A filter-assisted method for leaching and removing iron from secondary zinc oxide

A sub-zinc oxide and leaching technology is applied in the field of leaching and iron removal of sub-zinc oxide, which can solve the problems of unstable iron removal effect, difficult to filter iron removal slag, inability to filter or settle, etc. Guarantee the effect of removing iron and improving the filtration speed

Active Publication Date: 2022-05-31

JIYUAN LUTAI NANO MATERIAL CO LTD

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As the development and application of mineral raw materials is becoming wider and wider, the grade of sub-zinc oxide is getting lower and lower. In the actual operation of this method, the iron removal slag of most raw materials is not only difficult to filter (filter press filter), but also very easy to filter. The phenomenon of running and filtering occurs, resulting in unstable iron removal effect. When the content of ferrous ions in the solution reaches a certain amount, it cannot even be filtered or settled

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

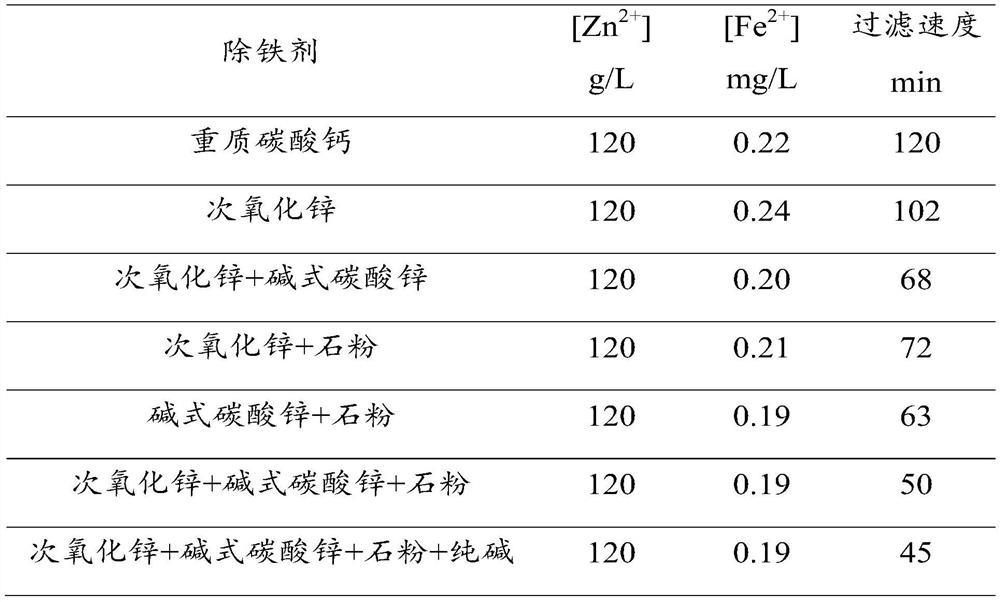

Embodiment 1

[0072] The raw material contains 51.63% zinc and 1.4% iron.

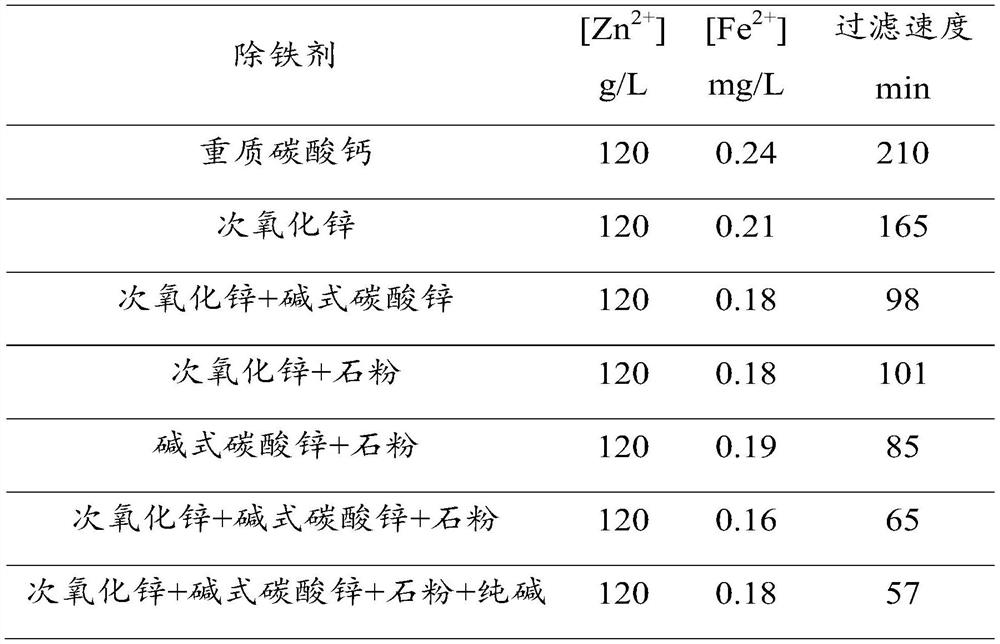

Embodiment 2

[0077] The raw material contains 42.63% zinc and 3.3% iron.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a filter aid method for leaching and removing iron from secondary zinc oxide, belonging to the technical field of chemical industry. The filtering aid method comprises the following steps: adding at least two of zinc suboxide, basic zinc carbonate and stone powder to the reaction system of the suboxide leaching solution and hydrogen peroxide, and reacting to Fe 2+ The content does not exceed 0.2μg / mL, and then solid-liquid separation. The above methods can improve the iron removal effect of oxidative water for different grades of secondary zinc oxide raw materials, and ensure that for different raw materials, under this process, [Fe in the leaching solution] 2+ ]≤0.2μg / ml, the content of ferrous ions in 95% active nano-zinc oxide is within 2ppm; greatly improve the filtration speed of the medium leaching slurry, and the filtration speed can be increased for medium leaching solutions with different ferrous ion contents 100‑300%; eliminate the phenomenon of running and filtering, ensure the effect of iron removal, and ensure the smoothness of the process.

Description

A kind of filter aid method for leaching and removing iron from secondary zinc oxide technical field The present invention relates to chemical technology field, specifically, relate to a kind of filter aid method of sub-zinc oxide leaching iron removal. Background technique At present, active nano zinc oxide is widely used in desulfurizer, rubber, ceramics, medical treatment, photocatalysis, cosmetics, feed and other industries. The active nano-zinc oxide prepared by wet method has more excellent surface activity and has become the first choice of zinc oxide desulfurizer. main ingreadient. In the wet process, sub-zinc oxide is used as the raw material. During the production process, it needs to go through various processes including iron removal. a purification measure. The iron content in the active nano-zinc oxide product is the molding of the zinc oxide desulfurizer production process and the desulfurizer One of the main factors affecting the crushing force and...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01G9/02B82Y40/00

CPCC01G9/02B82Y40/00C01P2006/80Y02P10/20

Inventor 齐磊王东王洋石磊

Owner JIYUAN LUTAI NANO MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com