Direct plug element, in particular for vehicle control devices

A plug-in component and direct technology, applied in the direction of electrical components, parts of the connection device, connection, etc., can solve the problems of contact wear, vibration movement of plug connection, complex wiring structure, etc., to achieve reliable connection, The effect of small space location requirements and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

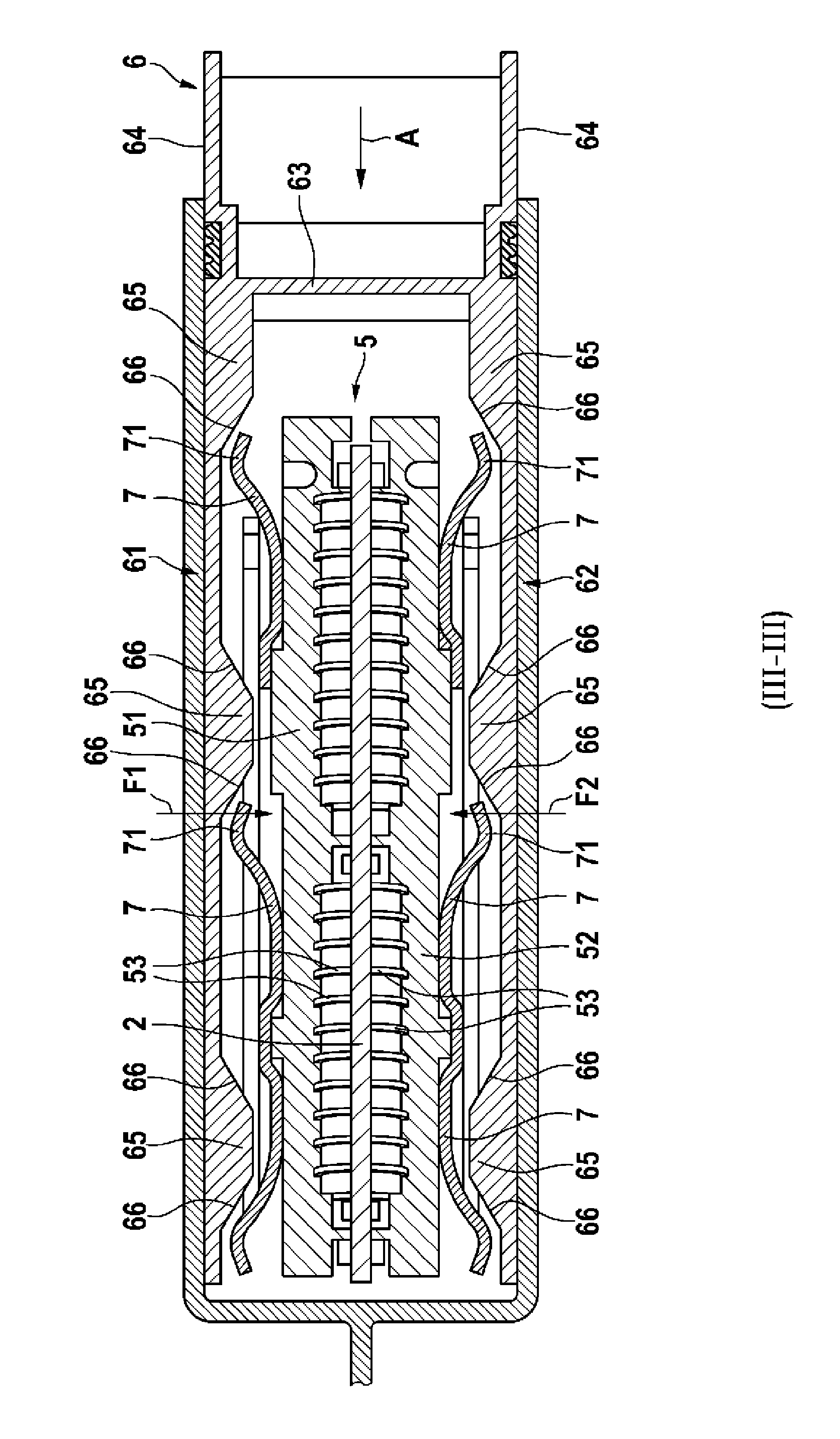

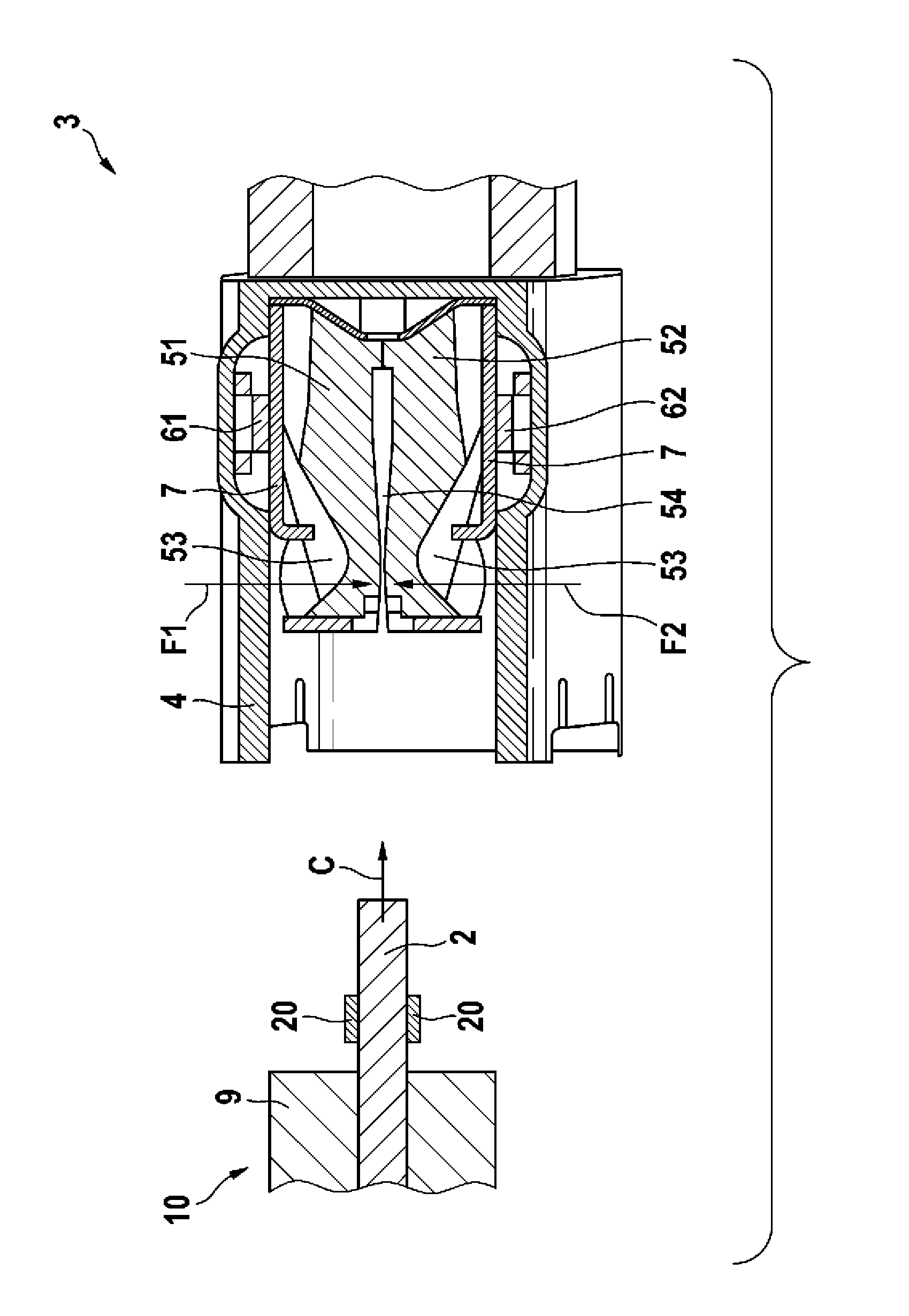

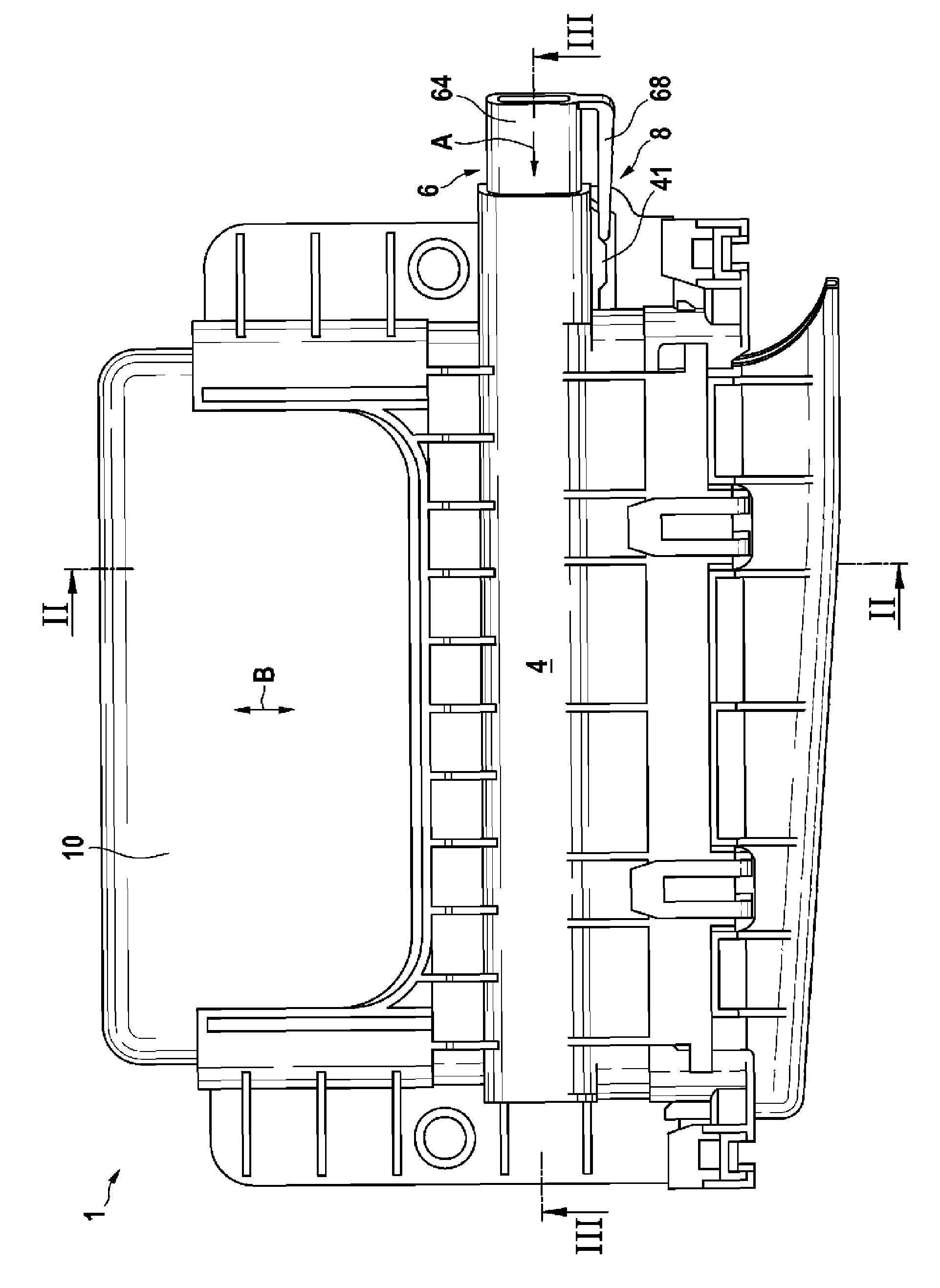

[0020] Refer below Figure 1 to Figure 4 The electrical device 1 and the direct plug element 3 according to an embodiment of the present invention will be described in detail.

[0021] The direct plug element 3 according to the invention comprises a housing preferably made of plastic and a two-part contact holder 5 arranged in the housing 4. The contact holder 5 includes a first contact holder part 51 and a second contact holder part 52. The contact holder parts 51, 52 are loosely arranged in the housing. The not-shown projections in the housing here prevent the loosely arranged contact carrier parts 51, 52 from falling out of the housing 4. Here, the gap between the loosely arranged contact holder parts 51, 52 in the housing 4 is set such that the contact holder parts 51, 52 cannot change directions in principle, for example, rotate 360° in the horizontal and vertical directions, but Maintain its main orientation. A plurality of direct contacts 53 are respectively arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com