System for preparing steel slag sintered bricks

A technology of sintered bricks and steel slag, applied in clay preparation devices, manufacturing tools, auxiliary molding equipment, etc., can solve the problems of poor strength and stability, low mixing efficiency, and no good removal mechanism, etc., to achieve improved efficiency and good strength and various performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

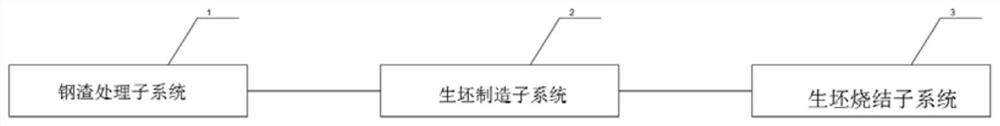

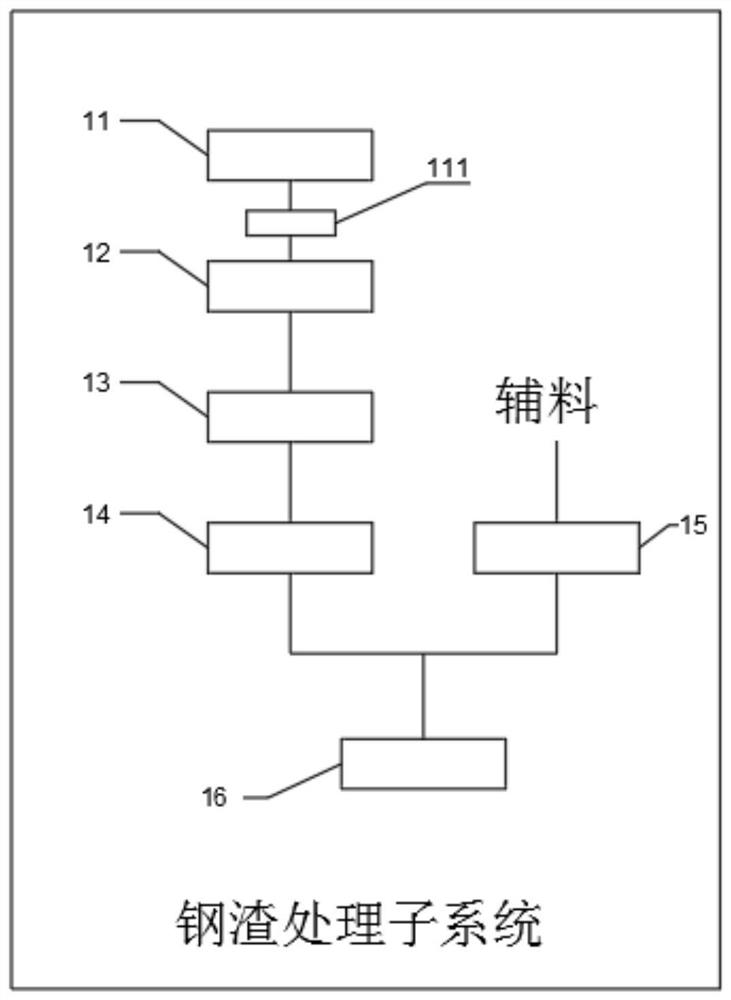

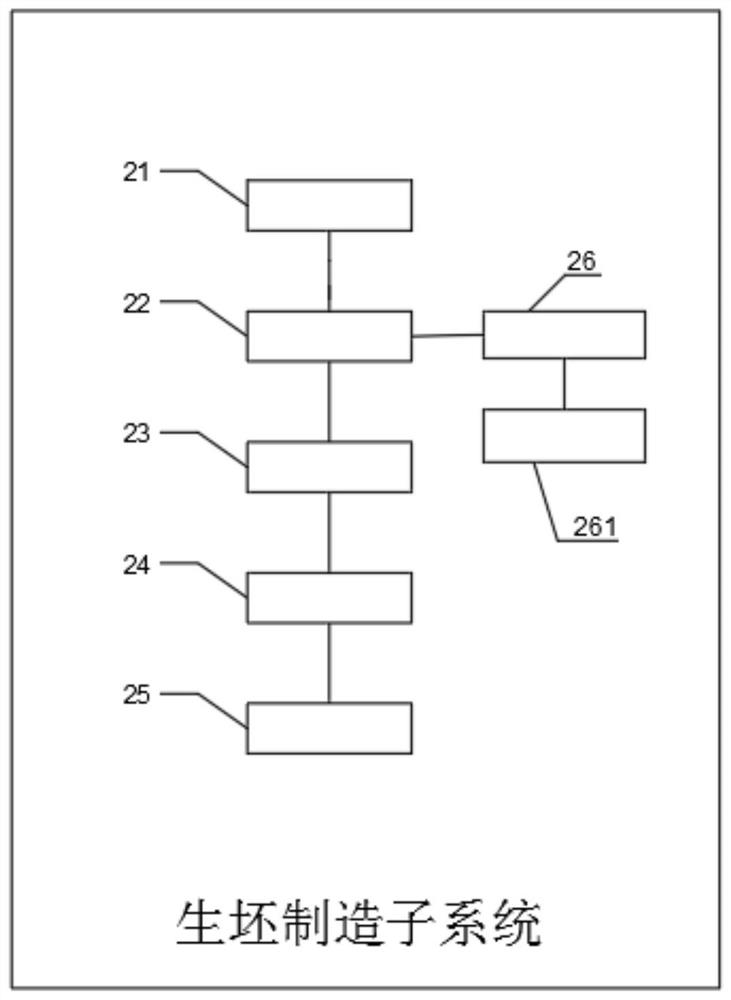

[0044] refer to Figure 1-4 , a system for preparing sintered steel slag bricks, comprising a steel slag processing subsystem 1, a green body manufacturing subsystem 2 and a green body sintering subsystem 3;

[0045] The steel slag processing subsystem 1 includes a steel slag conveyor 11 connected to the steel slag production line to transport the produced steel slag;

[0046] The steel slag dipping box 12 is connected to the steel slag conveyor 11, and the steel slag is transported to the steel slag dipping box 12, and the steel slag is impregnated and filtered to obtain solid residue. Put the steel slag into the steel slag dipping tank 12, turn on the electric hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com