High-emissivity low-stagnation-temperature all-glass evacuated collector tube

A technology of vacuum heat collecting tubes and high emissivity, which is applied in heating devices, solar thermal devices, solar thermal power generation, etc., can solve the problem of high vapor pressure of heat pipe working fluid, and achieve the effect of reducing the air drying temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

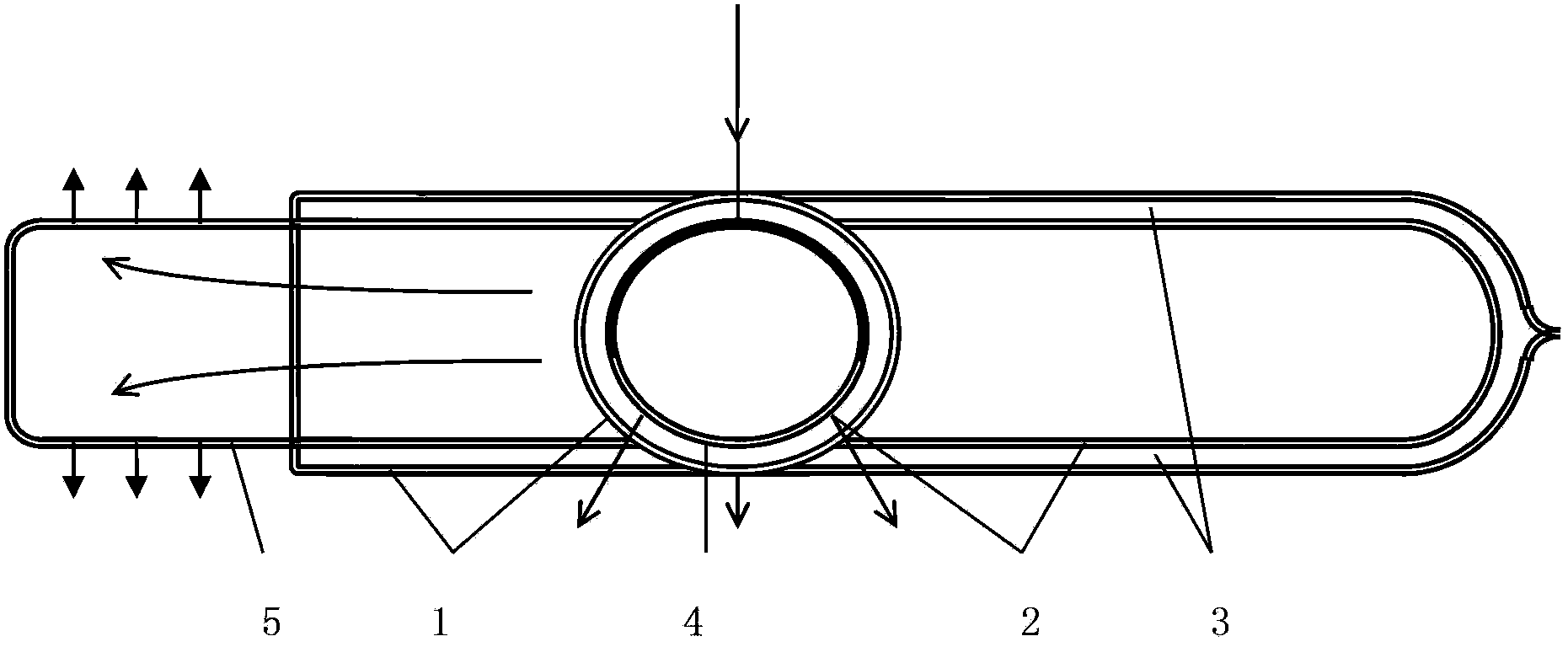

[0014] figure 1 An embodiment of the present invention is given.

[0015] figure 1 In this case, the cover glass tube 1 and the inner glass tube 2 are concentrically connected to form a jacket, and the interlayer of the jacket is evacuated to form a vacuum insulation layer 3 to form an all-glass vacuum heat collection tube. The backlight surface of the outer surface of the inner glass tube 2 contains an uncoated area 4 represented by a double line with a circumferential angle of about 140 degrees. The light-facing surface of the inner glass tube 2 is deposited with a film layer, that is, the so-called selective absorption film; the inner glass tube 2 extends outward at the melting point and is closed, and the inner glass tube 2 is evacuated and filled with working fluid and sealed Li made a heat pipe.

[0016] figure 1 The working principle of the embodiment: the sunlight passes through the cover glass tube 1 and is converted into heat energy on the film layer of the inner glas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com