Nickel package aluminum powder and preparing method thereof

A technology of nickel-coated aluminum and aluminum powder, which is applied in the field of preparation of nickel-coated aluminum powder surface, which can solve the problems of strong toxicity and corrosion, small experimental batch of nickel-coated aluminum powder, increased energy consumption, etc., to reduce energy input , Reduce preparation cost, reduce the effect of water usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

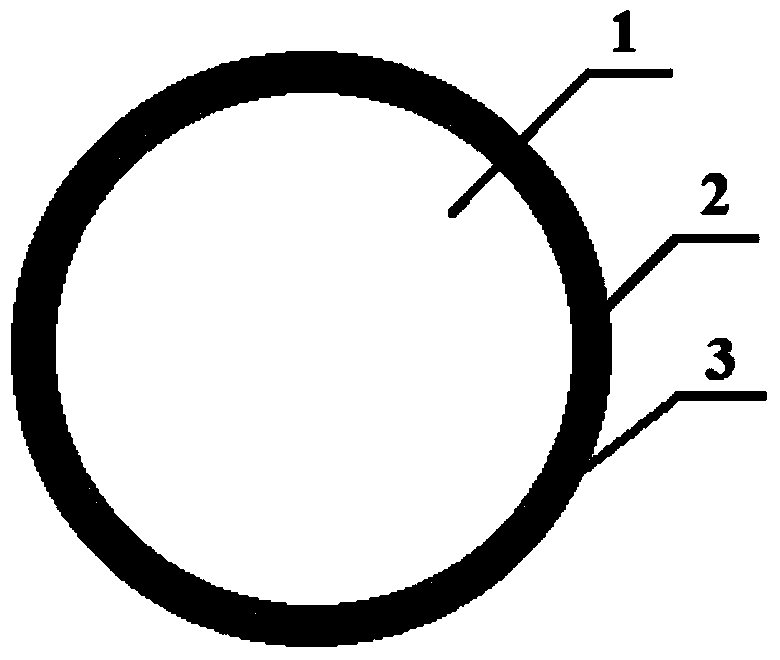

[0055] The nickel content of the design formula is 30%, and 10g of spherical aluminum powder with an average particle size of 40μm is selected. Prepare nickel-coated aluminum powder according to the following formula and steps:

[0056] a. Put the aluminum powder into a NaOH solution with a volume of 100mL and a concentration of 0.03mol / L, stir for 0.5-1min until the solution produces bubbles, quickly dilute the solution to 500mL, and then wash it with water three times. After the last wash, soak the aluminum powder in water .

[0057] b. Replacement method: Weigh 11.2g of nickel sulfate and 2g of citric acid, dissolve them in 500mL of water, add the aluminum powder in step a to the main salt solution and stir, weigh 0.08g of sodium dodecylbenzenesulfonate to dissolve In 20mL of water; weigh 3.7g of NH 4 Dissolve F in 30mL water; after the plating solution is mixed evenly, add the prepared NH at a constant speed within 1min. 4 F solution.

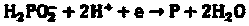

[0058] c. Chemical reduction me...

Embodiment 2

[0061] The nickel content of the design formula is 30%, and 100g of spherical aluminum powder with an average particle size of 10μm is selected. Prepare nickel-coated aluminum powder according to the following formula and steps:

[0062]a. Put the aluminum powder into a NaOH solution with a volume of 500mL and a concentration of 0.04mol / L, stir for 0.5-1min until the solution produces bubbles, quickly dilute the solution to 3000mL, and then wash it with water three times. After the last wash, soak the aluminum powder in water .

[0063] b. Replacement method: Weigh 112g of nickel sulfate and 11.2g of citric acid, dissolve them in 2000mL of water, add the aluminum powder in step a to the main salt solution and stir, then weigh 0.5g of sodium dodecylbenzenesulfonate Dissolve in 60mL water; weigh 37g of NH 4 Dissolve F in 370mL water; after the plating solution is evenly mixed, add the prepared NH at a constant speed within 1min. 4 F solution.

[0064] c. Chemical reduction m...

Embodiment 3

[0067] The nickel content of the design formula is 43%, and 100g of spherical aluminum powder with an average particle size of 30μm is selected. Its process of preparing nickel clad aluminum powder is different from embodiment 2 in that: NH in the b step 4 F solution consists of 37gNH 4 F is prepared by dissolving in 250mL water; the 1100mL second main salt solution in step c contains 227g nickel sulfate and 252g sodium citrate; 220g sodium hypophosphite is prepared into 800mL solution.

[0068] Finally, 171g of nickel-coated aluminum powder was obtained, the nickel content was estimated to be 41.5%, and the coating was uniform and complete.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap