A gearbox for a rotary cultivator with forward and reverse rotation and left and right steering functions

A forward-reversing, gearbox technology, applied in the field of gearboxes, can solve problems such as danger, cumbersome steering operation, and single function, and achieve the effects of saving purchase costs, safe and reliable operation, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

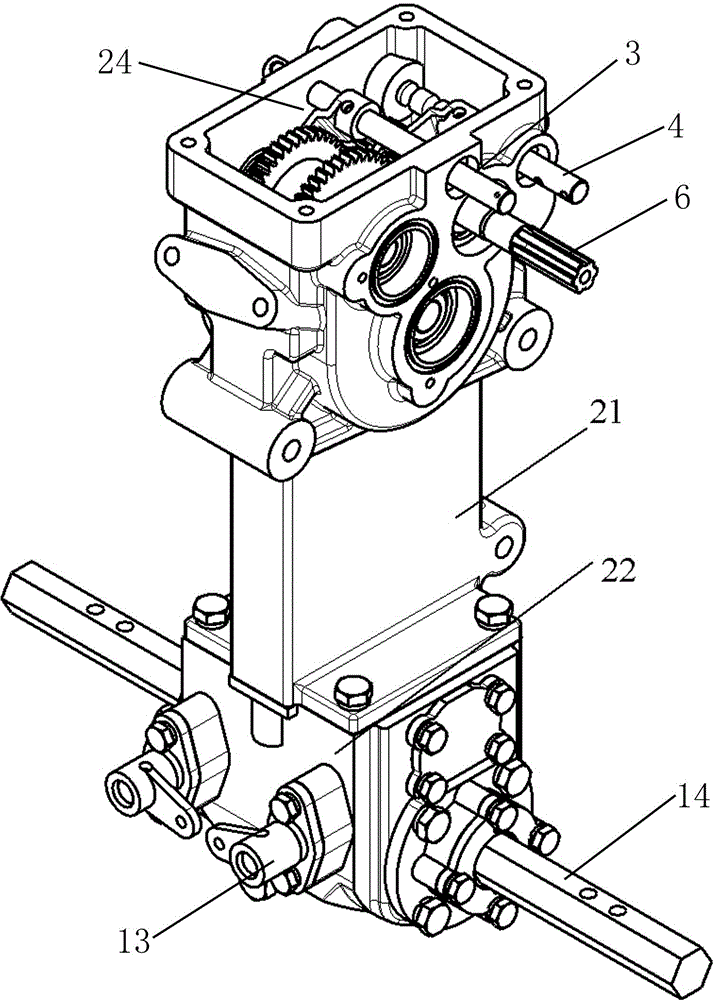

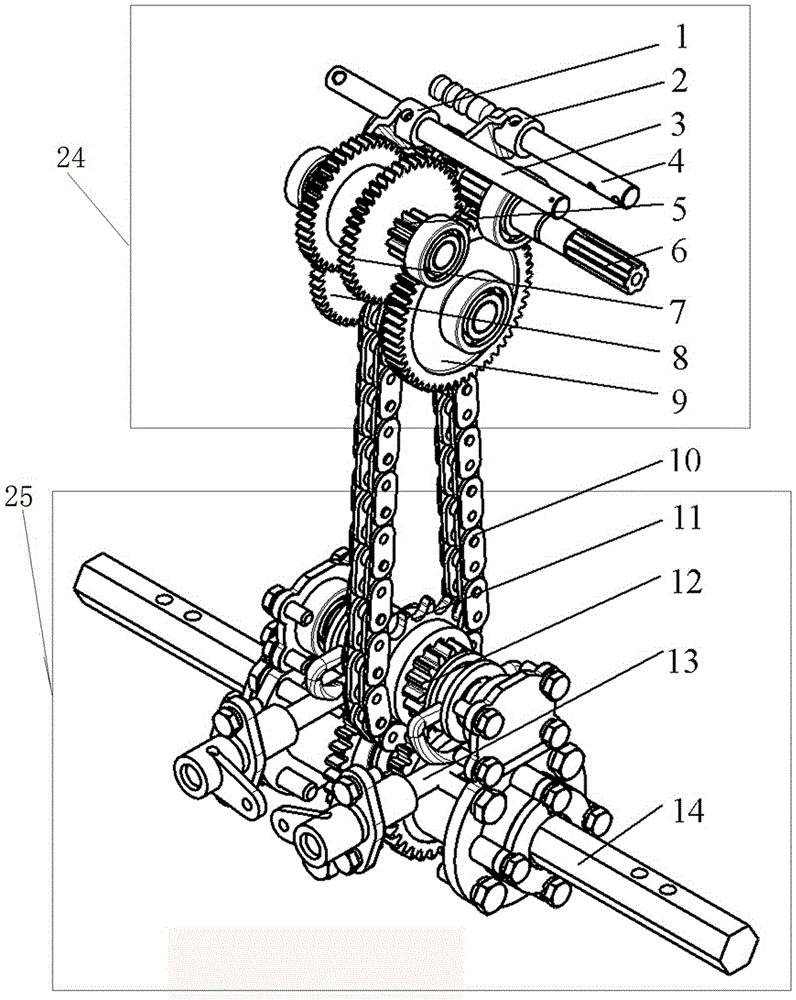

[0019] refer to Figure 1-3 , a gearbox for a rotary tiller with forward and reverse and left and right steering functions, including an upper case 21 and a lower case 22 that are matched and fitted, and a forward and reverse mechanism 24 and a device that are arranged in the upper case 21 The left and right steering mechanism 25 in the lower casing 22 is connected by a sprocket chain between the forward and reverse mechanism 24 and the left and right steering mechanism 25, and transmits the power of the upper part of the gearbox to the lower part of the gearbox.

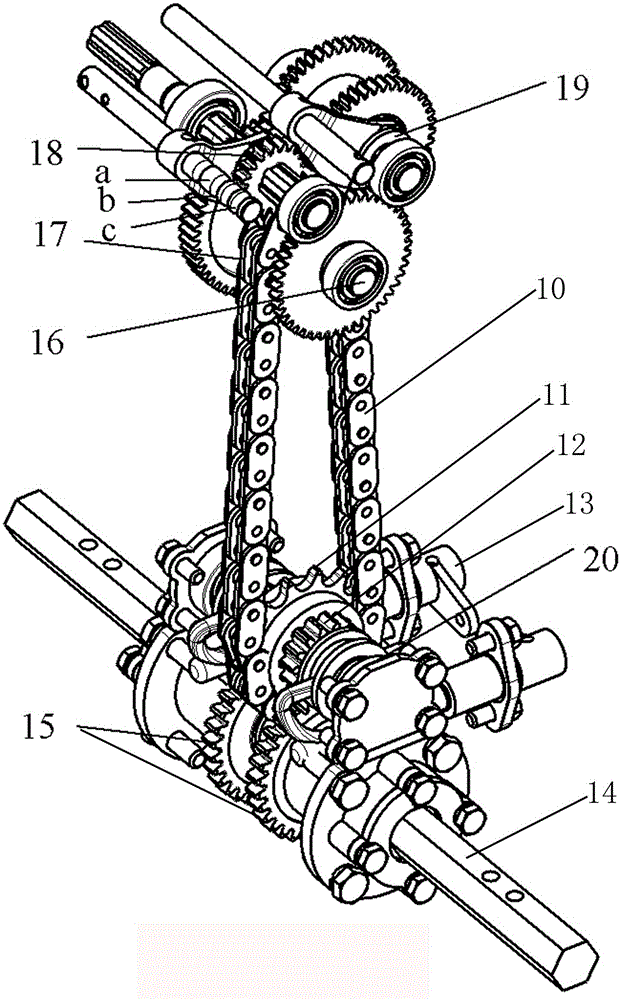

[0020] The forward and reverse mechanism 24 includes the shift fork shaft I 3, the shift fork shaft II 4, the gear shaft 5, the input shaft 6, and the middle spline shaft 16 erected on the upper box body 21; the shift fork shaft I 3 is provided with a shift fork Ⅰ 1, fork shaft Ⅱ 4 is provided with shift fork Ⅱ 2; gear shaft 5 is provided with transition double gear 7, clutch three-claw wheel 19, the inner hole of c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com