A centrifugal degassing pump

A delivery pump and centrifugal technology, applied in the field of centrifugal degassing delivery pumps, can solve the problems that the degassing effect cannot reach the best state, and achieve the convenience of automatic large-scale production, fast degassing and delivery speed, and low operation and maintenance costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

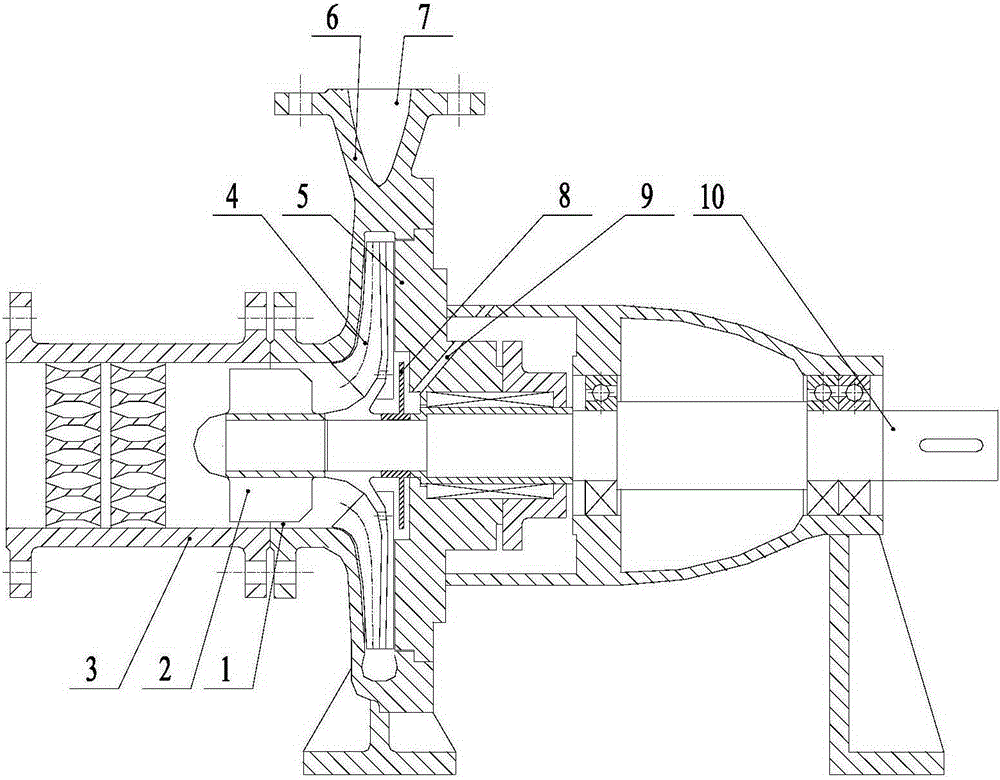

[0047] Such as figure 1 As shown, a centrifugal degassing delivery pump includes a housing 6 with a pump shaft 10 inside. The housing 6 is provided with an air pumping channel 9 for an external vacuum pumping device. The housing 6 is provided with an inlet 1 and a The outlet 7 and the inlet 1 of the housing are connected with a throttling device 3 for gas-liquid pre-separation. The pump shaft 10 is provided with a pre-separation impeller 2, a main impeller 4 and a first sealing impeller 8 in sequence along the axial direction. The separation impeller 2 is installed on the end of the pump shaft 10 close to the inlet, and the first sealing impeller 8 is arranged between the main impeller 4 and the suction passage 9 .

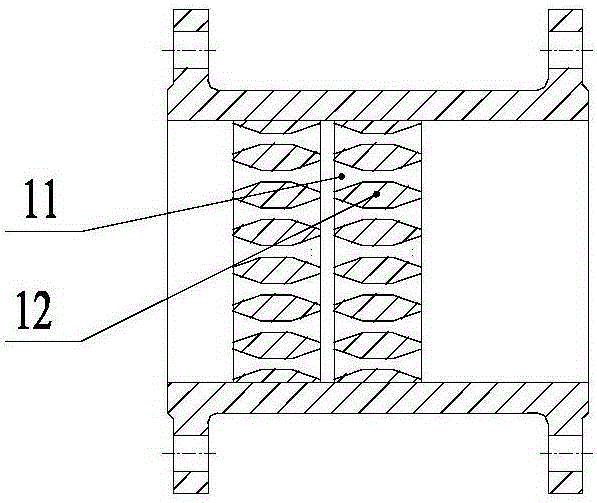

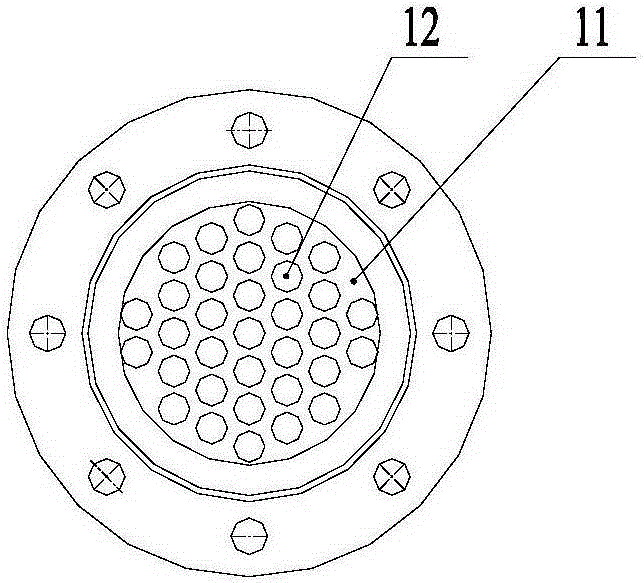

[0048] Such as figure 2 , As shown in 3, the throttling device 3 is an air analysis pipe, and the air analysis pipe is provided with a baffle 11 with a throttle hole 12 on the baffle. The function of the baffle is to increase the flow rate of the liquid, reduce...

Embodiment 2

[0056] Such as Figure 14 As shown, another form of centrifugal degassing delivery pump, this embodiment adds an exhaust channel 23 on the basis of embodiment 1, and the exhaust channel is arranged between the inlet 1 of the casing and the front separation impeller 2, the pump shaft 10 extends into the exhaust passage 23, and a second sealing impeller 24 fixed to the pump shaft and used to return the liquid is arranged in the exhaust passage 23. One end of the exhaust passage is connected with a vacuum pumping device, and an exhaust chamber 28 for accommodating the second sealed impeller 24 is provided in the exhaust passage 23. The inlet 27 connected to the inner cavity, and the outlet facing away from the pre-separation impeller 2; the pump shaft 10 extends from the inlet 27 to the exhaust chamber 28, and the exhaust chamber 28 is provided with a connection with the casing at a position far away from the axis of the pump shaft. The backflow channel 26 connected with the inn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap