Filtering aid method for leaching and removing iron from zinc hypoxide

A secondary zinc oxide and leaching technology is applied in the field of filtration aid for leaching and removing iron from secondary zinc oxide, which can solve the problems of inability to filter or settle, unstable iron removal effect, and difficulty in filtration of iron removal slag, so as to ensure the smoothness of the process, Guarantee the effect of removing iron and improving the filtration speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The raw material contains 51.63% zinc and 1.4% iron.

[0073]A. After putting 2.4 tons of zinc oxide into 9.7 tons of water to make slurry, after stirring for 10 minutes, add 2.2 tons of 98% concentrated sulfuric acid under stirring, and the detection temperature rises to 80°C. If the temperature is insufficient, the temperature of the reaction material is raised To 80°C, react for 60min, and detect pH=5.

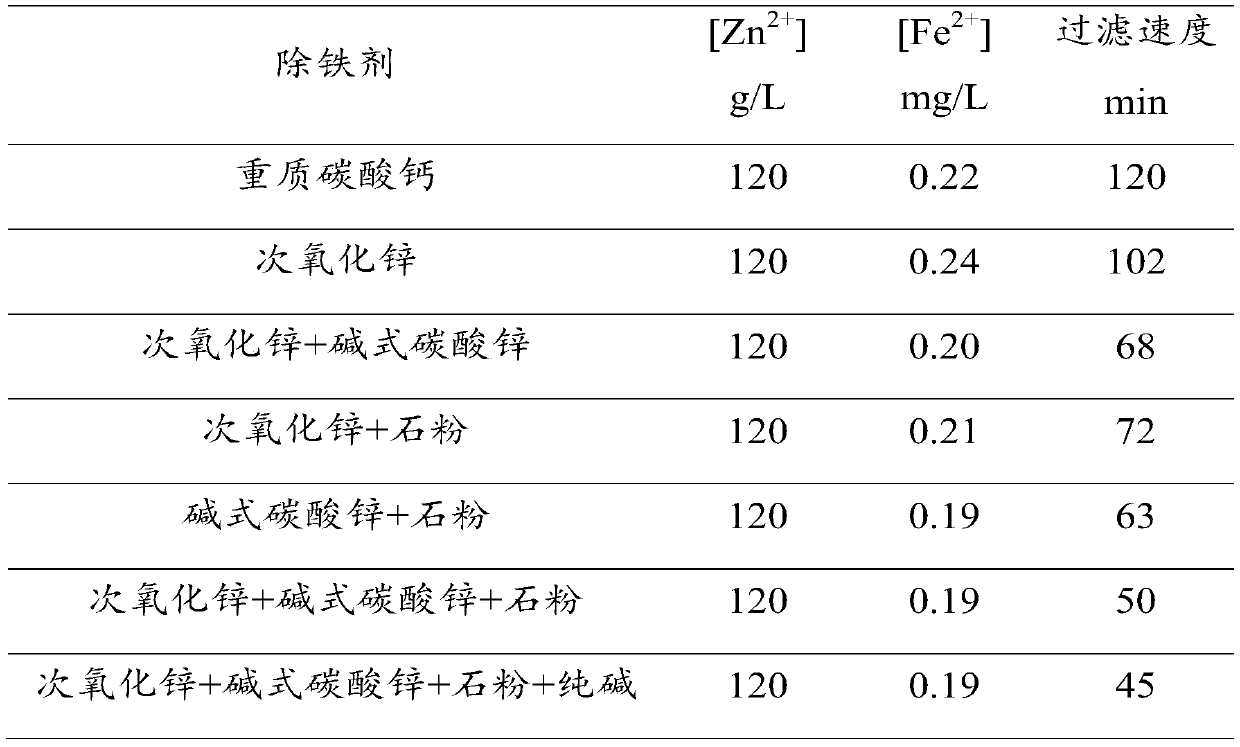

[0074] B. Detection of [Fe in the zinc oxide leaching solution 2+ ]=3.18g / L, keeping the material at 80°C, according to Fe in zinc oxide leaching solution 2 + In terms of the weight of the substance reacting with hydrogen peroxide, the Fe participating in the reaction is added 2+ 2 times (60 kg) of 30wt% hydrogen peroxide, and kept stirring for 10min. According to the amount of hydrogen peroxide added, 4 kg of secondary zinc oxide, 8 kg of zinc carbonate, and 30 kg of stone powder were put into it in proportion as iron remover and filter aid, stirred for 10 minut...

Embodiment 2

[0077] The raw material contains 42.63% zinc and 3.3% iron.

[0078] A. Put 2.4 tons of zinc oxide into 9.8 tons of water to make slurry, stir for 10 minutes, add 1.8 tons of 98% concentrated sulfuric acid under stirring, and heat up the reaction materials to 80 ° C. If the temperature is insufficient, the reaction materials Raise the temperature to 80°C, react for 60 minutes, and detect pH=5.

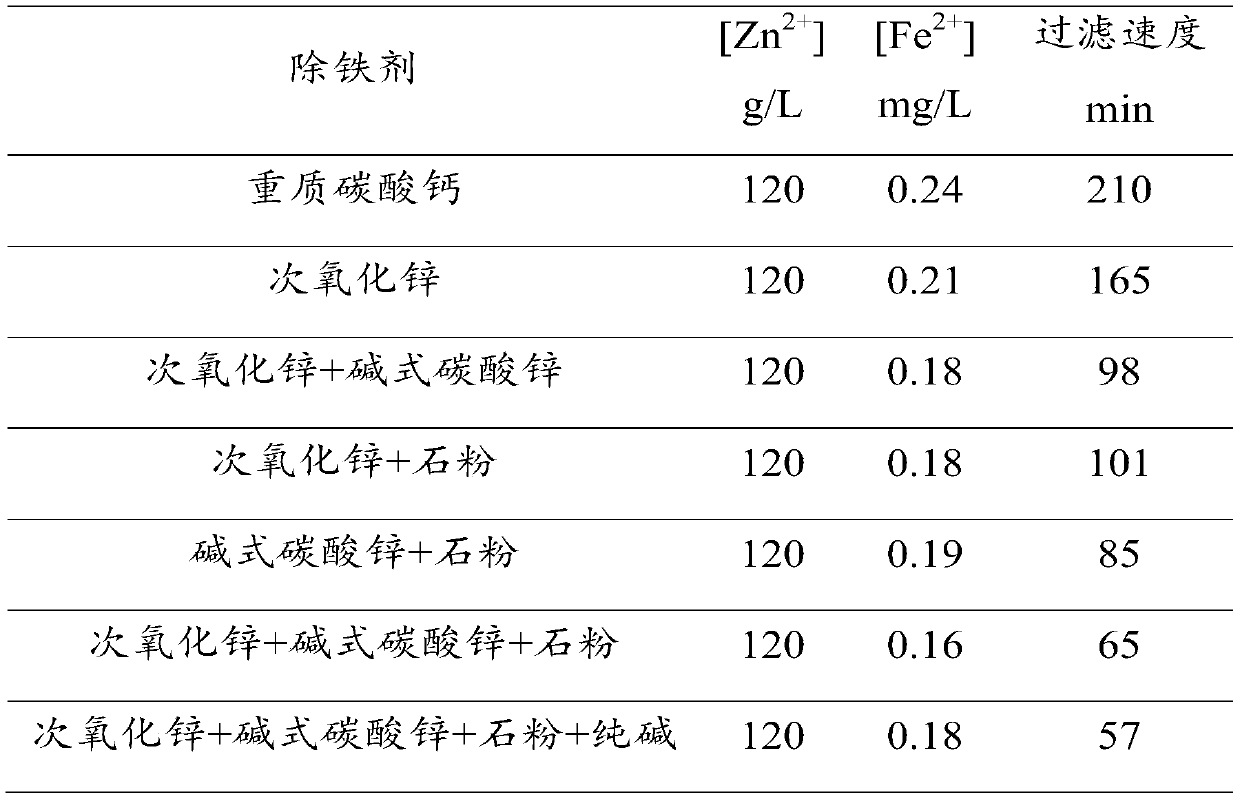

[0079] B. Detection of [Fe in the zinc oxide leaching solution 2+ ]=7.73g / L, keeping the material at 80°C, according to Fe in zinc oxide leaching solution 2 + Based on the weight of the substance reacting with hydrogen peroxide, 120 kg of 30wt% hydrogen peroxide was added, and the stirring was continued for 10 minutes. According to the amount of hydrogen peroxide added, 6 kg of secondary zinc oxide, 12 kg of zinc carbonate, 40 kg of stone powder and 1.2 kg of soda ash were put into it in proportion as iron remover and filter aid, stirred for 10 minutes, and the pH was detected to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com