Patents

Literature

34results about How to "Guaranteed iron removal effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

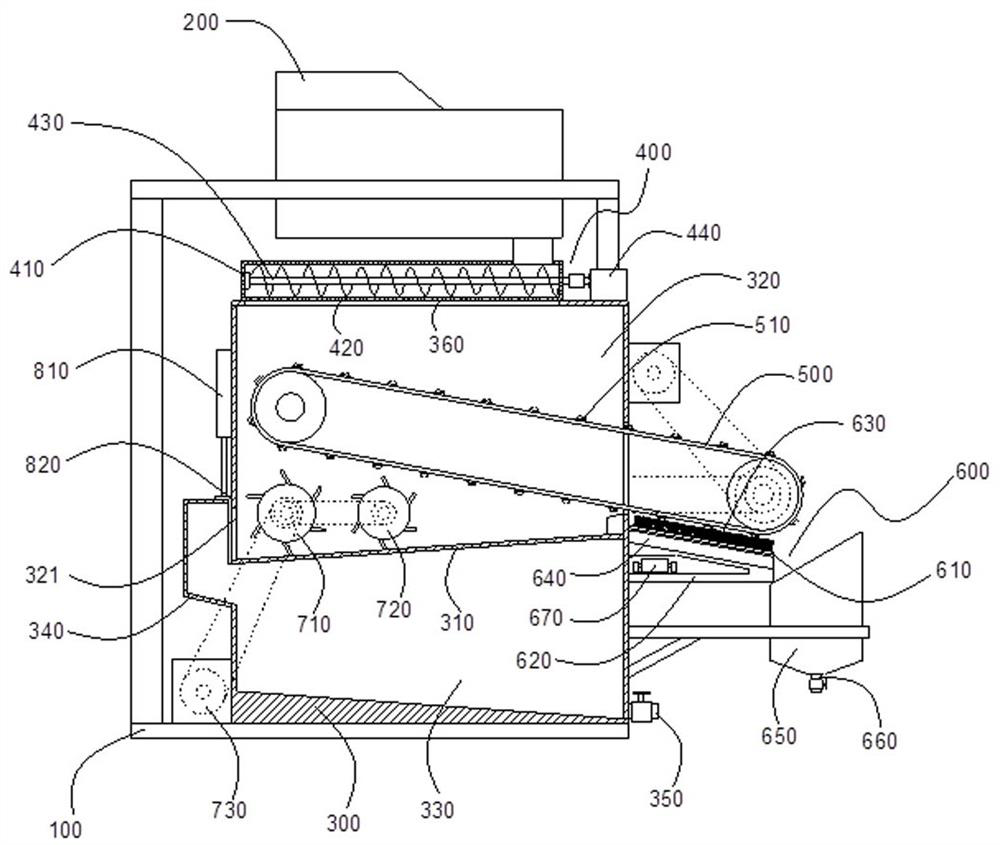

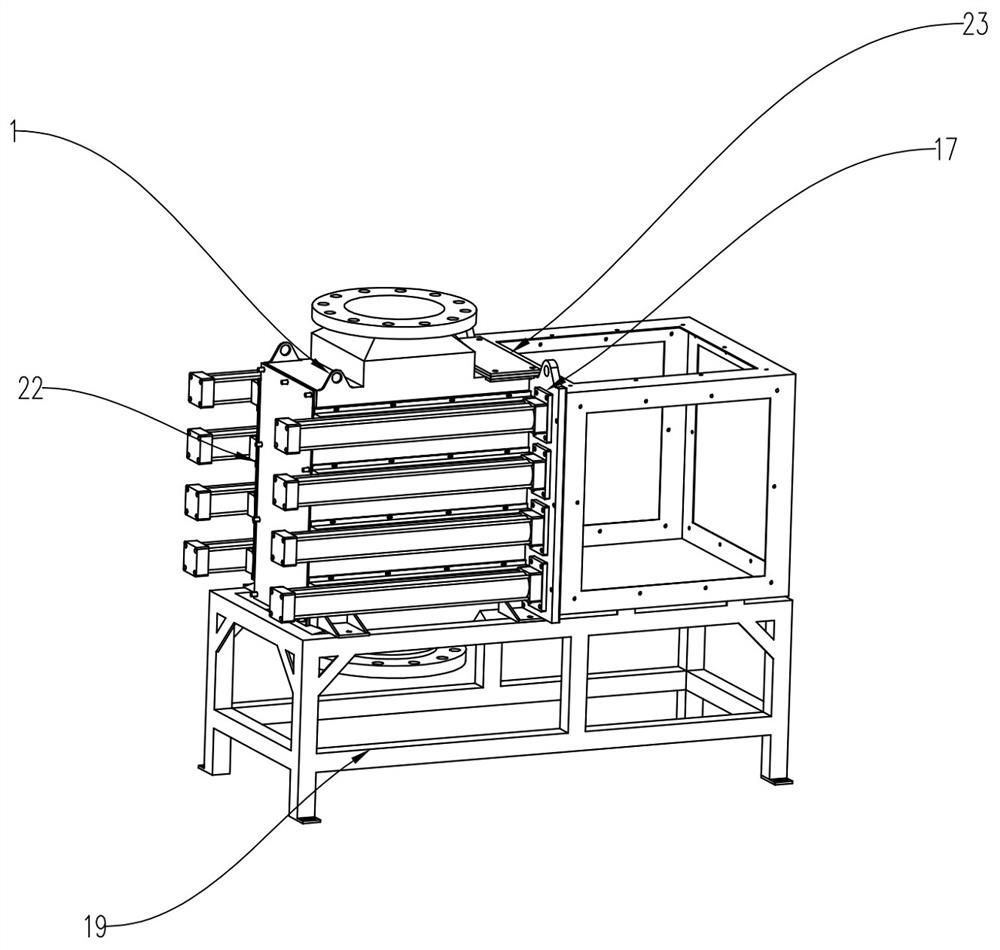

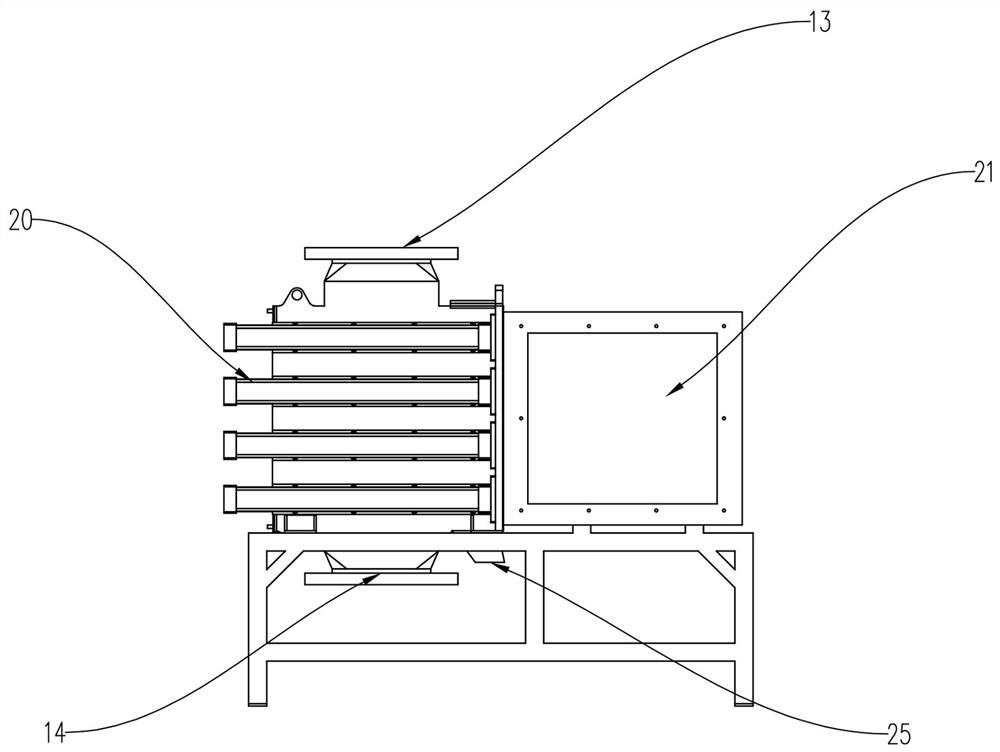

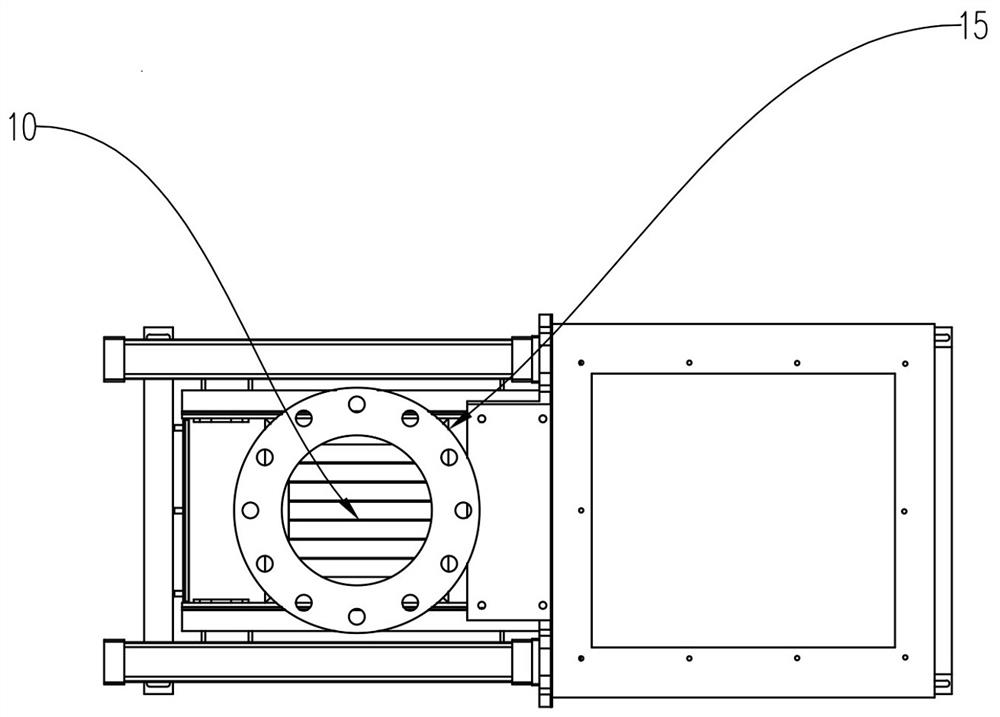

Rare metal powder preparation equipment

InactiveCN111701836ANovel structureImprove the magnetic effectSievingGas current separationIron removalEngineering

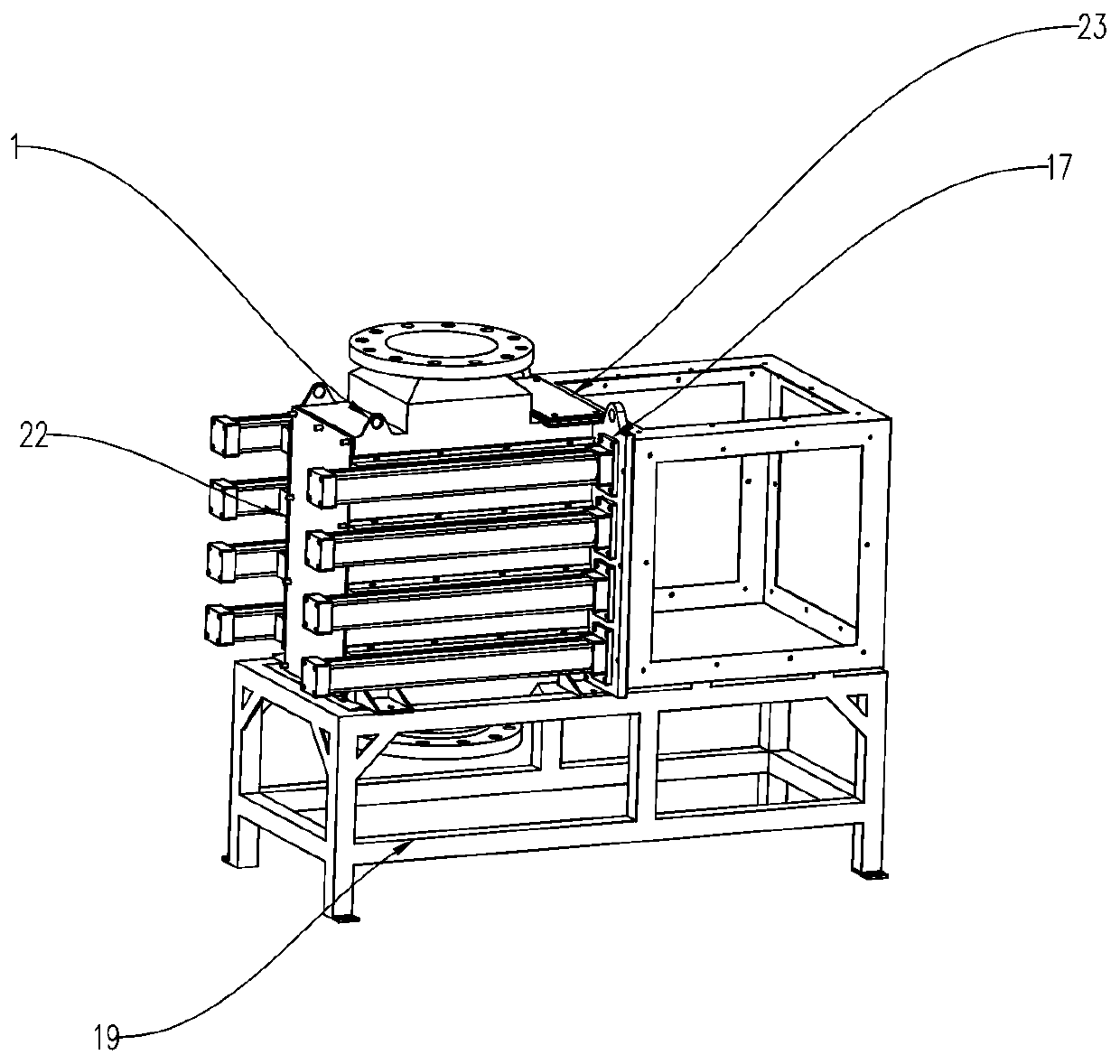

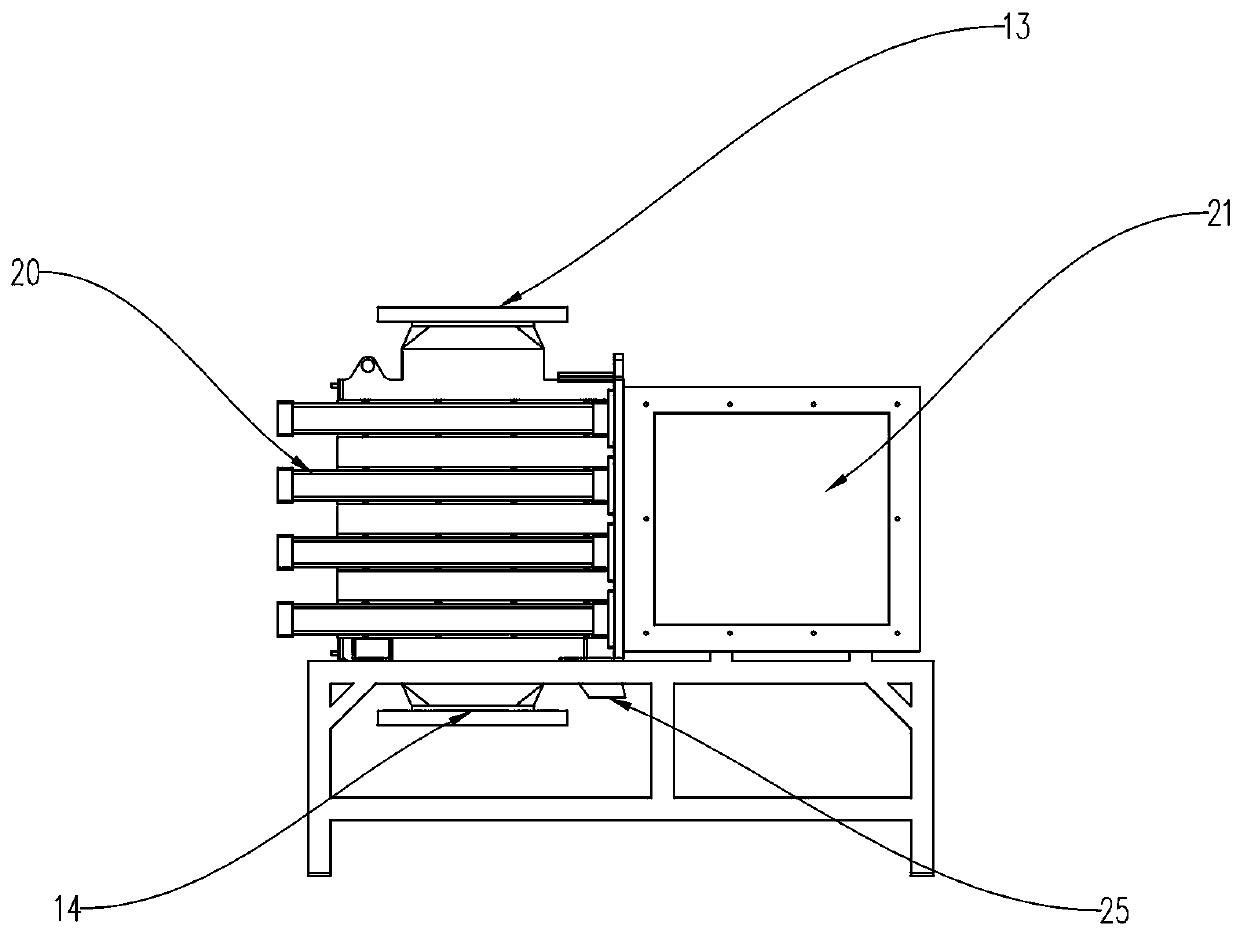

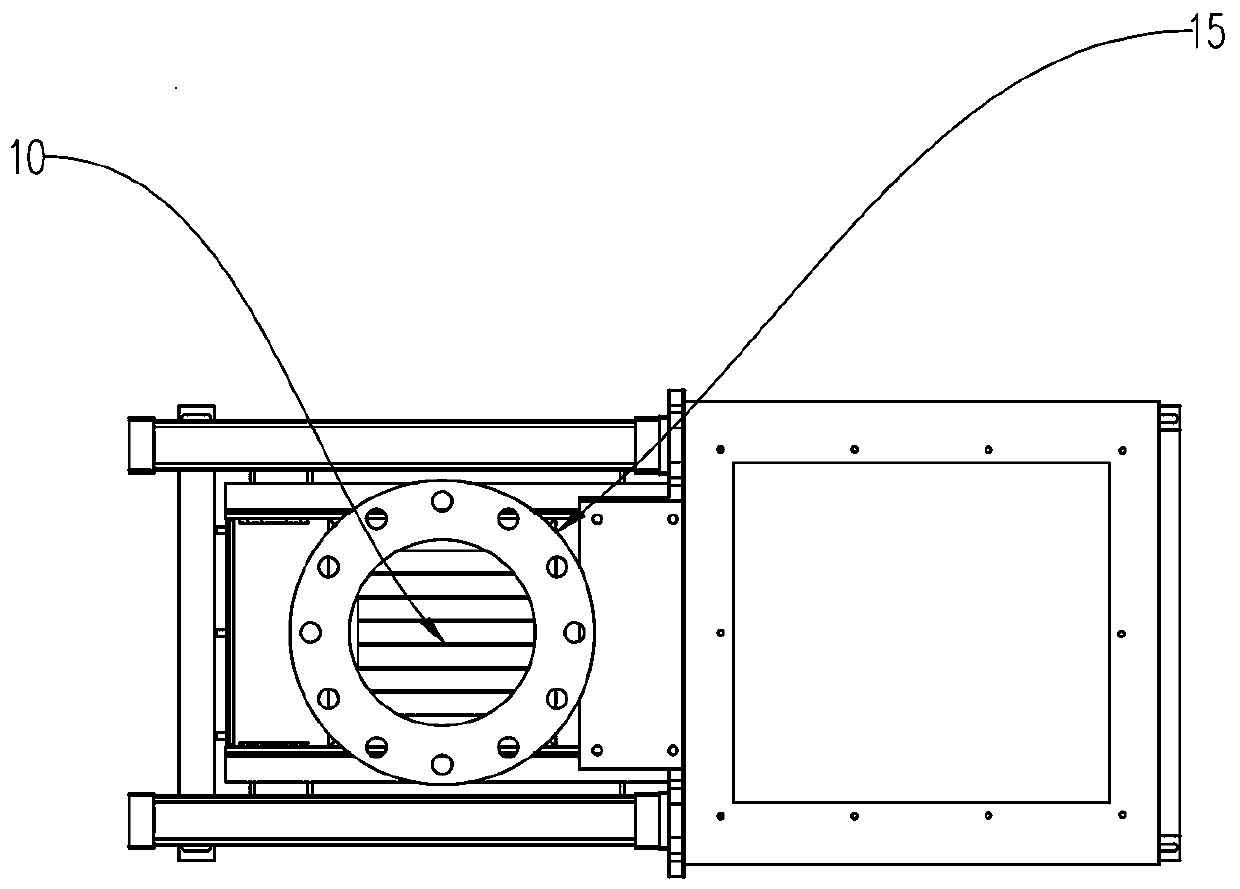

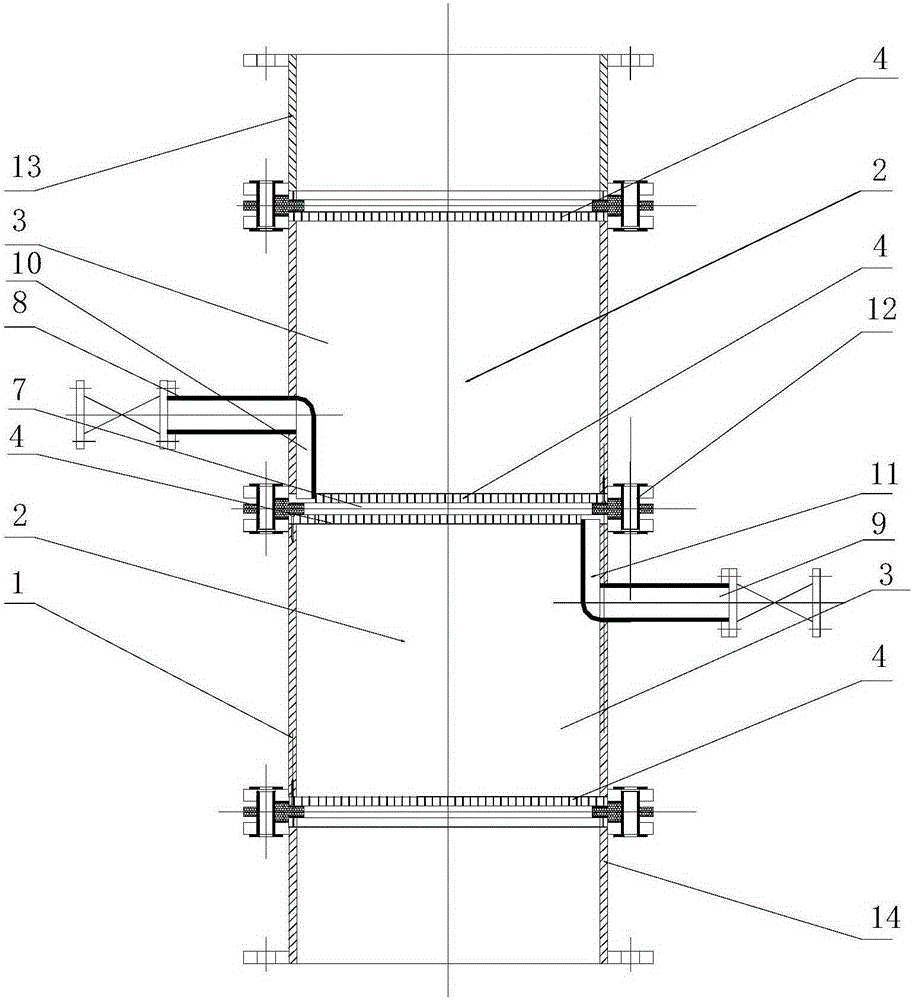

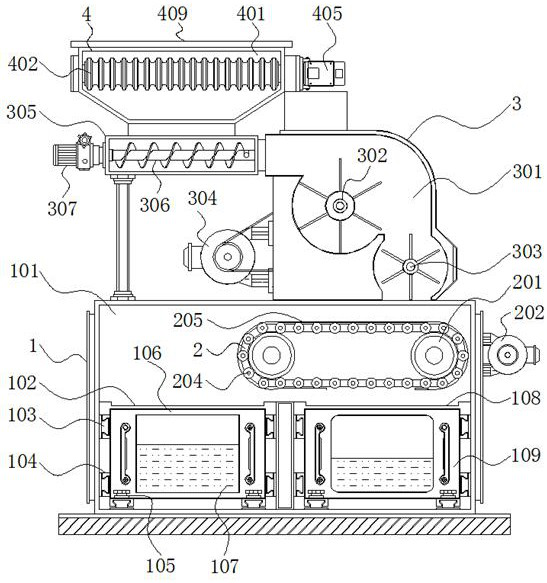

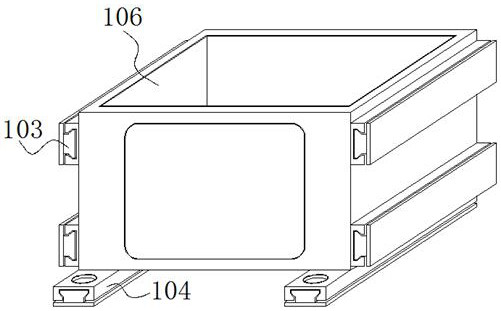

The invention provides rare metal powder preparation equipment which comprises a grinding machine and an iron removing device. The iron removing device comprises a box body, the inside of the box bodyis divided into an iron removing chamber and a storage chamber, a discharge opening is formed in one side with the lower inclination of the bottom of the iron removing chamber, an automatic gate is arranged on the outer side of the discharge opening, and a feeding hopper corresponding to the discharge opening is arranged in the storage chamber in a communicating mode. A spiral feeding machine isarranged outside a feeding port at the top of the iron removing chamber, and a feed inlet of the spiral feeding machine communicates with a discharging outlet of the grinding machine. A conveying beltis arranged at the position of the iron removing chamber in an inclined mode, one side of the end with the lower inclination of the conveying belt is located on the outer side of the box body, the conveying belt is of a mesh belt structure, a plurality of soft magnetic strips are arranged on the outer wall surface of the conveying belt, and a cleaning structure for cleaning and collecting scrap iron is arranged below the bottom of the end with the lower inclination of the conveying belt. By means of the equipment, metal powder can be subjected to scrap iron adsorption cleaning, scrap iron adhering to a cleaning piece is removed, and a good adsorption effect is maintained, so that continuous iron removal work is carried out, and the working efficiency is improved.

Owner:QINGYUAN JIAHE RARE METAL CO LTD

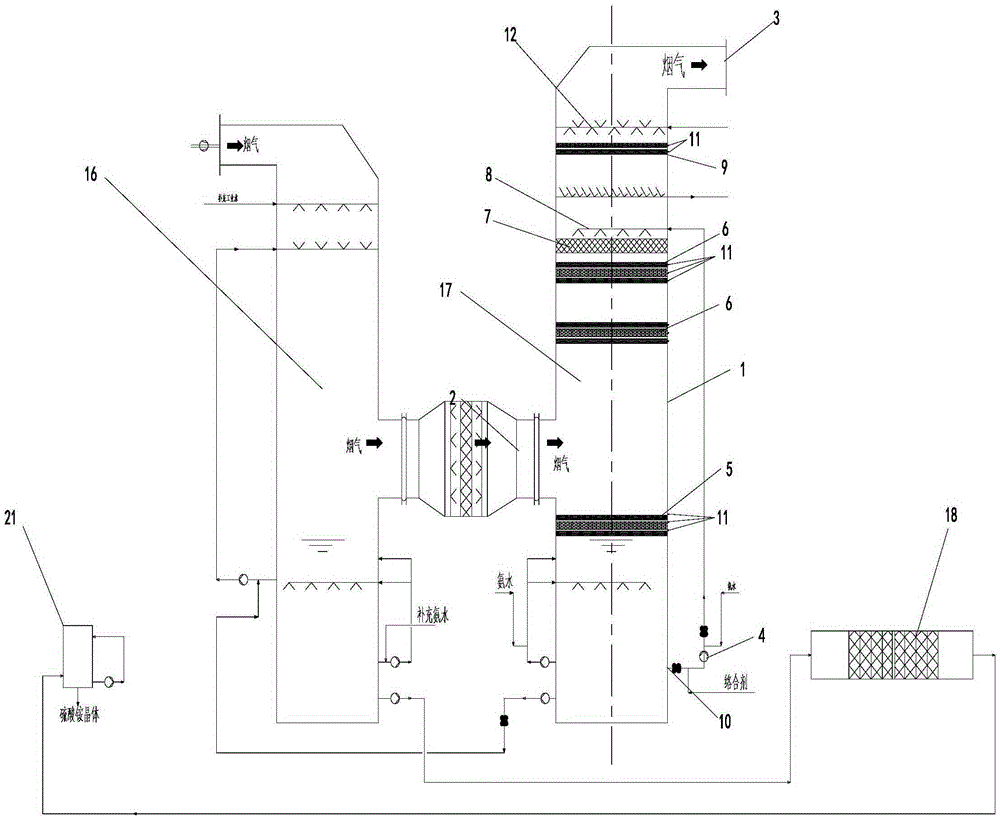

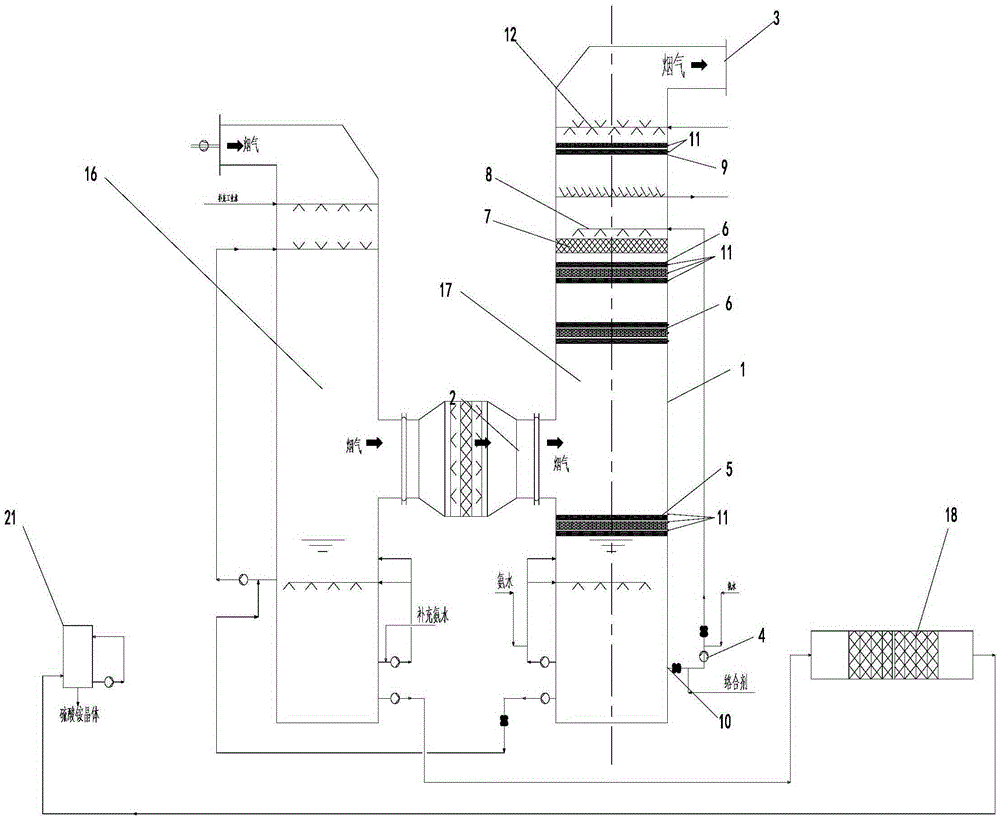

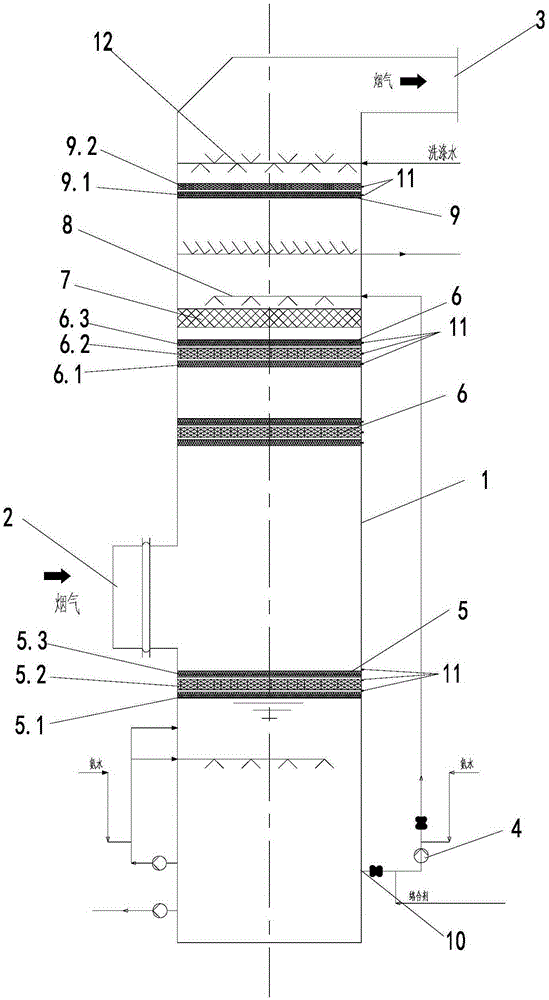

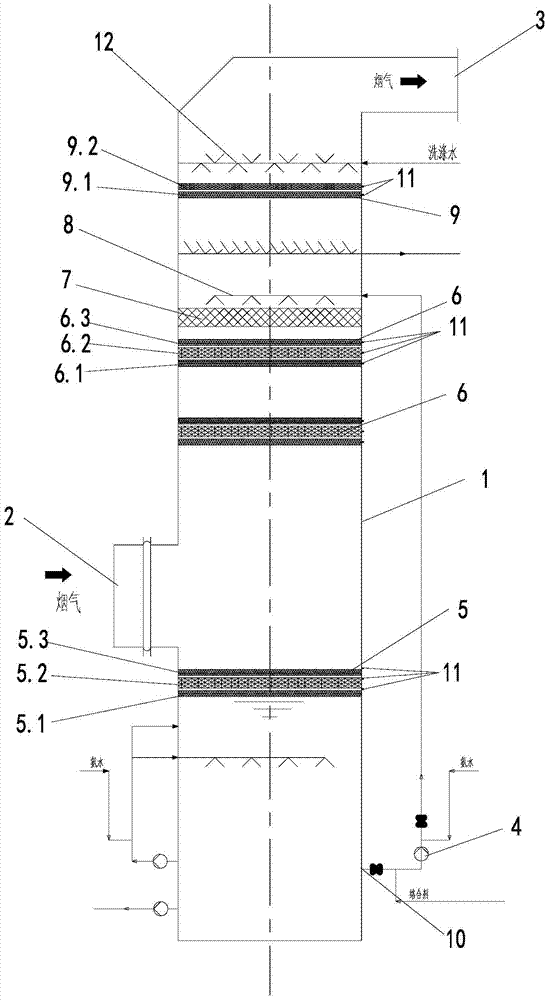

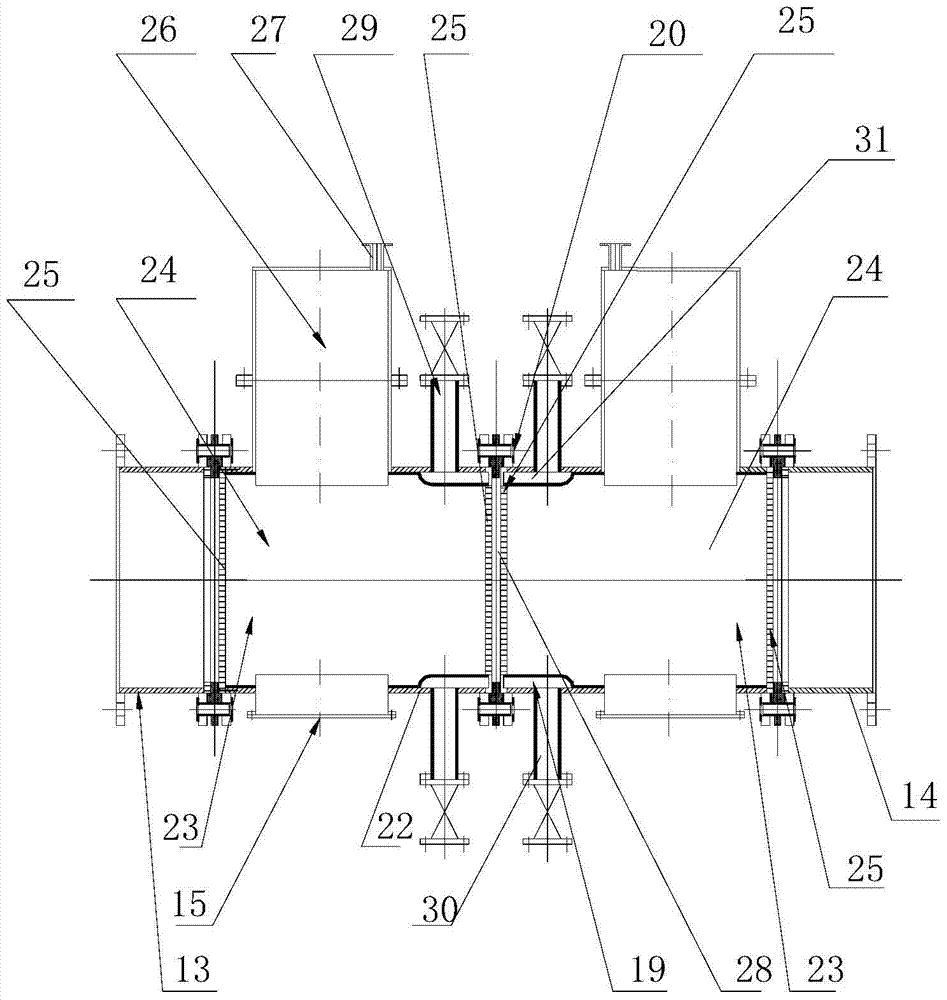

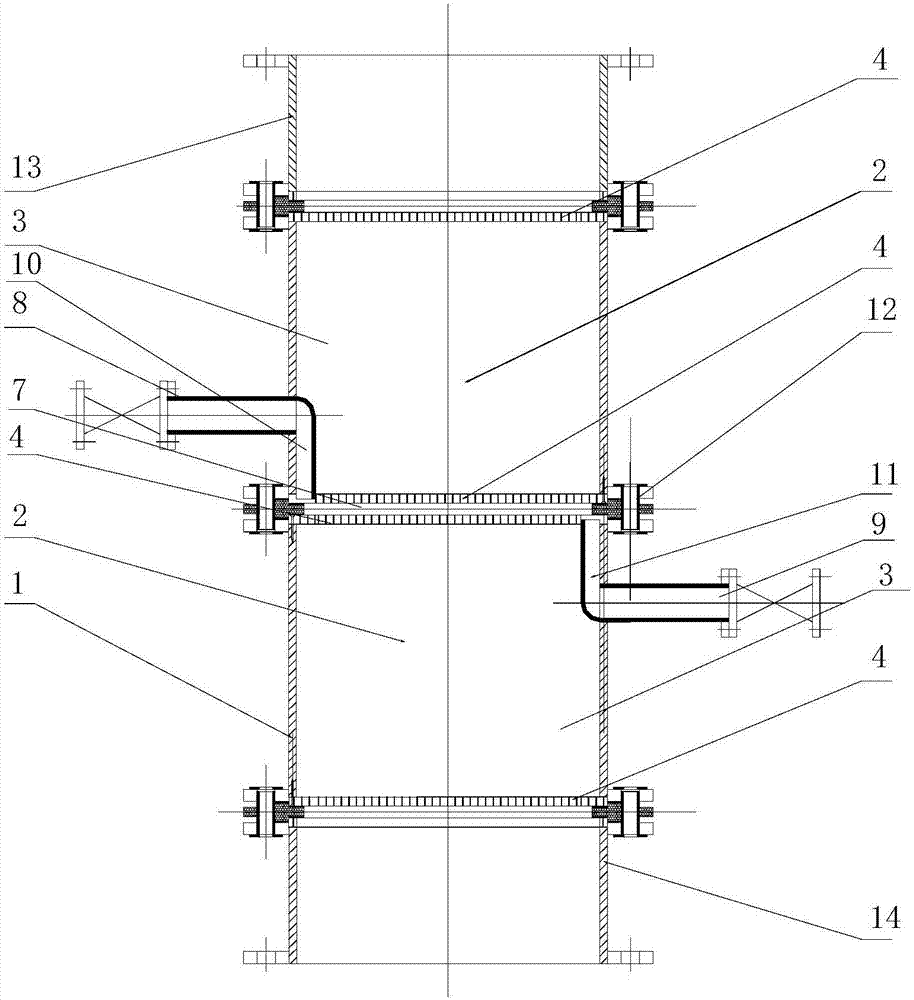

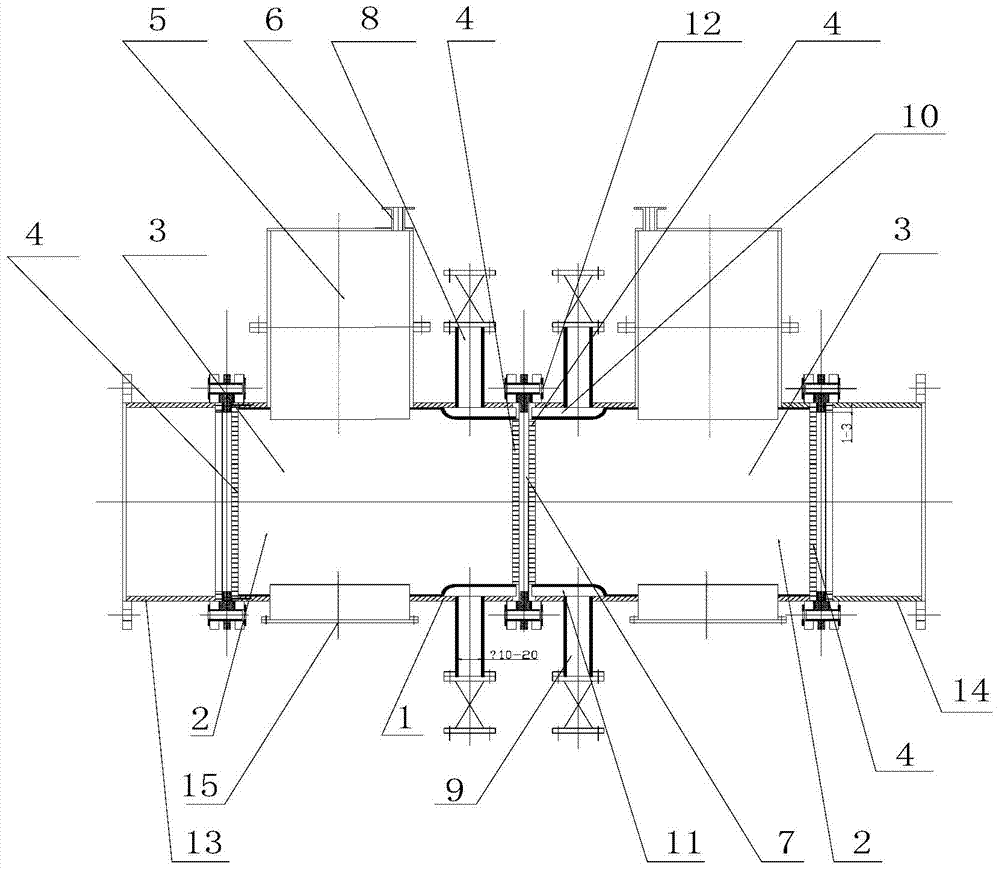

Ammonia desulphurization and denitrification process for flue gas by synchronization of complexing absorption and electrolytic regeneration

ActiveCN105413422AEfficient regenerationEffective in removing ironGas treatmentDispersed particle separationAmmonium sulfateFlue gas

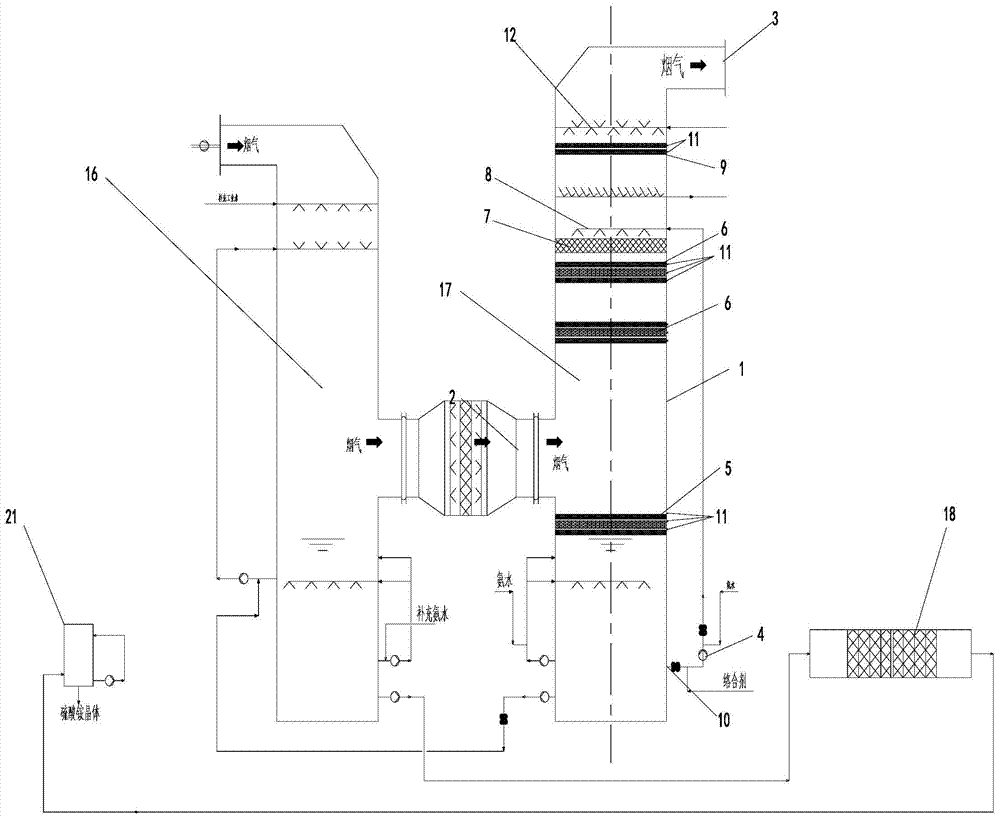

The invention discloses an ammonia desulphurization and denitrification process for flue gas by synchronization of complexing absorption and electrolytic regeneration and solves the problem of low absorption liquid regeneration efficiency in an existing synchronous ammonia desulphurization and denitrification process for the flue gas. The technical scheme includes that the flue gas is pressurized and then fed into a concentration tower to realize contact reaction with concentration liquid in the tower, the flue gas discharged from the concentration tower is fed into an absorption tower to realize contact reaction with cyclic absorption liquid in the absorption tower, the concentration liquid at the bottom of the concentration tower is subjected to deferrization through a first electrolytic reactor after reaction and then fed into an ammonium sulfate crystallization system, the absorption liquid at the bottom of the absorption tower is regenerated and then fed back to the upper portion of the absorption tower to serve as the cyclic absorption liquid, the concentration liquid enters an anode chamber of a reaction unit of the first electrolytic reactor to realize oxidation reaction and then enters a cathode chamber to realize a reduction reaction, and an electrolytic solution is discharged through a short outlet connection pipe of the reactor after reaction and fed into the ammonium sulfate crystallization system. The ammonia desulphurization and denitrification process for the flue gas by synchronization of complexing absorption and electrolytic regeneration has the advantages of simplicity, low investment cost and operation cost, high conversion efficiency and effectiveness in deferrization, desulphurization and denitrification.

Owner:武汉武钢绿色城市技术发展有限公司

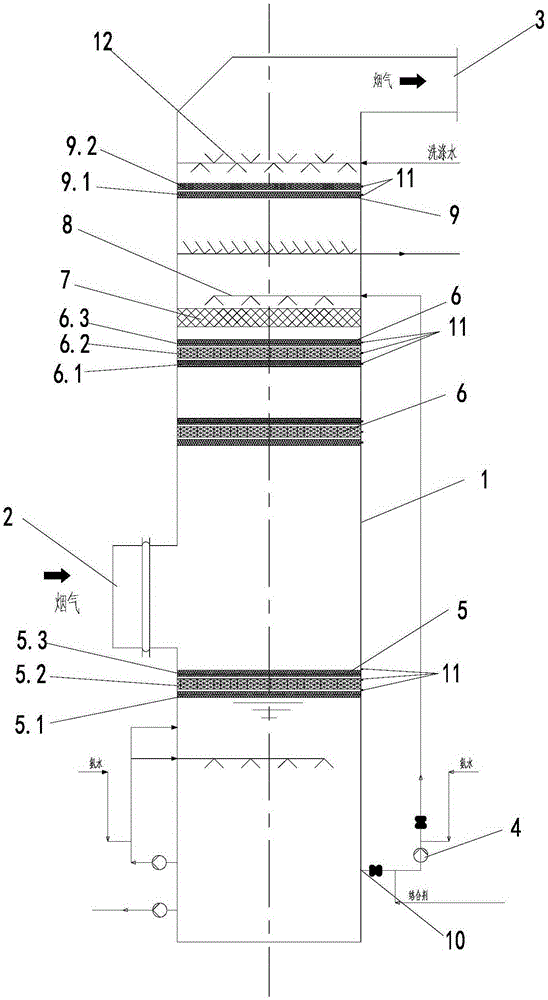

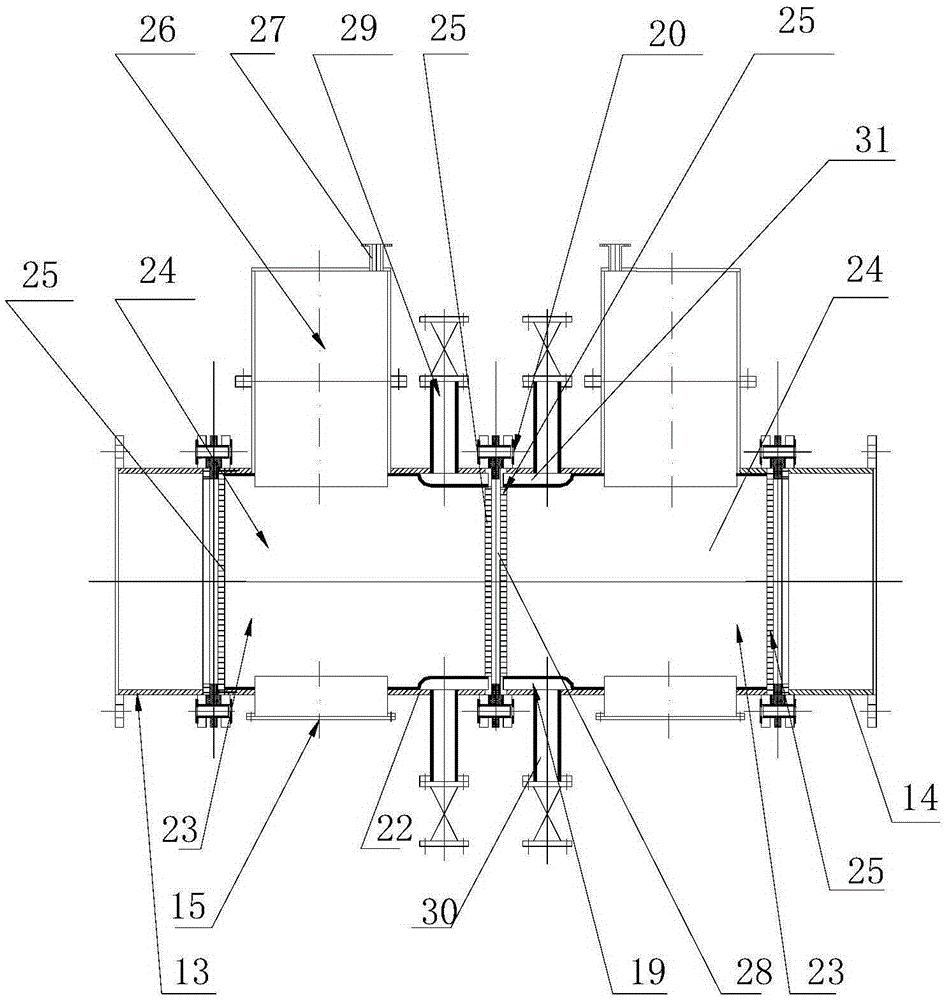

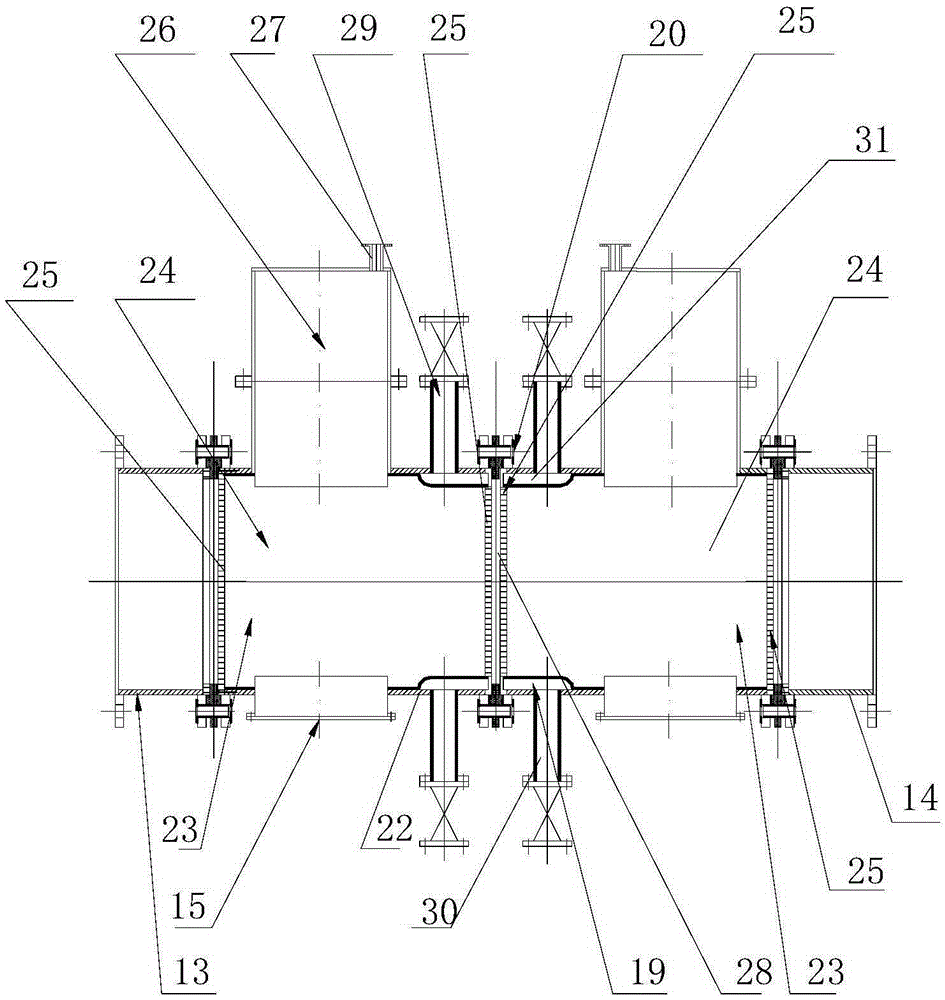

Flue gas pollutant cooperation removal technology based on electrolysis

InactiveCN105344215AImprove conversion rateSimple structureCombination devicesGas treatmentAmmonium sulfateElectrochemical response

The invention discloses a flue gas pollutant cooperation removal technology based on electrolysis. The problems are solved that technologies are complex, the pollutant treatment efficiency is low, investment and operation cost are high in present flue gas treatment. The technology comprises steps: flue gas is pressurized and sent to a concentration tower, a reaction is carried out, the flue gas going out from the concentration tower is sent to an absorbing tower and contacts and reacts with a circulating absorption solution sprayed from a spray layer at the upper part of the tower in a reverse manner, and the flue gas after reaction is discharged from the top of the absorbing tower; part of the concentrate at the tower bottom of the concentration tower is subjected to iron removal, then is sent to a ammonium sulfate crystallization system, the flue gas goes into the absorbing tower from a flue gas inlet at the middle part of the absorbing tower, goes through at least one absorbing and electrochemical reaction layer arranged at the upper part of the tower firstly, then contacts and reacts with a circulating absorption solution in a reverse manner, then goes through a filler layer and a spraying layer, and is discharged from a flue gas outlet. The technology is simple, the reaction efficiency is high, the operation and investment cost are low, the system land occupation area is small, and the technology is especially suitable for cooperation treatment of multiple pollutants of sulfur dioxide, nitrogen oxides, fine particles, dioxin and the like.

Owner:WUHAN WUTUO TECH +1

Process for synergic removal of flue gas pollutants through complexing absorption synchronous electrolytic reduction

InactiveCN105289254ASimple processing methodImprove controllabilityDispersed particle separationExternal electric electrostatic seperatorComing outElectrolysis

The invention discloses a process for synergic removal of flue gas pollutants through complexing absorption synchronous electrolytic reduction. The technical scheme is that the process comprises the steps that flue gas is pressurized and then fed into a concentrating tower to react; the flue gas coming out of the concentrating tower is fed into an absorption tower to be in reverse contact reaction with circulating absorption liquid sprayed out of a spraying layer on the upper portion of the tower and then is discharged out of the top of the absorption tower; part of concentrated solution at the bottom of the concentrating tower undergoes iron removal and then is fed into an ammonium sulfate crystallization system; the circulating absorption liquid sprayed out of the spraying layer is in reverse contact reaction with the flue gas downwards and then enters the bottom of the absorption tower through an electrolytic regeneration layer below a flue gas inlet, and a cathode layer, an anode layer and a cathode layer are sequentially arranged on the electrolytic regeneration layer from top to bottom. Each electrode layer is of a net structure made of a conductive material, every two adjacent electrode layers are insulated from each other, and the electrolytic regeneration layer is connected with a power supply through a binding post installed on the tower wall. The process is simple, high in reaction efficiency, low in running and investment cost, small in occupied space and particularly suitable for coordinating management of multiple flue gas pollutants.

Owner:WUHAN UNIV OF SCI & TECH +1

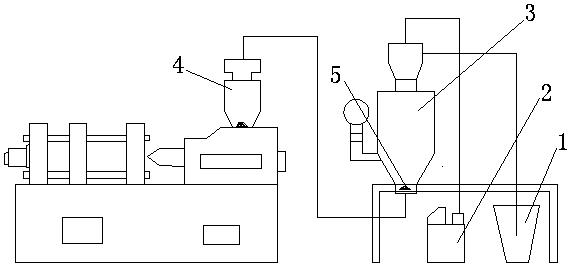

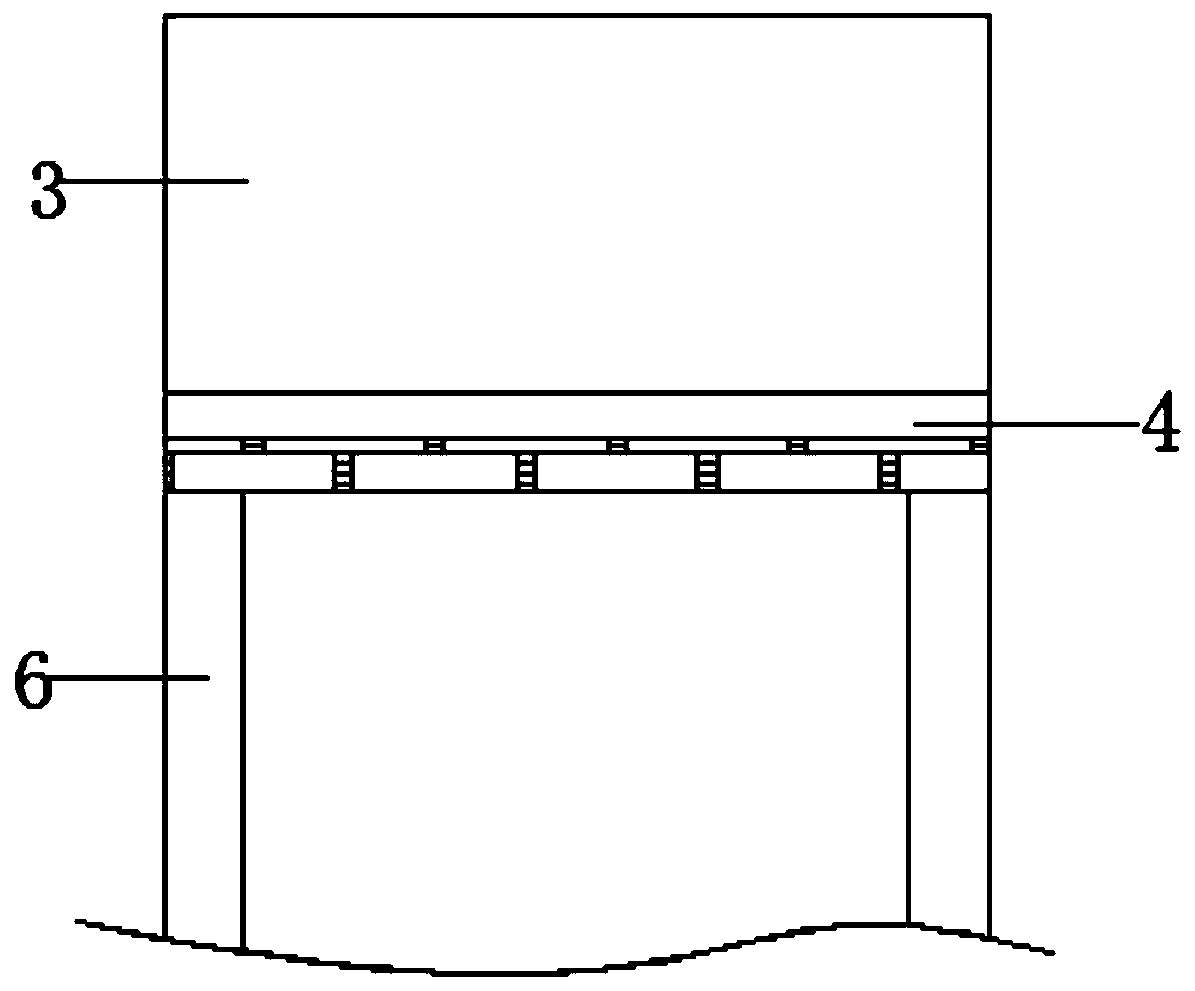

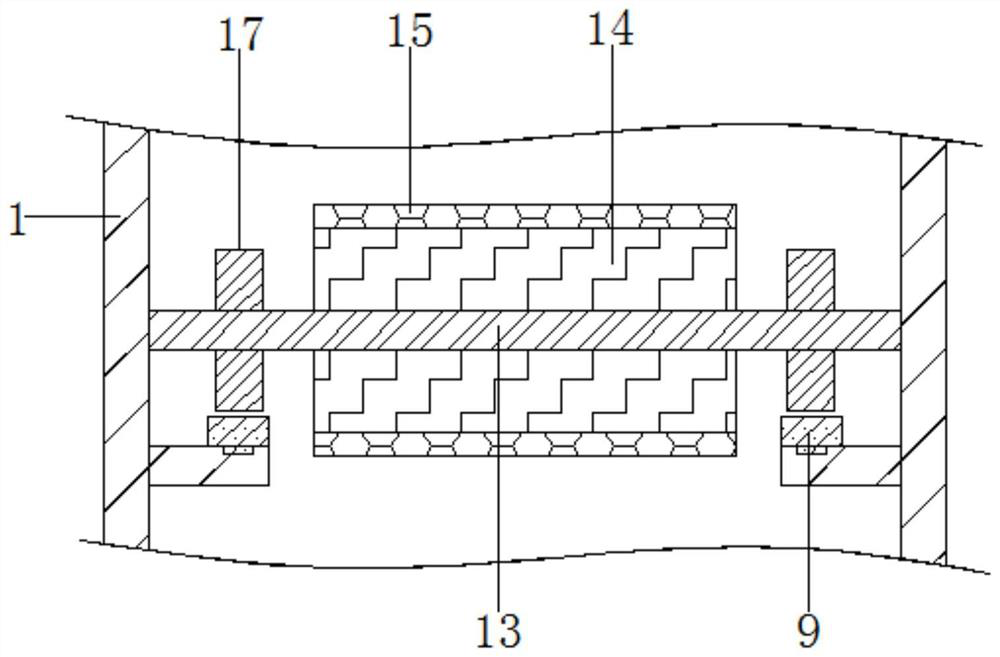

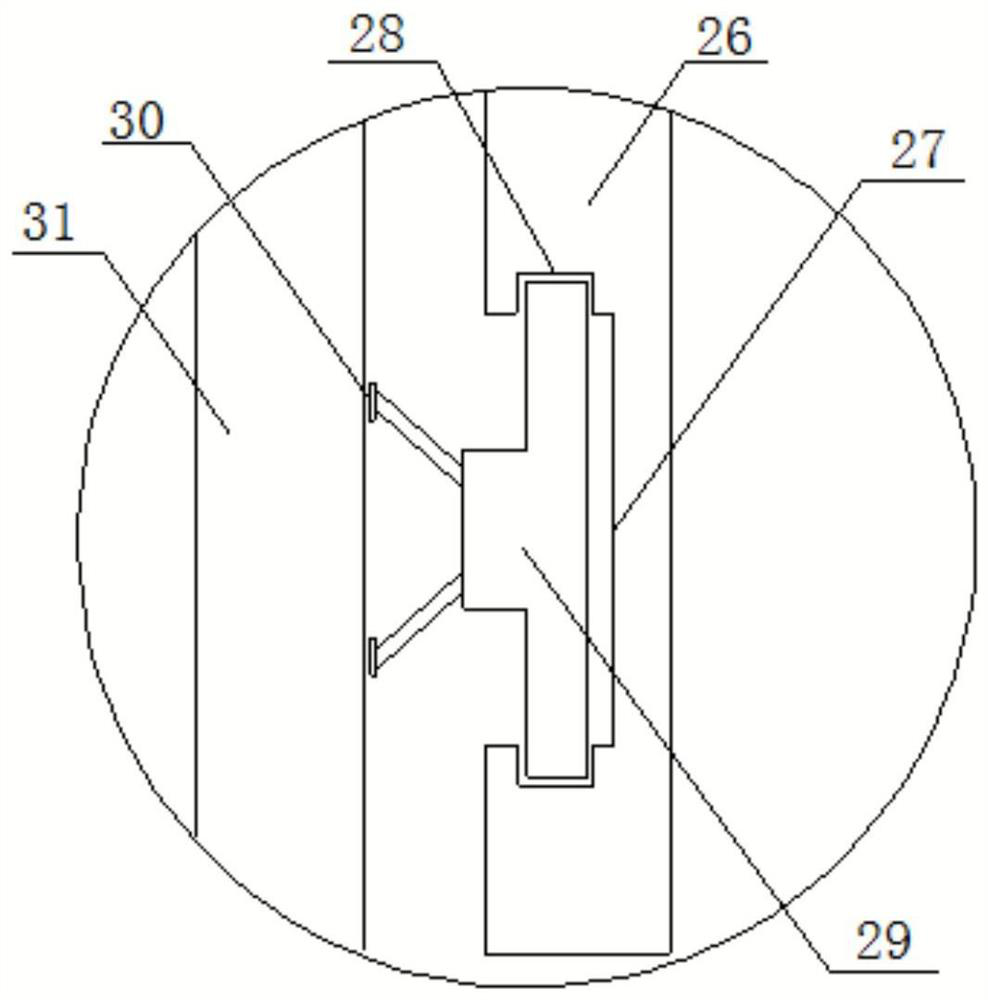

Treating device with deferrization effect on front end of injection moulding machine

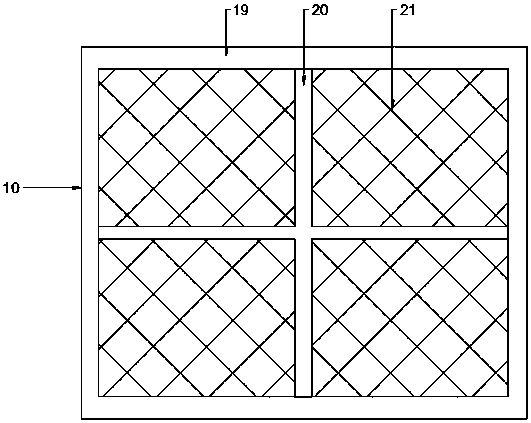

InactiveCN103722688AFlexible removalGuaranteed iron removal effectMagnetic separationMechanical engineeringInjection moulding

The invention relates to a treating device with a deferrization effect on the front end of an injection moulding machine. The treating device comprises a charging bucket, a suction feeder, a drying bucket and a mix machine, wherein the drying bucket and the mix machine which are connected in sequence are arranged on the back end of the suction feeder, and a discharge port of the drying bucket and the discharge port of the mix machine are respectively provided with magnetic devices. The discharge port of the drying bucket and the discharge port of the mix machine are respectively provided with the magnetic devices which can treat iron elements in plastic particles twice, thereby ensuring to effectively remove the iron elements in the plastic particles and reducing the influence of the iron elements on the subsequent injection moulding of the plastic particles to the minimum.

Owner:YIZHENG YINGLI AUTO PARTS MFG

Method for purifying and deferrizing electrolytic manganese leach solution

The invention relates to a method for purifying and deferrizing an electrolytic manganese leach solution, which comprises the following steps: when a compound leach solution of electrolytic manganese metal reaches to the leaching reaction end point, determining the total content of Fe<2+> in the leach solution, and adding MnO2, which is 0.6-1.2 times of the theoretical amount required by completely oxidizing all the Fe<2+>, into the leach solution; after finishing adding the MnO2, continuing stirring to react, determining the residual total content of Fe<2+> in the leach solution, and adding a strong oxidizer required by completely oxidizing the residual Fe<2+> so as to lower the concentration of the residual Fe<2+> to below 1mg / L; regulating the pH value of the solution with a neutralization reagent, and detecting the concentration of the Fe<2+> in the solution; and removing solid impurities from the solution by using a filter plant. The invention provides an oxidizing and deferrizing method by combining MnO2 and a strong oxidizer; and on the premise of ensuring the deferrizing effect, the invention prolongs the leaching reaction time, increases the concentration of Mn<2+> in thesolution and lowers the deferrizing cost.

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

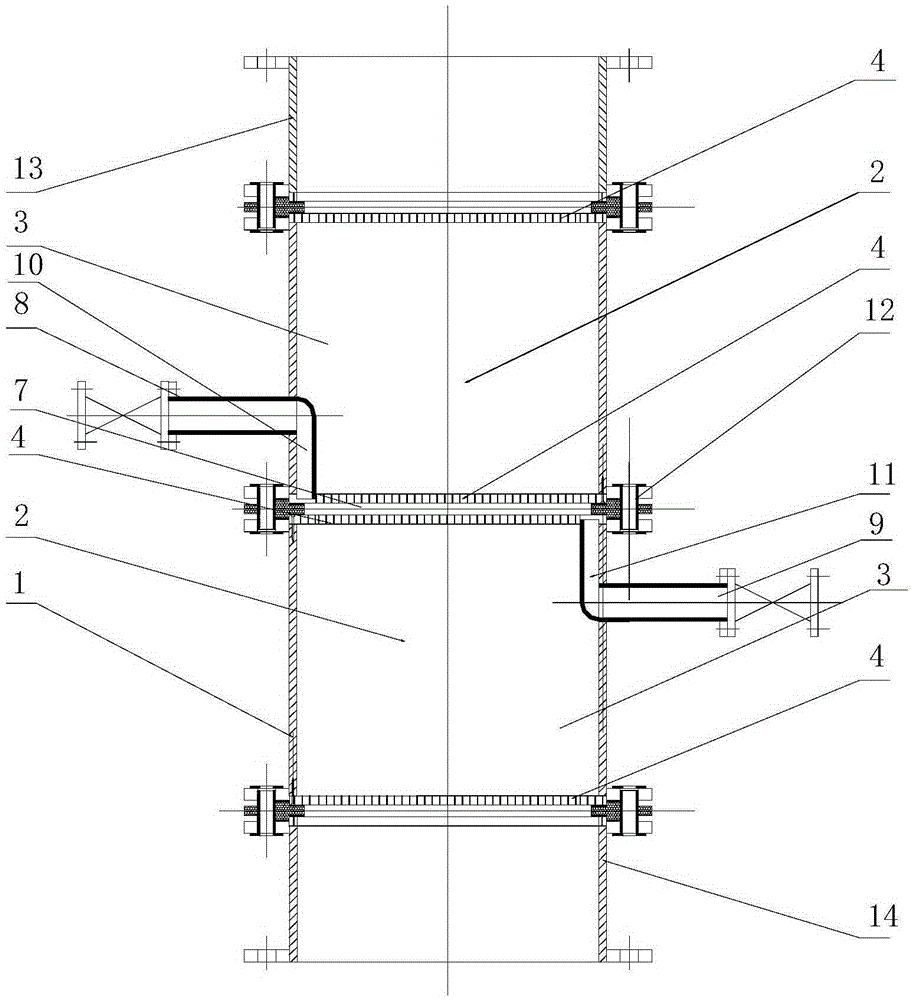

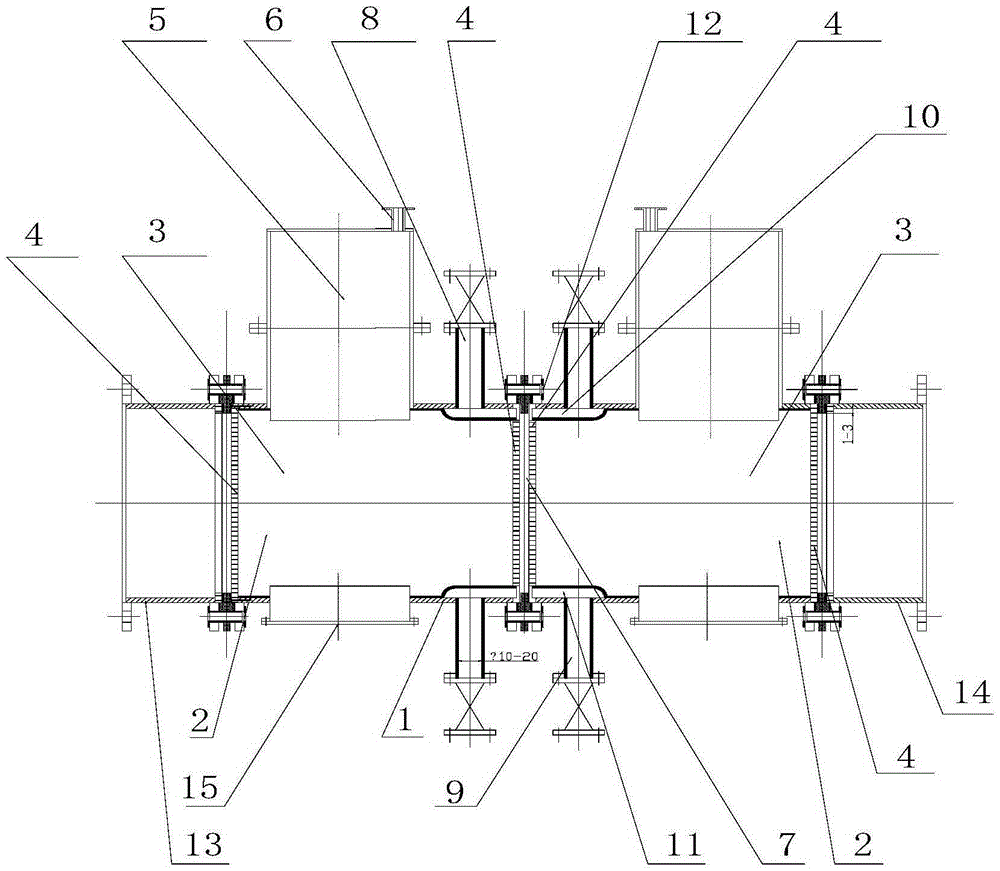

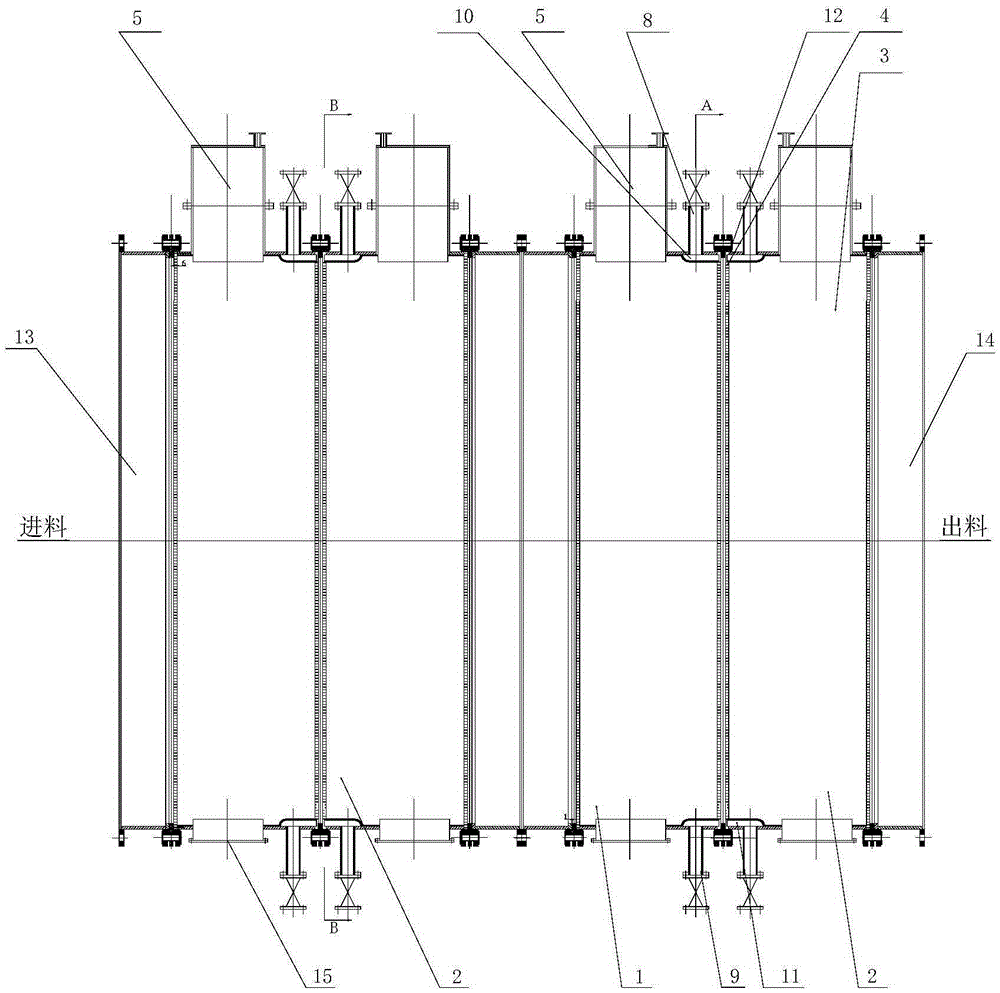

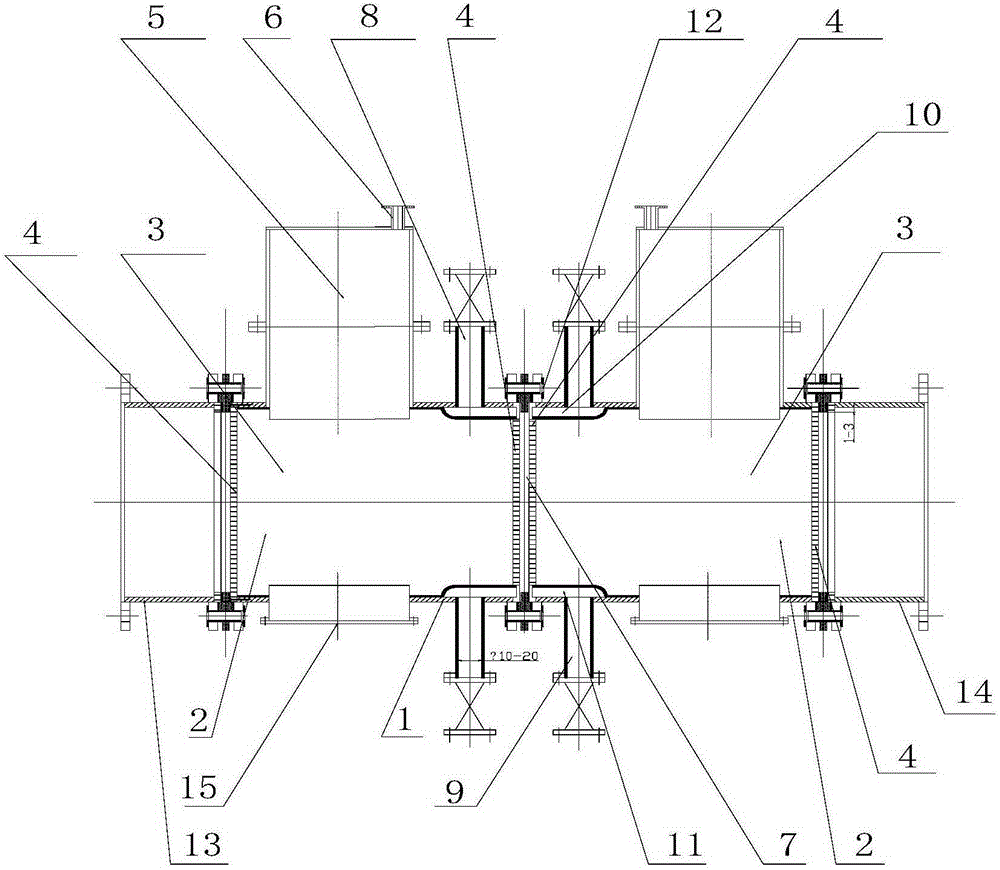

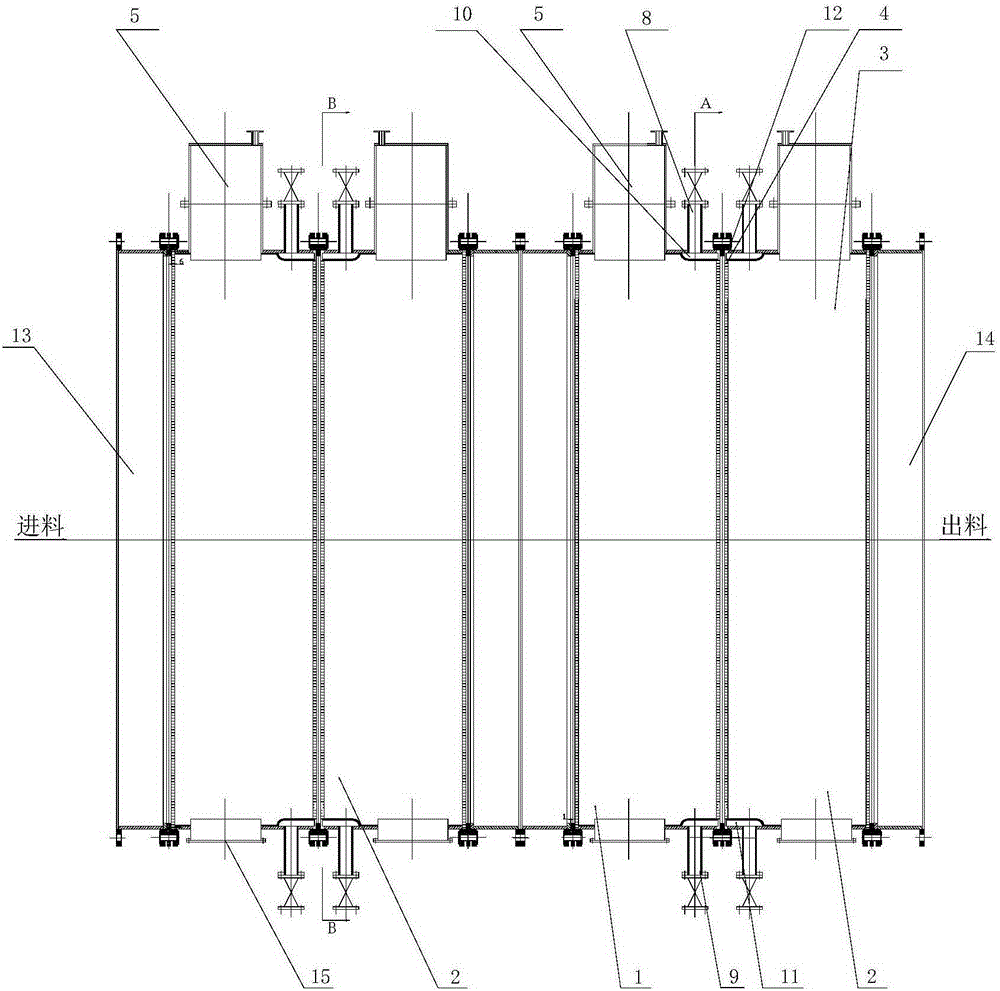

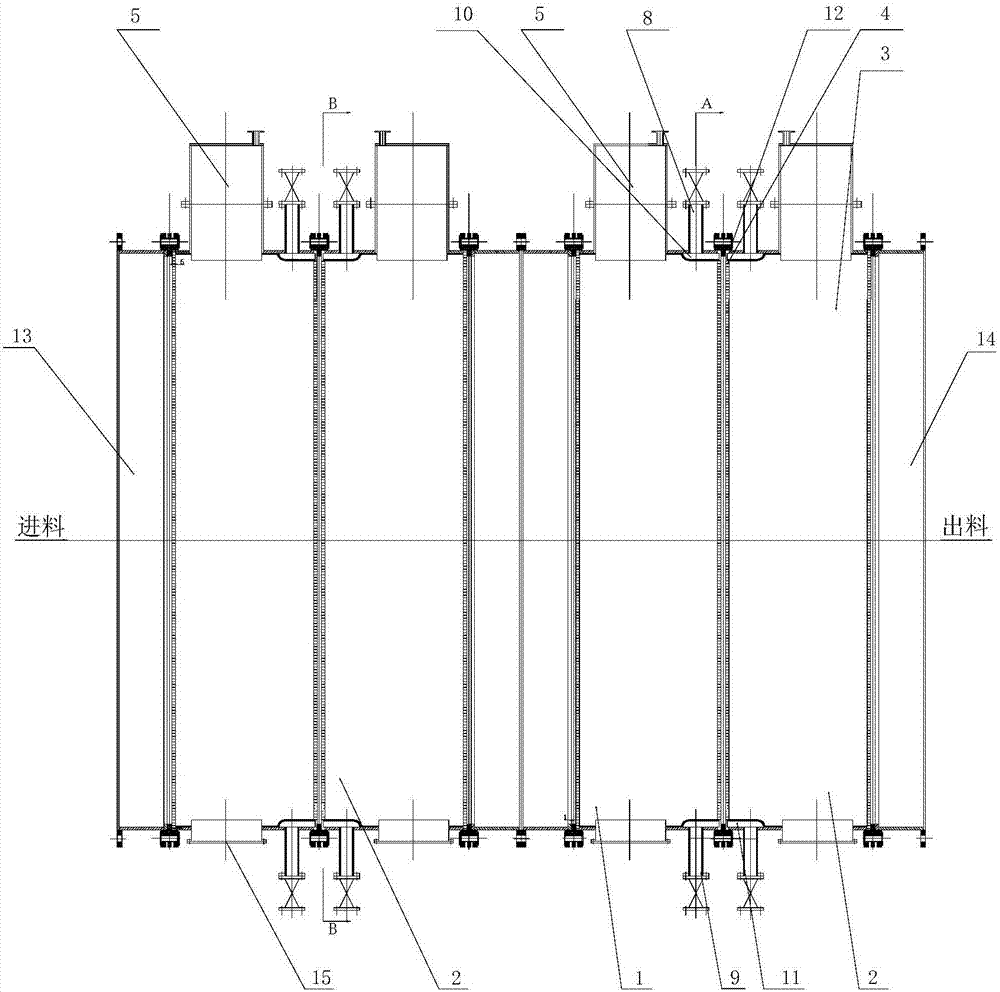

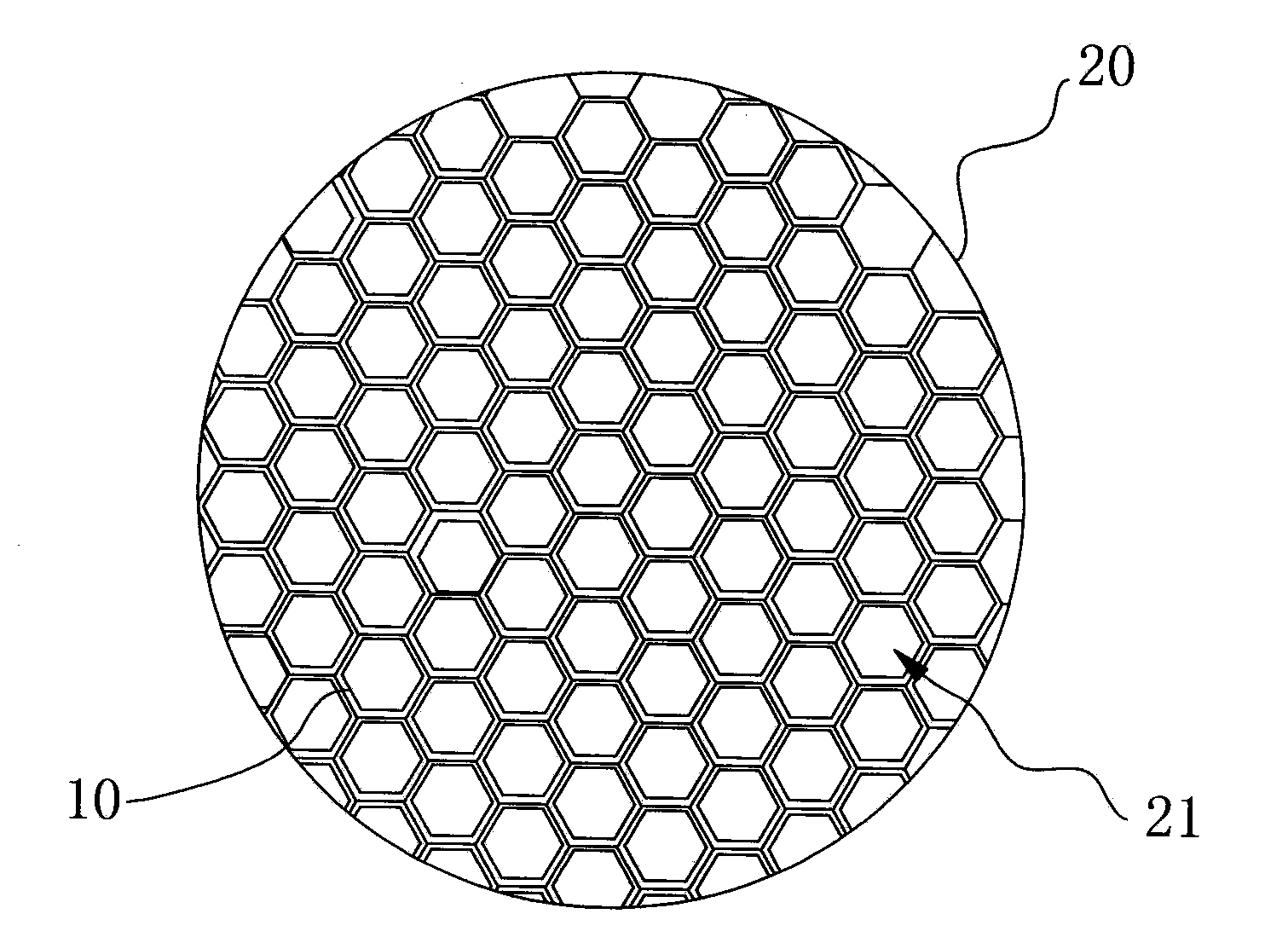

Double-seal scraper iron remover

ActiveCN111097596ANo need for manual cleaningImprove work efficiencyCleaning using toolsMagnetic separationIron removalEngineering

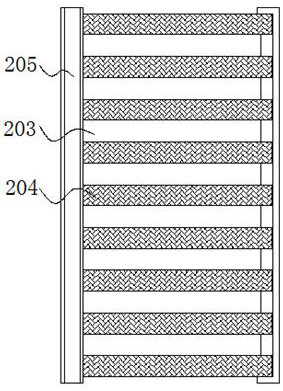

The invention discloses a double-seal scraper iron remover, and relates to the field of magnetic adsorption equipment. The iron remover comprises a cavity. At least two layers of drawers are arrangedin the cavity from top to bottom; the drawer comprises an outer panel and an inner panel; the outer panel is arranged outside the cavity, and inner panel is in the cavity; a plurality of magnetic rodsextending into the cavity are uniformly and horizontally arranged on the outer panel; the magnetic rods penetrate through the inner panel; the inner panel is provided with a guide column which penetrates through the cavity and can adsorb the outer panel in a non-fixed contact manner; a linear guide rail for controlling the drawer to advance is arranged outside the cavity; each magnetic rod is divided into a magnetic area and a non-magnetic area; the cavity comprises a feeding area and a cleaning area; the inner panel is located between the feeding area and the cleaning area in a general state, the non-magnetic areas of the magnetic rods are located at the tail of the feeding area; and the non-magnetic areas of the magnetic rods can advance into the cleaning area under the action of the linear guide rail, and the inner panel can advance to the side end of the cleaning area. Manual replacement is not needed in the whole iron removal process, the working efficiency is high, interferenceof the external environment is reduced, and the iron removal effect is good.

Owner:NINGBO SOUWEST MAGNETECH DEV

Technology of synchronous desulfurization and denitration through flue gas ammonia method based on electrolytic regeneration iron removal

ActiveCN105251330AEasy to fillGuaranteed reliabilityDispersed particle separationAmmonium sulfatesComing outCrystal system

The invention discloses a technology of synchronous desulfurization and denitration through a flue gas ammonia method based on electrolytic regeneration iron removal. The problem that for an existing desulfurization and denitration technology, the regeneration efficiency of an absorption solution is not high is solved. According to the technical scheme, the technology comprises the steps that pressurizing is conducted on flue gas, the flue gas is sent to a concentration tower to be reacted with a concentrated solution in the tower in a contacting mode, the flue gas coming out of the concentration tower is sent to an absorption tower to be reacted with the circulation absorption solution in the tower in a contacting mode, the concentrated solution reacted at the tower bottom part of the concentration tower is sent into an ammonium sulfate crystal system after iron is removed through a first electrolytic reactor, the absorption solution reacted at the tower bottom part of the absorption tower is sent back to the upper portion of the absorption tower to serve as the circulation absorption solution through regeneration, and the concentration solution enters an anode chamber in a reaction unit of the first electrolytic reactor to conduct an oxidation reaction and then enters a cathode chamber to conduct a reduction reaction; a reacted electrolyte is discharged from an outlet connection short pipe and sent into the ammonium sulfate crystal system. The technology of synchronous desulfurization and denitration through the flue gas ammonia method based on electrolytic regeneration iron removal has the advantages of being simple in method, low in investment cost and operating cost, high in conversion efficiency, good in iron removing effect and good in desulfurization and denitration effect.

Owner:武汉武钢绿色城市技术发展有限公司

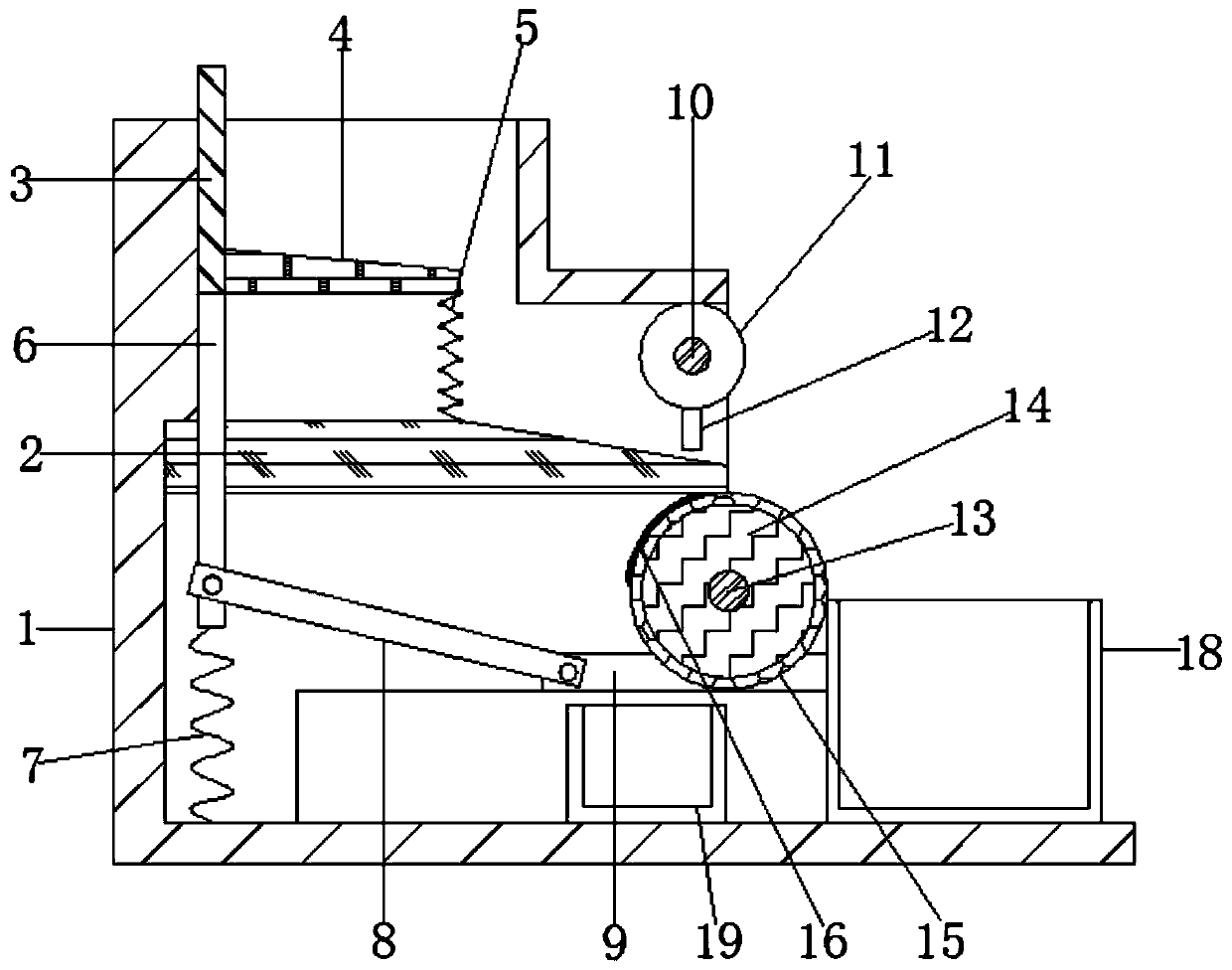

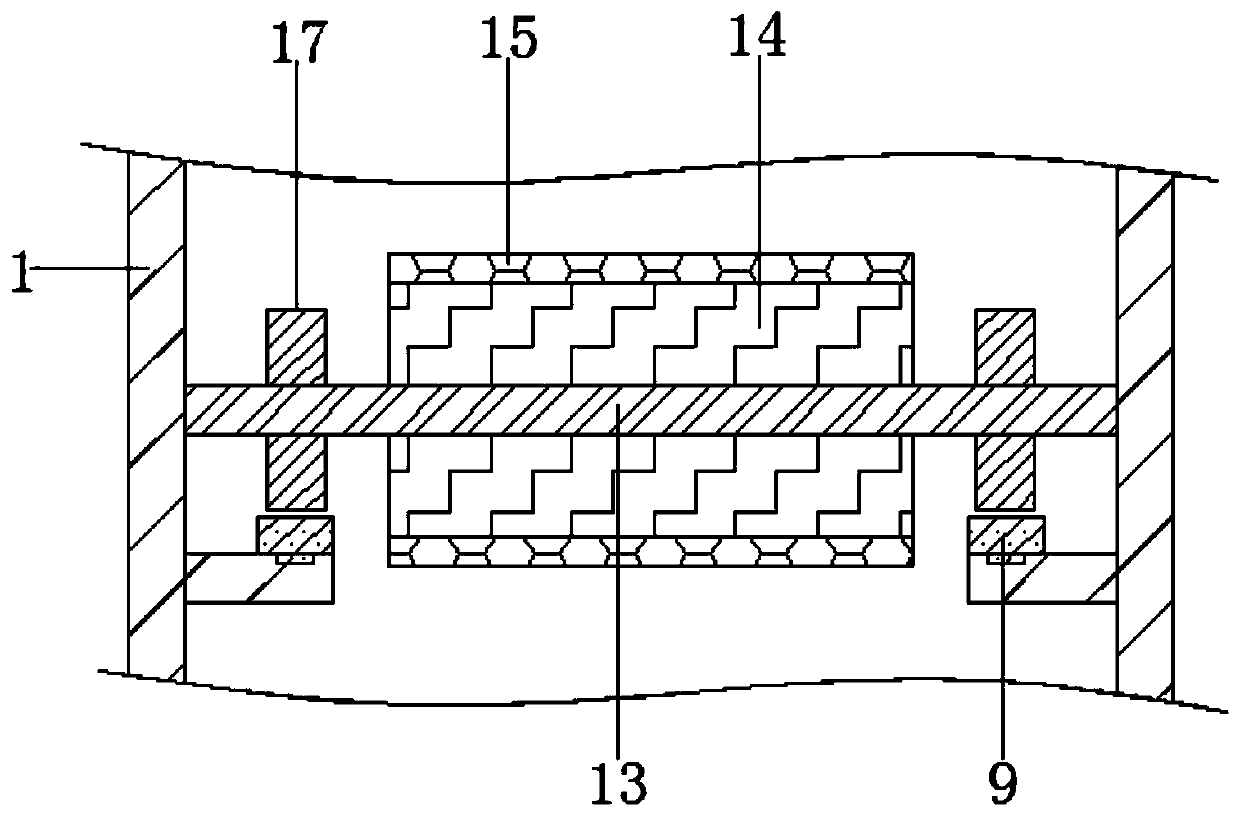

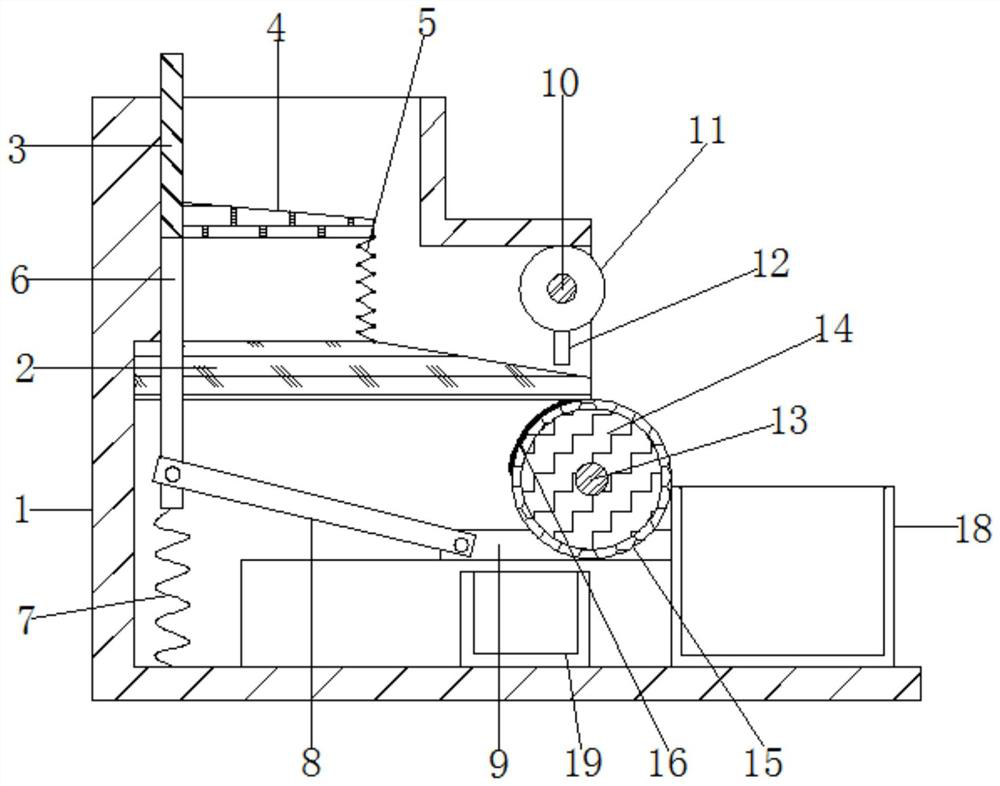

Fly ash iron removal device for building

ActiveCN111266188AEasy to remove ironThorough iron removalCleaning using toolsMagnetic separationIron removalGear wheel

The invention relates to the technical field of building materials, and further discloses a fly ash iron removal device for construction. The device comprises a housing, and a material sliding plate is arranged in the middle of the shell. A vertical plate is arranged above the material sliding plate; the right side of the vertical plate is connected with a bearing plate; the lower side of the vertical plate is connected with a vertical rod; the lower end of the vertical rod penetrates through the sliding plate and is connected with a spring at the bottom of the shell; a connecting rod is hinged to the lower portion of the vertical rod, a moving rod is hinged to the right end of the connecting rod, a first rotating cylinder is arranged on the upper right portion of the shell and connected with a material baffle, a second rotating cylinder is arranged below the material sliding plate, a magnetic block is arranged on the outer side of the second rotating cylinder, a scraping plate is connected to the lower side of the material sliding plate, and gears are fixedly connected to the two ends of the second rotating shaft. According to the fly ash iron removal device for the building, thescraping plate can scrape off iron adsorbed on the magnet through rotation of the second rotary drum, and the device has the advantages that the fly ash iron removal process can be conveniently controlled, and the adsorbed iron can be cleaned and collected in time.

Owner:上海碳澜环境集团有限公司

Cyclical magnetic attraction cable insulating material iron removing device

ActiveCN110237929AAvoid scratchesGuaranteed iron removal effectSievingScreeningElectric machineryMagnet

The invention discloses a cyclical magnetic attraction cable insulating material iron removing device comprises a feed port, a body, an outlet, a base, a motor seat, a motor and a transmission box, wherein the base is connected to the bottom of the body; the outlet is arranged on the side of the bottom of the body; the feed port is disposed on the top of the body; the motor seat is welded to the side of the body; the motor is mounted on the motor seat; the motor is in driving connection to the body through the transmission box; the body is provided therein with a filter net, an adjusting device, a baffle, a discharge port, a debris collection box, a magnetic attraction device, an import inlet; the filter net is arranged right below the outlet; and the import inlet is disposed below the filter net. The contact surface of a magnet and an insulating material can be continuously updated by a rotary iron ring. Thus, not only the magnet can be in direct contact with the surface of the insulating material, but also the previously adsorbed metal pieces can be prevented from being scraped off, thereby ensuring an iron removing effect. The metal debris adsorbed by the iron ring can be scraped off by a scraper, thereby contributing to the contact with the insulating material next time and ensuring a magnetic attraction effect.

Owner:新昌县姝达电力科技有限公司

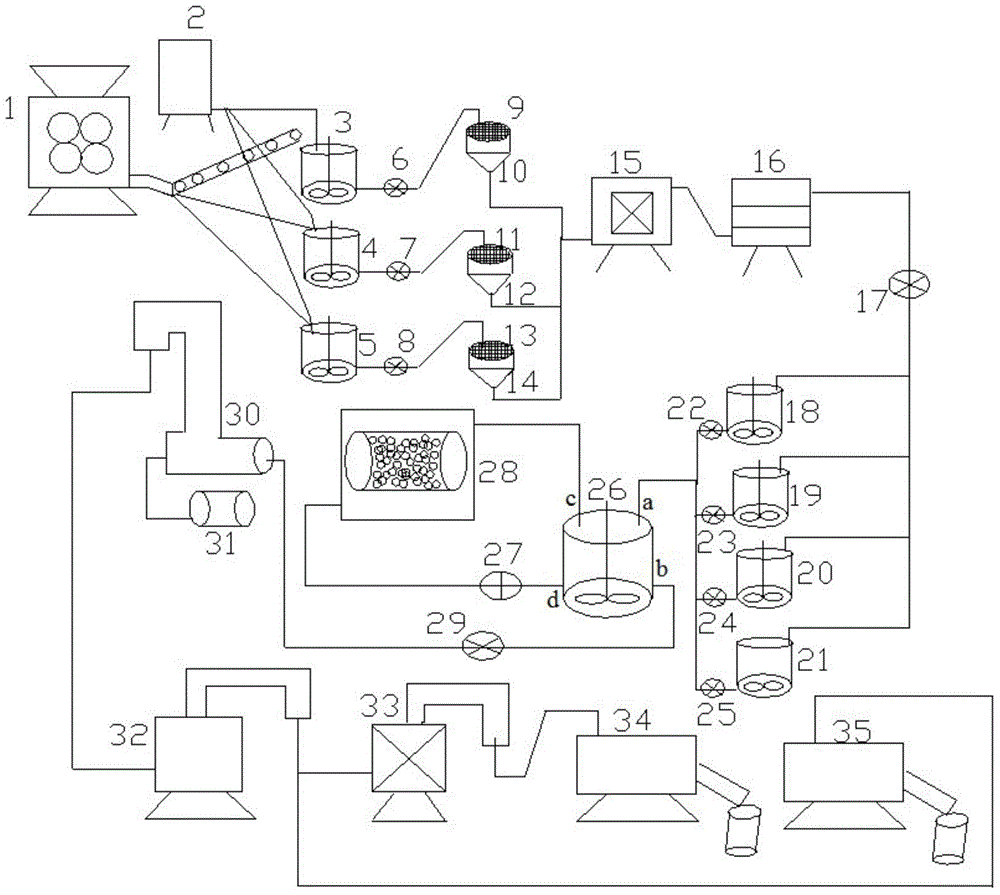

Illite/montmorillonite clay nanometer powder production device

ActiveCN103588213AClosely connectedImprove equipment utilization and productivityNanotechnologySilicon compoundsMagnetic separatorHot blast

The invention discloses an illite / montmorillonite clay nanometer powder production device and belongs to the technical field of a deep processing production line of ores. The illite / montmorillonite clay nanometer powder production device comprises a four-roll crusher, an automatic water supply facility, four stainless steel barrels, nine membrane pumps, three vibrating screens, three material collectors, an electromagnetic high-gradient magnetic separator, a permanent magnetic high-gradient magnetic separator, four chemical reaction tanks, a peristaltic pump, a superfine ball mill, a flash evaporation drying machine, a coal-fired type hot-blast stove, a superfine mechanical pulverizer, a continuous type powder coating modification machine, a first full-automatic packaging machine and a second full-automatic packaging machine. The illite / montmorillonite clay nanometer powder production device can be used for preparing illite / montmorillonite clay nanometer powder by a physical method, is environmentally-friendly and suitable for mass production and improves the production efficiency.

Owner:广西防城港市恒泰科技开发有限公司

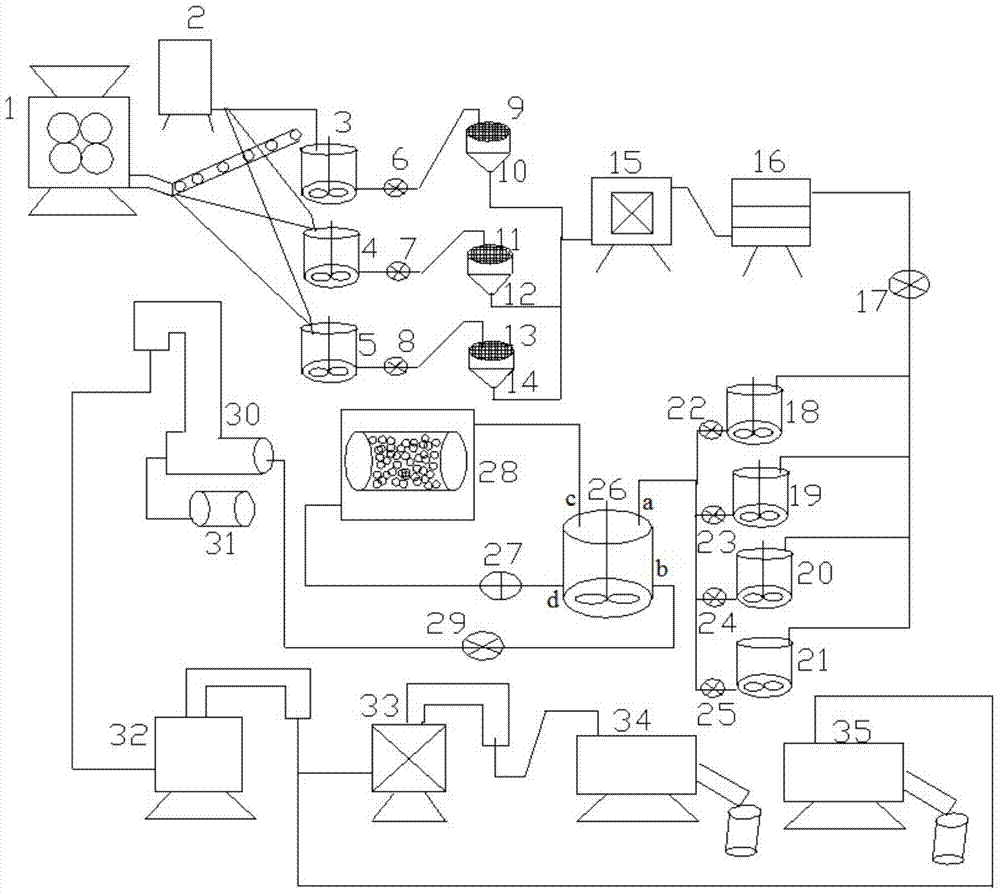

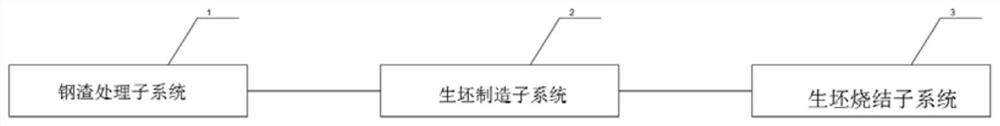

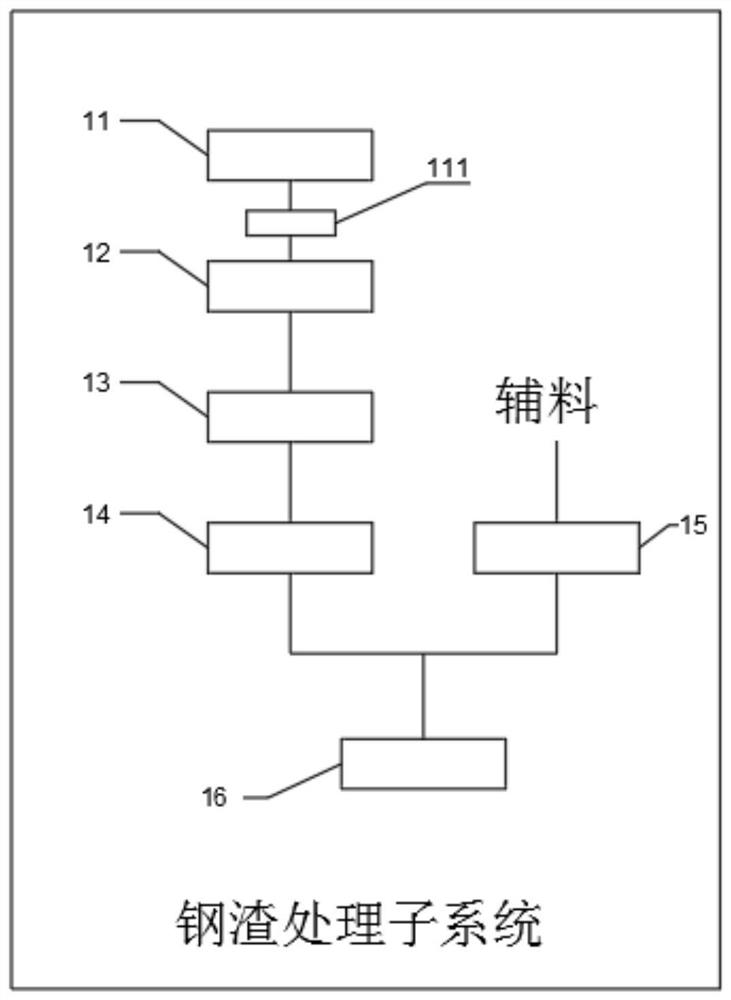

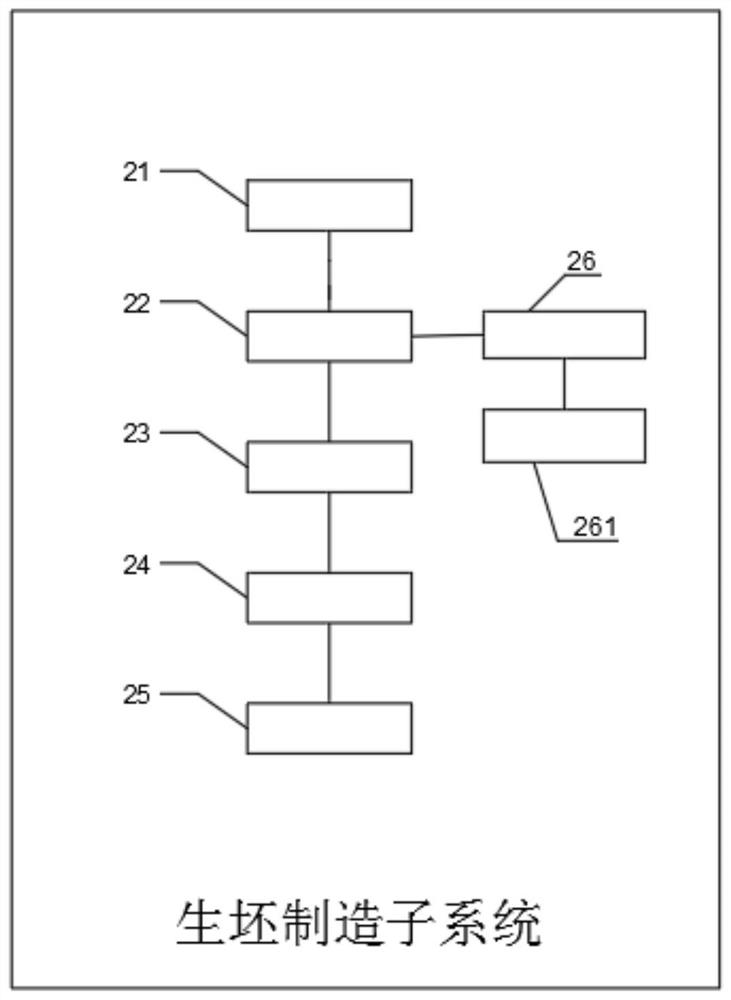

System for preparing steel slag sintered bricks

PendingCN113601694AImprove efficiencyGood strength and various propertiesCeramic shaping plantsAuxillary shaping apparatusSlagBall mill

The invention discloses a system for preparing steel slag sintered bricks, which comprises a steel slag treatment subsystem, a green body manufacturing subsystem and a green body sintering subsystem; the steel slag treatment subsystem comprises a steel slag conveyor, a steel slag receiving production line for conveying produced steel slag, a steel slag dipping box, a steel slag receiving conveyor for conveying the steel slag to the steel slag dipping box to dip and filter the steel slag to obtain solid residues, a washing dryer, a steel slag receiving and dipping box for washing and drying the filtered solid residues, a first ball mill connected with the washing dryer to grind the dried solid residues into steel slag powder with the particle size of 400-450 microns, and a second ball mill connected with an auxiliary material feeding hooper. According to the system for preparing the steel slag sintered bricks, the steel slag dipping box is arranged in the steel slag treatment subsystem and used for dipping the steel slag, so that part of free calcium oxide in the steel slag can be removed, and the problem of poor volume stability caused by the free calcium oxide is fundamentally controlled.

Owner:江西联达冶金有限公司

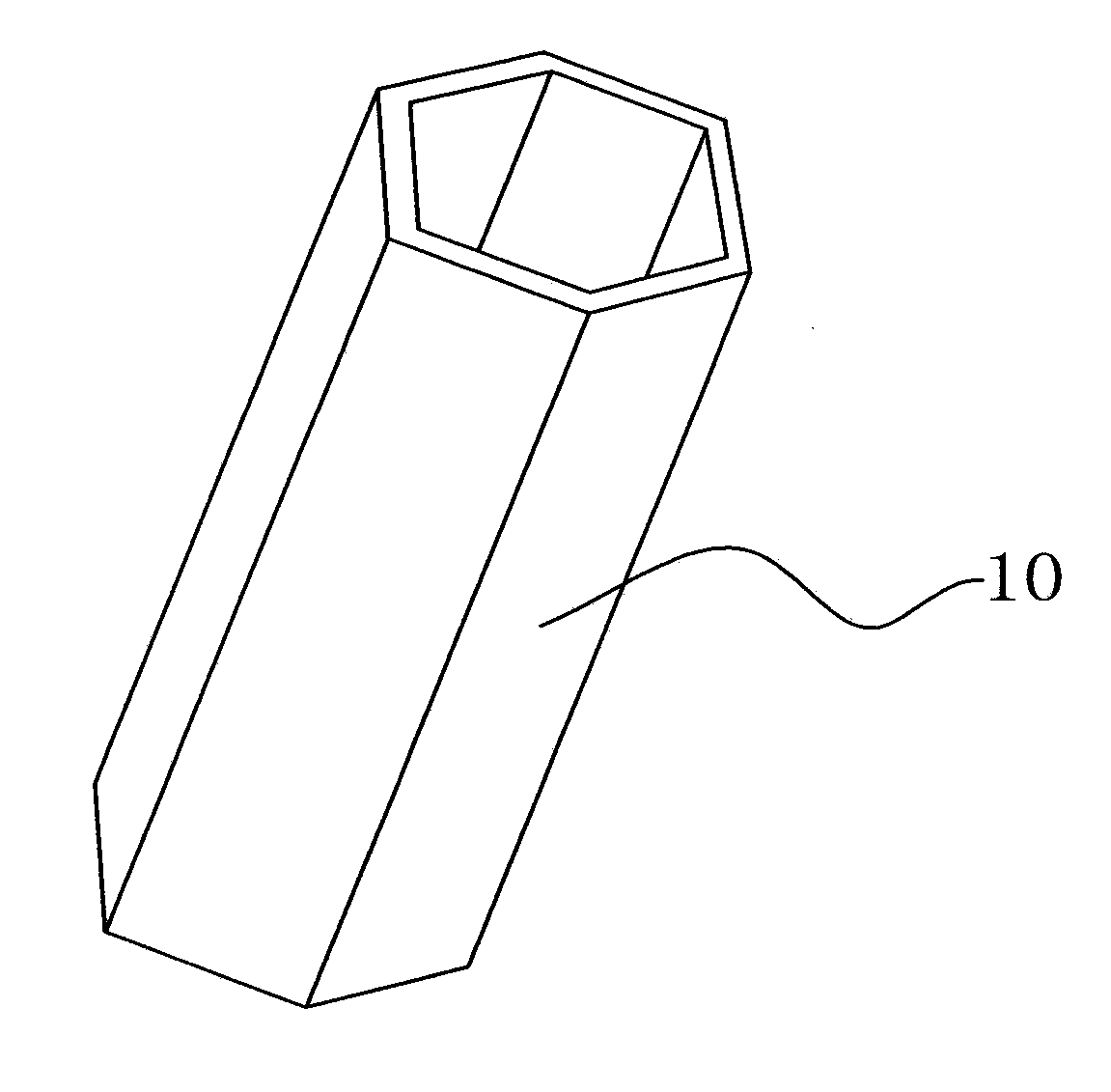

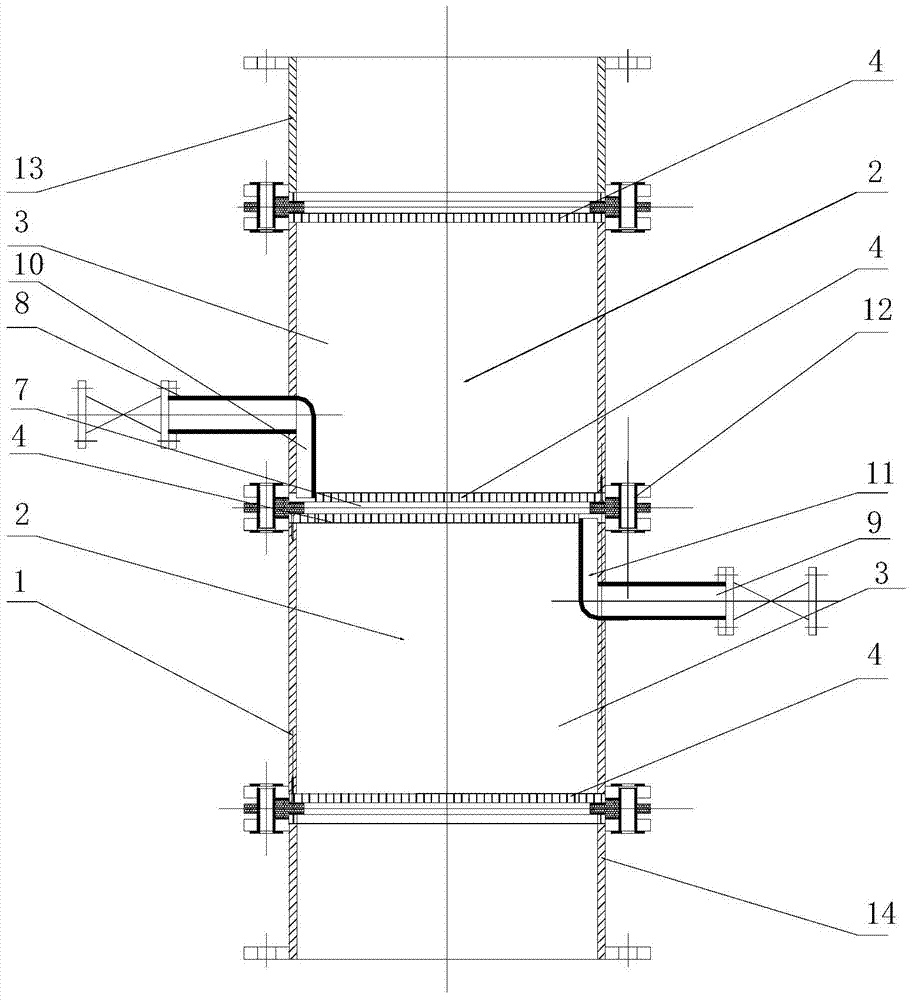

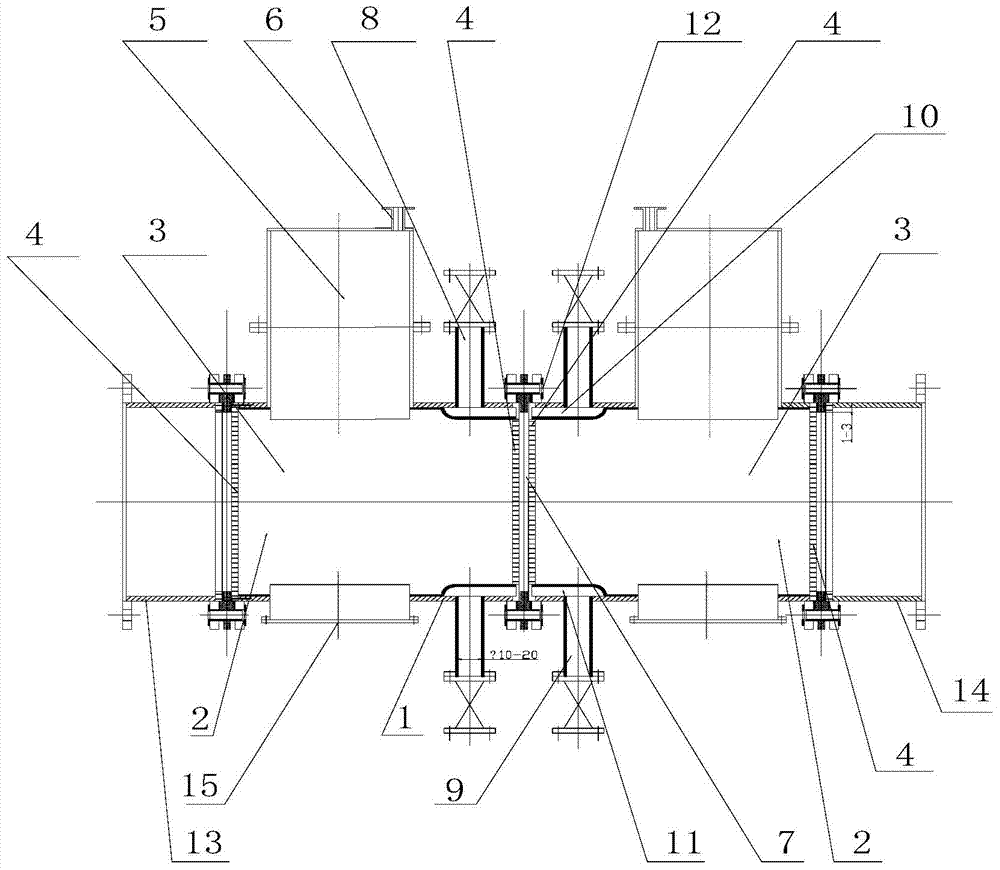

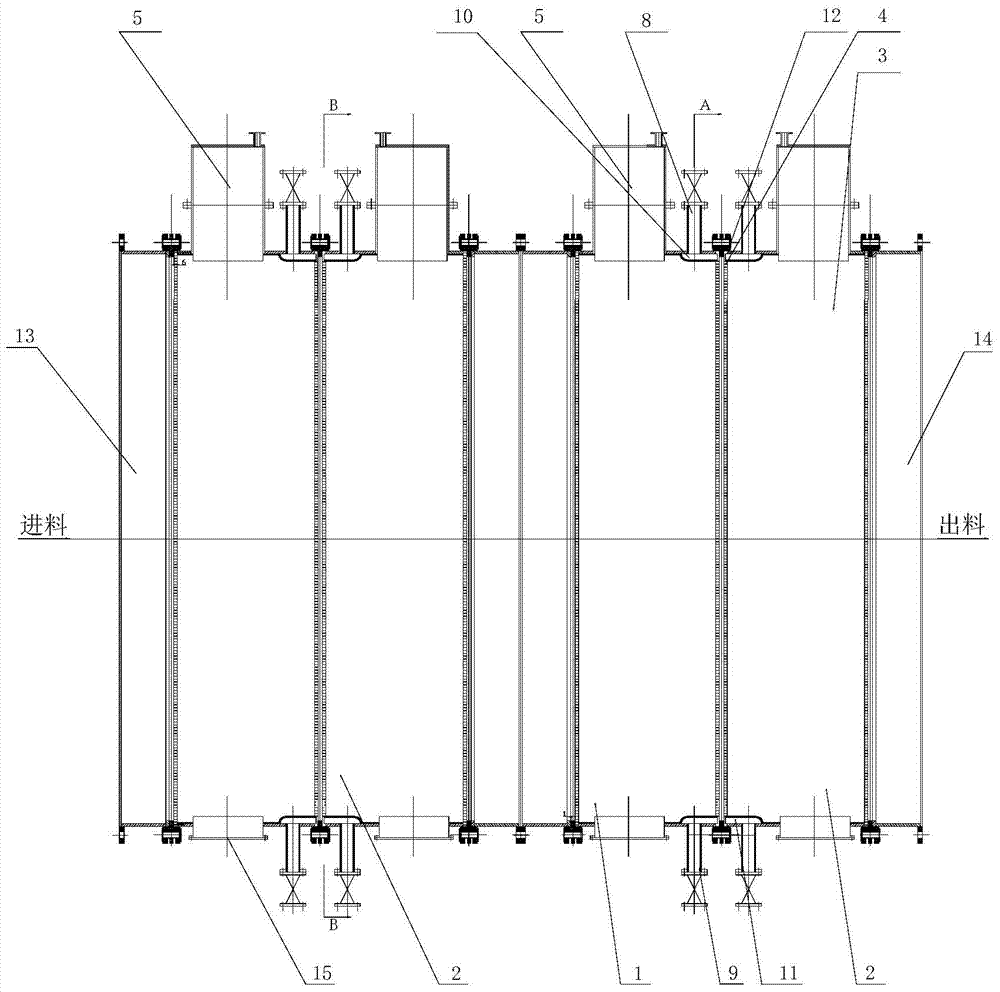

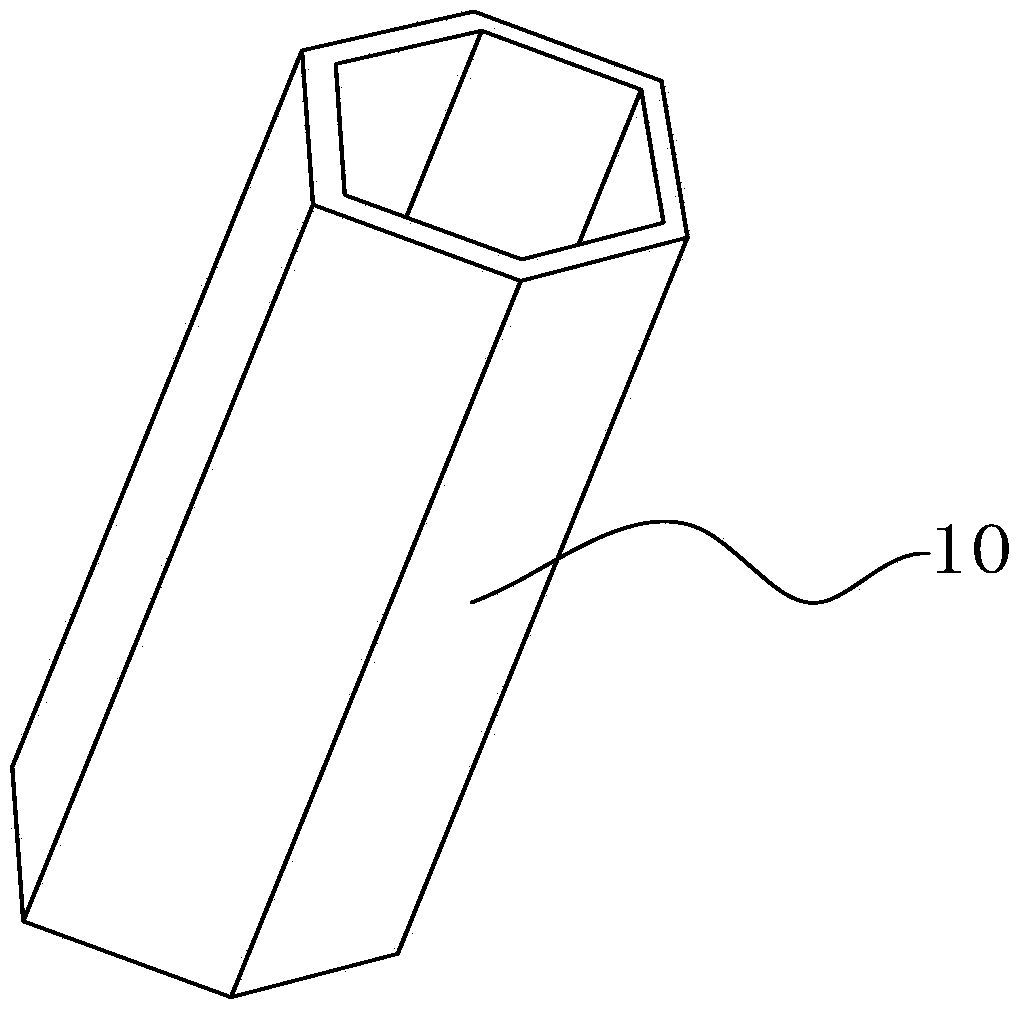

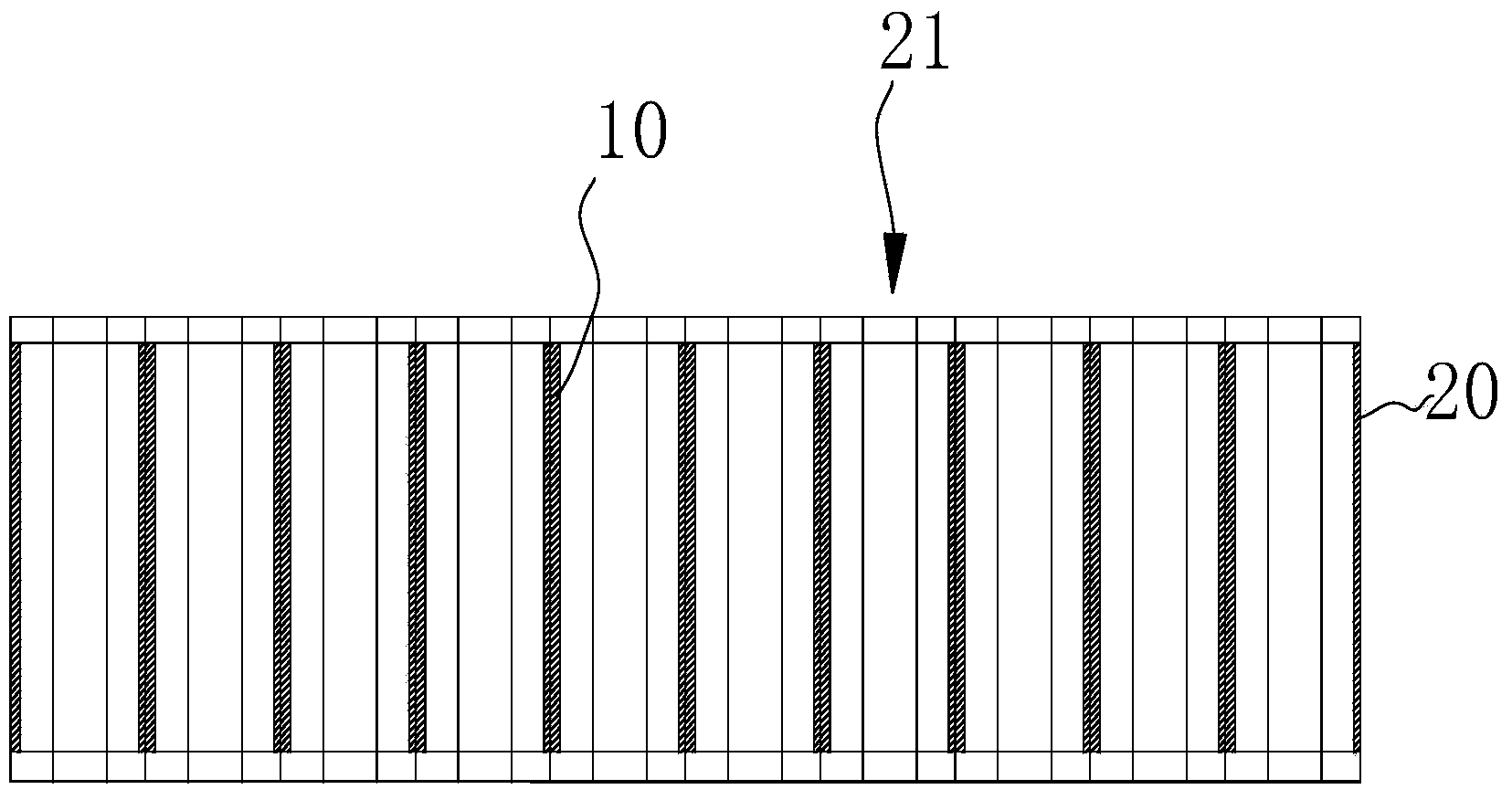

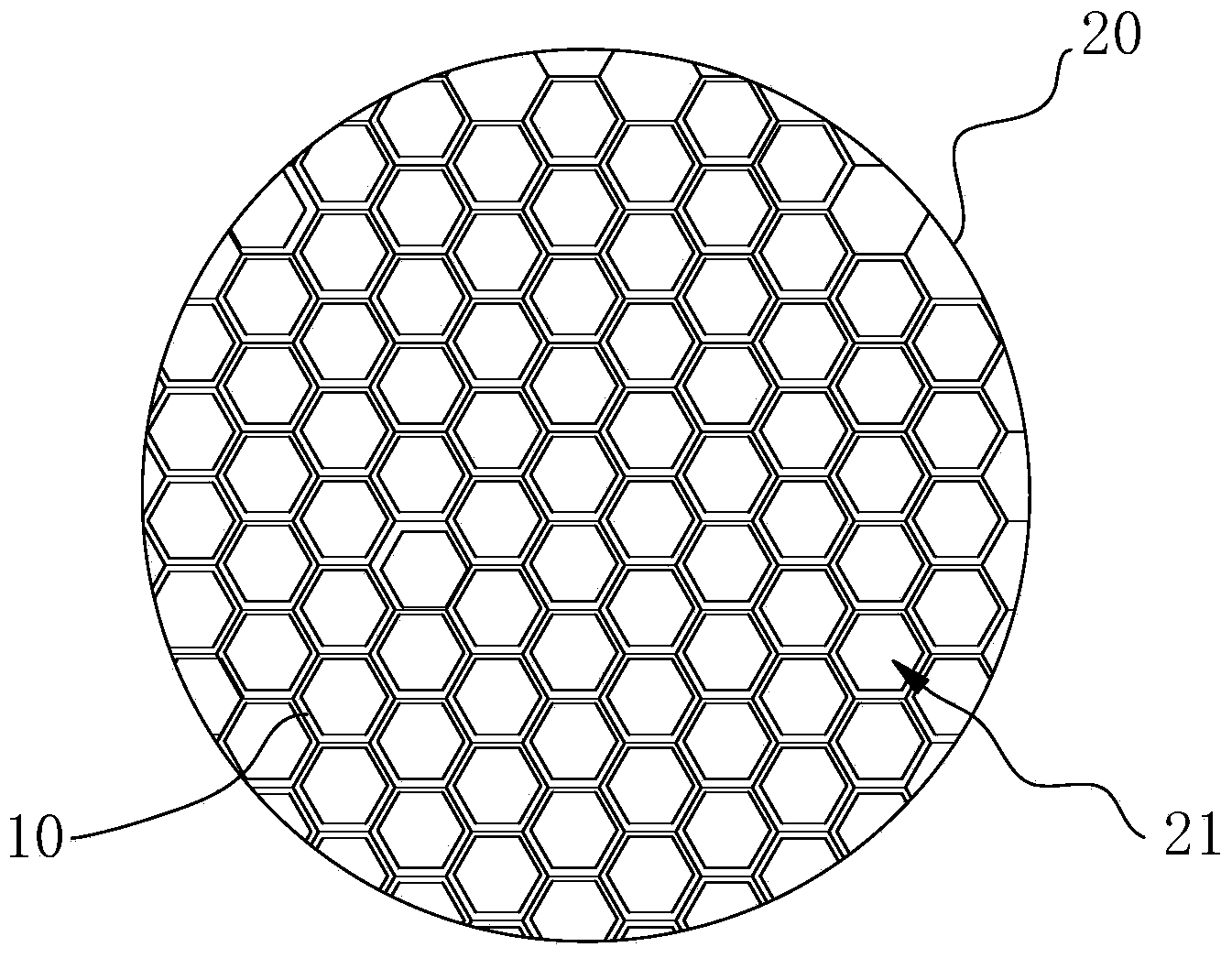

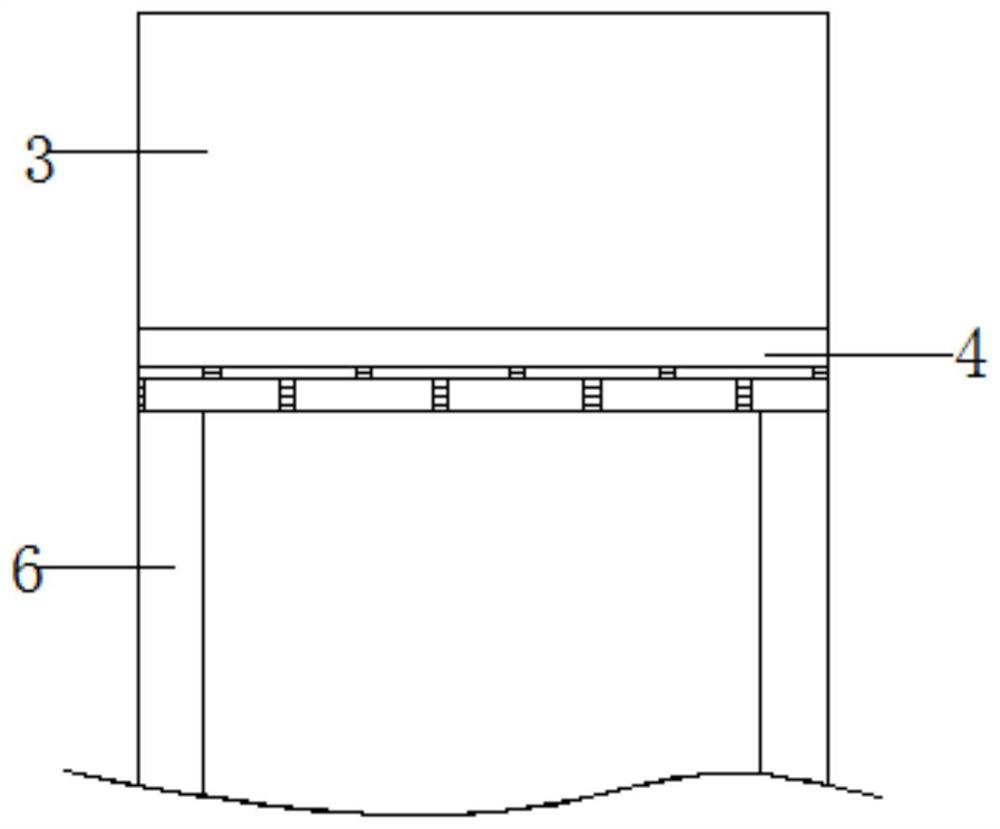

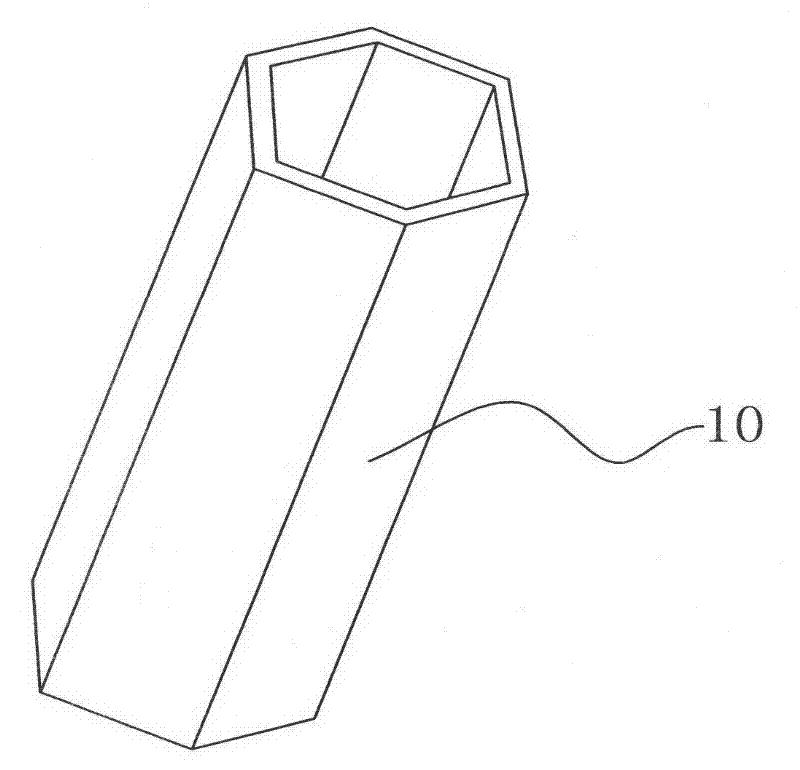

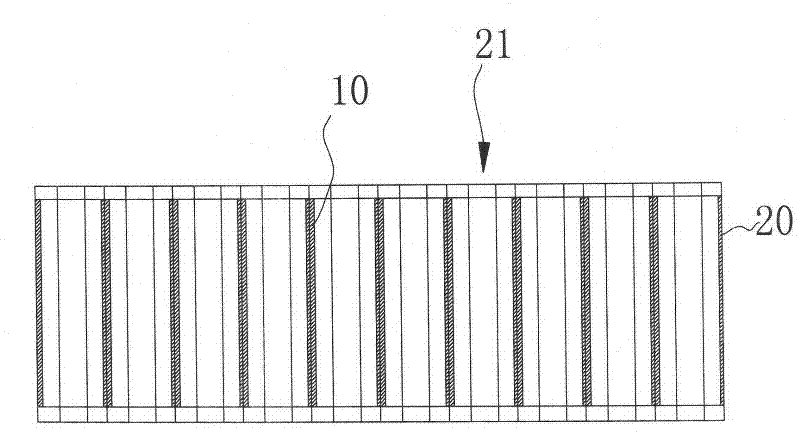

Universal high-efficiency iron removal device for various industries

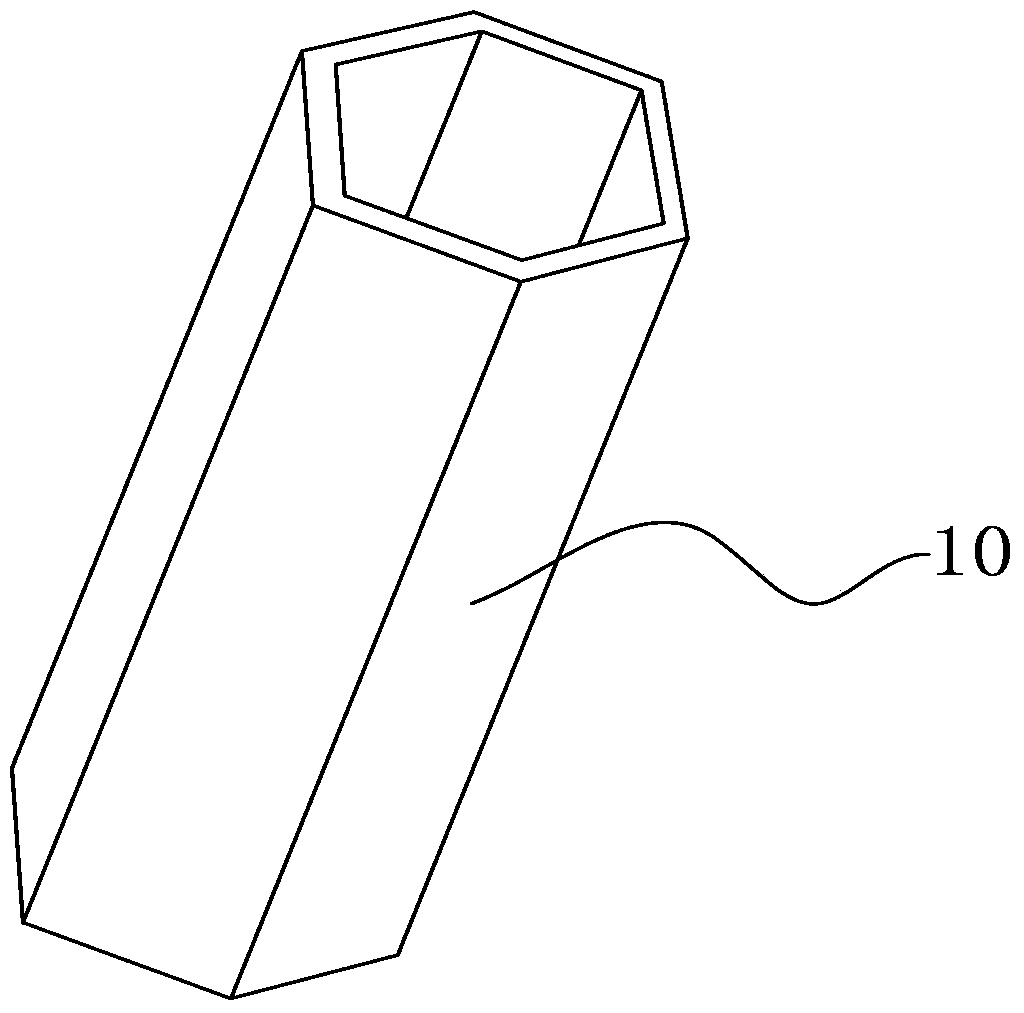

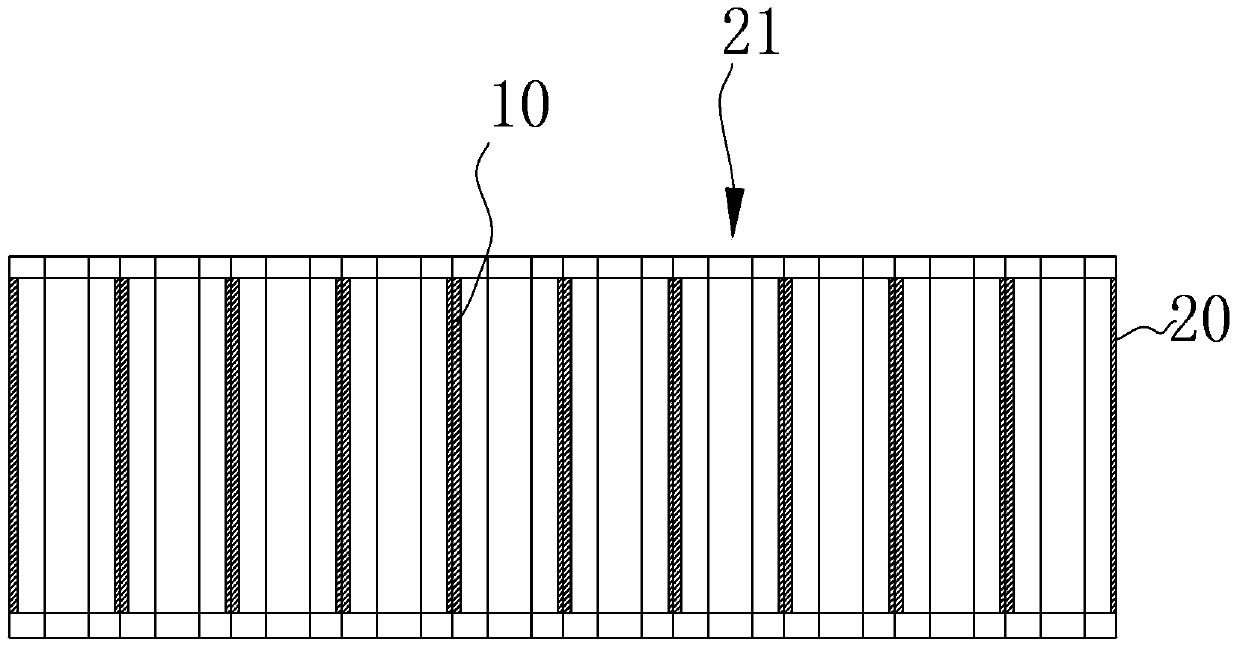

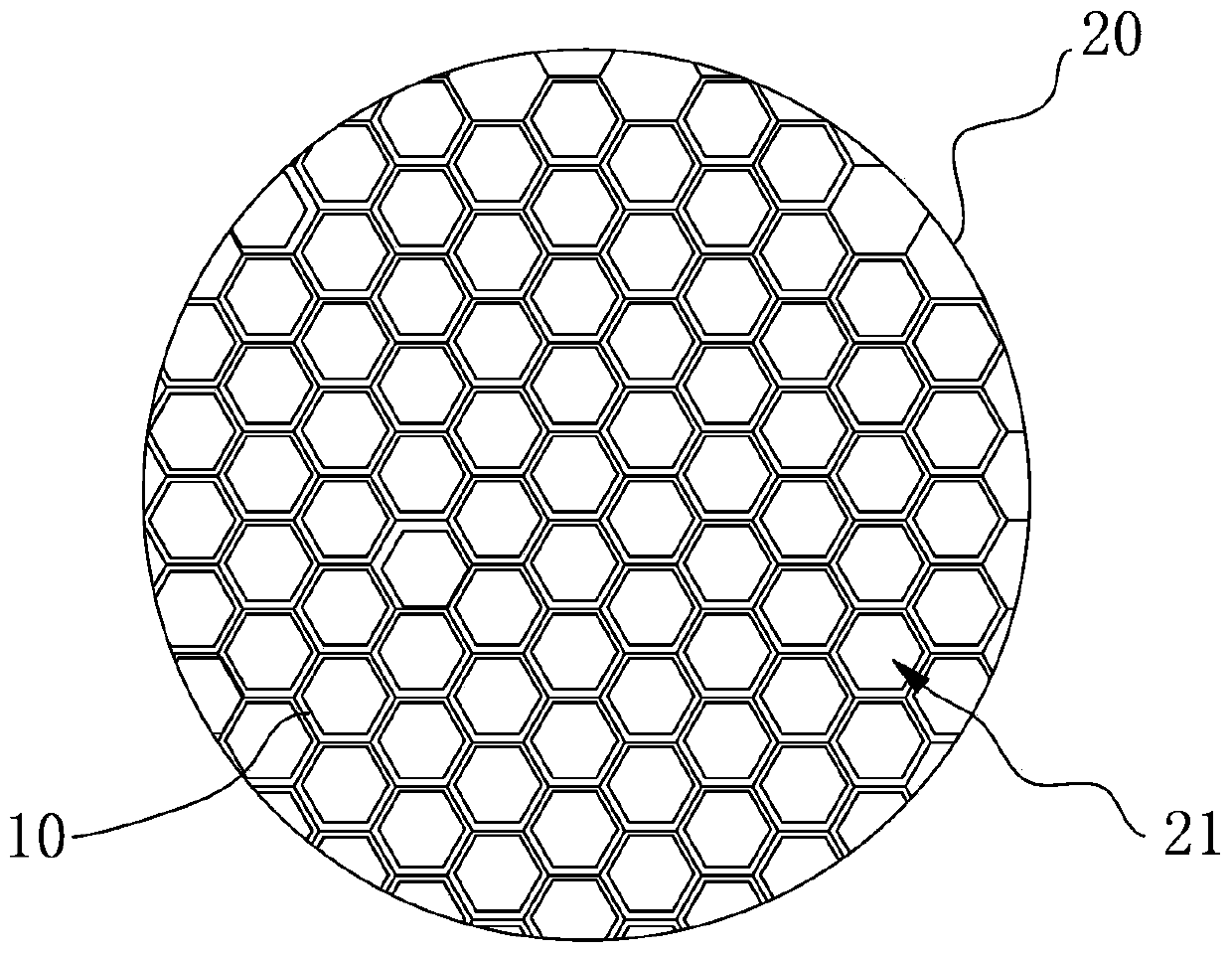

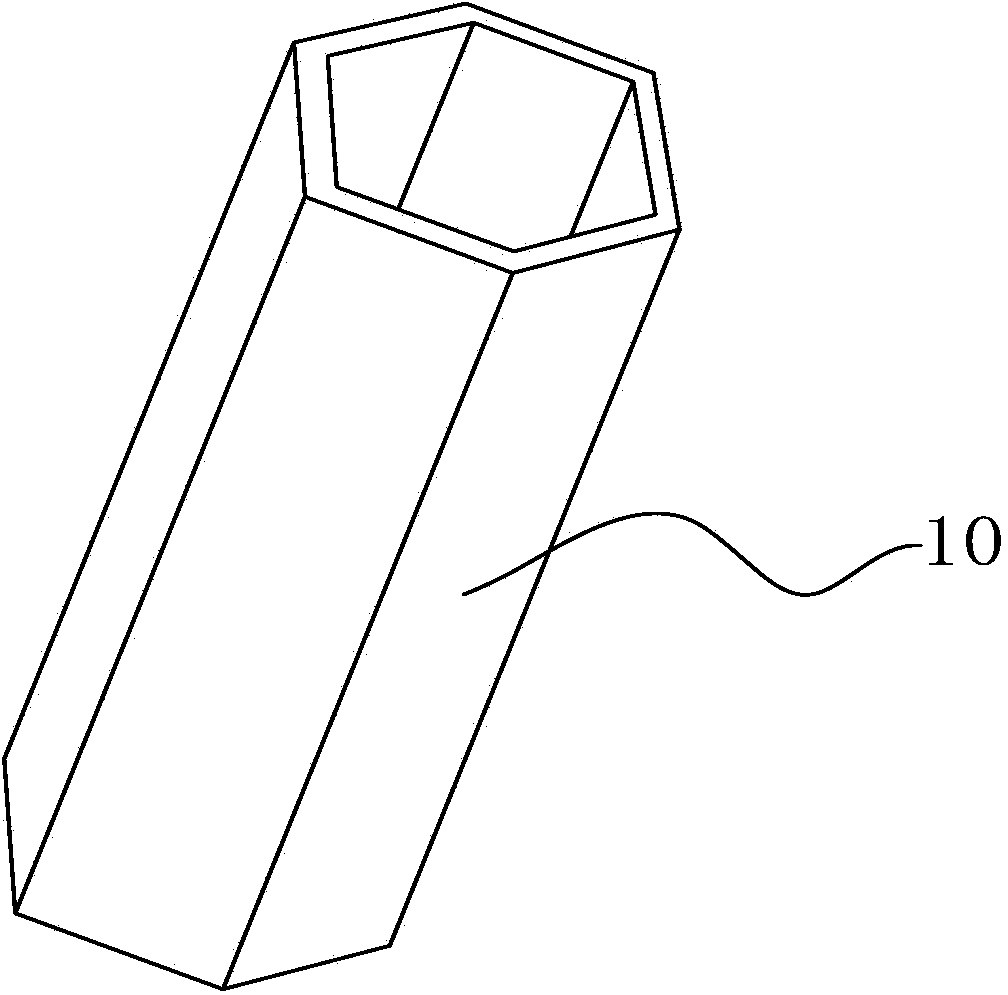

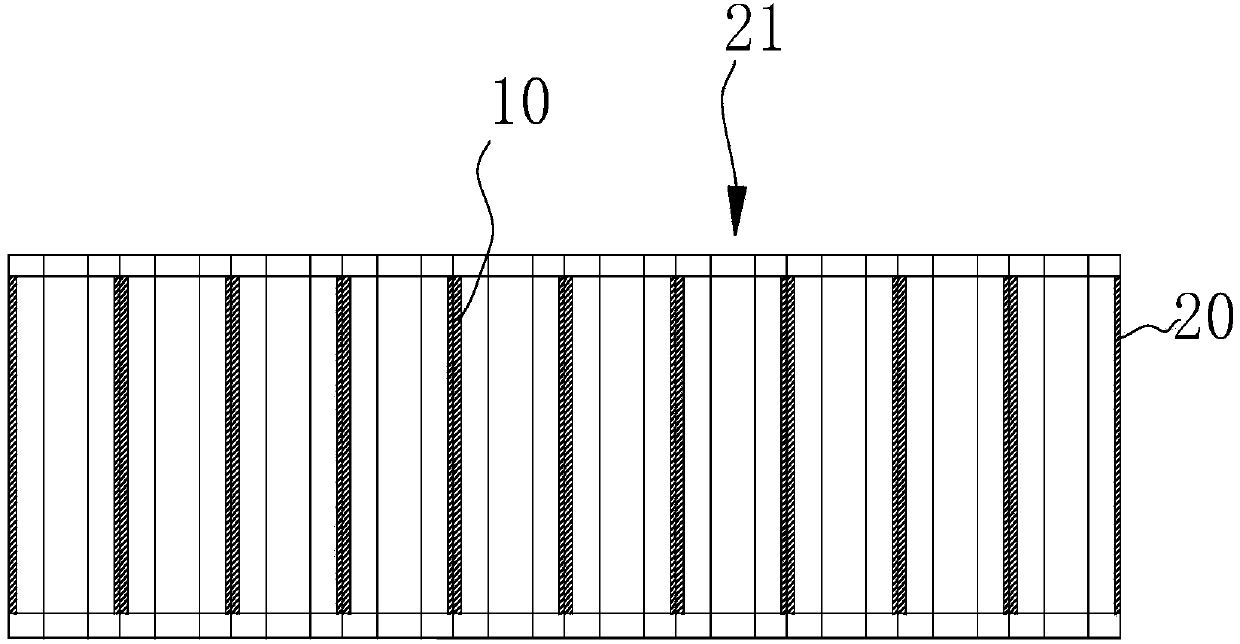

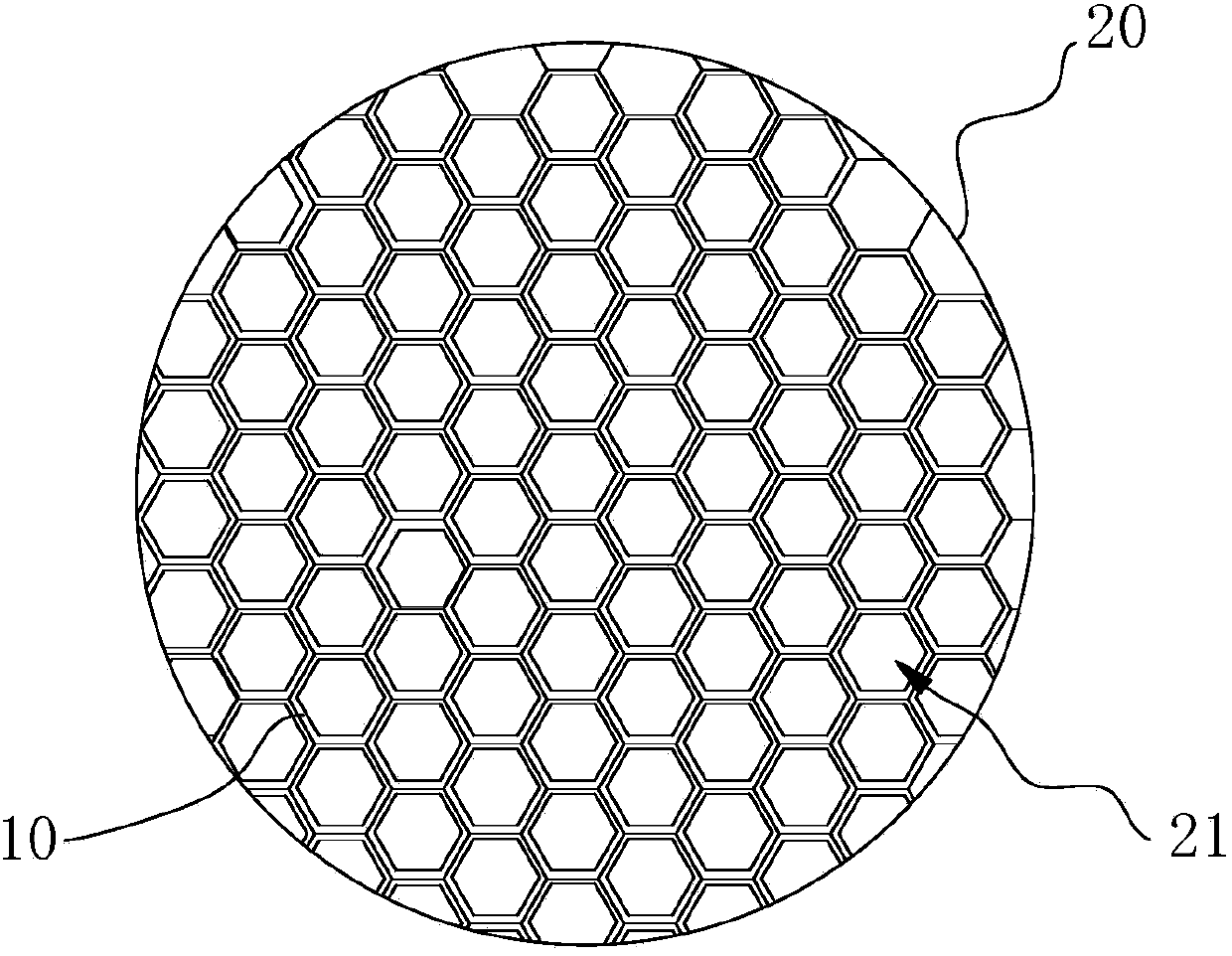

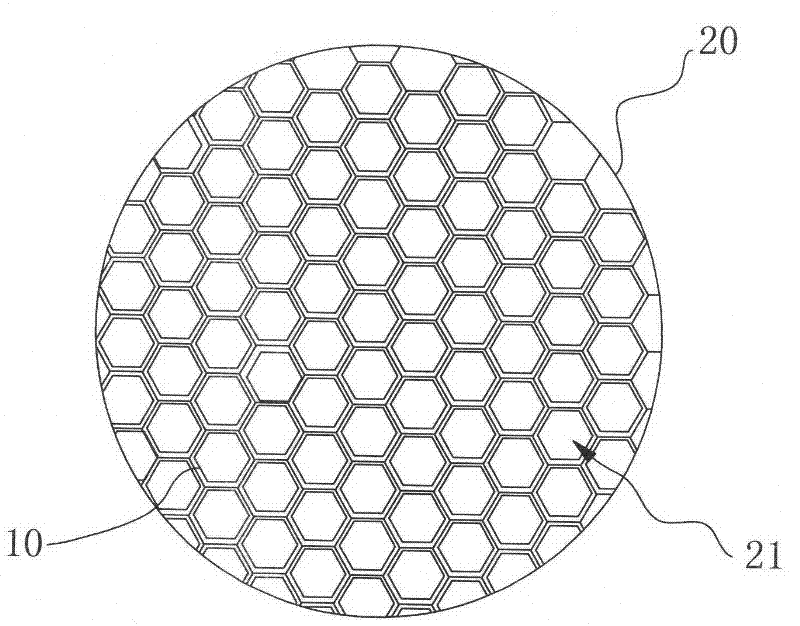

The invention relates to an iron removal device for removing iron chips or steel chips in a material, and particularly relates to an iron removal device which is reliable in iron removal effect and convenient to use. The iron removal device comprises magnets, wherein the magnets are uniformly arranged in a tube shape of which the cross section is in a regular hexagon shape or along the wall of a tube body of which the cross section is in a regular hexagon shape; and the magnets or material channels are arranged obliquely, and the inclination angle is 25-45 degrees. Thus, the tubular magnets or tube body can be directly installed in a material flow region. The material can be ensured to flow through in the tube body by using any prior art, and the magnets are uniformly distributed in a tube shape or along the wall of the tube body, and thus, can form an annular adsorption magnetic field for the iron chips or steel chips in the material flowing through the tube body, thereby having a reliable adsorption action and ensuring the iron removal effect. Meanwhile, the tubular magnets or the tube body with magnets arranged along the tube wall can be conveniently installed or used.

Owner:刘钊汐

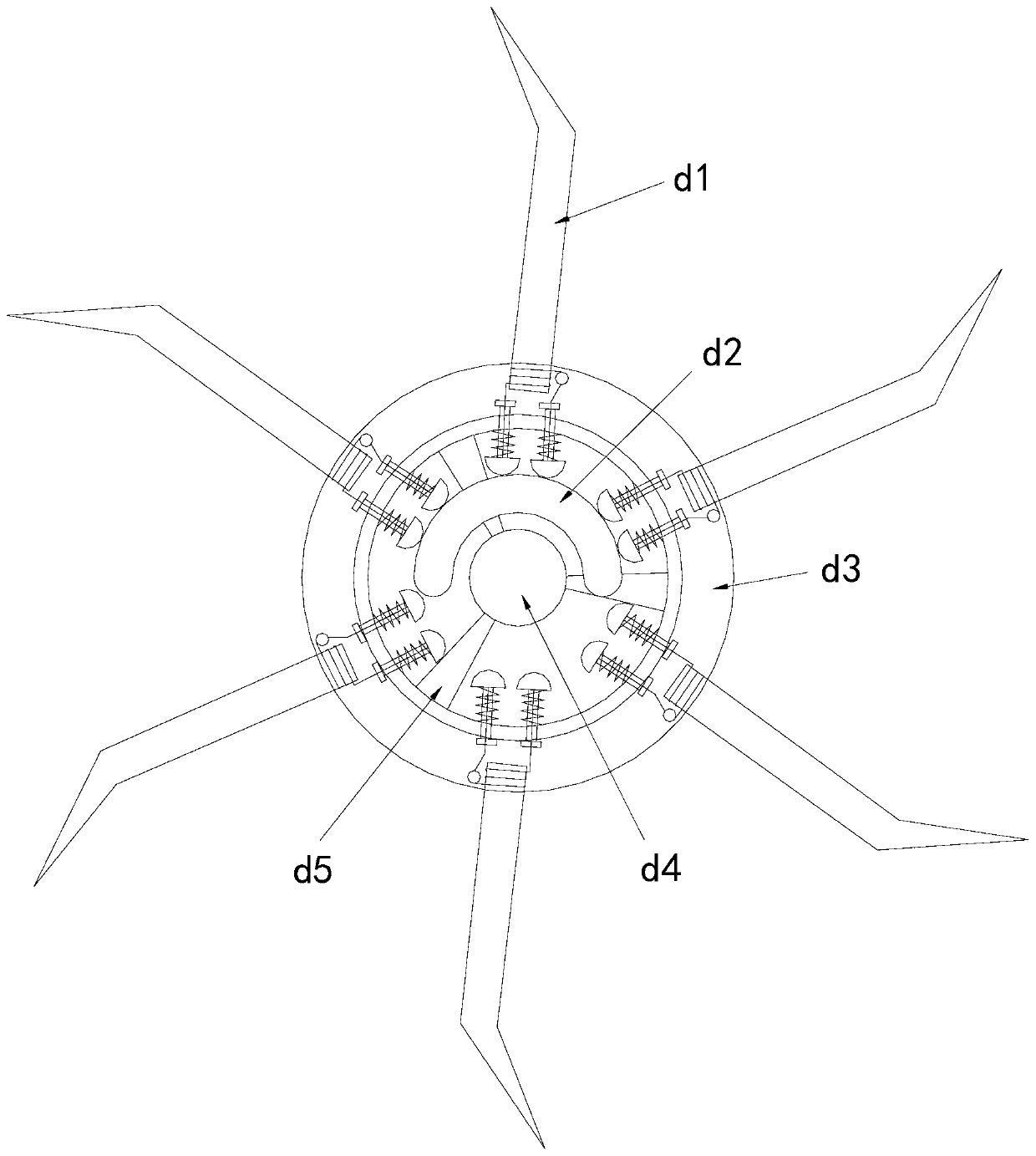

Iron removal device for mineral processing

PendingCN113019696AGuaranteed continuityGuaranteed validityMagnetic separationGrain treatmentsMineral collectingDrive motor

The invention discloses an iron removal device for mineral processing, and relates to the technical field of mineral processing. The iron removal device comprises a main body, a separation mechanism and a feeding mechanism, the separation mechanism is arranged on the upper side of the interior of the main body, and the upper end of the main body is connected with the feeding mechanism; and the feeding mechanism comprises a feeding bin, and the feeding bin is of a calabash-shaped hollow structure. A conveying belt is integrally formed by the insulating connecting pieces and the electromagnetic rod which are connected at intervals, the conveying belt is driven to rotate by matching a driving wheel with a driving motor, and the electromagnetic rod is electrified by matching conductive pieces arranged at the two ends of the electromagnetic rod, so that the electromagnetic rod adsorbs iron in minerals in the mineral conveying process. When the mineral is conveyed to the left end, the mineral falls into a mineral collecting bin due to the gravity of the mineral, iron continues to be conveyed through adsorption of the electromagnetic rod, when the mineral is conveyed to the notches of the conductive pieces, the electromagnetic rod is powered off, the iron falls into the iron collecting bin due to the gravity of the iron, and the work of separating the iron in the mineral is achieved.

Owner:KUNMING UNIV OF SCI & TECH

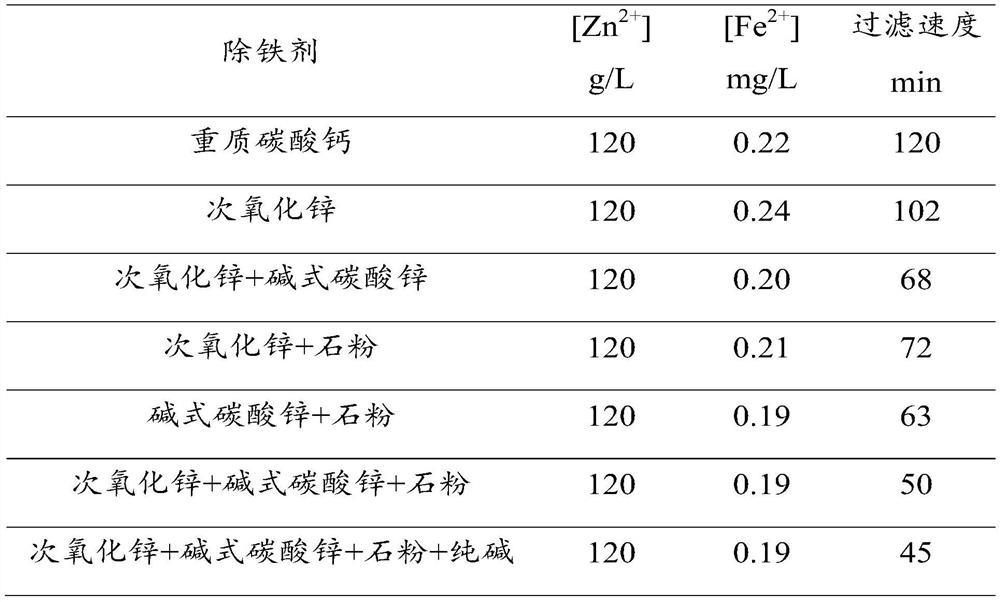

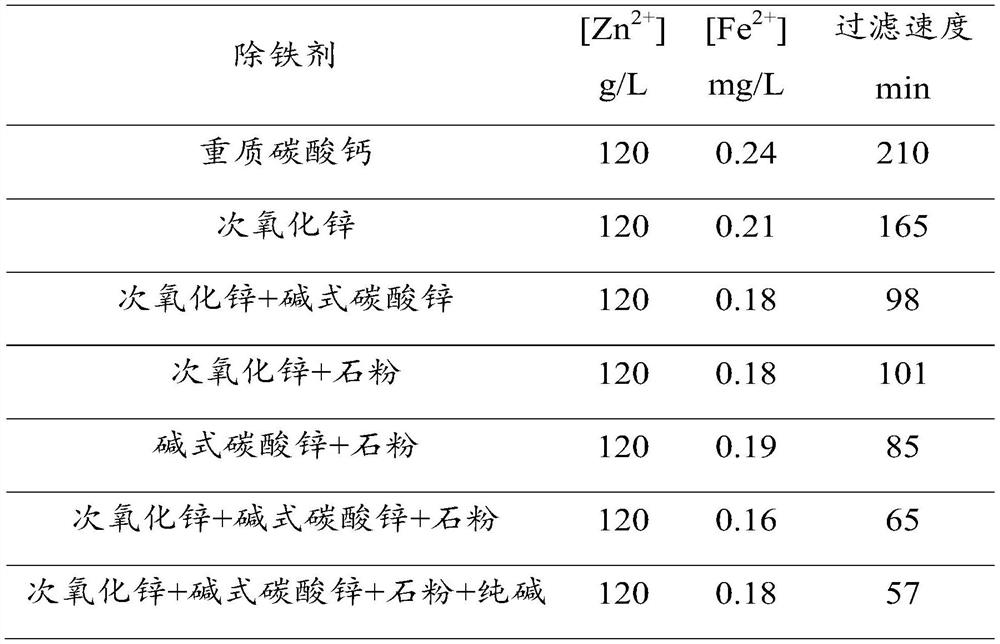

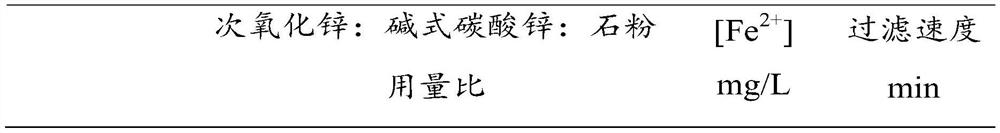

A filter-assisted method for leaching and removing iron from secondary zinc oxide

ActiveCN111233024BImprove the effect of oxidative hydrolysis of ironSpeed up filteringZinc oxides/hydroxidesNanotechnologyZinc peroxidePregnant leach solution

The invention provides a filter aid method for leaching and removing iron from secondary zinc oxide, belonging to the technical field of chemical industry. The filtering aid method comprises the following steps: adding at least two of zinc suboxide, basic zinc carbonate and stone powder to the reaction system of the suboxide leaching solution and hydrogen peroxide, and reacting to Fe 2+ The content does not exceed 0.2μg / mL, and then solid-liquid separation. The above methods can improve the iron removal effect of oxidative water for different grades of secondary zinc oxide raw materials, and ensure that for different raw materials, under this process, [Fe in the leaching solution] 2+ ]≤0.2μg / ml, the content of ferrous ions in 95% active nano-zinc oxide is within 2ppm; greatly improve the filtration speed of the medium leaching slurry, and the filtration speed can be increased for medium leaching solutions with different ferrous ion contents 100‑300%; eliminate the phenomenon of running and filtering, ensure the effect of iron removal, and ensure the smoothness of the process.

Owner:JIYUAN LUTAI NANO MATERIAL CO LTD

A double-seal scraper iron remover

ActiveCN111097596BNo need for manual cleaningImprove work efficiencyCleaning using toolsMagnetic separationIron removalMechanical engineering

Owner:NINGBO SOUWEST MAGNETECH DEV

Universal iron removal device for various industries

The invention relates to an iron removal device for removing iron chips or steel chips in a material, and particularly relates to an iron removal device which is reliable in iron removal effect and convenient to use. The iron removal device comprises magnets, wherein the magnets are uniformly arranged in a tube shape of which the cross section is in a regular hexagon shape or along the wall of a tube body of which the cross section is in a regular hexagon shape; and the magnets or material channels are arranged obliquely, and the inclination angle is 25-45 degrees. Thus, the tubular magnets or tube body can be directly installed in a material flow region. The material can be ensured to flow through in the tube body by using any prior art, and the magnets are uniformly distributed in a tube shape or along the wall of the tube body, and thus, can form an annular adsorption magnetic field for the iron chips or steel chips in the material flowing through the tube body, thereby having a reliable adsorption action and ensuring the iron removal effect. Meanwhile, the tubular magnets or the tube body with magnets arranged along the tube wall can be conveniently installed or used.

Owner:刘钊汐

A Cooperative Removal Process of Flue Gas Pollutants Based on Electrolysis

InactiveCN105344215BSimple processing methodImprove controllabilityCombination devicesGas treatmentReaction layerElectrochemical response

The invention discloses a flue gas pollutant cooperation removal technology based on electrolysis. The problems are solved that technologies are complex, the pollutant treatment efficiency is low, investment and operation cost are high in present flue gas treatment. The technology comprises steps: flue gas is pressurized and sent to a concentration tower, a reaction is carried out, the flue gas going out from the concentration tower is sent to an absorbing tower and contacts and reacts with a circulating absorption solution sprayed from a spray layer at the upper part of the tower in a reverse manner, and the flue gas after reaction is discharged from the top of the absorbing tower; part of the concentrate at the tower bottom of the concentration tower is subjected to iron removal, then is sent to a ammonium sulfate crystallization system, the flue gas goes into the absorbing tower from a flue gas inlet at the middle part of the absorbing tower, goes through at least one absorbing and electrochemical reaction layer arranged at the upper part of the tower firstly, then contacts and reacts with a circulating absorption solution in a reverse manner, then goes through a filler layer and a spraying layer, and is discharged from a flue gas outlet. The technology is simple, the reaction efficiency is high, the operation and investment cost are low, the system land occupation area is small, and the technology is especially suitable for cooperation treatment of multiple pollutants of sulfur dioxide, nitrogen oxides, fine particles, dioxin and the like.

Owner:WUHAN WUTUO TECH +1

A Simultaneous Desulfurization and Denitrification Process Based on Electrolytic Regeneration for Iron Removal in Flue Gas and Ammonia

ActiveCN105251330BWith uniform effectWith updateDispersed particle separationAmmonium sulfatesElectrolysisAbsorption column

The invention discloses a flue gas ammonia synchronous desulfurization and denitrification process based on electrolytic regeneration to remove iron, which solves the problem of low regeneration efficiency of absorption liquid in the existing desulfurization and denitrification process. The technical scheme includes that after the flue gas is pressurized, it is sent to the concentration tower to contact and react with the concentrated liquid in the tower. After iron removal by the first electrolytic reactor, it is sent to the ammonium sulfate crystallization system. The absorbed liquid after partial reaction at the bottom of the absorption tower is regenerated and returned to the upper part of the absorption tower as a circulating absorption liquid. The concentrated liquid first enters the first electrolytic reactor The anode chamber in the reaction unit undergoes an oxidation reaction, and then enters the cathode chamber to undergo a reduction reaction; the reacted electrolyte is discharged from the short outlet pipe of the reactor and sent to the ammonium sulfate crystallization system. The invention has the advantages of simple method, low investment cost and operation cost, high conversion efficiency, good iron removal effect, and good desulfurization and denitrification effect.

Owner:武汉武钢绿色城市技术发展有限公司

Illite/montmorillonite clay nanometer powder production device

ActiveCN103588213BClosely connectedIncrease profitNanotechnologySilicon compoundsPeristaltic pumpChemical reaction

The invention discloses an illite / montmorillonite clay nanometer powder production device and belongs to the technical field of a deep processing production line of ores. The illite / montmorillonite clay nanometer powder production device comprises a four-roll crusher, an automatic water supply facility, four stainless steel barrels, nine membrane pumps, three vibrating screens, three material collectors, an electromagnetic high-gradient magnetic separator, a permanent magnetic high-gradient magnetic separator, four chemical reaction tanks, a peristaltic pump, a superfine ball mill, a flash evaporation drying machine, a coal-fired type hot-blast stove, a superfine mechanical pulverizer, a continuous type powder coating modification machine, a first full-automatic packaging machine and a second full-automatic packaging machine. The illite / montmorillonite clay nanometer powder production device can be used for preparing illite / montmorillonite clay nanometer powder by a physical method, is environmentally-friendly and suitable for mass production and improves the production efficiency.

Owner:广西防城港市恒泰科技开发有限公司

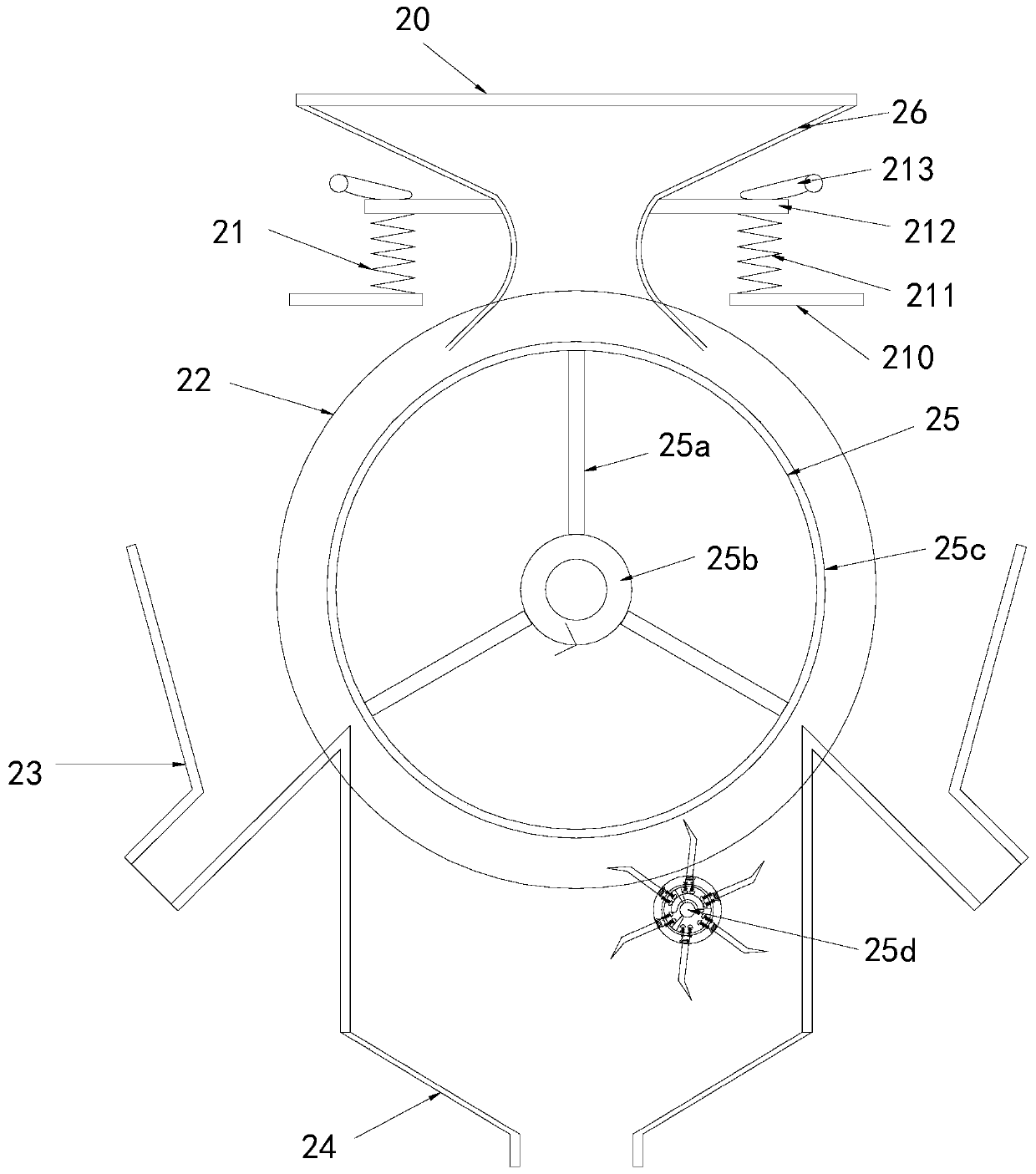

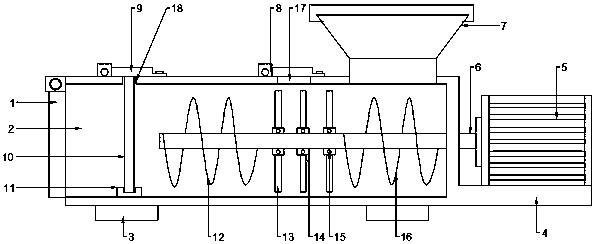

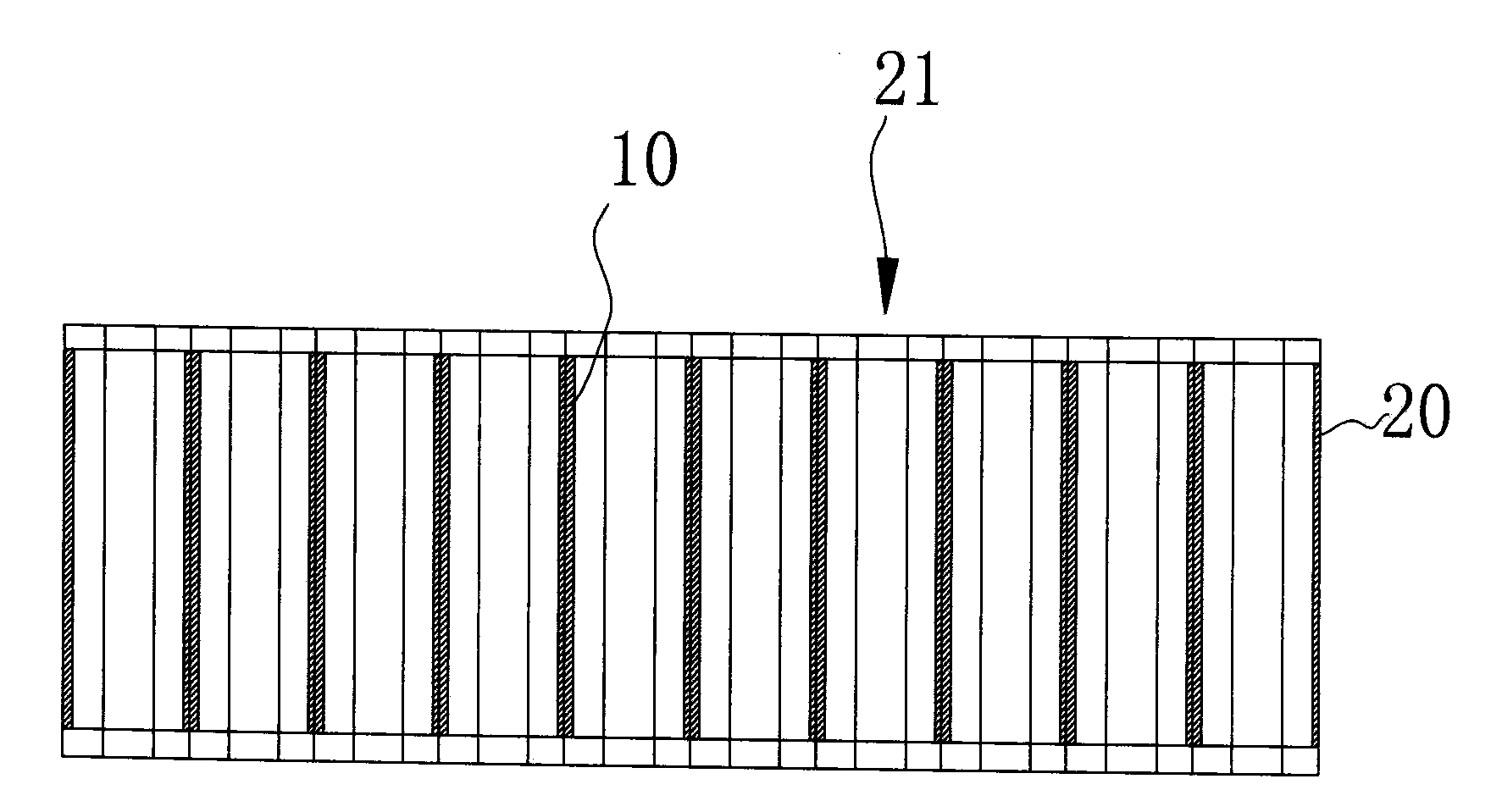

Pipelined mechanical iron removal coal separator

InactiveCN108452944AImprove the quality of iron removalHigh iron removal efficiencyMagnetic separationGrain treatmentsIron removalBiochemical engineering

The invention discloses a pipelined mechanical iron removal coal separator. The pipelined mechanical iron removal coal separator comprises an iron removing pipe body, a rotating shaft and an iron removing device, a charging hopper is mounted on the iron removing pipe body, the rotating shaft is inserted inside the iron removing pipe body in a penetrated manner, the right end of the rotating shaftis fixed on the output shaft of a motor, the rotating shaft is provided with a first auger, a rotating rod and a second auger inside the iron removing pipe body, a fixing frame is arranged on the ironremoving device, and in the shape of a rectangle, a fixing rack is fixed inside the fixing frame, an iron removing net and the rotating rod are fixed inside the fixing frame by matching with the fixing rack, and a layer of magnetic materials is arranged on the surface of each of the iron removing net, the fixing rack and the fixing frame. The pipelined mechanical iron removal coal separator disclosed by the invention is high in iron removal efficiency, high in iron removal speed, high in coal iron removal quality and good iron removal effect.

Owner:黄港

Iron removal device

The invention relates to an iron removal device for removing iron scrap or steel scrap in a material. The iron removal device which has a reliable iron removal effect and is convenient to use comprises magnets, wherein the magnets are tubular or uniformly arranged along the tube wall of a tube body, so that the tubular magnets or the tube body can be directly arranged in a material circulation area, and the material can flow through the tube body by any prior art; the magnets are tubular or uniformly distributed along the tube wall of the tube body, so a complete annular adsorption magnetic field can be formed for the iron scrap or the steel scrap in the flowing material, a reliable adsorption effect is achieved, and the iron removal effect is ensured; meanwhile, the tubular magnets or the tube body on which the magnets are arranged along the tube wall can be conveniently arranged and used.

Owner:KUNMING PURETOWN ENVIRONMENTAL TECH

A flue gas ammonia desulfurization and denitrification process with complexation absorption and synchronous electrolysis regeneration

ActiveCN105413422BEfficient regenerationEffective in removing ironGas treatmentDispersed particle separationElectrolysisAmmonium sulfate

The invention discloses an ammonia desulphurization and denitrification process for flue gas by synchronization of complexing absorption and electrolytic regeneration and solves the problem of low absorption liquid regeneration efficiency in an existing synchronous ammonia desulphurization and denitrification process for the flue gas. The technical scheme includes that the flue gas is pressurized and then fed into a concentration tower to realize contact reaction with concentration liquid in the tower, the flue gas discharged from the concentration tower is fed into an absorption tower to realize contact reaction with cyclic absorption liquid in the absorption tower, the concentration liquid at the bottom of the concentration tower is subjected to deferrization through a first electrolytic reactor after reaction and then fed into an ammonium sulfate crystallization system, the absorption liquid at the bottom of the absorption tower is regenerated and then fed back to the upper portion of the absorption tower to serve as the cyclic absorption liquid, the concentration liquid enters an anode chamber of a reaction unit of the first electrolytic reactor to realize oxidation reaction and then enters a cathode chamber to realize a reduction reaction, and an electrolytic solution is discharged through a short outlet connection pipe of the reactor after reaction and fed into the ammonium sulfate crystallization system. The ammonia desulphurization and denitrification process for the flue gas by synchronization of complexing absorption and electrolytic regeneration has the advantages of simplicity, low investment cost and operation cost, high conversion efficiency and effectiveness in deferrization, desulphurization and denitrification.

Owner:武汉武钢绿色城市技术发展有限公司

Device for removing iron

The invention relates to an iron removing device for removing iron scales or steel scales in materials and particularly relates to the iron removing device with a reliable iron-removing effect and convenience in use. The iron removing device comprises magnets, wherein the magnets are uniformly distributed in a pipe shape with the cross section being a regular hexagon or along the pipe walls of a pipe body with the cross section being a regular hexagon; the magnets or material channels are obliquely arranged with the oblique angle being 25-45 degrees. Therefore, the iron removing device has the advantages that the pipe-shaped magnets or the pipe body can be directly arranged at the area for material circulation, the flowing of the materials through the inner part of the pipe body can be guaranteed by utilizing any prior art, the magnets are uniformly distributed in a pipe shape or along the pipe wall of the pipe body, so that a complete ring-shaped absorption magnetic field can be formed for the iron scales or the steel scales in the flowing materials, the reliable absorption effect can be achieved, and the iron removing effect can be guaranteed; and simultaneously, the pipe-shaped magnets or the pipe body provided with the magnets arranged along the pipe wall can be conveniently installed and used.

Owner:JIANGYIN PUDUN PLASTIC

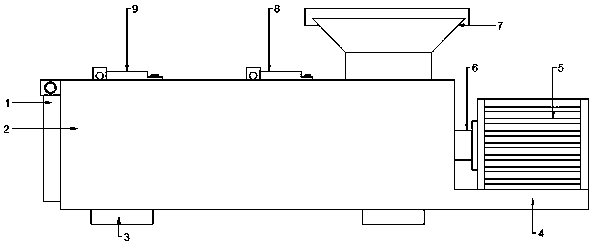

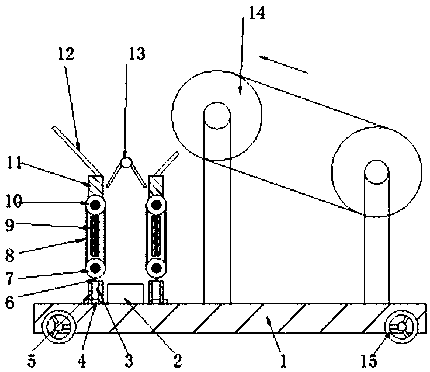

A high-efficiency tea drying and iron removal device

InactiveCN106172900BRemove in timeGuaranteed iron removal effectPre-extraction tea treatmentEngineeringUltimate tensile strength

The invention discloses a high-efficiency tea drying and deironing apparatus. The tea drying and deironing apparatus comprises a pedestal, a supporting seat, a scrape brush, a lower belt wheel, a transmission band, an electromagnet, an upper belt wheel, upper fixed plates, a guide plate, a material distributing plate, a mesh-belt dryer and a roller. The roller is arranged at the side surface of the pedestal, the mesh-belt dryer is arranged at the left upper end of the pedestal, two upper fixed plates are arranged at the left side of the mesh-belt dryer at intervals, the guide plate is arranged on the upper fixed plate, the material distributing plate is arranged between the upper fixed plates, the transmission band is arranged at the lower end of the upper fixed plate, the electromagnet is arranged in the transmission band, an upper belt wheel and a lower belt wheel are respectively arranged at two ends of the transmission band, the supporting seat is arranged at the lower end of the lower belt wheel, and the scrape brush is arranged at the upper end of the supporting seat. The high-efficiency tea drying and deironing apparatus can guarantee the deironing effect, continuous work of the high-efficiency tea drying and deironing apparatus cannot be influenced during an iron filings removing and adsorption process, so that the work efficiency of the high-efficiency tea drying and deironing apparatus is increased, and the labor intensity for cleaning the high-efficiency tea drying and deironing apparatus is reduced.

Owner:LINYI UNIVERSITY

A device for removing iron from fly ash for construction

ActiveCN111266188BEasy to remove ironThorough iron removalCleaning using toolsMagnetic separationIron removalGear wheel

The invention relates to the technical field of building materials, and discloses a fly ash iron removal device for construction, which includes a casing, a sliding plate is arranged in the middle of the casing, a vertical plate is arranged above the sliding plate, and the vertical plate The right side of the vertical rod is connected with a receiving plate, the lower side of the vertical plate is connected with a vertical rod, the lower end of the vertical rod passes through the sliding plate and is connected with the spring at the bottom of the shell, the lower part of the vertical rod is hinged with a connecting rod, and the right end of the connecting rod is hinged There is a moving rod, the upper right of the housing is provided with a first drum, the first drum is connected with a stopper plate, the lower part of the sliding plate is provided with a second drum, and the outer side of the second drum is provided with a magnetic block. A scraper is connected to the lower side of the sliding material plate, and gears are fixedly connected to both ends of the second rotating shaft. The fly ash iron removal device for construction can scrape off the iron adsorbed on the magnet by the scraper through the rotation of the second drum, which can facilitate the control of the fly ash iron removal process, and can clean and collect the adsorbed iron in time Advantages of iron.

Owner:上海碳澜环境集团有限公司

Iron removal device

The invention relates to an iron removal device for removing iron scrap or steel scrap in a material. The iron removal device which has a reliable iron removal effect and is convenient to use comprises magnets, wherein the magnets are tubular or uniformly arranged along the tube wall of a tube body, so that the tubular magnets or the tube body can be directly arranged in a material circulation area, and the material can flow through the tube body by any prior art; the magnets are tubular or uniformly distributed along the tube wall of the tube body, so a complete annular adsorption magnetic field can be formed for the iron scrap or the steel scrap in the flowing material, a reliable adsorption effect is achieved, and the iron removal effect is ensured; meanwhile, the tubular magnets or the tube body on which the magnets are arranged along the tube wall can be conveniently arranged and used.

Owner:KUNMING PURETOWN ENVIRONMENTAL TECH

Method for purifying and deferrizing electrolytic manganese leach solution

Owner:CHINESE RES ACAD OF ENVIRONMENTAL SCI

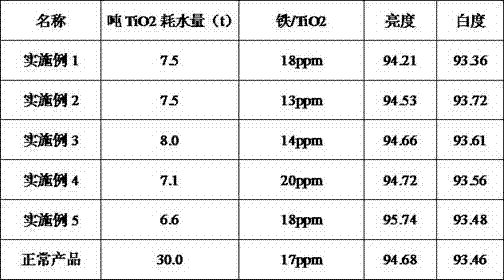

Method for reducing washing water in production process of titanium dioxide

InactiveCN107324385AEmission reductionSignificant environmental protection and economic benefitsTitanium dioxideWash waterSalt water

Inventor of Sichuan Longmang: The present invention relates to a method for reducing washing water in the production process of titanium dioxide, including a secondary washing step of metatitanic acid. Water washing is carried out with a small flow of desalted water. In the second washing step of metatitanic acid, by controlling the flow rate of desalted water in stages, the method can not only effectively reduce the amount of washing water, but also ensure the iron removal effect.

Owner:SICHUAN LOMON TITANIUM IND CO LTD

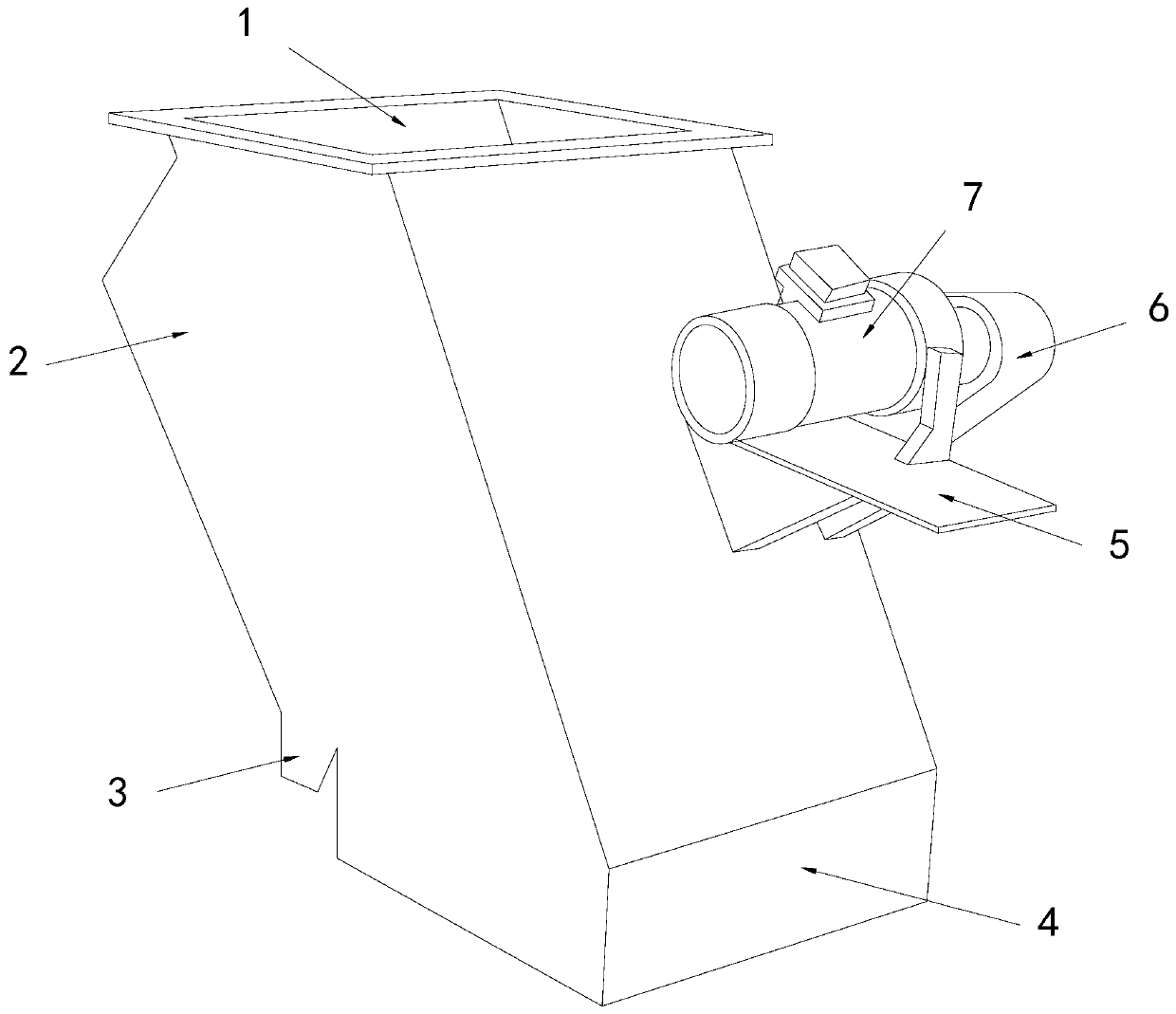

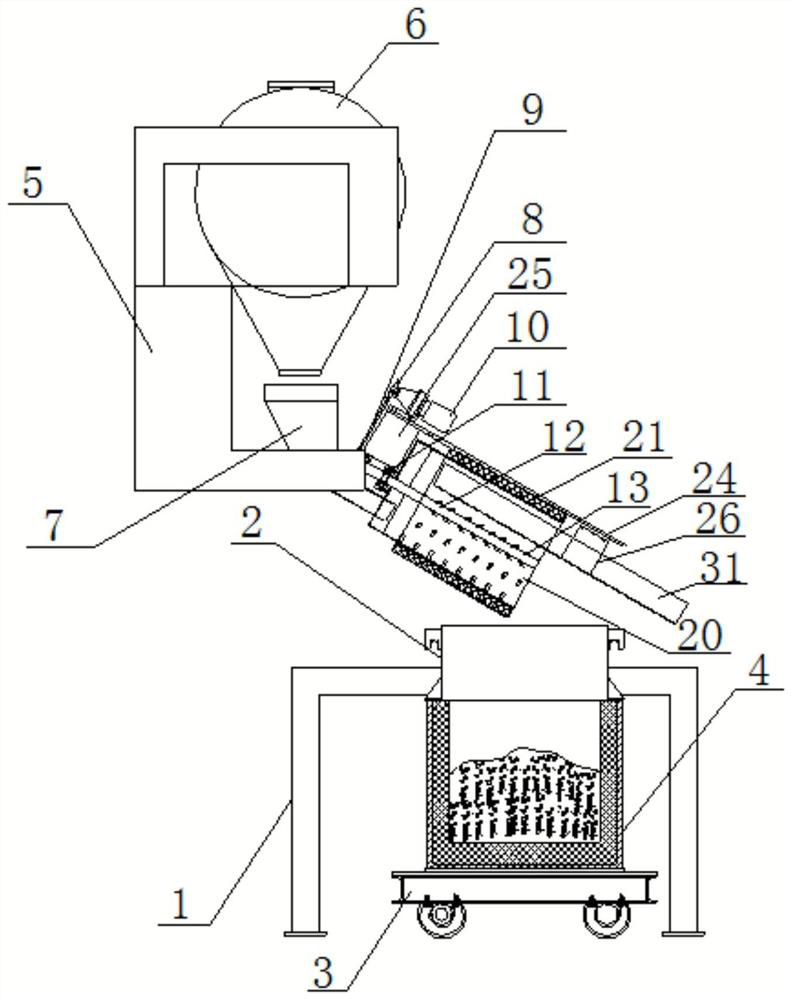

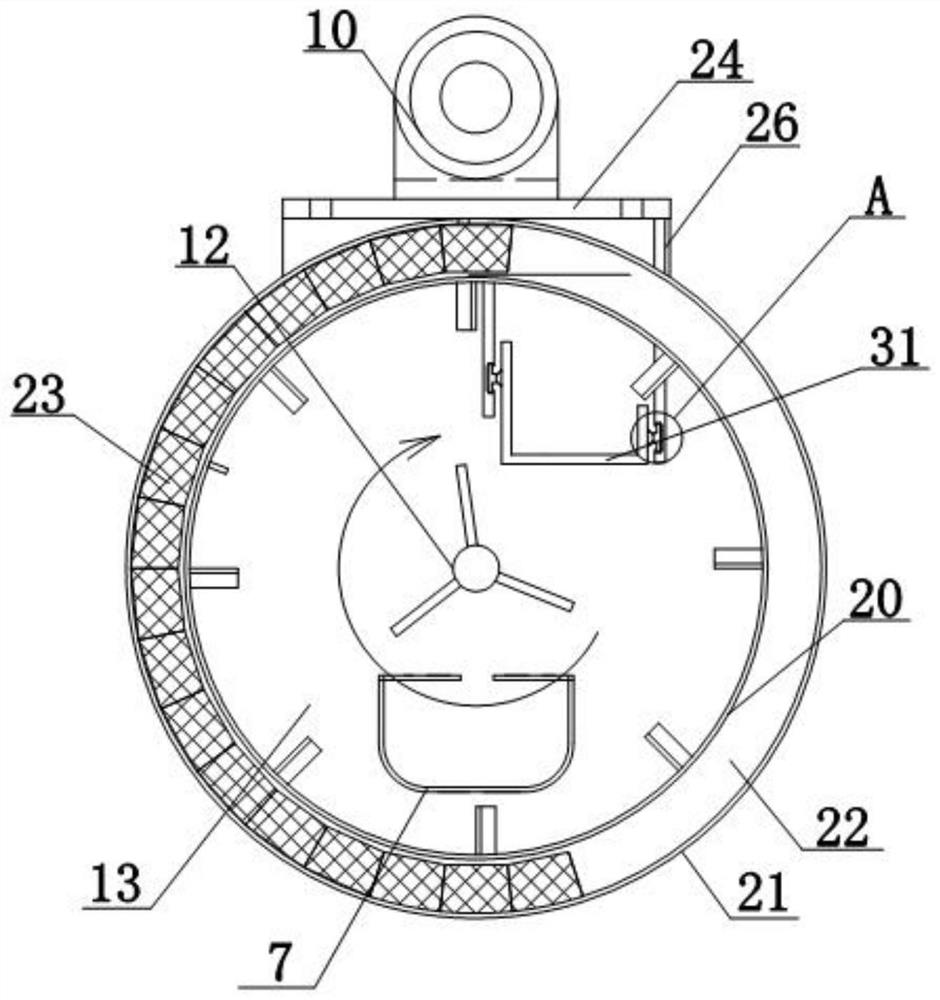

A thermal reduction material mixing system with a rotary iron removal device

ActiveCN110180478BSimple structureTo achieve the purpose of iron removalRotating receptacle mixersTransportation and packagingIron removalEngineering

The invention discloses a heat reduction material mixing system with a rotary iron removal device, which comprises a mixer, a stirring drum type iron removal mechanism and a reactor, the mixer is fixed on a fixed frame, and the stirring drum type iron removal mechanism includes an Feed trough, power transmission mechanism, inner drum and outer sleeve, the inner drum and outer sleeve are installed obliquely, the feeding trough is movable on the inner drum, the inner drum is equipped with a stirring shaft, and one end of the power transmission mechanism is movable with the stirring shaft The other end is fixedly installed on the fixed plate, the mounting seat is fixedly connected to the bottom of the fixed plate, and the iron removal groove is installed in the mounting seat, the outer sleeve is sleeved outside the inner drum, and the lower inner wall of the outer sleeve is movable There are permanent magnet blocks, stirring blades are movable on the stirring shaft, and the reactor is movable on the platform truck; this material mixing system can not only stir to prevent agglomeration, but also ensure good iron removal effect and prevent iron impurities from affecting Perform secondary pollution while improving the reliability of the entire structure.

Owner:HEBEI SITONG NEW METAL MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com