Universal high-efficiency iron removal device for various industries

A technology of magnets and material passages, applied in the field of iron removal devices, can solve problems such as unreliable iron removal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

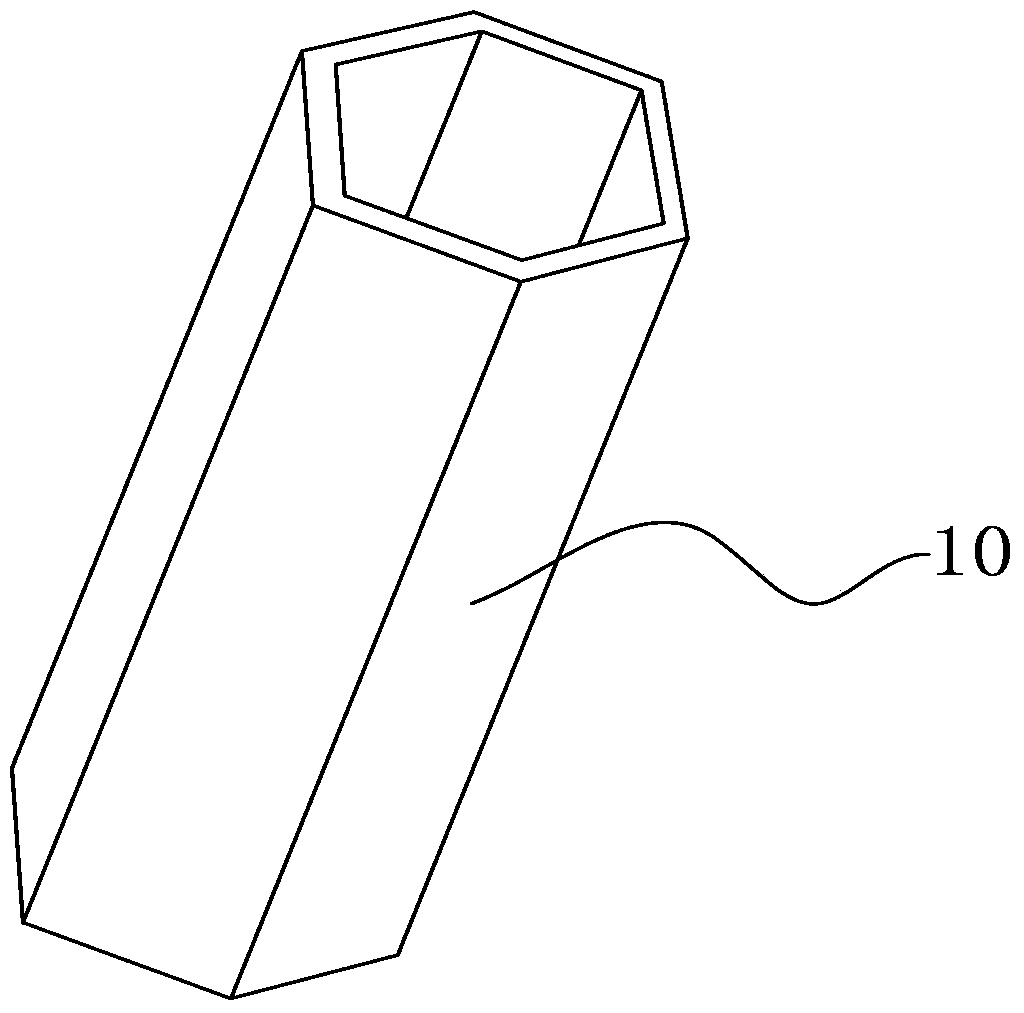

[0011] A kind of deironing device, comprises magnet 10, and magnet 10 is tubular, as figure 1 shown. Or the magnet 10 is evenly arranged along the pipe wall of the pipe body. That is, they are evenly arranged along the circumference of the pipe wall to form a uniform magnetic field surrounding the material. Of course, it is best to arrange multiple sets of surrounding magnetic fields along the length direction at the same time. Make the iron removal effect more reliable. Alternatively, the tubular magnet 10 may be coaxially fixed in a tubular body.

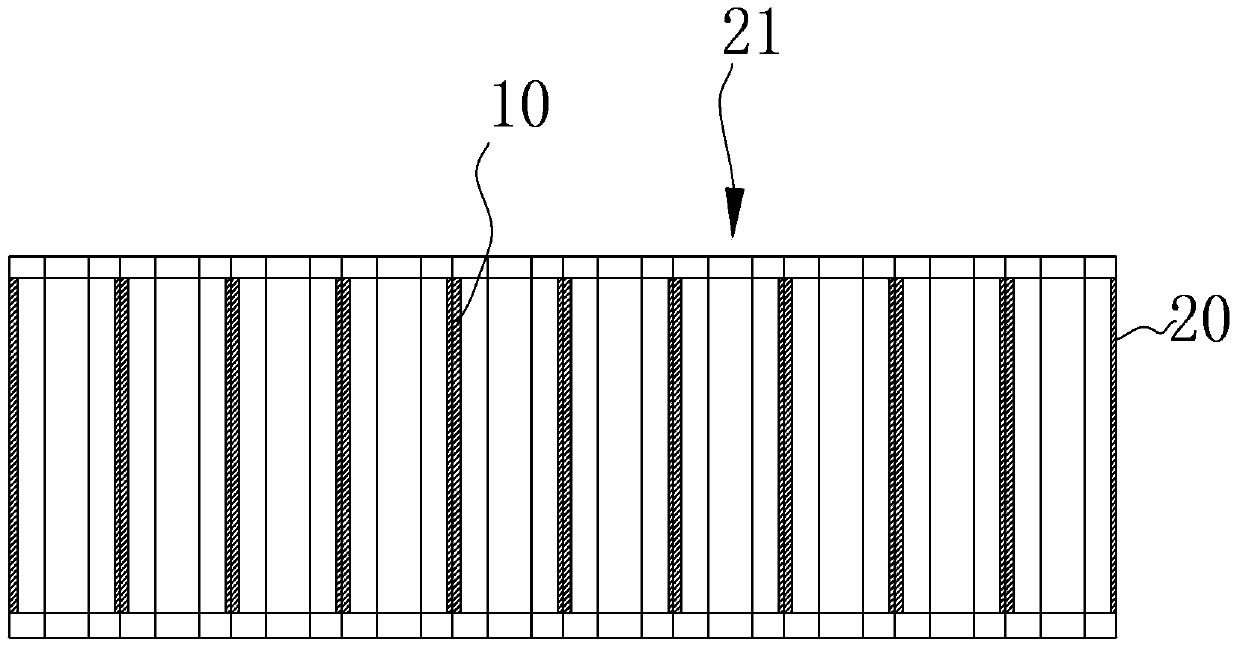

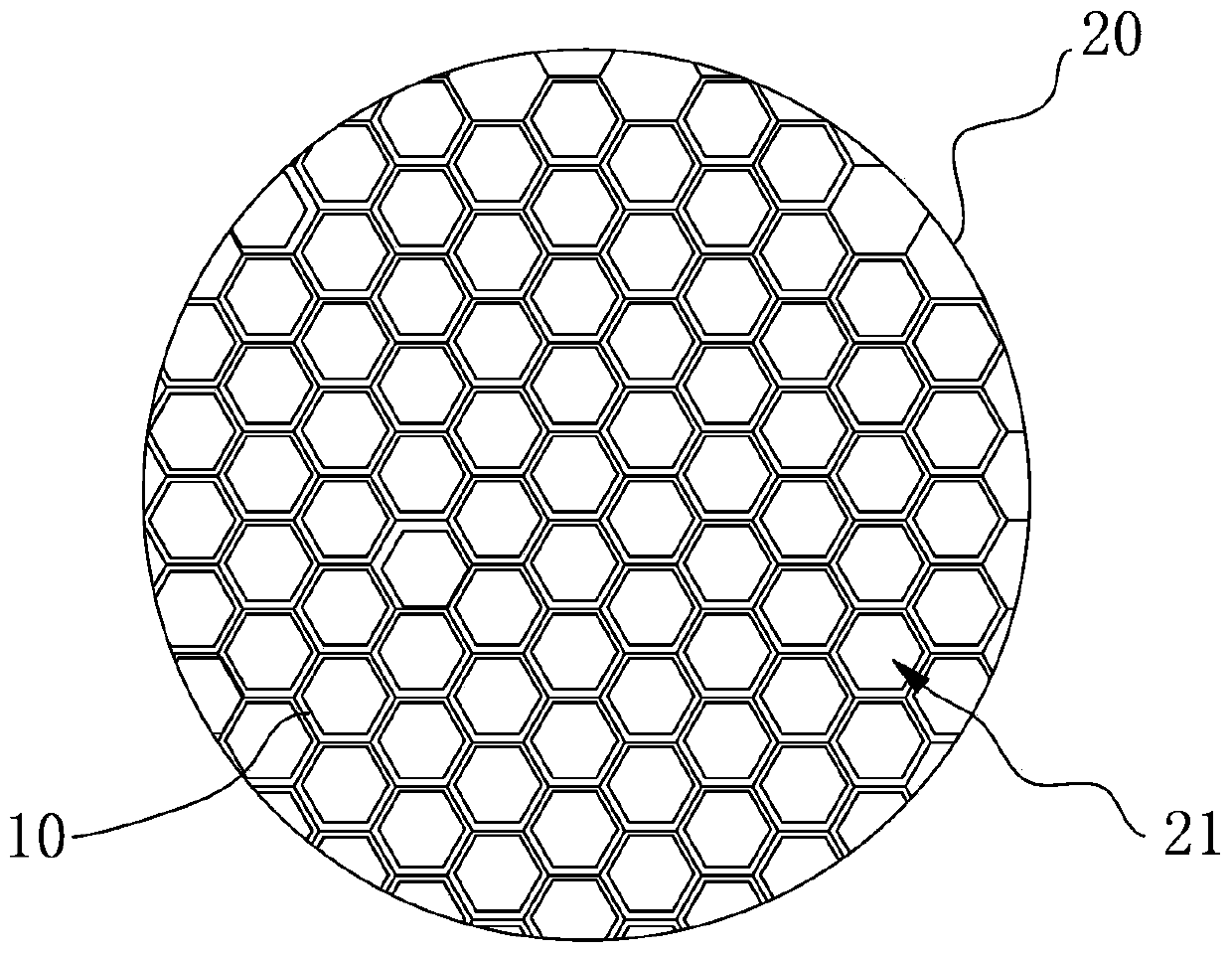

[0012] Further, such as figure 1 As shown, the magnet 10 is in the shape of a tube with a regular hexagonal cross section or evenly arranged along the tube wall of a tube body with a regular hexagonal cross section. Such tubular magnets 10 or pipe bodies are suitable for a plurality of juxtaposed arrangements, forming such as figure 2 , 3 The iron removal device shown. Such a plurality of tubular magnets 10 or tubes with m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com