Treating device with deferrization effect on front end of injection moulding machine

A processing device and injection molding machine technology, applied in the directions of magnetic separation, solid separation, chemical instruments and methods, etc., can solve problems such as equipment damage and increase in production cost, and achieve the effect of convenient removal, flexible removal, and guaranteed iron removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

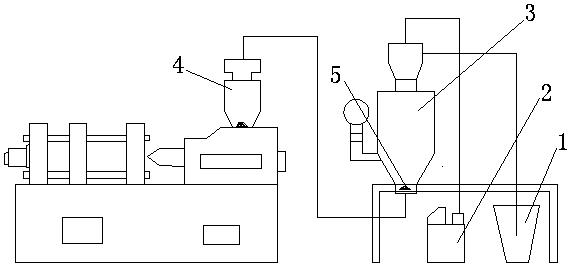

[0014] The present invention comprises a material barrel 1, a material suction machine 2, and a drying barrel 3 and a mixing machine 4 which are arranged on the rear end of the material suction machine 2 and are sequentially connected. There is a magnetic device 5 .

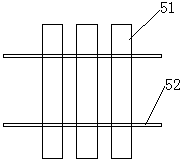

[0015] The magnetic device 5 includes several strong magnets 51 arranged in parallel, which are respectively fixed in the discharge port of the drying barrel 3 and the discharge port of the mixer 4 through support rods 52 .

[0016] The magnetic device 5 is detachably arranged in the outlet of the drying barrel 3 and the outlet of the mixer 4 .

[0017] The working process of the present invention is as follows: the plastic particles are sucked into the drying barrel 3 by the material suction machine 2 from the material barrel 1, and after passing through the drying barrel 3, the iron element is carried out by the strong magnet 51 arranged at the discharge port of the drying barrel 3. The first attraction; then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com