Swing type water-cooled vacuum plug-in valve and valve core assembly

A vacuum inserting and swinging technology, which is applied in the direction of sliding valves, engine components, valve details, etc., can solve the problems of "O"-shaped sealing rings such as short life, inability to implement automatic control, large longitudinal dimension of valves, etc., and achieve swing angle Compact, shortened length, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

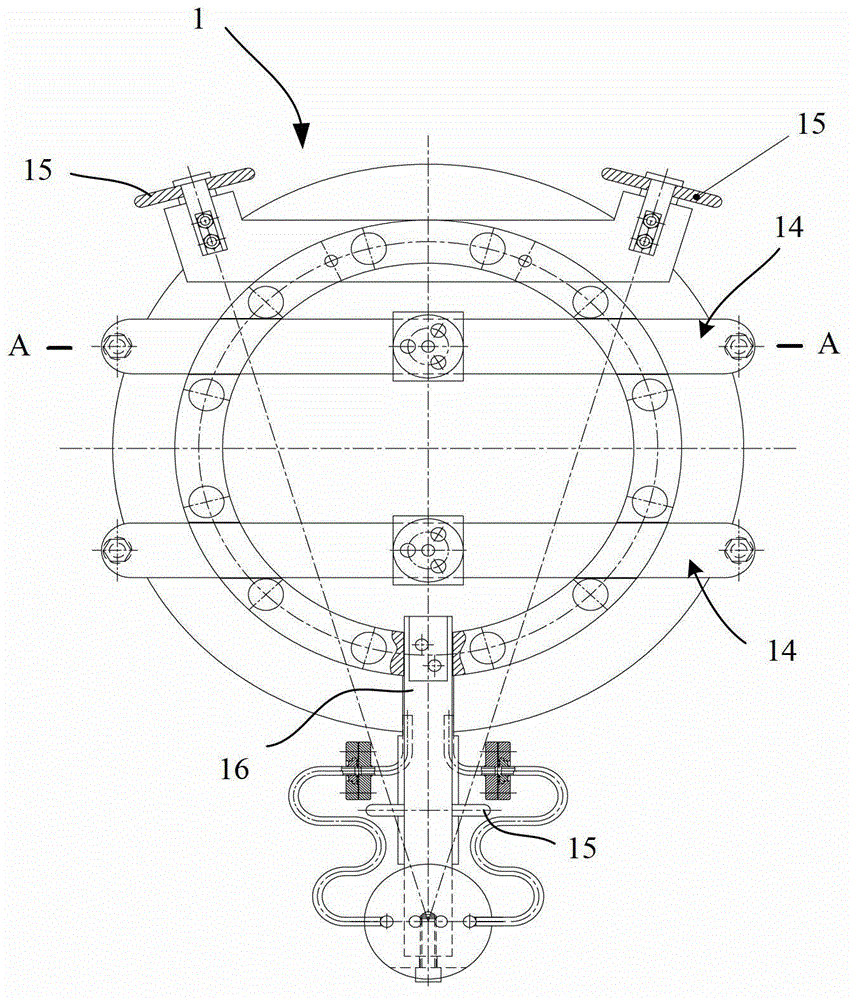

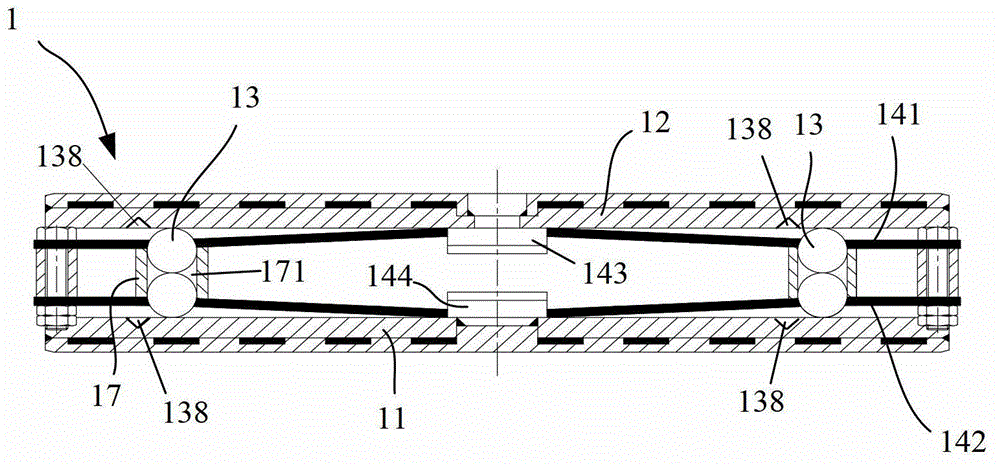

[0027] like figure 1 and figure 2 As shown, the valve core assembly 1 includes a valve plate (lower valve plate) 11 , a support plate (upper valve plate) 12 , a steel ball 13 , a spring plate 14 and a steel ball holder 17 . The steel ball frame 17 is circular and has a plurality of ball holes 171 in the circumferential direction. Two steel balls 13 are placed in each ball hole 171. The steel ball 13 above protrudes from the upper edge of the ball hole 171 and supports The lower surface of the plate 12 is in contact, and the lower edge of the steel ball 13 protruding from the ball hole 171 is in contact with the upper surface of the valve plate 11, as figure 1 In the shown embodiment, there are altogether 12 nanoball holes in the steel ball frame 17 . The steel ball frame 17 is fixedly clamped by two groups of spring plates 14, and each group of spring plates 14 comprises an upper spring plate 141 positioned at the upper side of the steel ball frame 17, a lower spring plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com