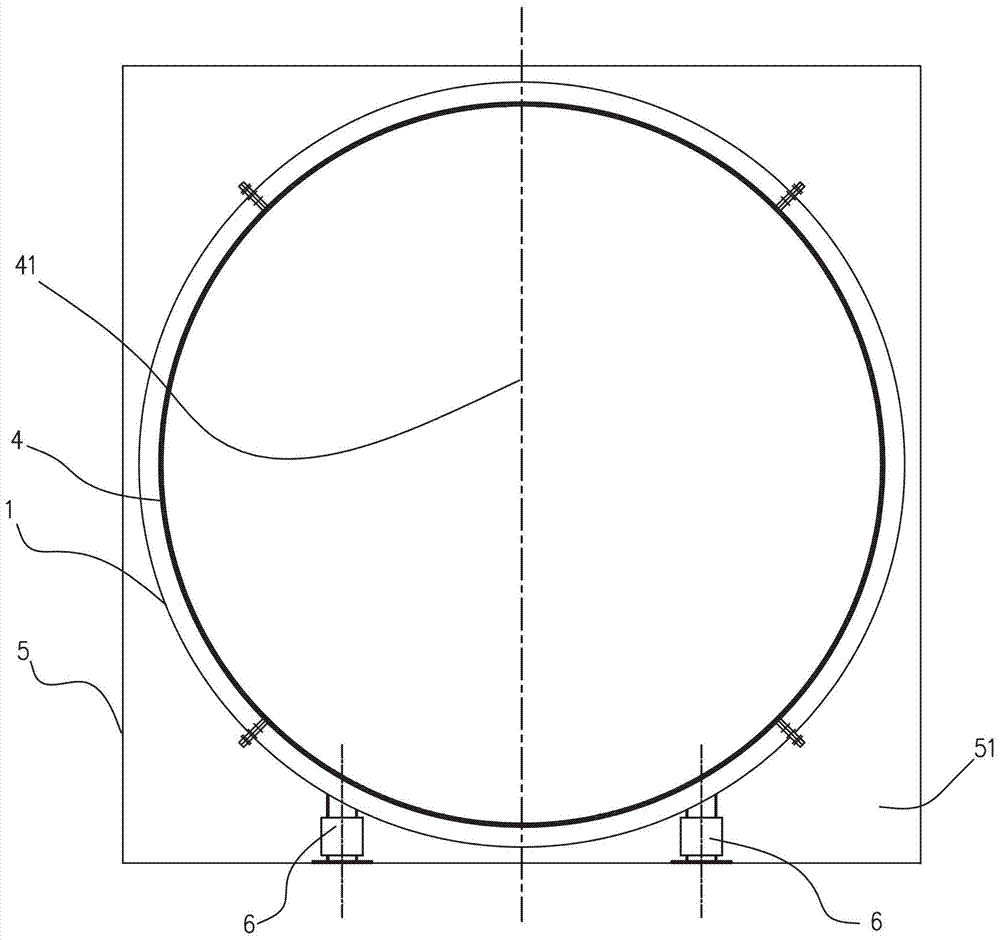

[0023] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

[0024] Explanation of technical terms

[0025] Chimney inner cylinder and chimney outer cylinder: Thermal power plant chimneys generally adopt telescopic chimneys, which are composed of inner cylinder and outer cylinder. channel. The outer cylinder of the chimney is provided with a hole for the horizontal section of the inner cylinder of the chimney to pass through.

[0026] Non-rigid support and suspension system: it is a system composed of support and suspension devices with a certain deformation capacity. Stress, so as to avoid buckling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com