Adhesive sticker plane die cutting method

A flat die-cutting and die-cutting technology, applied in metal processing and other directions, can solve problems such as the inability to complete die-cutting normally, and achieve the effect of broadening the scope of use, improving enterprise efficiency and reducing processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] The first step is to draw step-by-step blade graphics.

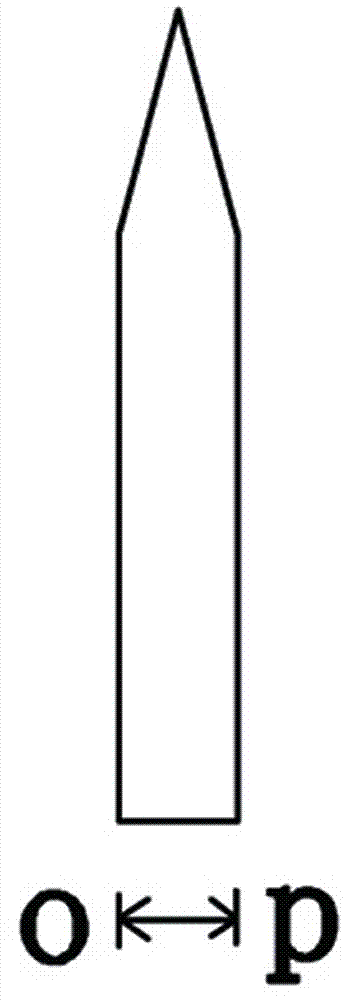

[0062] Based on the shapes of the two tangent stickers, draw a knife edge shape that is the same shape as the edge of the two tangent stickers. CAD software can be used to draw. The two tangent self-adhesive labels are respectively a first self-adhesive label and a second self-adhesive label.

[0063] This is the case where the lending line EF in the tool is the same as the paper pulling direction.

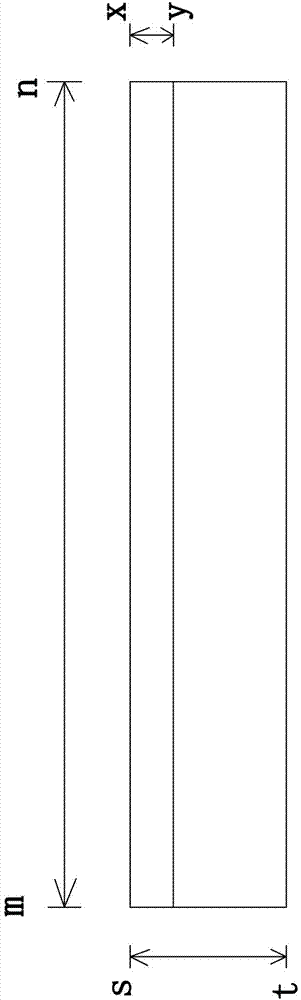

[0064] The blade pattern on the borrow line and its left part is called the first blade graph 1, and the blade graph on the right part (excluding the borrow line) of the borrow line is called the second blade graph 2, which is called a line, as Figure 6 shown. Both the length of the first blade pattern 1 and the second blade pattern 2 are a, and the widths are both b. At this time, the paper pulling step length is L=b+c. The distance between two adjacent rows of blade patterns is c.

[0065] Bundle Figure 6 a...

Embodiment 2

[0081] The first step is to draw step-by-step blade graphics.

[0082] According to the shapes of the two tangent stickers, draw a knife-edge figure with the same shape as the edges of the two tangent stickers, which is called a row.

[0083] This is the case where the lending line EF in the tool is perpendicular to the paper-drawing direction.

[0084] The blade pattern of the loan line and its upper part is called the first blade pattern 1, and the blade pattern of the part below the loan line (excluding the loan line) is called the second blade pattern 2, as Figure 13 , the length of the first blade pattern 1 and the second blade pattern 2 is a, the width is b, and the distance between two adjacent rows of blade patterns is c. At this time, the paper pulling step length L=2b+c.

[0085] Bundle Figure 13 according to Figure 13 The paper-drawing step length L and then copy a group such as Figure 14 .

[0086] Keep the first blade pattern 1 in the first row, and dele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com