A bottle embryo fixture head and accompanying fixture

A fixture head and bottle preform technology, applied in the field of preform fixture heads and accompanying fixtures, can solve the problems of rising temperature of the preform fixture head, increasing the blow molding defect rate, unstable bottle mouth size, etc., reducing the contact area, The effect of reducing the blow molding defect rate and avoiding dimensional deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings.

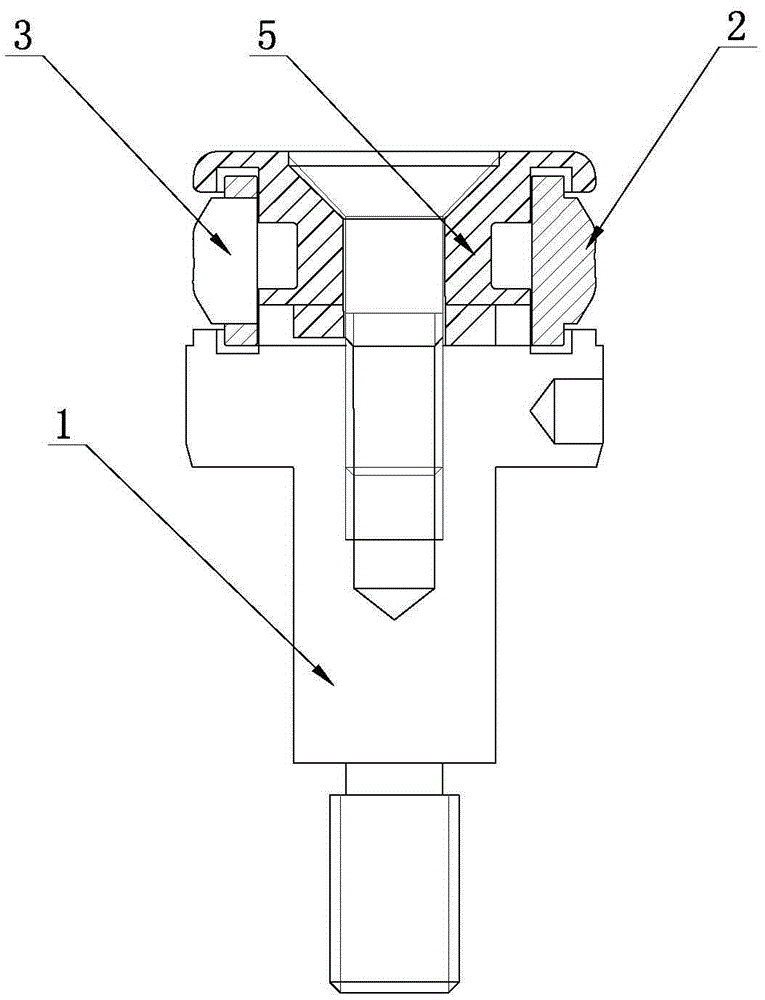

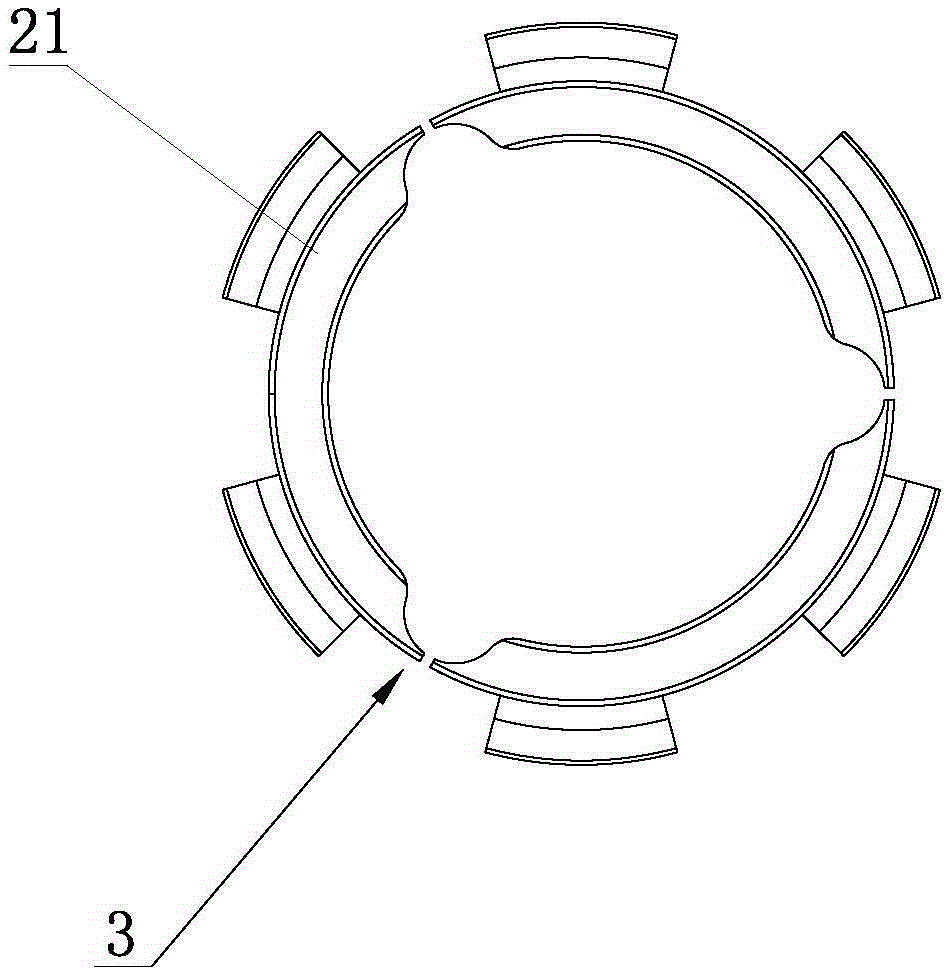

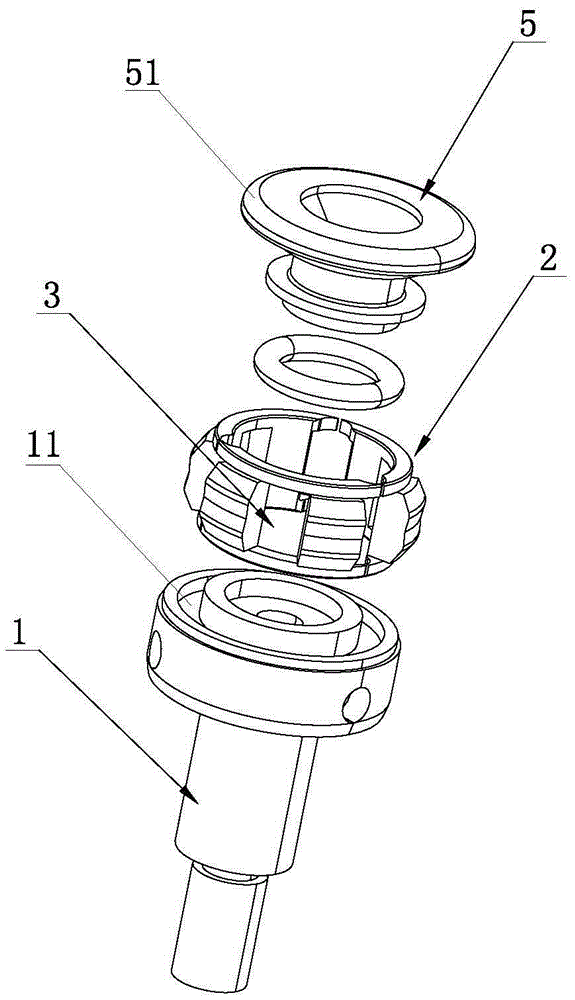

[0027] Such as Figure 1 to Figure 4 As shown, a preform fixture head of the present invention includes a fixture head seat 1, and the fixture head seat 1 is provided with a cooling ring 2 for fixing the preform 10. The inside of the cooling ring 2 is hollow, and the circumference of the cooling ring 2 Several cooling holes 3 are provided. The contact area between the cooling ring 2 and the preform opening can be reduced by setting the heat dissipation hole 3, reducing heat transfer, avoiding dimensional deformation of the preform opening due to high temperature, and reducing the defective rate of blow molding.

[0028] Preferably, the number of the heat dissipation holes 3 is six, and the six heat dissipation holes 3 are evenly distributed on the circumference of the heat dissipation ring 2. The setting of the six heat dissipation holes 3 reduces the contact betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com