Method for reducing washing water in production process of titanium dioxide

A production process, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of a large amount of solid waste calcium sulfate, pollute the environment, increase production costs, etc., achieve major environmental protection and economic benefits, and reduce sewage discharge , Guarantee the effect of iron removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

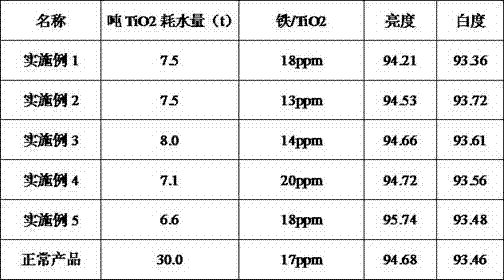

Examples

Embodiment 1

[0017] Fe in metatitanic acid before second washing 2+ / TiO 2 =1030ppm. Second washing filter press feed 3t (with TiO 2 count), after the end of feeding, start the second wash. In the first 30 minutes, the electric valve of the secondary washing water supply pump is used to adjust the washing water flow rate to 21m 3 / h; after washing for 30 minutes, adjust the valve opening of the water supply pump and adjust the washing water flow rate to 6 m 3 / h, the duration is 120min. The entire washing process controls the washing water pressure to 0.36mpa through the outlet pipe.

Embodiment 2

[0019] Fe in metatitanic acid before second washing 2+ / TiO 2 =800ppm. Second washing filter press feed 3t (with TiO 2 count), after the end of feeding, start the second wash. In the first 50 minutes, the electric valve of the secondary washing water supply pump is used to adjust the washing water flow rate to 15m 3 / h; after washing for 50 minutes, adjust the valve opening of the water supply pump and adjust the washing water flow rate to 5m 3 / h, the duration is 120min. The entire washing process controls the washing water pressure to 0.35mpa through the outlet pipe.

Embodiment 3

[0021] Fe in metatitanic acid before second washing 2+ / TiO 2 =700ppm. Second washing filter press feed 3t (with TiO 2 count), after the end of feeding, start the second washing. In the first 40 minutes, the electric valve of the secondary washing water supply pump is used to adjust the washing water flow rate to 18m 3 / h; after washing for 40 minutes, adjust the valve opening of the water supply pump and adjust the washing water flow rate to 6 m 3 / h, the duration is 120min. The entire washing process controls the washing water pressure to 0.4mpa through the outlet pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com