single roll crusher

A single-roller crusher and toothed roller technology, which is applied in grain processing and other directions, can solve the problems of the motor affecting the service life of the equipment, uneven axial force, and damage to the reducer, so as to achieve uniform axial force, improve the force on the main shaft, The effect of reducing the load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

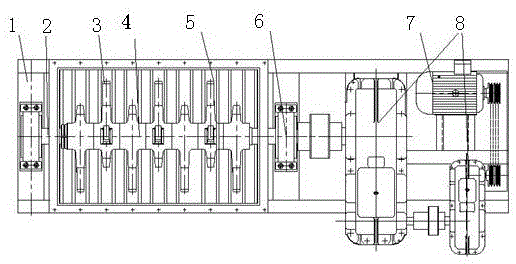

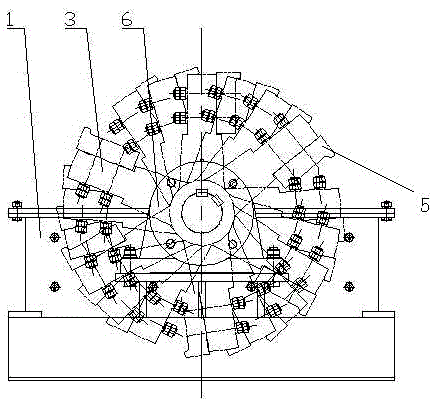

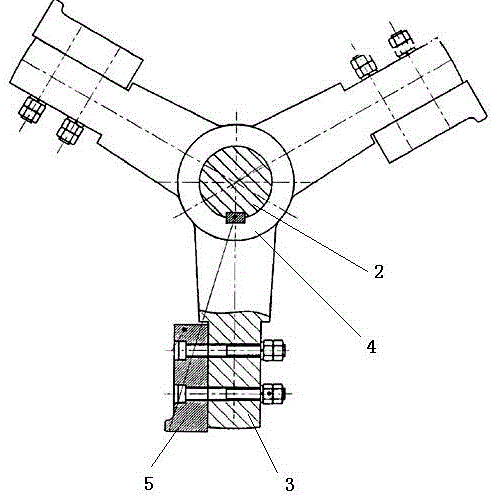

[0018] see figure 1 , 2 , 3. The names of the components are as follows: frame 1, main shaft 2, single tooth 3, gear roller 4, hammer head 5, bearing housing 6, drive mechanism 7, and speed reduction mechanism 8.

[0019] see figure 1 , 2 3. The single-roller crusher includes a frame 1 with a rotating main shaft 2 on the frame 1. Seven toothed rollers 4 are evenly arranged side by side on the main shaft 2, and three single teeth 3 are evenly distributed along the circumference of each toothed roller 4. , the angle between each single tooth 3 is 120 degrees, and an alloy hammer head 5 is fixed on the pointed side of each single tooth 3 . The main shaft 2 is supported on the bearing housings 6 mounted on both sides of the frame 1, and the main shaft 2 is driven by a driving mechanism 7 (electric motor) and a reduction mechanism 8. The toothed roller 4 starts from the transmission direction, and starts from the second toothed roller 4. Each toothed roller 4 is evenly offset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com