Lifting type filling bin

A filling, lift-type technology, applied in the field of filling silos, can solve the problems of inapplicability of large granular spherical magnesium ore, reducing the reliability and practicability of blanking, and easy breaking of magnesium ore, so as to ensure the service life. , Reducing the number of fillings, the effect of not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

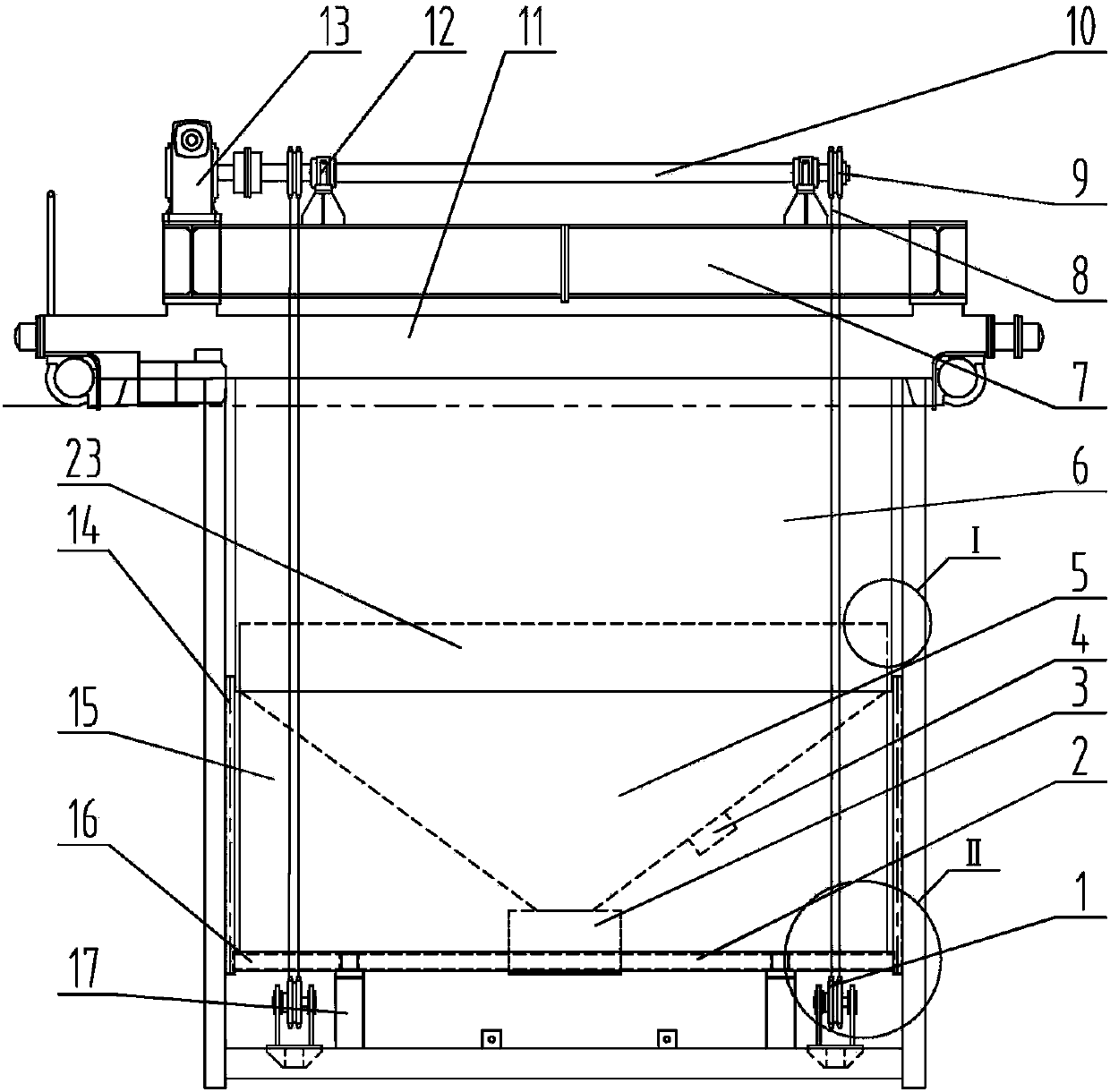

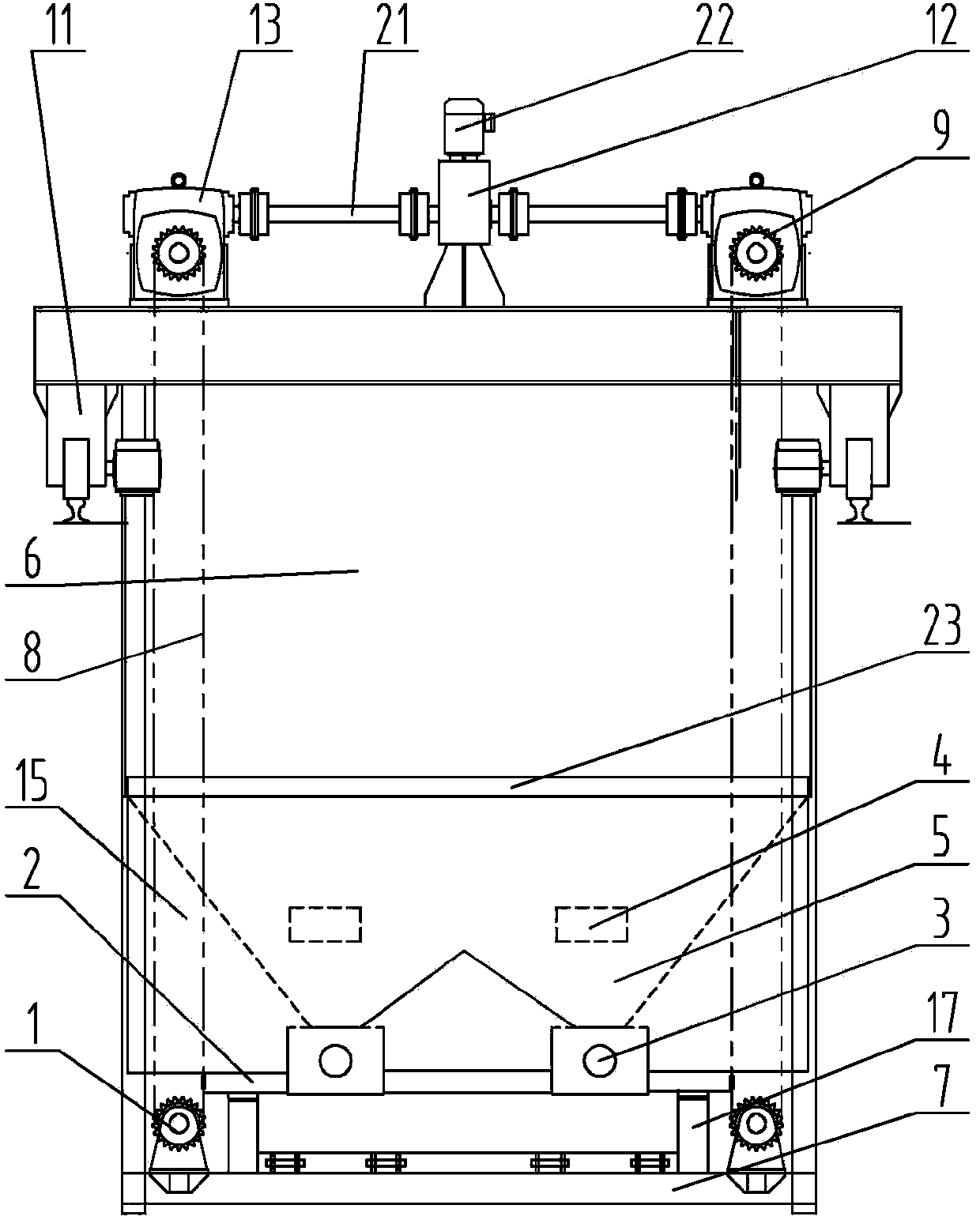

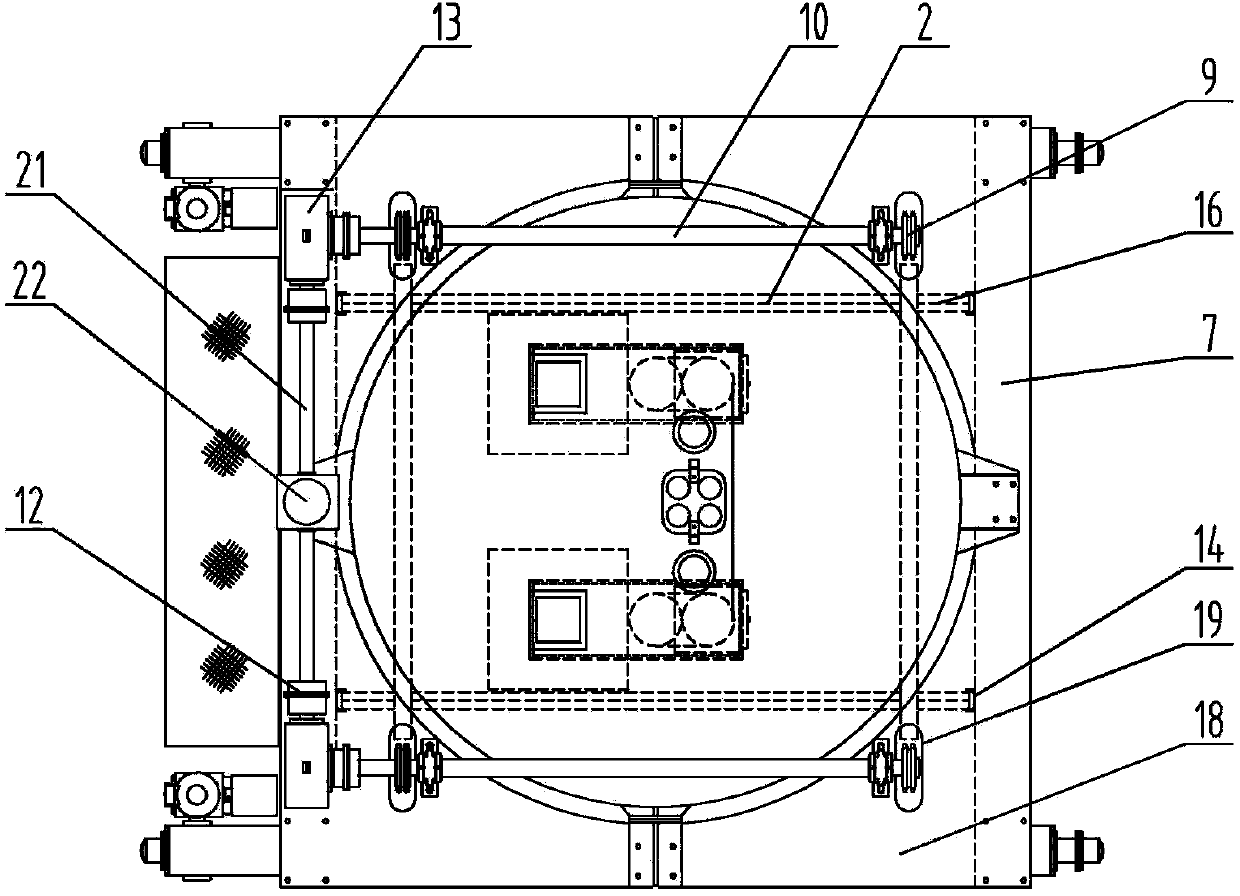

[0042] The present invention includes a cylindrical upper material bin 6 arranged on the frame 7, the upper material bin 6 is provided with a lower material bin 23 with an opening at the top and a discharge port at the bottom; Rack 7.

[0043] As a preferred solution of the present invention, the bottom of the lower bin 23 is provided with a lifting frame 2; the bottom of the frame 7 is provided with a driven sprocket 1; The lifting motor 22 on the top, the lifting motor 22 is connected with the driving sprocket 9 above the frame 7; the driving sprocket 9 is connected with the driven sprocket 1 through the chain 8; the lifting frame 2 at the bottom of the lower bin 23 Be fixed on the chain link of chain 8.

[0044] Further, the frame 7 includes a table top 18, and the lifting motor 22 is arranged on the table 18; both sides of the lifting motor 22 are provided with drive shafts 21, and the two drive shafts 21 pass through the worm gear reducer 13 respectively. Link to each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com